- [Korean]

- The Use of TiH2 to Refine Y2Ti2O7 in a Nano Mo-ODS Alloy

-

Yuncheol Ha, Chun Woong Park, Won Hee Lee, Jongmin Byun, Young Do Kim

-

J Powder Mater. 2024;31(5):399-405. Published online October 31, 2024

-

DOI: https://doi.org/10.4150/jpm.2024.00178

-

-

Abstract Abstract

PDF PDF

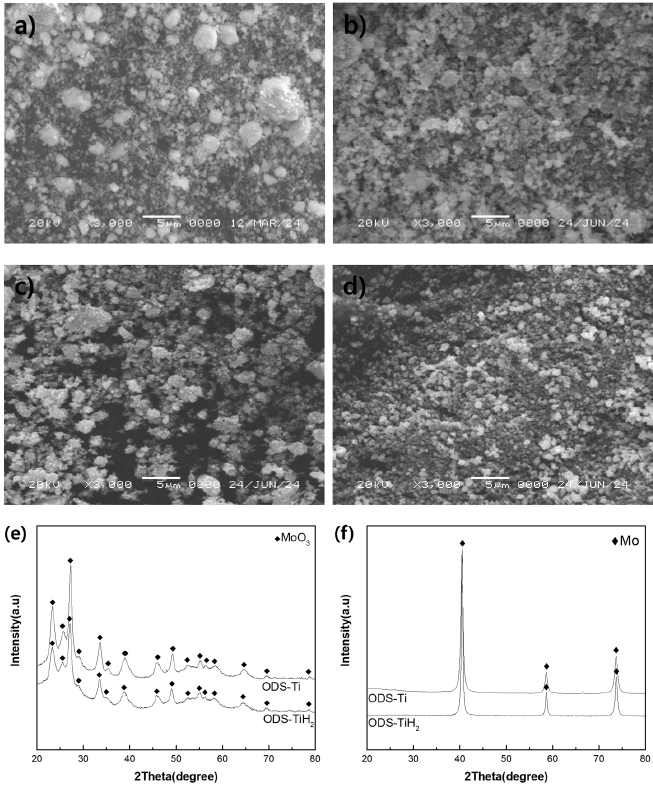

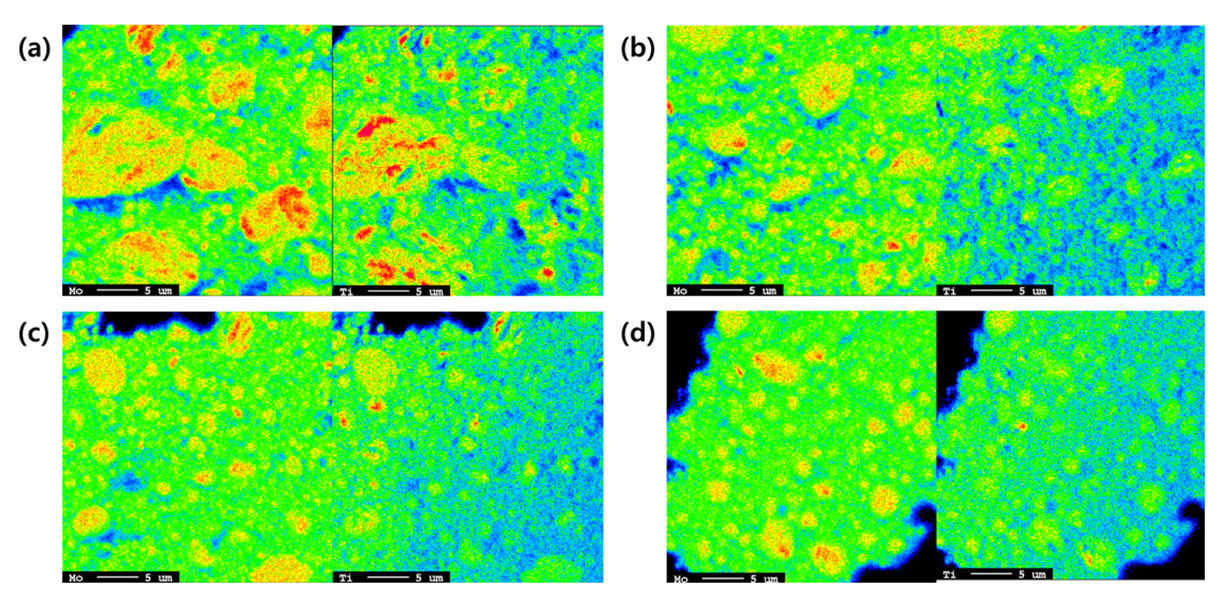

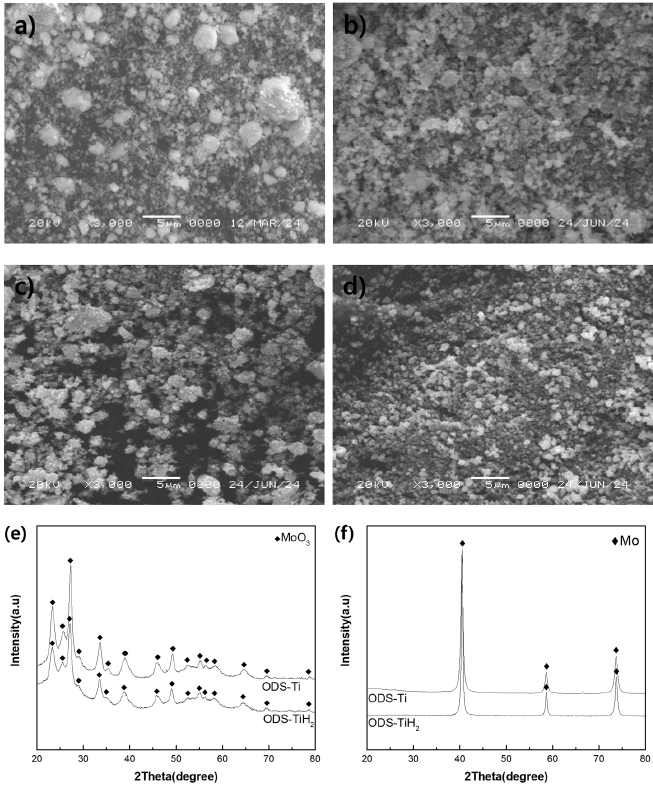

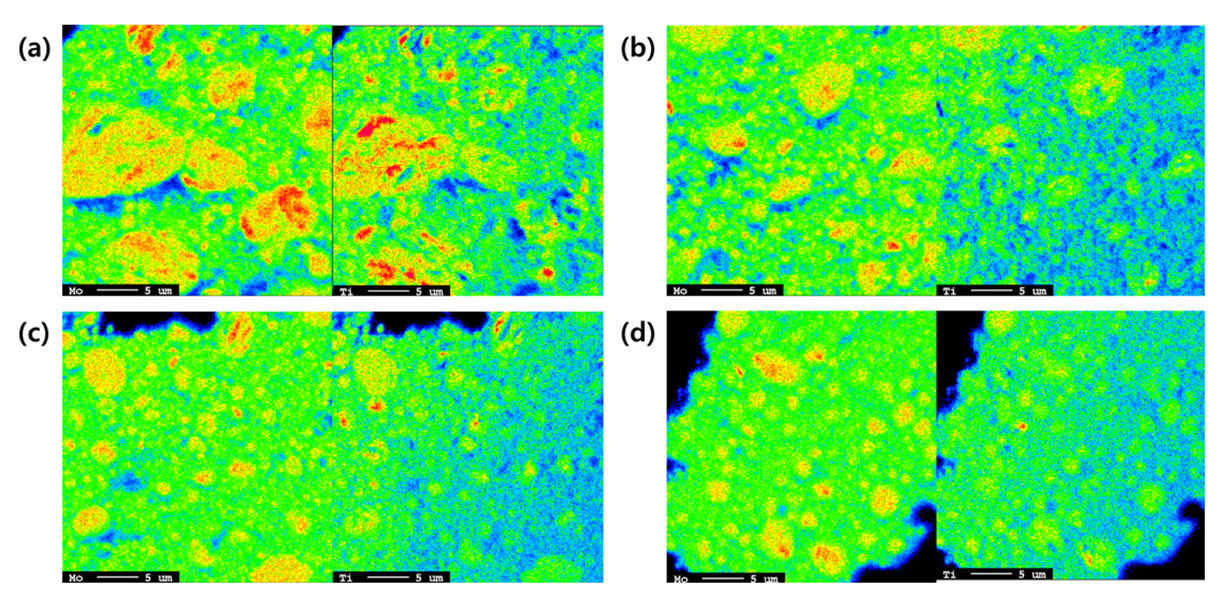

- Mo-ODS alloys have excellent mechanical properties, including an improved recrystallization temperature, greater strength due to dispersed oxides, and the ability to suppress grain growth at high temperatures. In ODS alloys, the dispersed Y2O3 and added Ti form Y-Ti-O complex oxides, producing finer particles than those in the initial Y2O3. The complex oxides increase high-temperature stability and improve the mechanical properties of the alloy. In particular, the use of TiH2 powder, which is more brittle than conventional Ti, can enable the distribution of finer oxides than is possible with conventional Ti powder during milling. Moreover, dehydrogenation leads to a more refined powder size in the reduction process. This study investigated the refinement of Y2Ti2O7 in a nano Mo-ODS alloy using TiH2. The alloy compositions were determined to be Mo-0.5Ti-0.5Y2O3 and Mo-1.0Ti-0.5Y2O3. The nano Mo-ODS alloys were fabricated using Ti and TiH2 to explore the effects of adding different forms of Ti. The sintered specimens were analyzed through X-ray diffraction for phase analysis, and the microstructure of the alloys was analyzed using scanning electron microscopy and transmission electron microscopy. Vickers hardness tests were conducted to determine the effect of the form of Ti added on the mechanical properties, and it was found that using TiH2 effectively improved the mechanical properties.

- [Korean]

- Fabrication of Ti-Mo Core-shell Powder and Sintering Properties for Application as a Sputtering Target

-

Won Hee Lee, Chun Woong Park, Heeyeon Kim, Yuncheol Ha, Jongmin Byun, Young Do Kim

-

J Powder Mater. 2024;31(1):43-49. Published online February 28, 2024

-

DOI: https://doi.org/10.4150/KPMI.2024.31.1.43

-

-

PDF PDF

- [Korean]

- Alloy Design and Powder Manufacturing of Al-Cu-Si alloy for Low-Temperature Aluminum Brazing

-

Heeyeon Kim, Chun Woong Park, Won Hee Lee, Young Do Kim

-

J Powder Mater. 2023;30(4):339-345. Published online August 1, 2023

-

DOI: https://doi.org/10.4150/KPMI.2023.30.4.339

-

-

Abstract Abstract

PDF PDF

This study investigates the melting point and brazing properties of the aluminum (Al)-copper (Cu)-silicon (Si)-tin (Sn) alloy fabricated for low-temperature brazing based on the alloy design. Specifically, the Al-20Cu-10Si-Sn alloy is examined and confirmed to possess a melting point of approximately 520°C. Analysis of the melting point of the alloy based on composition reveals that the melting temperature tends to decrease with increasing Cu and Si content, along with a corresponding decrease as the Sn content rises. This study verifies that the Al-20Cu-10Si-5Sn alloy exhibits high liquidity and favorable mechanical properties for brazing through the joint gap filling test and Vickers hardness measurements. Additionally, a powder fabricated using the Al-20Cu-10Si-5Sn alloy demonstrates a melting point of around 515°C following melting point analysis. Consequently, it is deemed highly suitable for use as a low-temperature Al brazing material.

- [Korean]

- Microstructure and Mechanical Property of Ti-Mn-Cu Alloys with Magnetic Pulsed Compaction

-

Ye Jun Yun, Chun Woong Park, Won June Choi, Jongmin Byun

-

J Korean Powder Metall Inst. 2021;28(1):20-24. Published online February 1, 2021

-

DOI: https://doi.org/10.4150/KPMI.2021.28.1.20

-

-

Abstract Abstract

PDF PDF

Ti-based alloys are widely used in biomaterials owing to their excellent biocompatibility. In this study, Ti- Mn-Cu alloys are prepared by high-energy ball milling, magnetic pulsed compaction, and pressureless sintering. The microstructure and microhardness of the Ti-Mn-Cu alloys with variation of the Cu addition and compaction pressure are analyzed. The correlation between the composition, compaction pressure, and density is investigated by measuring the green density and sintered density for samples with different compositions, subjected to various compaction pressures. For all compositions, it is confirmed that the green density increases proportionally as the compaction pressure increases, but the sintered density decreases owing to gas formation from the pyrolysis of TiH2 powders and reduction of oxides on the surface of the starting powders during the sintering process. In addition, an increase in the amount of Cu addition changes the volume fractions of the α-Ti and β-Ti phases, and the microstructure of the alloys with different compositions also changes. It is demonstrated that these changes in the phase volume fraction and microstructure are closely related to the mechanical properties of the Ti-Mn-Cu alloys.

- [Korean]

- Fabrication of Molybdenum Alloys with Improved Fracture Toughness through the Dispersion of Lanthanum Oxide

-

Won June Choi, Chun Woong Park, Jung Hyo Park, Young Do Kim, Jongmin Byun

-

J Korean Powder Metall Inst. 2019;26(3):208-213. Published online June 1, 2019

-

DOI: https://doi.org/10.4150/KPMI.2019.26.3.208

-

-

733

View

-

1

Download

-

2

Citations

-

Abstract Abstract

PDF PDF

In this study, lanthanum oxide (La2O3) dispersed molybdenum (Mo–La2O3) alloys are fabricated using lanthanum nitrate solution and nanosized Mo particles produced by hydrogen reduction of molybdenum oxide. The effect of La2O3 dispersion in a Mo matrix on the fracture toughness at room temperature is demonstrated through the formation behavior of La2O3 from the precursor and three-point bending test using a single-edge notched bend specimen. The relative density of the Mo–0.3La2O3 specimen sintered by pressureless sintering is approximately 99%, and La2O3 with a size of hundreds of nanometers is uniformly distributed in the Mo matrix. It is also confirmed that the fracture toughness is 19.46 MPa·m1/2, an improvement of approximately 40% over the fracture toughness of 13.50 MPa·m1/2 on a pure-Mo specimen without La2O3, and this difference in the fracture toughness occurs because of the changes in fracture mode of the Mo matrix caused by the dispersion of La2O3. -

Citations

Citations to this article as recorded by  - Sintering property of micro/nano core-shell molybdenum powder synthesized by mechanochemical process

Chun Woong Park, Heeyeon Kim, Won Hee Lee, Wonjune Choi, Jongmin Byun, Young Do Kim

International Journal of Refractory Metals and Hard Materials.2024; 119: 106532. CrossRef - Novel design of Mo-Si-B + La2O3 powder with multi-shell structure for ideal microstructure and enhanced mechanical property

Wonjune Choi, Chun Woong Park, Young Do Kim, Jongmin Byun

International Journal of Refractory Metals and Hard Materials.2024; 120: 106611. CrossRef

- [Korean]

- Analysis on Milling Behavior of Oxide Dispersion Strengthened Ni-based Atomizing Powder with Ni5Y Intermetallic Phase

-

Chun Woong Park, Jong Min Byun, Won June Choi, Young Do Kim

-

J Korean Powder Metall Inst. 2019;26(2):101-106. Published online April 1, 2019

-

DOI: https://doi.org/10.4150/KPMI.2019.26.2.101

-

-

911

View

-

3

Download

-

2

Citations

-

Abstract Abstract

PDF PDF

Ni-based oxide dispersion strengthened (ODS) alloys have a higher usable temperature and better hightemperature mechanical properties than conventional superalloys. They are therefore being explored for applications in various fields such as those of aerospace and gas turbines. In general, ODS alloys are manufactured from alloy powders by mechanical alloying of element powders. However, our research team produces alloy powders in which the Ni5Y intermetallic phase is formed by an atomizing process. In this study, mechanical alloying was performed using a planetary mill to analyze the milling behavior of Ni-based oxide dispersions strengthened alloy powder in which the Ni5Y is the intermetallic phase. As the milling time increased, the Ni5Y intermetallic phase was refined. These results are confirmed by SEM and EPMA analysis on microstructure. In addition, it is confirmed that as the milling increased, the mechanical properties of Ni-based ODS alloy powder improve due to grain refinement by plastic deformation. -

Citations

Citations to this article as recorded by  - Efficient prediction of corrosion behavior in ternary Ni-based alloy systems: Theoretical calculations and experimental verification

Xuelian Xiao, Keke Chang, Kai Xu, Ming Lou, Liping Wang, Qunji Xue

Journal of Materials Science & Technology.2023; 167: 94. CrossRef - Effect of high-energy ball milling on the microstructure and mechanical properties of Ni-based ODS alloys fabricated using gas-atomized powder

Chun Woong Park, Won June Choi, Jongmin Byun, Young Do Kim

Journal of Materials Science.2022; 57(38): 18195. CrossRef

- [Korean]

- Research Trends of the Mo-Si-B Alloys as Next Generation Ultra-high-temperature Alloys

-

Won June Choi, Chun Woong Park, Jung Hyo Park, Young Do Kim, Jong Min Byun

-

J Korean Powder Metall Inst. 2019;26(2):156-165. Published online April 1, 2019

-

DOI: https://doi.org/10.4150/KPMI.2019.26.2.156

-

-

1,367

View

-

22

Download

-

4

Citations

-

Abstract Abstract

PDF PDF

Over the last decade, the next generation’s ultra-high-temperature materials as an alternative to Nickel-based superalloys have been highlighted. Ultra-high-temperature materials based on refractory metals are one of several potential candidates. In particular, molybdenum alloys with small amounts of silicon and boron (Mo-Si-B alloys) have superior properties at high temperature. However, research related to Mo-Si-B alloys were mainly conducted by several developed countries but garnered little interest in Korea. Therefore, in this review paper, we introduce the development history of Mo-Si-B alloys briefly and discuss the properties, particularly the mechanical and oxidation properties of Mo-Si-B alloys. We also introduce the latest research trends of Mo-Si-B alloys based on the research paper. Finally, for domestic research related to this field, we explain why Mo-Si-B alloys should be developed and suggest the potential directions for Mo-Si-B alloys research. -

Citations

Citations to this article as recorded by  - Thermal Stability and Weight Reduction of Al0.75V2.82CrZr Refractory High Entropy Alloy Prepared Via Mechanical Alloying

Minsu Kim, Hansung Lee, Byungmin Ahn

journal of Korean Powder Metallurgy Institute.2023; 30(6): 478. CrossRef - Preparation and Structure of Chromium Coatings Doped with Diamond Nanoparticles Deposited Directly on a Monolithic Composite of Molybdenum and Aluminum

V. P. Petkov, M. K. Aleksandrova, R. V. Valov, V. P. Korzhov, V. M. Kiiko, I. S. Zheltyakova

Protection of Metals and Physical Chemistry of Surfaces.2023; 59(3): 396. CrossRef - A Review of Mo-Si Intermetallic Compounds as Ultrahigh-Temperature Materials

Liang Jiang, Bin Zheng, Changsong Wu, Pengxiang Li, Tong Xue, Jiandong Wu, Fenglan Han, Yuhong Chen

Processes.2022; 10(9): 1772. CrossRef - Heat-Resistant Molybdenum Borosilicate Alloys Hardened with Titanium Carbides: Mo–Si–B–TiC (Survey)

I. L. Svetlov, O. G. Ospennikova, M. I. Karpov, Yu. V. Artemenko

Inorganic Materials: Applied Research.2021; 12(4): 866. CrossRef

- [Korean]

- Fabrication of Molybdenum Silicide-based Composites with Uniformly Dispersed Silicon Carbide

-

Won June Choi, Chun Woong Park, Young Do Kim, Jong Min Byun

-

J Korean Powder Metall Inst. 2018;25(5):402-407. Published online October 1, 2018

-

DOI: https://doi.org/10.4150/KPMI.2018.25.5.402

-

-

Abstract Abstract

PDF PDF

Molybdenum silicide has gained interest for high temperature structural applications. However, poor fracture toughness at room temperatures and low creep resistance at elevated temperatures have hindered its practical applications. This study uses a novel powder metallurgical approach applied to uniformly mixed molybdenum silicidebased composites with silicon carbide. The degree of powder mixing with different ball milling time is also demonstrated by Voronoi diagrams. Core-shell composite powder with Mo nanoparticles as the shell and β-SiC as the core is prepared via chemical vapor transport. Using this prepared core-shell composite powder, the molybdenum silicide-based composites with uniformly dispersed β-SiC are fabricated using pressureless sintering. The relative density of the specimens sintered at 1500°C for 10 h is 97.1%, which is similar to pressure sintering owing to improved sinterability using Mo nanoparticles.

- [Korean]

- Photocatalytic activity of rutile TiO2 powders coupled with anatase TiO2 nanoparticles using surfactant

-

Jong Min Byun, Chun Woong Park, Young In Kim, Young Do Kim

-

J Korean Powder Metall Inst. 2018;25(3):257-262. Published online June 1, 2018

-

DOI: https://doi.org/10.4150/KPMI.2018.25.3.257

-

-

955

View

-

9

Download

-

2

Citations

-

Abstract Abstract

PDF PDF

The coupling of two semiconducting materials is an efficient method to improve photocatalytic activity via the suppression of recombination of electron-hole pairs. In particular, the coupling between two different phases of TiO2, i.e., anatase and rutile, is particularly attractive for photocatalytic activity improvement of rutile TiO2 because these coupled TiO2 powders can retain the benefits of TiO2, one of the best photocatalysts. In this study, anatase TiO2 nanoparticles are synthesized and coupled on the surface of rutile TiO2 powders using a microemulsion method and heat treatment. Triton X-100, as a surfactant, is used to suppress the aggregation of anatase TiO2 nanoparticles and disperse anatase TiO2 nanoparticles uniformly on the surface of rutile TiO2 powders. Rutile TiO2 powders coupled with anatase TiO2 nanoparticles are successfully prepared. Additionally, we compare the photocatalytic activity of these rutile-anatase coupled TiO2 powders under ultraviolet (UV) light and demonstrate that the reason for the improvement of photocatalytic activity is microstructural. -

Citations

Citations to this article as recorded by  - Refractory Metal Oxide–Doped Titanate Nanotubes: Synthesis and Photocatalytic Activity under UV/Visible Light Range

Min-Sang Kim, Hyun-Joo Choi, Tohru Sekino, Young-Do Kim, Se-Hoon Kim

Catalysts.2021; 11(8): 987. CrossRef - Effect of Surfactant on the Dispersion Stability of Slurry for Semiconductor Silicon CMP

Hye Won Yun, Doyeon Kim, Do Hyung Han, Dong Wan Kim, Woo-Byoung Kim

Journal of Korean Powder Metallurgy Institute.2018; 25(5): 395. CrossRef

- [English]

- The Synthesis and Photocatalytic activity of Carbon Nanotube-mixed TiO2 Nanotubes

-

Chun Woong Park, Young Do Kim, Tohru Sekino, Se Hoon Kim

-

J Korean Powder Metall Inst. 2017;24(4):279-284. Published online August 1, 2017

-

DOI: https://doi.org/10.4150/KPMI.2017.24.4.279

-

-

1,295

View

-

11

Download

-

1

Citations

-

Abstract Abstract

PDF PDF

The formation mechanism and photocatalytic properties of a multiwalled carbon nanotube (MWCNT)/TiO2- based nanotube (TNTs) composite are investigated. The CNT/TNT composite is synthesized via a solution chemical route. It is confirmed that this 1-D nanotube composite has a core-shell nanotubular structure, where the TNT surrounds the CNT core. The photocatalytic activity investigated based on the methylene blue degradation test is superior to that of with pure TNT. The CNTs play two important roles in enhancing the photocatalytic activity. One is to act as a template to form the core-shell structure while titanate nanosheets are converted into nanotubes. The other is to act as an electron reservoir that facilitates charge separation and electron transfer from the TNT, thus decreasing the electronhole recombination efficiency. -

Citations

Citations to this article as recorded by  - Low-Dimensional Carbon and Titania Nanotube Composites via a Solution Chemical Process and Their Nanostructural and Electrical Properties for Electrochemical Devices

Sunghun Eom, Sung Hun Cho, Tomoyo Goto, Myoung Pyo Chun, Tohru Sekino

ACS Applied Nano Materials.2019; 2(10): 6230. CrossRef

- [Korean]

- Research Trend of Fe/Ni Based Oxide Dispersion Strengthened Alloys

-

Chun Woong Park, Jong Min Byun, Jong Kwan Park, Young Do Kim

-

J Korean Powder Metall Inst. 2016;23(1):61-68. Published online February 1, 2016

-

DOI: https://doi.org/10.4150/KPMI.2016.23.1.61

-

-

1,679

View

-

27

Download

-

1

Citations

-

PDF PDF

-

Citations

Citations to this article as recorded by  - Effect of high-energy ball milling on the microstructure and mechanical properties of Ni-based ODS alloys fabricated using gas-atomized powder

Chun Woong Park, Won June Choi, Jongmin Byun, Young Do Kim

Journal of Materials Science.2022; 57(38): 18195. CrossRef

|