Search

- Page Path

- HOME > Search

- [Korean]

- Microstructure and Mechanical Properties of AA3003 Tube for Heat Exchanger Processed by Floating Plug Drawing

- Hyeon-Jun Heo, Sung Jun Oh, Seong-Hee Lee

- J Powder Mater. 2025;32(6):459-465. Published online December 31, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00346

- 616 View

- 7 Download

-

Abstract

Abstract

PDF

PDF - An AA3003 tube was severely deformed by cold floating plug drawing, and then annealed at temperatures from 210 to 460℃. The as drawn Al tube exhibited a typical deformation structure in which the grains were greatly elongated along the drawing direction. The hardness increased with increasing the reduction of cross-sectional area (RA), became 68Hv after RA= 99%. Up to 310℃, the Al tube still mainly exhibited a deformed structure. While complete recrystallization occurred at temperatures above 360℃. The hardness decreased with increasing the annealing temperature, and it became 33Hv after annealing at 410℃. Both the tensile and yield strengths also decreased with increasing the annealing temperature, but the decrease was larger in yield strength than in tensile strength. The elongation increased with increasing the annealing temperature. The changes in the strength and the elongation with the annealing temperature were the largest at 360℃, in which the complete recrystallization occurred.

- [English]

- The Effect of Aluminum Powder Size on the Structure and Mechanical Properties of Foam

- Seunghyeok Choi, Sungjin Kim, Tae-Young Ahn, Yu-Song Choi, Jae-Gil Jung, Seung Bae Son, Seok-Jae Lee

- J Powder Mater. 2025;32(3):232-243. Published online June 30, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00157

- 1,278 View

- 50 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF - In this study, we analyzed the structural and mechanical properties of aluminum foams fabricated using aluminum powders of varying sizes and mixtures. The effects of sintering and pore structure at each size on the integrity and mechanical properties of the foams were investigated. Structural characteristics were examined using scanning electron microscopy and micro–computed tomography, while mechanical properties were evaluated through compression testing. The experimental results demonstrated that smaller powder sizes improved foam integrity, reduced porosity and pore size, and resulted in thinner cell walls. In combination, these effects increased compressive strength as the powder size decreased. The findings of this study contribute to the understanding and improvement of the mechanical properties of aluminum foams and highlight their potential for use in a wide range of applications.

-

Citations

Citations to this article as recorded by- Sustainable Manufacturing of Graphene–Aluminum Composites: A Comparative Life Cycle Assessment

Xinwei Yang, Qian Peng, Changke Chen, Qingcui Liu, Yudai Huang

Journal of Sustainable Metallurgy.2026; 12(1): 727. CrossRef

- Sustainable Manufacturing of Graphene–Aluminum Composites: A Comparative Life Cycle Assessment

- [Korean]

- Friction Stir Spot Welding Characteristics of Dissimilar Materials of Aluminum-Based Damping Composites and Steel Plates

- Si-Seon Park, Young-Keun Jeong

- J Powder Mater. 2025;32(1):43-49. Published online February 28, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00010

- 620 View

- 10 Download

-

Abstract

Abstract

PDF

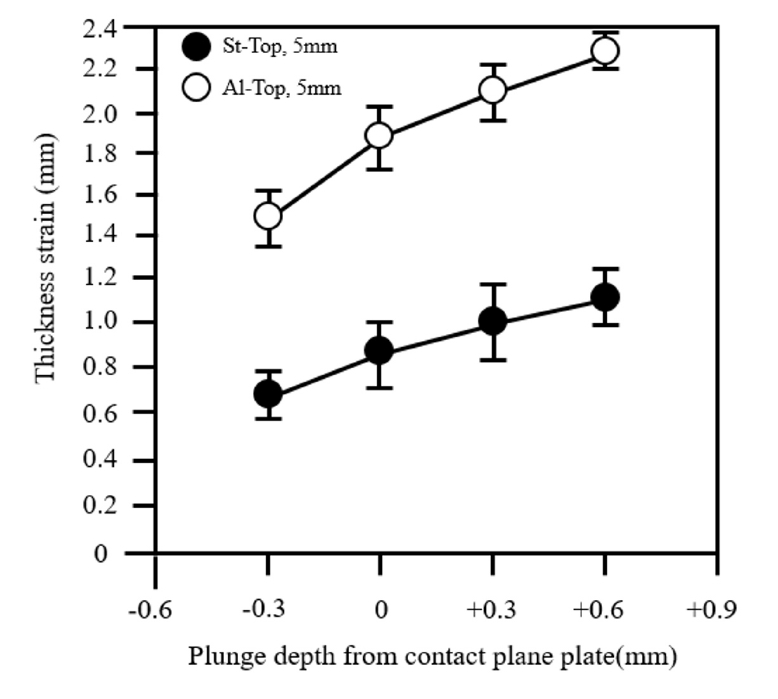

PDF - Friction Stir Spot Welding (FSSW) is a solid-state welding technology that is rapidly growing in the automotive industry. Achieving superior welding characteristics requires the proper selection of tool geometry and process conditions. In this study, FSSW was performed on dissimilar materials comprising AA5052-HO/hot-melt aluminum alloy sheets and Steel Plate Cold Rolled for Deep Drawing Use(SPCUD) steel sheets. The effects of tool geometry, plate arrangement, and tool plunge depth on the welding process were investigated. At the joint interface between the aluminum alloy and the steel sheet, new intermetallic compounds (IMCs) were observed. As the plunge depth increased, thicker and more continuous IMC layers were formed. However, excessive plunge depth led to discontinuous layers and cracking defects. An analysis of the IMCs revealed a correlation between the IMC thickness and the shear tensile load. Furthermore, compared to the conventional Al-Top arrangement, the St-Top arrangement exhibited reduced deformation and superior shear tensile load values. These findings indicate that plate arrangement significantly influences the mechanical properties of the joint.

- [Korean]

- Fabrication of Al18B4O33 Spherical Powder with Increased Fluidity via Control of B2O3 Particle Size and Distribution

- Kiho Song, Sang in Lee, Hyunseung Song, Changui Ahn

- J Powder Mater. 2024;31(6):513-520. Published online December 31, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00304

- 858 View

- 23 Download

-

Abstract

Abstract

PDF

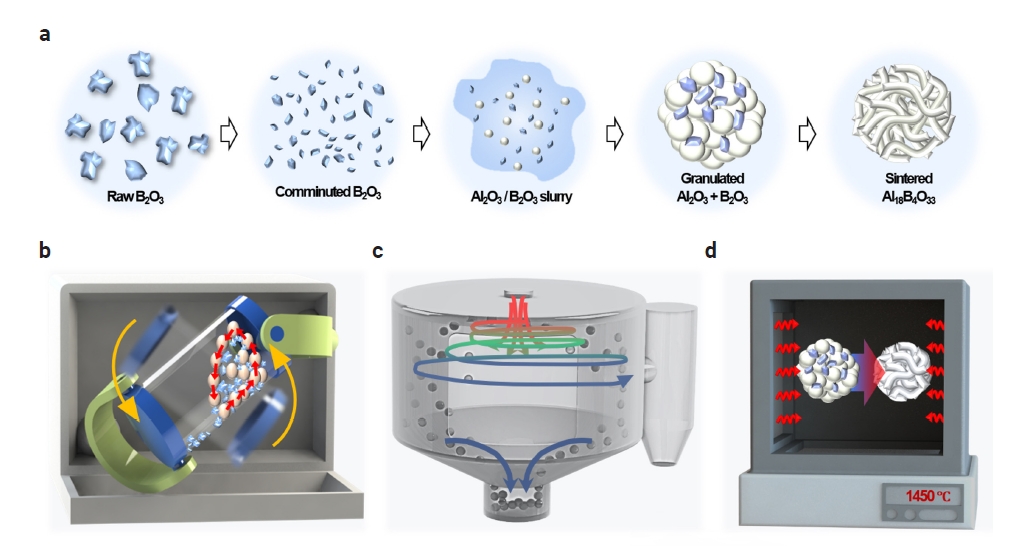

PDF - Ceramic materials have become essential due to their high durability, chemical stability, and excellent thermal stability in various advanced industries such as aerospace, automotive, and semiconductor. However, high-performance ceramic materials face limitations in commercialization due to the high cost of raw materials and complex manufacturing processes. Aluminum borate (Al₁₈B₄O₃₃) has emerged as a promising alternative due to its superior mechanical strength and thermal stability, despite its simple manufacturing process and low production cost. In this study, we propose a method for producing Al₁₈B₄O₃₃ spherical powder with increased uniformity and high flowability by controlling the particle size of B₂O₃. The content ratio of the manufactured Al18B4O33 spherical powder was Al2O3: B2O3 = 87:13, and it exhibited a 17% reduction in the Hausner ratio (1.04) and a 29% decrease in the angle of repose (23.9°) compared to pre-milling conditions, demonstrating excellent flowability.

- [English]

- Machine Learning Modeling of the Mechanical Properties of Al2024-B4C Composites

- Maurya A. K., Narayana P. L., Wang X.-S., Reddy N. S.

- J Powder Mater. 2024;31(5):382-389. Published online October 31, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00234

- 1,372 View

- 28 Download

-

Abstract

Abstract

PDF

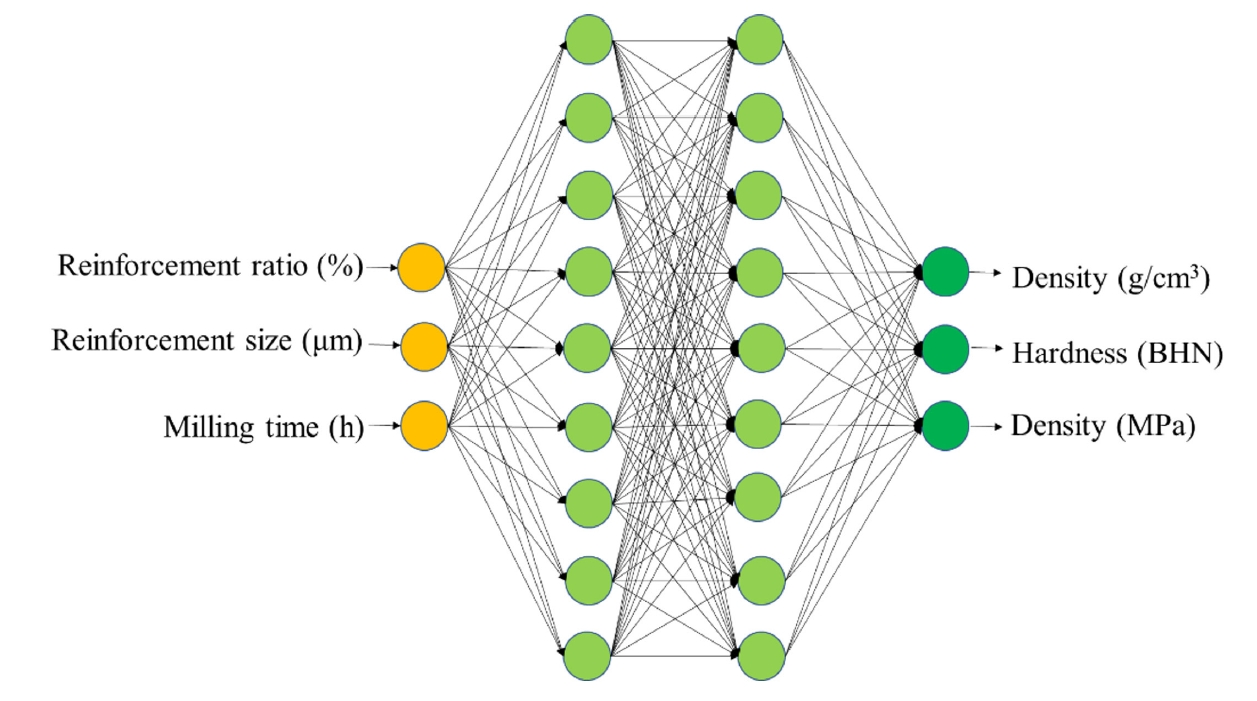

PDF - Aluminum-based composites are in high demand in industrial fields due to their light weight, high electrical conductivity, and corrosion resistance. Due to its unique advantages for composite fabrication, powder metallurgy is a crucial player in meeting this demand. However, the size and weight fraction of the reinforcement significantly influence the components' quality and performance. Understanding the correlation of these variables is crucial for building high-quality components. This study, therefore, investigated the correlations among various parameters—namely, milling time, reinforcement ratio, and size—that affect the composite’s physical and mechanical properties. An artificial neural network model was developed and showed the ability to correlate the processing parameters with the density, hardness, and tensile strength of Al2024-B4C composites. The predicted index of relative importance suggests that the milling time has the most substantial effect on fabricated components. This practical insight can be directly applied in the fabrication of high-quality Al2024-B4C composites.

- [Korean]

- Effect of Heat Treatment on Microstructure and Mechanical Properties of Al–Zn–Mg–Cu–Si Sintered Alloys with and Without High-energy Ball Milling

- Junho Lee, Seonghyun Park, Sang-Hwa Lee, Seung Bae Son, Seok-Jae Lee, Jae-Gil Jung

- J Powder Mater. 2023;30(6):470-477. Published online December 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.6.470

- 2,730 View

- 32 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF The effects of annealing on the microstructure and mechanical properties of Al–Zn–Mg–Cu–Si alloys fabricated by high-energy ball milling (HEBM) and spark plasma sintering (SPS) were investigated. The HEBM-free sintered alloy primarily contained Mg2Si, Q-AlCuMgSi, and Si phases. Meanwhile, the HEBM-sintered alloy contains Mg-free Si and θ-Al2Cu phases due to the formation of MgO, which causes Mg depletion in the Al matrix. Annealing without and with HEBM at 500°C causes partial dissolution and coarsening of the Q-AlCuMgSi and Mg2Si phases in the alloy and dissolution of the θ-Al2Cu phase in the alloy, respectively. In both alloys, a thermally stable α-AlFeSi phase was formed after long-term heat treatment. The grain size of the sintered alloys with and without HEBM increased from 0.5 to 1.0 μm and from 2.9 to 6.3 μm, respectively. The hardness of the sintered alloy increases after annealing for 1 h but decreases significantly after 24 h of annealing. Extending the annealing time to 168 h improved the hardness of the alloy without HEBM but had little effect on the alloy with HEBM. The relationship between the microstructural factors and the hardness of the sintered and annealed alloys is discussed.

-

Citations

Citations to this article as recorded by- Microstructural evolution and thermal stability of Al–Zn–Mg–Cu–Si–Zr alloy fabricated via spark plasma sintering

Junho Lee, Seonghyun Park, Sang-Hwa Lee, Seung Bae Son, Hanjung Kwon, Seok-Jae Lee, Jae-Gil Jung

Journal of Materials Research and Technology.2024; 31: 205. CrossRef

- Microstructural evolution and thermal stability of Al–Zn–Mg–Cu–Si–Zr alloy fabricated via spark plasma sintering

- [Korean]

- Fabrication of Polymer Composite with Enhanced Insulation and Mechanical Properties using Aluminum Borate Nanowhiskers

- Junhyeok Choi, Sangin Lee, Kiho Song, Taekyung Kim, Changui Ahn

- J Powder Mater. 2023;30(4):356-362. Published online August 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.4.356

- 914 View

- 2 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF Inorganic-organic composites find extensive application in various fields, including electronic devices and light-emitting diodes. Notably, encapsulation technologies are employed to shield electronic devices (such as printed circuit boards and batteries) from stress and moisture exposure while maintaining electrical insulation. Polymer composites can be used as encapsulation materials because of their controllable mechanical and electrical properties. In this study, we propose a polymer composite that provides good electrical insulation and enhanced mechanical properties. This is achieved by using aluminum borate nanowhiskers (ABOw), which are fabricated using a facile synthesis method. The ABOw fillers are created via a hydrothermal method using aluminum chloride and boric acid. We confirm that the synthesis occurs in various morphologies based on the molar ratio. Specifically, nanowhiskers are synthesized at a molar ratio of 1:3 and used as fillers in the composite. The fabricated ABOw/epoxy composites exhibit a 48.5% enhancement in mechanical properties, similar to those of pure epoxy, while maintaining good electrical insulation.

-

Citations

Citations to this article as recorded by- Fabrication of Al18B4O33 Spherical Powder with Increased Fluidity via Control of B2O3 Particle Size and Distribution

Kiho Song, Sang in Lee, Hyunseung Song, Changui Ahn

Journal of Powder Materials.2024; 31(6): 513. CrossRef

- Fabrication of Al18B4O33 Spherical Powder with Increased Fluidity via Control of B2O3 Particle Size and Distribution

- [Korean]

- Alloy Design and Powder Manufacturing of Al-Cu-Si alloy for Low-Temperature Aluminum Brazing

- Heeyeon Kim, Chun Woong Park, Won Hee Lee, Young Do Kim

- J Powder Mater. 2023;30(4):339-345. Published online August 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.4.339

- 1,448 View

- 13 Download

-

Abstract

Abstract

PDF

PDF This study investigates the melting point and brazing properties of the aluminum (Al)-copper (Cu)-silicon (Si)-tin (Sn) alloy fabricated for low-temperature brazing based on the alloy design. Specifically, the Al-20Cu-10Si-Sn alloy is examined and confirmed to possess a melting point of approximately 520°C. Analysis of the melting point of the alloy based on composition reveals that the melting temperature tends to decrease with increasing Cu and Si content, along with a corresponding decrease as the Sn content rises. This study verifies that the Al-20Cu-10Si-5Sn alloy exhibits high liquidity and favorable mechanical properties for brazing through the joint gap filling test and Vickers hardness measurements. Additionally, a powder fabricated using the Al-20Cu-10Si-5Sn alloy demonstrates a melting point of around 515°C following melting point analysis. Consequently, it is deemed highly suitable for use as a low-temperature Al brazing material.

- [Korean]

- Microstructures and Mechanical Properties of Al-B4C Composites Fabricated by DED Process

- Yu-Jeong An, Ju-Yeon Han, Hyunjoo Choi, Se-Eun Shin

- J Powder Mater. 2023;30(3):262-267. Published online June 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.3.262

- 981 View

- 8 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF Boron carbide (B4C) is highly significant in the production of lightweight protective materials when added to aluminum owing to its exceptional mechanical properties. In this study, a method for fabricating Al-B4C composites using high-energy ball milling and directed energy deposition (DED) is presented. Al-4 wt.% B4C composites were fabricated under 21 different laser conditions to analyze the microstructure and mechanical properties at different values of laser power and scan speeds. The composites fabricated at a laser power of 600 W and the same scan speed exhibited the highest hardness and generated the fewest pores. In contrast, the composites fabricated at a laser power of 1000 W exhibited the lowest hardness and generated a significant number of large pores. This can be explained by the influence of the microstructure on the energy density at different values of laser power.

-

Citations

Citations to this article as recorded by- Development of Aluminum Alloys for Additive Manufacturing Using Machine Learning

Sungbin An, Juyeon Han, Seoyeon Jeon, Dowon Kim, Jae Bok Seol, Hyunjoo Choi

Journal of Powder Materials.2025; 32(3): 202. CrossRef

- Development of Aluminum Alloys for Additive Manufacturing Using Machine Learning

- [Korean]

- Exploration of Aluminum Alloy using Multi-feeder 3D Additive Manufacturing-based Combinatorial Experiment

- Suwon Park, Yongwook Song, Jiyoon Yeo, Songyun Han, Hyunjoo Choi

- J Powder Mater. 2023;30(3):255-261. Published online June 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.3.255

- 1,534 View

- 8 Download

- 3 Citations

-

Abstract

Abstract

PDF

PDF Aluminum alloys are widely utilized in diverse industries, such as automobiles, aerospace, and architecture, owing to their high specific strength and resistance to oxidation. However, to meet the increasing demands of the industry, it is necessary to design new aluminum alloys with excellent properties. Thus, a new method is required to efficiently test additively manufactured aluminum alloys with various compositions within a short period during the alloy design process. In this study, a combinatory approach using a direct energy deposition system for metal 3D printing process with a dual feeder was employed. Two types of aluminum alloy powders, namely Al6061 and Al-12Cu, were utilized for the combinatory test conducted through 3D printing. Twelve types of Al-Si-Cu-Mg alloys were manufactured during this combinatory test, and the relationship between their microstructures and properties was investigated.

-

Citations

Citations to this article as recorded by- Trends in Materials Modeling and Computation for Metal Additive Manufacturing

Seoyeon Jeon, Hyunjoo Choi

journal of Korean Powder Metallurgy Institute.2024; 31(3): 213. CrossRef - Microstructural Effects on the Mechanical Properties of Ti-6Al-4V Fabricated by Direct Energy Deposition

Juho Kim, Seoyeon Jeon, Hwajin Park, Taeyoel Kim, Hyunjoo Choi

Journal of Powder Materials.2024; 31(4): 302. CrossRef - Combinatorial Experiment for Al-6061 and Al-12Si alloy Based on Directed Energy Deposition (DED) Process

Seoyeon Jeon, Suwon Park, Yongwook Song, Jiwon Park, Hyunyoung Park, Boram Lee, Hyunjoo Choi

journal of Korean Powder Metallurgy Institute.2023; 30(6): 463. CrossRef

- Trends in Materials Modeling and Computation for Metal Additive Manufacturing

- [Korean]

- Analysis of the Effects of Process Variables and Alloy Composition on the Relative density and Mechanical Properties of 3D Printed Aluminum Alloys

- Suwon Park, Jiyoon Yeo, Songyun Han, Hyunjoo Choi

- J Powder Mater. 2023;30(3):223-232. Published online June 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.3.223

- 2,976 View

- 16 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF Metal additive manufacturing (AM) has transformed conventional manufacturing processes by offering unprecedented opportunities for design innovation, reduced lead times, and cost-effective production. Aluminum alloy, a material used in metal 3D printing, is a representative lightweight structural material known for its high specific strength and corrosion resistance. Consequently, there is an increasing demand for 3D printed aluminum alloy components across industries, including aerospace, transportation, and consumer goods. To meet this demand, research on alloys and process conditions that satisfy the specific requirement of each industry is necessary. However, 3D printing processes exhibit different behaviors of alloy elements owing to rapid thermal dynamics, making it challenging to predict the microstructure and properties. In this study, we gathered published data on the relationship between alloy composition, processing conditions, and properties. Furthermore, we conducted a sensitivity analysis on the effects of the process variables on the density and hardness of aluminum alloys used in additive manufacturing.

-

Citations

Citations to this article as recorded by- Effect of Heat Treatment on Microstructure and Mechanical Properties of Al–Zn–Mg–Cu–Si Sintered Alloys with and Without High-energy Ball Milling

Junho Lee, Seonghyun Park, Sang-Hwa Lee, Seung Bae Son, Seok-Jae Lee, Jae-Gil Jung

journal of Korean Powder Metallurgy Institute.2023; 30(6): 470. CrossRef

- Effect of Heat Treatment on Microstructure and Mechanical Properties of Al–Zn–Mg–Cu–Si Sintered Alloys with and Without High-energy Ball Milling

- [Korean]

- Interfacial Reaction between Spark Plasma Sintered High-entropy Alloys and Cast Aluminum

- Min-Sang Kim, Hansol Son, Cha Hee Jung, Juyeon Han, Jung Joon Kim, Young-Do Kim, Hyunjoo Choi, Se Hoon Kim

- J Powder Mater. 2022;29(3):213-218. Published online June 1, 2022

- DOI: https://doi.org/10.4150/KPMI.2022.29.3.213

- 837 View

- 5 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF This study investigates the interfacial reaction between powder-metallurgy high-entropy alloys (HEAs) and cast aluminum. HEA pellets are produced by the spark plasma sintering of Al0.5CoCrCu0.5FeNi HEA powder. These sintered pellets are then placed in molten Al, and the phases formed at the interface between the HEA pellets and cast Al are analyzed. First, Kirkendall voids are observed due to the difference in the diffusion rates between the liquid Al and solid HEA phases. In addition, although Co, Fe, and Ni atoms, which have low mixing enthalpies with Al, diffuse toward Al, Cu atoms, which have a high mixing enthalpy with Al, tend to form Al–Cu intermetallic compounds. These results provide guidelines for designing Al matrix composites containing high-entropy phases.

-

Citations

Citations to this article as recorded by- Simultaneous enhancement of strength and ductility of Al matrix composites enabled by submicron-sized high-entropy alloy phases

Chahee Jung, Seungin Nam, Hansol Son, Juyeon Han, Jaewon Jeong, Hyokyung Sung, Hyoung Seop Kim, Seok Su Sohn, Hyunjoo Choi

Journal of Materials Research and Technology.2024; 33: 1470. CrossRef

- Simultaneous enhancement of strength and ductility of Al matrix composites enabled by submicron-sized high-entropy alloy phases

- [Korean]

- The Effects of TiC Content on Microstructure of Modified A6013-3wt.%Si Alloy Powder Compact

- Hyo-Sang Yoo, Yong-Ho Kim, Hyeon-Taek Son

- J Powder Mater. 2022;29(1):28-33. Published online February 1, 2022

- DOI: https://doi.org/10.4150/KPMI.2022.29.1.28

- 897 View

- 5 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF Aluminum-based powders have attracted attention as key materials for 3D printing owing to their low density, high specific strength, high corrosion resistance, and formability. This study describes the effects of TiC addition on the microstructure of the A6013 alloy. The alloy powder was successfully prepared by gas atomization and further densified using an extrusion process. We have carried out energy dispersive X-ray spectrometry (EDS) and electron backscatter diffraction (EBSD) using scanning electron microscopy (SEM) in order to investigate the effect of TiC addition on the microstructure and texture evolution of the A6013 alloy. The atomized A6013-xTiC alloy powder is fine and spherical, with an initial powder size distribution of approximately 73 μm which decreases to 12.5, 13.9, 10.8, and 10.0 μm with increments in the amount of TiC.

-

Citations

Citations to this article as recorded by- Influence of Curing Agent Amount on Properties of Dynamic Vulcanized Phenyl Silicone Rubber-SEBS-SBS System

Chunxu Zhao, Bobing He, Xian Chen

Polymers.2022; 14(24): 5443. CrossRef

- Influence of Curing Agent Amount on Properties of Dynamic Vulcanized Phenyl Silicone Rubber-SEBS-SBS System

- [Korean]

- Development of Aluminum Matrix Composites Containing Nano-carbon Materials

- Jungjoon Kim, Daeyoung Kim, Hyunjoo Choi

- J Korean Powder Metall Inst. 2021;28(3):253-258. Published online June 1, 2021

- DOI: https://doi.org/10.4150/KPMI.2021.28.3.253

- 809 View

- 6 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF There is increasing demand for the development of a new material with high strength, high stiffness, and good electrical conductivity that can be used for high-voltage direct current cables. In this study, we develop aluminumbased composites containing C60 fullerenes, carbon nanotubes, or graphene using a powder metallurgical route and evaluate their strength, stiffness, coefficient of thermal expansion, and electrical conductivity. By optimizing the process conditions, a material with a tensile strength of 800 MPa, an elastic modulus of 90 GPa, and an electrical conductivity of 40% IACS is obtained, which may replace iron-core cables. Furthermore, by designing the type and volume fraction of the reinforcement, a material with a tensile strength of 380 MPa, elastic modulus of 80 GPa, and electrical conductivity of 54% IACS is obtained, which may compete with AA 6201 aluminum alloys for use in all-aluminum conductor cables.

-

Citations

Citations to this article as recorded by- Synergistic strengthening of aluminum with SiC by grain refinement and dispersion hardening

Kanhu C. Nayak, Juyeon Han, Suwon Park, Miran Joo, Kon‐Bae Lee, Donghyun Bae, Hyunjoo Choi

Journal of the American Ceramic Society.2023; 106(12): 7340. CrossRef - Synergetic effect of milling speed and duration on particle morphology and mechanical properties of nanocrystalline Al matrix containing SiC

K.C. Nayak, J.Y. Han, C.H. Jung, M.R. Joo, K.B. Lee, D.H. Bae, H.J. Choi

Powder Metallurgy.2023; 66(5): 519. CrossRef

- Synergistic strengthening of aluminum with SiC by grain refinement and dispersion hardening

- [English]

- A Study on the Removal of Heavy Metal with Mg-Modified Zeolite

- Jei-Pil Wang, Gyu-Cheol Kim, Min-Seok Go

- J Korean Powder Metall Inst. 2020;27(4):287-292. Published online August 1, 2020

- DOI: https://doi.org/10.4150/KPMI.2020.27.4.287

- 1,758 View

- 23 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF The subject of this study is a zeolite generated as a by-product of recycling LAS (lithium-aluminum-silicate) resources, a kind of glass and ceramic produced by induction. The zeolite by-product is modified into Mg-zeolite using Mg as a cation to absorb Pb, a heavy metal generated from water pollution caused by recent industrial wastewater. An ion-exchange method is used to carry out the modification process, from zeolite byproduct to Mg-zeolite, and simultaneously absorb the Pb in the heavy-metal solution (99.032 mg/L). It is found that the sodium zeolite in the raw material residue can be modified to magnesium zeolite by reacting it with a mixture solution at 1 M concentration for 24 h. As a result, it is found that the residual Pb (0.130 mg/L) in the heavy metal solution is shown to be absorbed by 99.86%, with successful formation of a Mg-modified zeolite.

-

Citations

Citations to this article as recorded by- Penentuan Kualitas Kaolin sebagai Prekursor Sintesis Zeolit pada Kegiatan Praktikum

Rohmat Ismail, Manasye Erlangga, Ari Himawan, Givana Indah Nurul Afiah

Jurnal Pengelolaan Laboratorium Pendidikan.2025; 7(2): 81. CrossRef - Y-Type Zeolite Synthesized from an Illite Applied for Removal of Pb(II) and Cu(II) Ions from Aqueous Solution: Box-Behnken Design and Kinetics

Kinjal J. Shah, Jiacheng Yu, Ting Zhang, Zhaoyang You

Water.2023; 15(6): 1171. CrossRef

- Penentuan Kualitas Kaolin sebagai Prekursor Sintesis Zeolit pada Kegiatan Praktikum

- [Korean]

- Effect of Sn Addition on Microstructure of Al Alloy Powder for Brazing Process

- Yong-Ho Kim, Hyo-Sang Yoo, Sang-Su Na, Hyeon-Taek Son

- J Korean Powder Metall Inst. 2020;27(2):139-145. Published online April 1, 2020

- DOI: https://doi.org/10.4150/KPMI.2020.27.2.139

- 664 View

- 2 Download

-

Abstract

Abstract

PDF

PDF The powder manufacturing process using the gas atomizer process is easy for mass production, has a fine powder particle size, and has excellent mechanical properties compared to the existing casting process, so it can be applied to various industries such as automobiles, electronic devices, aviation, and 3D printers. In this study, a modified A4032-xSn (x = 0, 1, 3, 5, and 10 wt.%) alloy with low melting point properties is investigated. After maintaining an argon (Ar) gas atmosphere, the main crucible is tilted; containing molten metal at 1,000°C by melting the master alloy at a high frequency, and Ar gas is sprayed at 10 bar gas pressure after the molten metal inflow to the tundish crucible, which is maintained at 800°C. The manufactured powder is measured using a particle size analyzer, and FESEM is used to observe the shape and surface of the alloy powder. DSC is performed to investigate the change in shape, according to the melting point and temperature change. The microstructure of added tin (Sn) was observed by heat treatment at 575°C for 10 min. As the content of Sn increased, the volume fraction increased to 1.1, 3.1, 6.4, and 10.9%.

- [Korean]

- Effects of Sintering Additives on the Thermal and Mechanical Properties of AlN by Pressureless Sintering

- Jin Uk Hwang, So Youn Mun, Sang Yong Nam, Hwan Soo Dow

- J Korean Powder Metall Inst. 2019;26(5):395-404. Published online October 1, 2019

- DOI: https://doi.org/10.4150/KPMI.2019.26.5.395

- 2,186 View

- 50 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF Aluminum nitride (AlN) has excellent electrical insulation property, high thermal conductivity, and a low thermal expansion coefficient; therefore, it is widely used as a heat sink, heat-conductive filler, and heat dissipation substrate. However, it is well known that the AlN-based materials have disadvantages such as low sinterability and poor mechanical properties. In this study, the effects of addition of various amounts (1-6 wt.%) of sintering additives Y2O3 and Sm2O3 on the thermal and mechanical properties of AlN samples pressureless sintered at 1850°C in an N2 atmosphere for a holding time of 2 h are examined. All AlN samples exhibit relative densities of more than 97%. It showed that the higher thermal conductivity as the Y2O3 content increased than the Sm2O3 additive, whereas all AlN samples exhibited higher mechanical properties as Sm2O3 content increased. The formation of secondary phases by reaction of Y2O3, Sm2O3 with oxygen from AlN lattice influenced the thermal and mechanical properties of AlN samples due to the reaction of the oxygen contents in AlN lattice.

-

Citations

Citations to this article as recorded by- Effects of YH2 addition on pressureless sintered AlN ceramics

Liang Wang, Wei-Ming Guo, Peng-Fei Sheng, Li-Fu Lin, Xiao Zong, Shang-Hua Wu

Journal of the European Ceramic Society.2023; 43(3): 862. CrossRef

- Effects of YH2 addition on pressureless sintered AlN ceramics

- [Korean]

- Synthesis of Graphene Coated Aluminum Powders by Self-assemble Reaction

- Jin Uk Hwang, Woo Seong Tak, Sang Yong Nam, Woo Sik Kim

- J Korean Powder Metall Inst. 2019;26(5):383-388. Published online October 1, 2019

- DOI: https://doi.org/10.4150/KPMI.2019.26.5.383

- 902 View

- 2 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF To improve the mechanical properties of aluminum, graphene has been used as a reinforcing material, yielding graphene-reinforced aluminum matrix composites (GRAMCs). Dispersion of graphene materials is an important factor that affects the properties of GRAMCs, which are mainly manufactured by mechanical mixing methods such as ball milling. However, the use of only mechanical mixing process is limited to achieve homogeneous dispersion of graphene. To overcome this problem, in this study, we have prepared composite materials by coating aluminum particles with graphene by a self-assembly reaction using poly vinylalcohol and ethylene diamine as coupling agents. The scanning electron microscopy and Fourier-transform infrared spectroscopy results confirm the coating of graphene on the Al surface. Bulk density of the sintered composites by spark plasma sintering achieved a relative density of over 99% up to 0.5 wt.% graphene oxide content.

-

Citations

Citations to this article as recorded by- Laser-Induced Porous Graphene Electrodes for Flexible Heater

Min Gi An, Jaehak Lee, Jung Hwan Park

Journal of Powder Materials.2025; 32(6): 492. CrossRef

- Laser-Induced Porous Graphene Electrodes for Flexible Heater

- [Korean]

- Fabrication and Characterization of Highly Reactive Al/CuO Nano-composite using Graphene Oxide

- YeSeul Lim

- J Korean Powder Metall Inst. 2019;26(3):220-224. Published online June 1, 2019

- DOI: https://doi.org/10.4150/KPMI.2019.26.3.220

- 743 View

- 6 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF The aluminum (Al)/copper oxide (CuO) complex is known as the most promising material for thermite reactions, releasing a high heat and pressure through ignition or thermal heating. To improve the reaction rate and wettability for handling safety, nanosized primary particles are applied on Al/CuO composite for energetic materials in explosives or propellants. Herein, graphene oxide (GO) is adopted for the Al/CuO composites as the functional supporting materials, preventing a phase-separation between solvent and composites, leading to a significantly enhanced reactivity. The characterizations of Al/CuO decorated on GO(Al/CuO/GO) are performed through scanning electron microscopy, transmission electron microscopy, and energy dispersive X-ray spectroscopy mapping analysis. Moreover, the functional bridging between Al/CuO and GO is suggested by identifying the chemical bonding with GO in X-ray photoelectron spectroscopy analysis. The reactivity of Al/CuO/GO composites is evaluated by comparing the maximum pressure and rate of the pressure increase of Al/CuO and Al/CuO/GO. The composites with a specific concentration of GO (10 wt%) demonstrate a well-dispersed mixture in hexane solution without phase separation.

-

Citations

Citations to this article as recorded by- Controlling Particle Size of Recycled Copper Oxide Powder for Copper Thermite Welding Characteristics

Hansung Lee, Minsu Kim, Byungmin Ahn

journal of Korean Powder Metallurgy Institute.2023; 30(4): 332. CrossRef

- Controlling Particle Size of Recycled Copper Oxide Powder for Copper Thermite Welding Characteristics

- [Korean]

- Development of Metal Composite Powder Non-corrosive Flux for Low Temperature Forming of the Aluminum Brazing Filler Material

- Dae-Young Kim, Ha-Neul Jang, Dae-Ho Yoon, Yun-Ho Shin, Seong-Ho Kim, Hyun-Joo Choi

- J Korean Powder Metall Inst. 2019;26(1):16-21. Published online February 1, 2019

- DOI: https://doi.org/10.4150/KPMI.2019.26.1.16

- 766 View

- 8 Download

-

Abstract

Abstract

PDF

PDF In aluminum brazing processes, corrosive flux, which is used in preventing oxidation, is currently raising environmental concerns because it generates many pollutants such as dioxin. The brazing process involving noncorrosive flux is known to encounter difficulties because the melting temperature of the flux is similar to that of the base material. In this study, a new brazing filler material is developed based on aluminum and non-corrosive flux composite powder. To minimize the interference of consolidation aluminum alloy powder by the flux, the flux is intentionally embedded in the aluminum alloy powder using a mechanical milling process. This study demonstrates that the morphology of the composite powder can be varied according to the mixing process, and this significantly affects the relative density and mechanical properties of the final filler samples.

- [Korean]

- Synthesis of Nickel Nanoparticle-adsorbed Aluminum Powders for Energetic Applications

- Dong Won Kim, Gu Hyun Kwon, Kyung Tae Kim

- J Korean Powder Metall Inst. 2016;24(3):242-247. Published online June 1, 2016

- DOI: https://doi.org/10.4150/KPMI.2017.24.3.242

- 1,187 View

- 8 Download

- 8 Citations

-

Abstract

Abstract

PDF

PDF In this study, the electroless nickel plating method has been investigated for the coating of Ni nanoparticles onto fine Al powder as promising energetic materials. The adsorption of nickel nanoparticles onto the surface of Al powders has been studied by varying various process parameters, namely, the amounts of reducing agent, complexing agent, and pH-controller. The size of nickel nanoparticles synthesized in the process has been optimized to approximately 200 nm and they have been adsorbed on the Al powder. TGA results clearly show that the temperature at which oxidation of Al mainly occurs is lowered as the amount of Ni nanoparticles on the Al surface increases. Furthermore, the Ni-plated Al powders prepared for all conditions show improved exothermic reaction due to the selfpropagating high-temperature synthesis (SHS) between Ni and Al. Therefore, Al powders fully coated by Ni nanoparticles show the highest exothermic reactivity: this demonstrates the efficiency of Ni coating in improving the energetic properties of Al powders.

-

Citations

Citations to this article as recorded by- Synthesis and oxidation behavior of Al@Ni-Fe core-shell energetic composite powders

Khawar Yaqoob, Asifa Kusar, Amena Mohsin, Onur Ertuğrul, Ahmet Çağrı Kılınç, Fahad Ali, Rub Nawaz Shahid, Naeem ul Haq Tariq, Hassan Wahab, Hasan Bin Awais

Energetic Materials Frontiers.2025;[Epub] CrossRef - Study Progress in Improving the Energy Release Rate of Al Powders

永鹏 陈

Material Sciences.2024; 14(08): 1178. CrossRef - Study on the Combustion Characteristics of Ethanol Nanofuel

Kwanyoung Noh, Hyemin Kim, Siwook Nam, Soonho Song

Aerospace.2023; 10(10): 878. CrossRef - The Self-Reduction during the Thermal Decomposition of an Ammonium Molybdate

Kyoungkeun Yoo, Won Beom Koo, Hanggoo Kim, Sang-hun Lee

Minerals.2023; 13(2): 133. CrossRef - Increased exothermic reactivity of polytetrafluoroethylene-coated aluminum powders: Impact of powder size reduction

Soo-ho Jung, Kyung Tae Kim, Jinhee Bae, Yoon Jeong Choi, Jae Min Kim, Jeong-Yun Sun

Materials Letters.2023; 351: 135009. CrossRef - High energy Al@Ni preparation of core-shell particles by adjusting nickel layer thickness

Yongpeng Chen, Jianguo Zhang, Jiawei Zhu, Ning Xiang, Huichao Zhang, Zunning Zhou

Vacuum.2022; 205: 111344. CrossRef - Electroless deposition of Ni nanoparticles on micron-sized boron carbide particles: Physicochemical and oxidation properties

Prashant Ravasaheb Deshmukh, Hyung Soo Hyun, Youngku Sohn, Weon Gyu Shin

Korean Journal of Chemical Engineering.2020; 37(3): 546. CrossRef - Synthesis and exothermic reactions of ultra-fine snowman-shaped particles with directly bonded Ni/Al interfaces

Gu Hyun Kwon, Kyung Tae Kim, Dong Won Kim, Jungho Choe, Jung Yeul Yun, Jong-Man Kim

Applied Surface Science.2019; 476: 481. CrossRef

- Synthesis and oxidation behavior of Al@Ni-Fe core-shell energetic composite powders

- [Korean]

- Spark Plasma Sintering Behavior and Heat Dissipation Characteristics of the Aluminum Matrix Composite Materials with the Contents of Graphite

- Hansang Kwon, Jehong Park, Sungwook Joo, Sanghwui Hong, Jihoon Mun

- J Korean Powder Metall Inst. 2016;23(3):195-201. Published online June 1, 2016

- DOI: https://doi.org/10.4150/KPMI.2016.23.3.195

- 985 View

- 4 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF Composite materials consisting of pure aluminum matrix reinforced with different amounts of graphite particles are successfully fabricated by mechanical ball milling and spark plasma sintering (SPS) processes. The shrinkage rates of the composite powders vary with the amount of graphite particles and the lowest shrinkage value is observed for the composite with the highest amount of graphite particles. The current slopes of time increase with increase in the amount of graphite particles whereas the current slopes of temperature show the opposite trend. The highest thermal conductivity is achieved for the composite with the least amount of graphite particles. Therefore, the thermal properties of the composite materials can be controlled by controlling the amount of the graphite particles during the SPS process.

-

Citations

Citations to this article as recorded by- Sintering Behavior and Thermal Properties of Cu-Graphite Materials by a Spark Plasma Sintering Method

Min-hyeok Yang, Bum-soon Park, Hyoung-seok Moon, Jae-cheol Park, Hyun-kuk Park

Korean Journal of Metals and Materials.2024; 62(6): 411. CrossRef - Effect of processing parameters on the microstructural and mechanical properties of aluminum–carbon nanotube composites produced by spark plasma sintering

B. Sadeghi, M. Shamanian, P. Cavaliere, F. Ashrafizadeh

International Journal of Materials Research.2018; 109(10): 900. CrossRef

- Sintering Behavior and Thermal Properties of Cu-Graphite Materials by a Spark Plasma Sintering Method

- [Korean]

- Shape Control of Anodic Aluminum Oxide and Effect as Support of Silicon Powder Electrode

- Ju-Seok Song, Jong-Keun Ha, Yoo-Young Kim, Dong-Kyu Park, In-Shup Ahn, Jou-Hyeon Ahn, Kwon-Koo Cho

- J Korean Powder Metall Inst. 2015;22(4):240-246. Published online August 1, 2015

- DOI: https://doi.org/10.4150/KPMI.2015.22.4.240

- 689 View

- 1 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF Anodic aluminum oxide (AAO) has been widely used for the development and fabrication of nano-powder with various morphologies such as particle, wire, rod, and tube. So far, many researchers have reported about shape control and fabrication of AAO films. However, they have reported on the shape control with different diameter and length of anodic aluminum oxide mainly. We present a combined mild-hard (or hard-mild) anodization to prepare shape-controlled AAO films. Two main parameters which are combination mild-hard (or hard-mild) anodization and run-time of voltage control are applied in this work. The voltages of mild and hard anodization are respectively 40 and 80 V. Anodization was conducted on the aluminum sheet in 0.3 mole oxalic acid at 4°C. AAO films with morphologies of varying interpore distance, branch-shaped pore, diameter-modulated pore and long funnel-shaped pore were fabricated. Those shapes will be able to apply to fabricate novel nano-materials with potential application which is especially a support to prevent volume expansion of inserted active materials, such as metal silicon or tin powder, in lithium ion battery. The silicon powder electrode using an AAO as a support shows outstanding cycle performance as 1003 mAh/g up to 200 cycles.

-

Citations

Citations to this article as recorded by- Nano silicon encapsulated in modified copper as an anode for high performance lithium ion battery

Jong-Keun Ha, Anupriya K. Haridas, Gyu-Bong Cho, Hyo-Jun Ahn, Jou-Hyeon Ahn, Kwon-Koo Cho

Applied Surface Science.2019; 481: 307. CrossRef

- Nano silicon encapsulated in modified copper as an anode for high performance lithium ion battery

TOP

KPMI

KPMI

First

First Prev

Prev