Search

- Page Path

- HOME > Search

- [English]

- Characterization of the Manufacturing Process and Mechanical Properties of CoCrFeMnNi High-Entropy Alloys via Metal Injection Molding and Hot Isostatic Pressing

- Eun Seong Kim, Jae Man Park, Do Won Lee, Hyojeong Ha, Jungho Choe, Jaemin Wang, Seong Jin Park, Byeong-Joo Lee, Hyoung Seop Kim

- J Powder Mater. 2024;31(3):243-254. Published online June 27, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00059

- 2,235 View

- 56 Download

-

Abstract

Abstract

PDF

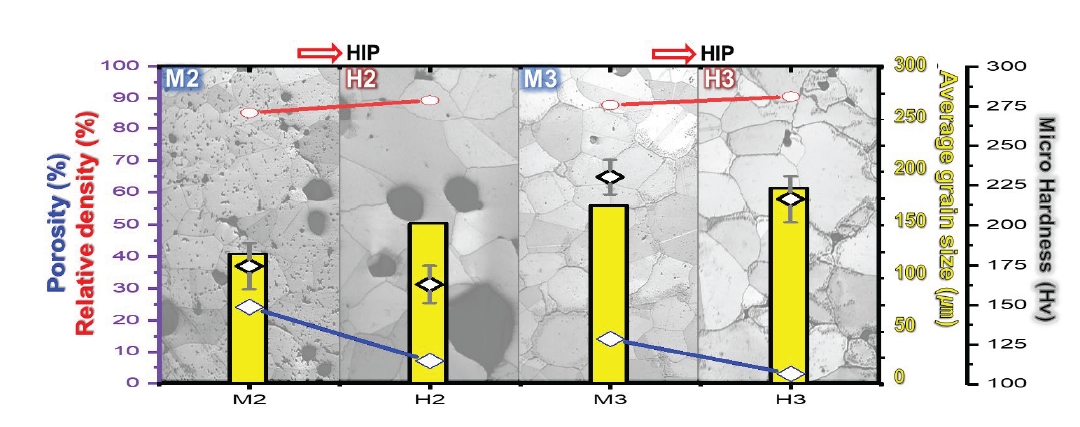

PDF - High-entropy alloys (HEAs) have been reported to have better properties than conventional materials; however, they are more expensive due to the high cost of their main components. Therefore, research is needed to reduce manufacturing costs. In this study, CoCrFeMnNi HEAs were prepared using metal injection molding (MIM), which is a powder metallurgy process that involves less material waste than machining process. Although the MIM-processed samples were in the face-centered cubic (FCC) phase, porosity remained after sintering at 1200°C, 1250°C, and 1275°C. In this study, the hot isostatic pressing (HIP) process, which considers both temperature (1150°C) and pressure (150 MPa), was adopted to improve the quality of the MIM samples. Although the hardness of the HIP-treated samples decreased slightly and the Mn composition was significantly reduced, the process effectively eliminated many pores that remained after the 1275°C MIM process. The HIP process can improve the quality of the alloy.

- [English]

- Fabrication of Equiatomic CoCrFeMnNi High-Entropy Alloy by Metal Injection Molding Process Using Coarse-Sized Powders

- Eun Seong Kim, Jae Man Park, Ji Sun Lee, Jungho Choe, Soung Yeoul Ahn, Sang Guk Jeong, Do Won Lee, Seong Jin Park, Hyoung Seop Kim

- J Powder Mater. 2023;30(1):1-6. Published online February 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.1.1

- 1,794 View

- 33 Download

- 3 Citations

-

Abstract

Abstract

PDF

PDF High-entropy alloys (HEAs) are attracting attention because of their excellent properties and functions; however, they are relatively expensive compared with commercial alloys. Therefore, various efforts have been made to reduce the cost of raw materials. In this study, MIM is attempted using coarse equiatomic CoCrFeMnNi HEA powders. The mixing ratio (powder:binder) for HEA feedstock preparation is explored using torque rheometer. The block-shaped green parts are fabricated through a metal injection molding process using feedstock. The thermal debinding conditions are explored by thermogravimetric analysis, and solvent and thermal debinding are performed. It is densified under various sintering conditions considering the melting point of the HEA. The final product, which contains a small amount of non-FCC phase, is manufactured at a sintering temperature of 1250°C.

-

Citations

Citations to this article as recorded by- Development of 3D interconnected nanoporous TiZrHfNbTaNi high-entropy alloy via liquid metal dealloying and subsequent synthesis of (TiZrHfNbTaNi)O high-entropy oxide

Jae Hyuk Lee, Soo Vin Ha, Jihye Seong, Akira Takeuchi, Ruirui Song, Hidemi Kato, Soo-Hyun Joo

Journal of Materials Research and Technology.2025; 35: 5204. CrossRef - Development of 3D interconnected heterogeneous high-entropy alloy composites with enhanced multifunctionality via liquid metal dealloying

Munsu Choi, Gang Hee Gu, Jongun Moon, Jae Wung Bae, Hidemi Kato, Seung Zeon Han, Hyoung Seop Kim, Yongseok Choi, Soo-Hyun Joo

Journal of Materials Research and Technology.2025; 37: 5672. CrossRef - Characterization of the Manufacturing Process and Mechanical Properties of CoCrFeMnNi High-Entropy Alloys via Metal Injection Molding and Hot Isostatic Pressing

Eun Seong Kim, Jae Man Park, Do Won Lee, Hyojeong Ha, Jungho Choe, Jaemin Wang, Seong Jin Park, Byeong-Joo Lee, Hyoung Seop Kim

journal of Korean Powder Metallurgy Institute.2024; 31(3): 243. CrossRef

- Development of 3D interconnected nanoporous TiZrHfNbTaNi high-entropy alloy via liquid metal dealloying and subsequent synthesis of (TiZrHfNbTaNi)O high-entropy oxide

- [English]

- Effect of 50 μm class granules on the Injection Behavior of Brushite Bone Cement Prepared via Pre-dissolution Route

- Da Hye Mun, Sang Cheon Lee, Kyung-Sik Oh

- J Korean Powder Metall Inst. 2020;27(6):468-476. Published online December 1, 2020

- DOI: https://doi.org/10.4150/KPMI.2020.27.6.468

- 837 View

- 1 Download

-

Abstract

Abstract

PDF

PDF The bone cement used for vertebroplasty must be sufficiently injectable. The introduction of granules reduces the amount of liquid required for liquefaction, implying that higher fluidity is achieved with the same amount of liquid. By employing β-tricalcium phosphate granules with an average diameter of 50 μm, changes in injectability are observed based on the paste preparation route and granular fraction. To obtain acceptable injectability, phase separation must be suppressed during injection, and sufficient capillary pressure to combine powder and liquid must work evenly throughout the paste. To achieve this, the granules should be evenly distributed. Reduced injection rates are observed for dry mixing and excessive granular content, owing to phase separation. All these correspond to conditions under which the clustered granules weakened the capillary pressure. The injected ratio of the paste formed by wet mixing displayed an inverted U-type shift with the granular fraction. The mixture of granules and powder resulted in an increase in the solid volume fraction, and a decrease in the liquid limit. This resulted in the enhancement of the liquidity, owing to the added liquid. It is inferred that the addition of granules improves the injectability, provided that the capillary pressure in the paste is maintained.

- [English]

- Optimization of Process Condition for Fe Nano Powder Injection Molding

- Joo Won Oh, Won Sik Lee, Seong Jin Park

- J Korean Powder Metall Inst. 2017;24(3):223-228. Published online June 1, 2017

- DOI: https://doi.org/10.4150/KPMI.2017.24.3.223

- 1,166 View

- 2 Download

- 3 Citations

-

Abstract

Abstract

PDF

PDF Nanopowders provide better details for micro features and surface finish in powder injection molding processes. However, the small size of such powders induces processing challenges, such as low solid loading, high feedstock viscosity, difficulty in debinding, and distinctive sintering behavior. Therefore, the optimization of process conditions for nanopowder injection molding is essential, and it should be carefully performed. In this study, the powder injection molding process for Fe nanopowder has been optimized. The feedstock has been formulated using commercially available Fe nanopowder and a wax-based binder system. The optimal solid loading has been determined from the critical solid loading, measured by a torque rheometer. The homogeneously mixed feedstock is injected as a cylindrical green body, and solvent and thermal debinding conditions are determined by observing the weight change of the sample. The influence of the sintering temperature and holding time on the density has also been investigated. Thereafter, the Vickers hardness and grain size of the sintered samples have been measured to optimize the sintering conditions.

-

Citations

Citations to this article as recorded by- Investigation of stainless steel 316L/zirconia joint part fabricated by powder injection molding

Chang Woo Gal, Sang Soo Han, Jun Sae Han, Dongguo Lin, Seong Jin Park

International Journal of Applied Ceramic Technology.2019; 16(1): 315. CrossRef - Fabrication and properties of Si3N4 based ceramics using combustion synthesized powders

Chang Woo Gal, Gi Woung Song, Woon Hyung Baek, Hyung Kyu Kim, Dae Keun Lee, Ki Wook Lim, Seong Jin Park

International Journal of Refractory Metals and Hard Materials.2019; 81: 325. CrossRef - Powder Injection Molding Process in Industrial Fields

Joo Won OH, Chang Woo GAL, Daseul SHIN, Jae Man PARK, Woo Seok YANG, Seong Jin PARK

Journal of the Japan Society of Powder and Powder Metallurgy.2018; 65(9): 539. CrossRef

- Investigation of stainless steel 316L/zirconia joint part fabricated by powder injection molding

- [Korean]

- Preparation of Ni(OH)2 Hollow Spheres by Solvent Displacement Crystallization Using Micro-Injection Device

- Seiki Kim, Kyungsoo Park, Kwang-Il Jung

- J Korean Powder Metall Inst. 2016;23(4):311-316. Published online August 1, 2016

- DOI: https://doi.org/10.4150/KPMI.2016.23.4.311

- 1,040 View

- 9 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF Ni(OH)2 hollow spheres have been prepared by solvent displacement crystallization using a micro-injection device, and the effect of process parameters such as concentration and the relative ratio of the injection speed of the precursor solution, which is an aqueous solution of NiSO4·6H2O, to isopropyl alcohol of displacement solvent have been investigated. The crystal phases after NaOH treatment are in the β-phase for all process parameters. A higher concentration of NiSO4·6H2O aqueous solution is injected by a micro-injection device and bigger Ni(OH)2 hollow spheres with a narrower particle size distribution are formed. The crystallinity and hardness of the as-obtained powder are so poor that hydrothermal treatment of the as-obtained Ni(OH)2 at 120°C for 24 h in distilled water is performed in order to greatly improve the crystallinity. It is thought that a relative ratio of the injection speed of NiSO4·6H2O to that of isopropyl alcohol of at least more than 1 is preferable to synthesize Ni(OH)2 hollow spheres. It is confirmed that this solution- based process is very effective in synthesizing ceramic hollow spheres by simple adjustment of the process parameters such as the concentration and the injection speed.

-

Citations

Citations to this article as recorded by- The Effects of Hexamethylenetetramine Concentration on the Structural and Electrochemical Performances of Ni(OH)2 Powder for Pseudocapacitor Applications

Dong Yeon Kim, Young-Min Jeong, Seong-Ho Baek, Injoon Son

Journal of Korean Powder Metallurgy Institute.2019; 26(3): 231. CrossRef

- The Effects of Hexamethylenetetramine Concentration on the Structural and Electrochemical Performances of Ni(OH)2 Powder for Pseudocapacitor Applications

- [English]

- Development of Powder Injection Molding Process for a Piezoelectric PAN-PZT Ceramics

- Jun Sae Han, Dong Yong Park, Dongguo Lin, Kwang Hyun Chung, Ravi Bollina, Seong Jin Park

- J Korean Powder Metall Inst. 2016;23(2):112-119. Published online April 1, 2016

- DOI: https://doi.org/10.4150/KPMI.2016.23.2.112

- 1,590 View

- 11 Download

- 4 Citations

-

Abstract

Abstract

PDF

PDF A powder injection molding process is developed and optimized for piezoelectric PAN-PZT ceramics. Torque rheometer experiments are conducted to determine the optimal solids loading, and the rheological property of the feedstock is evaluated using a capillary rheometer. Appropriate debinding conditions are chosen using a thermal gravity analyzer, and the debound specimens are sintered using sintering conditions determined in a preliminary investigation. Piezoelectric performance measures, including the piezoelectric charge constant and dielectric constant, are measured to verify the developed process. The average values of the measured piezoelectric charge constant and dielectric constant are 455 pC/N and 1904, respectively. Powder injection molded piezoelectric ceramics produced by the optimized process show adequate piezoelectric performance compared to press-sintered piezoelectric ceramics.

-

Citations

Citations to this article as recorded by- Study on Rheological Behavior and Mechanical Properties of PMN–PZT Ceramic Feedstock

Jae Man Park, Jun Sae Han, Joo Won Oh, Seong Jin Park

Metals and Materials International.2021; 27(5): 1069. CrossRef - Investigation of stainless steel 316L/zirconia joint part fabricated by powder injection molding

Chang Woo Gal, Sang Soo Han, Jun Sae Han, Dongguo Lin, Seong Jin Park

International Journal of Applied Ceramic Technology.2019; 16(1): 315. CrossRef - Fabrication of pressureless sintered Si3N4 ceramic balls by powder injection molding

Chang Woo Gal, Gi Woung Song, Woon Hyung Baek, Hyung Kyu Kim, Dae Keun Lee, Ki Wook Lim, Seong Jin Park

Ceramics International.2019; 45(5): 6418. CrossRef - Experimental analysis for fabrication of high-aspect-ratio piezoelectric ceramic structure by micro-powder injection molding process

Jun Sae Han, Chang Woo Gal, Jae Man Park, Jong Hyun Kim, Seong Jin Park

Materials Research Express.2018; 5(4): 046303. CrossRef

- Study on Rheological Behavior and Mechanical Properties of PMN–PZT Ceramic Feedstock

- [English]

- Development of Powder Injection Molding Process for Fabrication of Glass Component

- Dongguo Lin, Junghyun Lee, Seong Jin Park

- J Korean Powder Metall Inst. 2016;23(1):26-32. Published online February 1, 2016

- DOI: https://doi.org/10.4150/KPMI.2016.23.1.26

- 2,415 View

- 22 Download

- 8 Citations

-

Abstract

Abstract

PDF

PDF Powder injection molding (PIM), which combines the advantages of powder metallurgy and plastic injection molding technologies, has become one of the most efficient methods for the net-shape production of both metal and ceramic components. In this work, plasma display panel glass bodies are prepared by the PIM process. After sintering, the hot isostatic pressing (HIP) process is adopted for improving the density and mechanical properties of the PIMed glass bodies. The mechanical and thermal behaviors of the prepared specimens are analyzed through bending tests and dilatometric analysis, respectively. After HIPing, the flexural strength of the prepared glass body reaches up to 92.17 MPa, which is 1.273 and 2.178 times that of the fused glass body and PIMed bodies, respectively. Moreover, a thermal expansion coefficient of 7.816 × 10−6/°C is obtained, which coincides with that of the raw glass powder (7.5-8.0 × 10−6/°C), indicating that the glass body is fully densified after the HIP process.

-

Citations

Citations to this article as recorded by- Fabrication and characteristics of Li2TiO3 pebbles manufactured by using powder injection molding (PIM) process

Young Ah Park, Yi-Hyun Park, Mu-Young Ahn, Young Soo Yoon

Journal of Nuclear Materials.2024; 597: 155140. CrossRef - Combined simulation of micro and nanoparticles in RF inductively coupled plasma torches with the variations of metallic species and feeding nozzle location

Cheongbin Cheon, Ho Jun Kim, Hae June Lee

Japanese Journal of Applied Physics.2023; 62(SA): SA1014. CrossRef - High-throughput injection molding of transparent fused silica glass

Markus Mader, Oliver Schlatter, Barbara Heck, Andreas Warmbold, Alex Dorn, Hans Zappe, Patrick Risch, Dorothea Helmer, Frederik Kotz, Bastian E. Rapp

Science.2021; 372(6538): 182. CrossRef - Controlling the sintering response in the development of multilayered components produced via powder injection molding route—a review

O. J. Ojo-kupoluyi, S. M. Tahir, T. T. Dele-Afolabi, M. S. Anuar

The International Journal of Advanced Manufacturing Technology.2020; 107(9-10): 3755. CrossRef - Fabrication of pressureless sintered Si3N4 ceramic balls by powder injection molding

Chang Woo Gal, Gi Woung Song, Woon Hyung Baek, Hyung Kyu Kim, Dae Keun Lee, Ki Wook Lim, Seong Jin Park

Ceramics International.2019; 45(5): 6418. CrossRef - Thermal decomposition behavior and modeling of PMN-PZT ceramic feedstock with varying binder compositions

Jae Man Park, Jun Sae Han, Chang Woo Gal, Joo Won Oh, Dongguo Lin, Jaebum Noh, Kunal H Kate, Sundar V Atre, Youngmoo Kim, Seong Jin Park

Materials Research Express.2019; 6(6): 065316. CrossRef - Powder Injection Molding Process in Industrial Fields

Joo Won OH, Chang Woo GAL, Daseul SHIN, Jae Man PARK, Woo Seok YANG, Seong Jin PARK

Journal of the Japan Society of Powder and Powder Metallurgy.2018; 65(9): 539. CrossRef - Optimization of Process Condition for Fe Nano Powder Injection Molding

Joo Won Oh, Won Sik Lee, Seong Jin Park

Journal of Korean Powder Metallurgy Institute.2017; 24(3): 223. CrossRef

- Fabrication and characteristics of Li2TiO3 pebbles manufactured by using powder injection molding (PIM) process

- [English]

- Simulation and Experiment of Injection Molding Process for Superalloy Feedstock

- Im Doo Jung, Youngmoo Kim, Seong Jin Park

- J Korean Powder Metall Inst. 2015;22(1):1-5. Published online February 1, 2015

- DOI: https://doi.org/10.4150/KPMI.2015.22.1.1

- 1,311 View

- 5 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF Powder injection molding is an important manufacturing technology to mass produce superalloy components with complex shape. Injection molding step is particularly important for realizing a desired shape, which requires much time and efforts finding the optimum process condition. Therefore computer aided engineering can be very useful to find proper injection molding conditions. In this study, we have conducted a finite element method based simulation for the spiral mold test of superalloy feedstock and compared the results with experimental ones. Sensitivity analysis with both of simulation and experiment reveals that the melt temperature of superalloy feedstock is the most important factor for the full filling of mold cavity. The FEM based simulation matches well the experimental results. This study contributes to the optimization of superalloy powder injection molding process.

-

Citations

Citations to this article as recorded by- Powder Injection Molding Process in Industrial Fields

Joo Won OH, Chang Woo GAL, Daseul SHIN, Jae Man PARK, Woo Seok YANG, Seong Jin PARK

Journal of the Japan Society of Powder and Powder Metallurgy.2018; 65(9): 539. CrossRef - Effect of Diamond Particle Size on the Thermal Shock Property of High Pressure High Temperature Sintered Polycrystalline Diamond Compact

Ji-Won Kim, Min-Seok Baek, Hee-Sub Park, Jin-Hyeon Cho, Kee-Ahn Lee

Journal of Korean Powder Metallurgy Institute.2016; 23(5): 364. CrossRef

- Powder Injection Molding Process in Industrial Fields

- [English]

- Powder Injection Molding of Translucent Alumina using Supercritical Fluid Debinding

- Hyung Soo Kim, Jong Min Byun, Myung Jin Suk, Young Do Kim

- J Korean Powder Metall Inst. 2014;21(6):407-414. Published online December 1, 2014

- DOI: https://doi.org/10.4150/KPMI.2014.21.6.407

- 1,032 View

- 1 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF The powder injection molding process having advantages in manufacturing three-dimensional precision parts essentially requires a debinding process before sintering to remove the binders used for preparing feedstock. In this study, powder injection molding of translucent alumina was performed, and carbon dioxide (CO2) is used as a supercritical fluid that makes it possible to remove a large amount of binder, which is paraffin wax. The relationship between the optical property of translucent alumina and the debinding condition (temperature and pressure) of supercritical CO2 was investigated. As temperature and pressure increased, extraction rate of the binder showed rising tendency and average grain size after sintering process was relatively fine. On the other hand, optical transmittance was reduced. As a result, the debinding condition at 50° and 20 MPa that represents the lowest extraction rate, 8.19 × 10−3 m2/sec, corresponds to the largest grain size of 14.7 μm and the highest optical transmittance of 45.2%.

-

Citations

Citations to this article as recorded by- Supercritical CO₂ debinding: A promising method for binder removal in ceramic fabrication with potential applications in additive manufacturing – A review

Adolor David Aiyeki

Journal of the European Ceramic Society.2026; 46(5): 117998. CrossRef - Experimental and numerical analysis of effects of supercritical carbon dioxide debinding on Inconel 718 MIM components

Dugauguez Olivier, Agne Aboubabky, Jimenez-Morales Antonia, Torralba José Manuel, Barriere Thierry

Powder Technology.2019; 355: 57. CrossRef

- Supercritical CO₂ debinding: A promising method for binder removal in ceramic fabrication with potential applications in additive manufacturing – A review

- [Korean]

- A study on the Powder Injection Molding of Translucent Alumina via Flowability Simulation of Powder/Binder Mixture

- Hyung Soo Kim, Jong Min Byun, Se Hoon Kim, Young Do Kim

- J Korean Powder Metall Inst. 2014;21(3):215-221. Published online June 1, 2014

- DOI: https://doi.org/10.4150/KPMI.2014.21.3.215

- 595 View

- 0 Download

-

Abstract

Abstract

PDF

PDF Translucent alumina is a potential candidate for high temperature application as a replacement of the glass or polymer. Recently, due to the increasing demand of high power light emitting diode (LED), there is a growing interest in the translucent alumina. Since the translucent property is very sensitive to the internal defect, such as voids inside or abnormal grain growth of sintered alumina, it is important to fabricate the defect-free product through the fabrication process. Powder injection molding (PIM) has been commonly applied for the fabrication of complex shaped products. Among the many parameters of PIM, the flowability of powder/binder mixture becomes more significant especially for the shape of the cavity with thin thickness. Two different positions of the gate were applied during PIM using the disc type of die. The binder was removed by solvent extraction method and the brown compact was sintered at 1750°C for 3 hours in a vacuum. The flowability was also simulated using moldflow (MPI 6.0) with two different types of gate. The effect of the flowability of powder/binder mixture on the microstructure of the sintered specimen was studied with the analysis of the simulation result.

- [English]

- Advanced PM Processes for Medical Technologies

- Frank Petzoldt, Vera Friederici, Philipp Imgrund, Claus Aumund-Kopp

- J Korean Powder Metall Inst. 2014;21(1):1-6. Published online February 1, 2014

- DOI: https://doi.org/10.4150/KPMI.2014.21.1.1

- 1,202 View

- 5 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF Medical technologies are gaining in importance because of scientific and technical progress in medicine and the increasing average lifetime of people. This has opened up a huge market for medical devices, where complex-shaped metallic parts made from biocompatible materials are in great demand. Today many of these components are already being manufactured by powder metallurgy technologies. This includes mass production of standard products and also customized components. In this paper some aspects related to metal injection molding of Ti and its alloys as well as modifications of microstructure and surface finish were discussed. The process chain of additive manufacturing (AM) was described and the current state of the art of AM processes like Selective Laser Melting and electron beam melting for medical applications was presented.

-

Citations

Citations to this article as recorded by- Enhancing corrosion resistance of Ti-based amorphous alloy powders via misch metal addition

Yeon Joo Lee, Hyokyung Sung, Jae Bok Seol, Kisub Cho, Hwi Jun Kim, Hyunjoo Choi

Powder Metallurgy.2025; 68(3): 230. CrossRef - Spontaneous Formation of Titanium Nitride on the Surface of a Ti Rod Induced by Electro-Discharge-Heat-Treatment in an N2 Atmosphere

W.H. Lee, Y.H. Yoon, Y.H. Kim, Y.K. Lee, J.Y. Kim, S.Y. Chang

Archives of Metallurgy and Materials.2017; 62(2): 1281. CrossRef

- Enhancing corrosion resistance of Ti-based amorphous alloy powders via misch metal addition

TOP

KPMI

KPMI

First

First Prev

Prev