Search

- Page Path

- HOME > Search

- [English]

- Research Trends in Electromagnetic Shielding using MXene-based Composite Materials

- Siyeon Kim, Jongmin Byun

- J Powder Mater. 2024;31(1):57-76. Published online February 28, 2024

- DOI: https://doi.org/10.4150/KPMI.2024.31.1.57

- 8,304 View

- 163 Download

- 4 Citations

-

Abstract

Abstract

PDF

PDF Recent advancements in electronic devices and wireless communication technologies, particularly the rise of 5G, have raised concerns about the escalating electromagnetic pollution and its potential adverse impacts on human health and electronics. As a result, the demand for effective electromagnetic interference (EMI) shielding materials has grown significantly. Traditional materials face limitations in providing optimal solutions owing to inadequacy and low performance due to small thickness. MXene-based composite materials have emerged as promising candidates in this context owing to their exceptional electrical properties, high conductivity, and superior EMI shielding efficiency across a broad frequency range. This review examines the recent developments and advantages of MXene-based composite materials in EMI shielding applications, emphasizing their potential to address the challenges posed by electromagnetic pollution and to foster advancements in modern electronics systems and vital technologies.

-

Citations

Citations to this article as recorded by- Designing dual phase hexaferrite (SrFe12O19) – Perovskite (La0.5Nd0.5FeO3) composites for enhanced electromagnetic wave absorption and band gap modulation

Pramod D. Mhase, Varsha C. Pujari, Santosh S. Jadhav, Abdullah G. Al-Sehemi, Sarah Alsobaie, Sunil M. Patange

Composites Communications.2025; 54: 102284. CrossRef - Microstructure tailoring of Nb-based MAX phase by low temperature synthesis with layer-structured Nb2C powder and molten salt method

Chaehyun Lim, Wonjune Choi, Jongmin Byun

Materials Characterization.2025; 225: 115106. CrossRef - Fabrication of MOF@MXene composites via surface modification of MXene under acidic conditions

Ji-Haeng Jeong, Woong-Ryeol Yu

Functional Composites and Structures.2025; 7(2): 025006. CrossRef - V2CTx MXene@ZIF-8 composite as an efficient adsorbent for Pb(II) removal from aqueous solution

Sarina Khojasteh Fard, Golshan Mazloom, Manoochehr Sobhani, Mohsen Tamtaji

Journal of Environmental Chemical Engineering.2025; 13(6): 120099. CrossRef

- Designing dual phase hexaferrite (SrFe12O19) – Perovskite (La0.5Nd0.5FeO3) composites for enhanced electromagnetic wave absorption and band gap modulation

- [Korean]

- Thermal Atomic Layer Etching of the Thin Films: A Review

- Hyeonhui Jo, Seo Hyun Lee, Eun Seo Youn, Ji Eun Seo, Jin Woo Lee, Dong Hoon Han, Seo Ah Nam, Jeong Hwan Han

- J Powder Mater. 2023;30(1):53-64. Published online February 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.1.53

- 5,261 View

- 222 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF Atomic layer etching (ALE) is a promising technique with atomic-level thickness controllability and high selectivity based on self-limiting surface reactions. ALE is performed by sequential exposure of the film surface to reactants, which results in surface modification and release of volatile species. Among the various ALE methods, thermal ALE involves a thermally activated reaction by employing gas species to release the modified surface without using energetic species, such as accelerated ions and neutral beams. In this study, the basic principle and surface reaction mechanisms of thermal ALE?processes, including “fluorination-ligand exchange reaction”, “conversion-etch reaction”, “conversion-fluorination reaction”, “oxidation-fluorination reaction”, “oxidation-ligand exchange reaction”, and “oxidation-conversion-fluorination reaction” are described. In addition, the reported thermal ALE processes for the removal of various oxides, metals, and nitrides are presented.

-

Citations

Citations to this article as recorded by- Self-Assembled Monolayers in Area-Selective Atomic Layer Deposition and Their Challenges

Si Eun Jung, Ji Woong Shin, Ye Jin Han, Byung Joon Choi

Journal of Powder Materials.2025; 32(3): 179. CrossRef

- Self-Assembled Monolayers in Area-Selective Atomic Layer Deposition and Their Challenges

- [Korean]

- Joint Interface Observation of V and 17-4PH Stainless Steel Dissimilar Materials Manufactured by Direct Energy Deposition

- Se-Hwan Lee, Hobeom Kim, Jeoung Han Kim

- J Powder Mater. 2022;29(1):8-13. Published online February 1, 2022

- DOI: https://doi.org/10.4150/KPMI.2022.29.1.8

- 611 View

- 5 Download

-

Abstract

Abstract

PDF

PDF In this study, we have prepared a Ti-6Al-4V/V/17-4 PH composite structure via a direct energy deposition process, and analyzed the interfaces using scanning electron microscopy (SEM) and transmission electron microscopy (TEM). The joint interfaces comprise two zones, one being a mixed zone in which V and 17-4PH are partially mixed and another being a fusion zone in the 17-4PH region which consists of Fe+FeV. It is observed that the power of the laser used in the deposition process affects the thickness of the mixed zone. When a 210 W laser is used, the thickness of the mixed zone is wider than that obtained using a 150 W laser, and the interface resembles a serrated shape. Moreover, irrespective of the laser power used, the expected σ phase is found to be absent in the V/17-4 PH stainless steel joint; however, many VN precipitates are observed.

- [Korean]

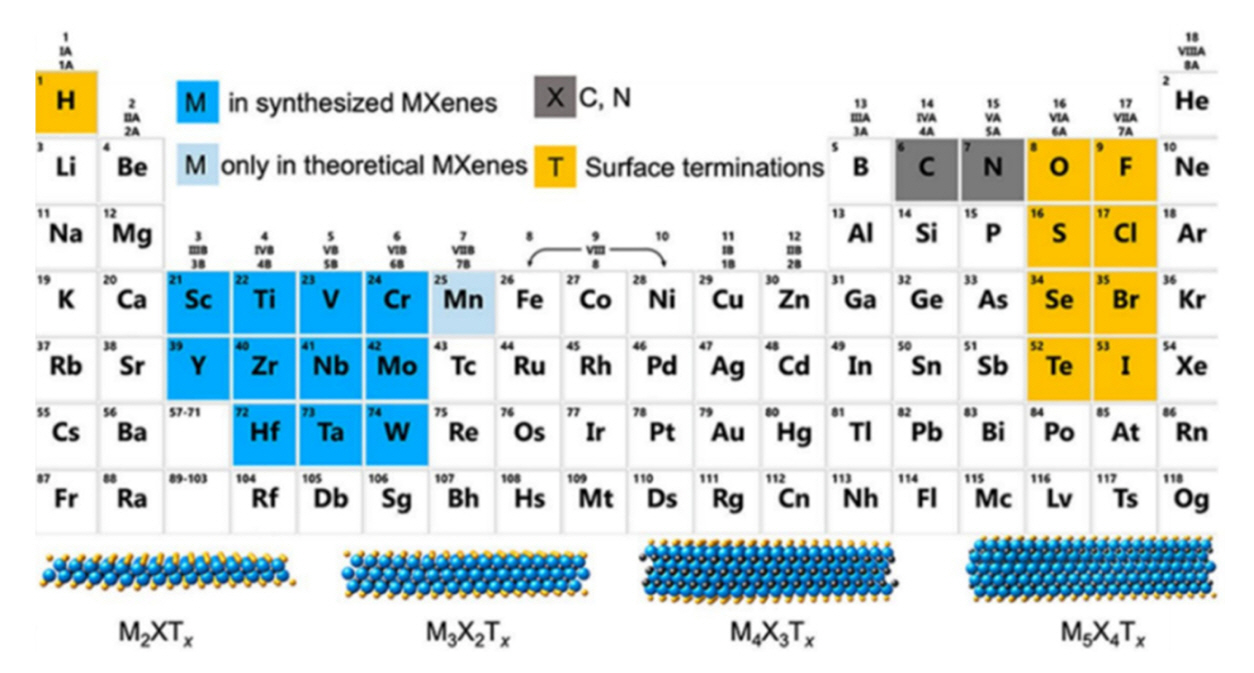

- Research trends of MXenes as the Next-generation Two-dimensional Materials

- Hojun Lee, Yejun Yun, Jinkwang Jang, Jongmin Byun

- J Korean Powder Metall Inst. 2021;28(2):150-163. Published online April 1, 2021

- DOI: https://doi.org/10.4150/KPMI.2021.28.2.150

- 3,521 View

- 106 Download

- 3 Citations

-

Abstract

Abstract

PDF

PDF Interest in eco-friendly materials with high efficiencies is increasing significantly as science and technology undergo a paradigm shift toward environment-friendly and sustainable development. MXenes, a class of two-dimensional inorganic compounds, are generally defined as transition metal carbides or nitrides composed of few-atoms-thick layers with functional groups. Recently MXenes, because of their desirable electrical, thermal, and mechanical properties that emerge from conductive layered structures with tunable surface terminations, have garnered significant attention as promising candidates for energy storage applications (e.g., supercapacitors and electrode materials for Li-ion batteries), water purification, and gas sensors. In this review, we introduce MXenes and describe their properties and research trends by classifying them into two main categories: transition metal carbides and nitrides, including Ti-based MXenes, Mo-based MXenes, and Nb-based MXenes.

-

Citations

Citations to this article as recorded by- Next-generation brackish water treatment: Exploring dual-ion capacitive deionization

Yize Li, Jing He, He Liu, Chao Yan

Journal of Environmental Chemical Engineering.2025; 13(2): 116037. CrossRef - Microstructure tailoring of Nb-based MAX phase by low temperature synthesis with layer-structured Nb2C powder and molten salt method

Chaehyun Lim, Wonjune Choi, Jongmin Byun

Materials Characterization.2025; 225: 115106. CrossRef - Review on 2D MXene and graphene electrodes in capacitive deionization

Hammad Younes, Ding Lou, Md. Mahfuzur Rahman, Daniel Choi, Haiping Hong, Linda Zou

Environmental Technology & Innovation.2022; 28: 102858. CrossRef

- Next-generation brackish water treatment: Exploring dual-ion capacitive deionization

- [Korean]

- Experimental Study on Improving Compressive Strength of Hexagonal Boron Nitride Reinforced Cement Composite

- Yomin Choi, Hyun‐Gyoo Shin

- J Korean Powder Metall Inst. 2020;27(6):503-508. Published online December 1, 2020

- DOI: https://doi.org/10.4150/KPMI.2020.27.6.503

- 643 View

- 1 Download

-

Abstract

Abstract

PDF

PDF The mechanical properties and microstructures of hexagonal boron nitride (h-BN)-reinforced cement composites are experimentally studied for three and seven curing days. Various sizes (5, 10, and 18 μm) and concentrations (0.1%, 0.25%, 0.5%, and 1.0%) of h-BN are dispersed by the tip ultrasonication method in water and incorporated into the cement composite. The compressive strength of the h-BN reinforced cements increases by 40.9%, when 0.5 wt% of 18 μm-sized h-BN is added. However, the compressive strength decreases when the 1.0 wt% cement composite is added, owing to the aggregation of the h-BNs in the cement composite. The microstructural characterization of the h-BN-reinforced cement composite indicates that the h-BNs act as bridges connecting the cracks, resulting in improved mechanical properties for the reinforced cement composite.

- [Korean]

- Effects of Sintering Additives on the Thermal and Mechanical Properties of AlN by Pressureless Sintering

- Jin Uk Hwang, So Youn Mun, Sang Yong Nam, Hwan Soo Dow

- J Korean Powder Metall Inst. 2019;26(5):395-404. Published online October 1, 2019

- DOI: https://doi.org/10.4150/KPMI.2019.26.5.395

- 2,277 View

- 53 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF Aluminum nitride (AlN) has excellent electrical insulation property, high thermal conductivity, and a low thermal expansion coefficient; therefore, it is widely used as a heat sink, heat-conductive filler, and heat dissipation substrate. However, it is well known that the AlN-based materials have disadvantages such as low sinterability and poor mechanical properties. In this study, the effects of addition of various amounts (1-6 wt.%) of sintering additives Y2O3 and Sm2O3 on the thermal and mechanical properties of AlN samples pressureless sintered at 1850°C in an N2 atmosphere for a holding time of 2 h are examined. All AlN samples exhibit relative densities of more than 97%. It showed that the higher thermal conductivity as the Y2O3 content increased than the Sm2O3 additive, whereas all AlN samples exhibited higher mechanical properties as Sm2O3 content increased. The formation of secondary phases by reaction of Y2O3, Sm2O3 with oxygen from AlN lattice influenced the thermal and mechanical properties of AlN samples due to the reaction of the oxygen contents in AlN lattice.

-

Citations

Citations to this article as recorded by- Effects of YH2 addition on pressureless sintered AlN ceramics

Liang Wang, Wei-Ming Guo, Peng-Fei Sheng, Li-Fu Lin, Xiao Zong, Shang-Hua Wu

Journal of the European Ceramic Society.2023; 43(3): 862. CrossRef

- Effects of YH2 addition on pressureless sintered AlN ceramics

- [Korean]

- Research trend in Fabrication of Metastable-phase Iron Nitrides for Hard Magnetic Applications

- Kyung Min Kim, Jung-Goo Lee, Kyung Tae Kim, Youn-Kyoung Baek

- J Korean Powder Metall Inst. 2019;26(2):146-155. Published online April 1, 2019

- DOI: https://doi.org/10.4150/KPMI.2019.26.2.146

- 1,721 View

- 23 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF Rare earth magnets are the strongest type of permanent magnets and are integral to the high tech industry, particularly in clean energies, such as electric vehicle motors and wind turbine generators. However, the cost of rare earth materials and the imbalance in supply and demand still remain big problems to solve for permanent magnet related industries. Thus, a magnet with abundant elements and moderate magnetic performance is required to replace rare-earth magnets. Recently, a”-Fe16N2 has attracted considerable attention as a promising candidate for next-generation non-rare-earth permanent magnets due to its gigantic magnetization (3.23 T). Also, metastable a”-Fe16N2 exhibits high tetragonality (c/a = 1.1) by interstitial introduction of N atoms, leading to a high magnetocrystalline anisotropy constant (K1 = 1.0MJ/m3). In addition, Fe has a large amount of reserves on the Earth compared to other magnetic materials, leading to low cost of raw materials and manufacturing for industrial production. In this paper, we review the synthetic methods of metastable a”-Fe16N2 with film, powder and bulk form and discuss the approaches to enhance magnetocrystalline anisotropy of a”-Fe16N2. Future research prospects are also offered with patent trends observed thus far.

-

Citations

Citations to this article as recorded by- Failure Cases according to Photocuring-Based Alumina 3D Printing

So-Young Ko, Shin-Il Go, Kyoung-Jun Jang, Sang-Jin Lee

Korean Journal of Materials Research.2024; 34(10): 457. CrossRef

- Failure Cases according to Photocuring-Based Alumina 3D Printing

- [English]

- Synthesis of Boron Nitride Nanotubes via inductively Coupled thermal Plasma process Catalyzed by Solid-state ammonium Chloride

- Mi Se Chang, Young Gyun Nam, Sangsun Yang, Kyung Tae Kim, Ji Hun Yu, Yong-Jin Kim, Jae Won Jeong

- J Korean Powder Metall Inst. 2018;25(2):120-125. Published online April 1, 2018

- DOI: https://doi.org/10.4150/KPMI.2017.25.2.120

- 683 View

- 7 Download

-

Abstract

Abstract

PDF

PDF Boron nitride nanotubes (BNNTs) are receiving great attention because of their unusual material properties, such as high thermal conductivity, mechanical strength, and electrical resistance. However, high-throughput and highefficiency synthesis of BNNTs has been hindered due to the high boiling point of boron (~ 4000°C) and weak interaction between boron and nitrogen. Although, hydrogen-catalyzed plasma synthesis has shown potential for scalable synthesis of BNNTs, the direct use of H2 gas as a precursor material is not strongly recommended, as it is extremely flammable. In the present study, BNNTs have been synthesized using radio-frequency inductively coupled thermal plasma (RF-ITP) catalyzed by solid-state ammonium chloride (NH4Cl), a safe catalyst materials for BNNT synthesis. Similar to BNNTs synthesized from h-BN (hexagonal boron nitride) + H2, successful fabrication of BNNTs synthesized from h-BN+NH4Cl is confirmed by their sheet-like properties, FE-SEM images, and XRD analysis. In addition, improved dispersion properties in aqueous solution are found in BNNTs synthesized from h-BN +NH4Cl.

- [Korean]

- Synthesis of Hexagonal Boron Nitride Nanocrystals and Their Application to Thermally Conductive Composites

- Jae-Yong Jung, Yang-Do Kim, Pyung-Woo Shin, Young-Kuk Kim

- J Korean Powder Metall Inst. 2016;23(6):414-419. Published online December 1, 2016

- DOI: https://doi.org/10.4150/KPMI.2016.23.6.414

- 1,503 View

- 20 Download

-

Abstract

Abstract

PDF

PDF Much attention has been paid to thermally conductive materials for efficient heat dissipation of electronic devices to maintain their functionality and to support lifetime span. Hexagonal boron nitride (h-BN), which has a high thermal conductivity, is one of the most suitable materials for thermally conductive composites. In this study, we synthesize h-BN nanocrystals by pyrolysis of cost-effective precursors, boric acid, and melamine. Through pyrolysis at 900°C and subsequent annealing at 1500°C, h-BN nanoparticles with diameters of ~80 nm are synthesized. We demonstrate that the addition of small amounts of Eu-containing salts during the preparation of melamine borate precursors significantly enhanced the crystallinity of h-BN. In particular, addition of Eu assists the growth of h-BN nanoplatelets with diameters up to ~200 nm. Polymer composites containing both spherical Al2O3 (70 vol%) and Eu-doped h-BN nanoparticles (4 vol%) show an enhanced thermal conductivity (λ ~ 1.72W/mK), which is larger than the thermal conductivity of polymer composites containing spherical Al2O3 (70 vol%) as the sole fillers (λ ~ 1.48W/mK).

TOP

KPMI

KPMI

First

First Prev

Prev