Search

- Page Path

- HOME > Search

- [Korean]

- The Manufacturing Process of Clean Ni-Cr-Co-Based Superalloy Powder Using a Plasma Rotating Electrode

- Kyu-Sik Kim, Dae Woong Kim, Yeontae Kim, Jung Hyo Park

- J Powder Mater. 2025;32(3):222-231. Published online June 30, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00171

- 784 View

- 23 Download

-

Abstract

Abstract

PDF

PDF - Ni-based superalloys are widely used for critical components in aerospace, defense, industrial power generation systems, and other applications. Clean superalloy powders and manufacturing processes, such as compaction and hot isostatic pressing, are essential for producing superalloy discs used in turbine engines, which operate under cyclic rotating loads and high-temperature conditions. In this study, the plasma rotating electrode process (PREP), one of the most promising methods for producing clean metallic powders, is employed to fabricate Ni-based superalloy powders. PREP leads to a larger powder size and narrower distribution compared to powders produced by vacuum induction melt gas atomization. An important finding is that highly spheroidized powders almost free of satellites, fractured, and deformed particles can be obtained by PREP, with significantly low oxygen content (approximately 50 ppm). Additionally, large grain size and surface inclusions should be further controlled during the PREP process to produce high-quality powder metallurgy parts.

- [Korean]

- Development of Aluminum Alloys for Additive Manufacturing Using Machine Learning

- Sungbin An, Juyeon Han, Seoyeon Jeon, Dowon Kim, Jae Bok Seol, Hyunjoo Choi

- J Powder Mater. 2025;32(3):202-211. Published online June 30, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00150

- 784 View

- 51 Download

-

Abstract

Abstract

PDF

PDF - The present study introduces a machine learning approach for designing new aluminum alloys tailored for directed energy deposition additive manufacturing, achieving an optimal balance between hardness and conductivity. Utilizing a comprehensive database of powder compositions, process parameters, and material properties, predictive models—including an artificial neural network and a gradient boosting regression model, were developed. Additionally, a variational autoencoder was employed to model input data distributions and generate novel process data for aluminum-based powders. The similarity between the generated data and the experimental data was evaluated using K-nearest neighbor classification and t-distributed stochastic neighbor embedding, with accuracy and the F1-score as metrics. The results demonstrated a close alignment, with nearly 90% accuracy, in numerical metrics and data distribution patterns. This work highlights the potential of machine learning to extend beyond multi-property prediction, enabling the generation of innovative process data for material design.

- [English]

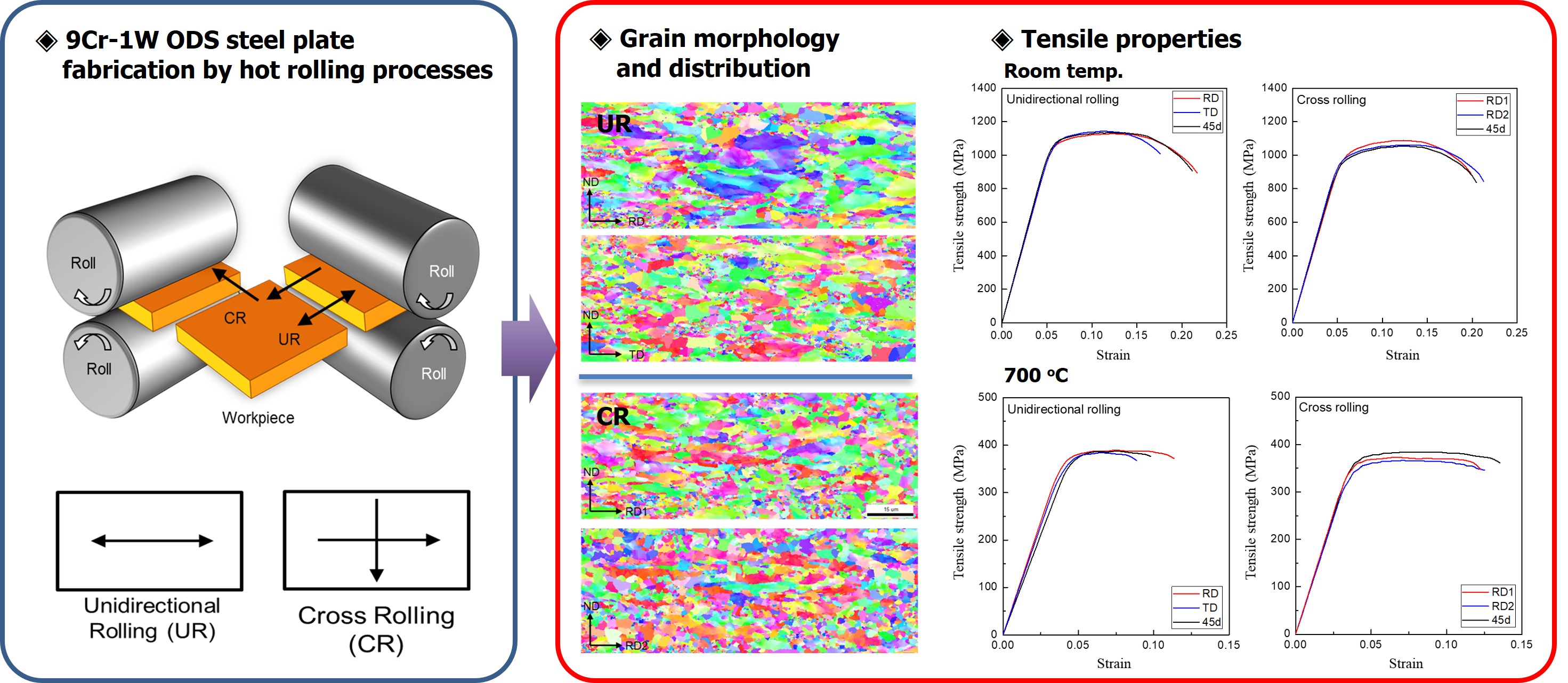

- Effect of the Cross-rolling Process on the Microstructures and Mechanical Properties of 9Cr-1W ODS Steel

- Bu-An Kim, Sanghoon Noh

- J Powder Mater. 2025;32(1):37-42. Published online February 28, 2025

- DOI: https://doi.org/10.4150/jpm.2024.00332

- 1,025 View

- 32 Download

-

Abstract

Abstract

PDF

PDF - This study employed a cross-rolling process to fabricate oxide dispersion strengthened (ODS) steel plates and investigated their microstructures and mechanical properties. The 9Cr-1W ODS ferritic steel was fabricated using mechanical alloying and hot isostatic pressing. The hot cross-rolling process produced thick ODS ferritic steel plates with a well-extended rectangular shape. The working direction greatly affected the grain structure and crystal texture of the ODS ferritic steel. Cross-rolled plates showed fine micro-grains with random crystal orientation, while unidirectionally rolled plates exhibited a strong orientation with larger, elongated grains. Transmission electron microscopy revealed a uniform distribution of nano-oxide particles in both rolling methods, with no major differences. Tensile tests of the ODS ferritic steel plates showed that the unidirectional rolled plates had anisotropic elongation, while cross-rolled plates exhibited isotropic behavior with uniform elongation. Cross-rolling produced finer, more uniform grains, reducing anisotropy and improving mechanical properties, making it ideal for manufacturing wide ODS steel components.

- [English]

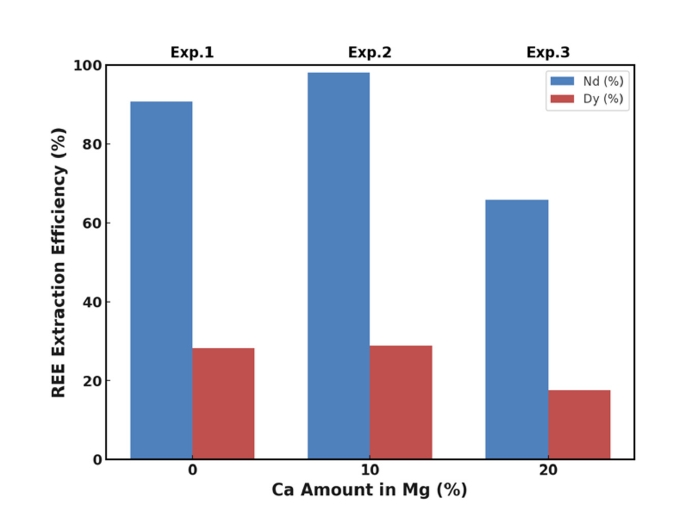

- Effect of Calcium Addition on the High-Temperature Recovery of Nd and Dy from Nd-Fe-B Scrap Using Mg-Based Extractants

- Hyoseop Kim

- J Powder Mater. 2024;31(6):493-499. Published online December 31, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00283

- 1,694 View

- 18 Download

-

Abstract

Abstract

PDF

PDF - This study investigated whether calcium (Ca) addition improved the recovery of neodymium (Nd) and dysprosium (Dy) from Nd-Fe-B magnet scrap using magnesium (Mg)-based liquid metal extraction (LME). Traditional LME processes are limited to temperatures up to 850 °C due to oxidation issues, reducing the efficiency of rare earth element (REE) recovery, especially for Dy. By adding 10 wt.% Ca to Mg and increasing the processing temperature to 1,000 °C, we achieved nearly 100% Nd and approximately 38% Dy recovery, compared to 91% and 28%, respectively, with pure Mg at 850 °C. However, excessive Ca addition (20 wt.%) decreased the recovery efficiency due to the formation of stable intermetallic compounds. These results highlight the critical role of Ca in optimizing REE recycling from Nd-Fe-B magnet scrap.

- [English]

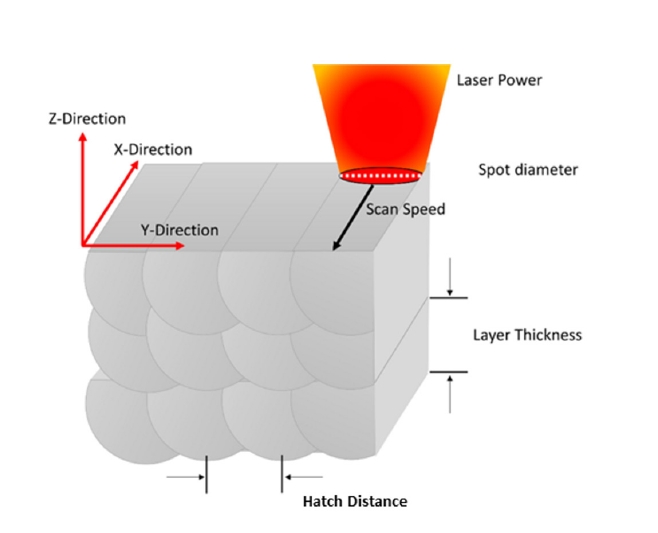

- A Parametric Study on the L-PBF Process of an AlSi10Mg Alloy for High-Speed Productivity of Automotive Prototype Parts

- Yeonha Chang, Hyomoon Joo, Wanghyun Yong, Yeongcheol Jo, Seongjin Kim, Hanjae Kim, Yeon Woo Kim, Kyung Tae Kim, Jeong Min Park

- J Powder Mater. 2024;31(5):390-398. Published online October 31, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00325

- 2,193 View

- 65 Download

- 3 Citations

-

Abstract

Abstract

PDF

PDF - The AlSi10Mg alloy has garnered significant attention for its application in laser powder bed fusion (L-PBF), due to its lightweight properties and good printability using L-PBF. However, the low production speed of the L-PBF process is the main bottleneck in the industrial commercialization of L-PBF AlSi10Mg alloy parts. Furthermore, while L-PBF AlSi10Mg alloy exhibits excellent mechanical properties, the properties are often over-specified compared to the target properties of parts traditionally fabricated by casting. To accelerate production speed in L-PBF, this study investigated the effects of process parameters on the build rate and mechanical properties of the AlSi10Mg alloy. Guidelines are proposed for high-speed additive manufacturing of the AlSi10Mg alloy for use in automotive parts. The results show a significant increase in the build rate, exceeding the conventional build rate by a factor of 3.6 times or more, while the L-PBF AlSi10Mg alloy met the specifications for automotive prototype parts. This strategy can be expected to offer significant cost advantages while maintaining acceptable mechanical properties of topology-optimized parts used in the automobile industry.

-

Citations

Citations to this article as recorded by- Data-Driven analysis relates mechanical properties to pore morphology in laser powder bed fusion

Jaemin Wang, Seungyeon Lee, Yeon Woo Kim, Kyung Tae Kim, Jeong Min Park, Dierk Raabe

Acta Materialia.2026; 304: 121751. CrossRef - Lightweight Design of a Connecting Rod Using Lattice-Structure Parameter Optimisation: A Test Case for L-PBF

Michele Amicarelli, Michele Trovato, Paolo Cicconi

Machines.2025; 13(3): 171. CrossRef - Effect of Support Structure on Residual Stress Distribution in Ti-6Al-4V Alloy Fabricated by Laser Powder Bed Fusion

Seungyeon Lee, Haeum Park, Min Jae Baek, Dong Jun Lee, Jae Wung Bae, Ji-Hun Yu, Jeong Min Park

Journal of Powder Materials.2025; 32(3): 244. CrossRef

- Data-Driven analysis relates mechanical properties to pore morphology in laser powder bed fusion

- [English]

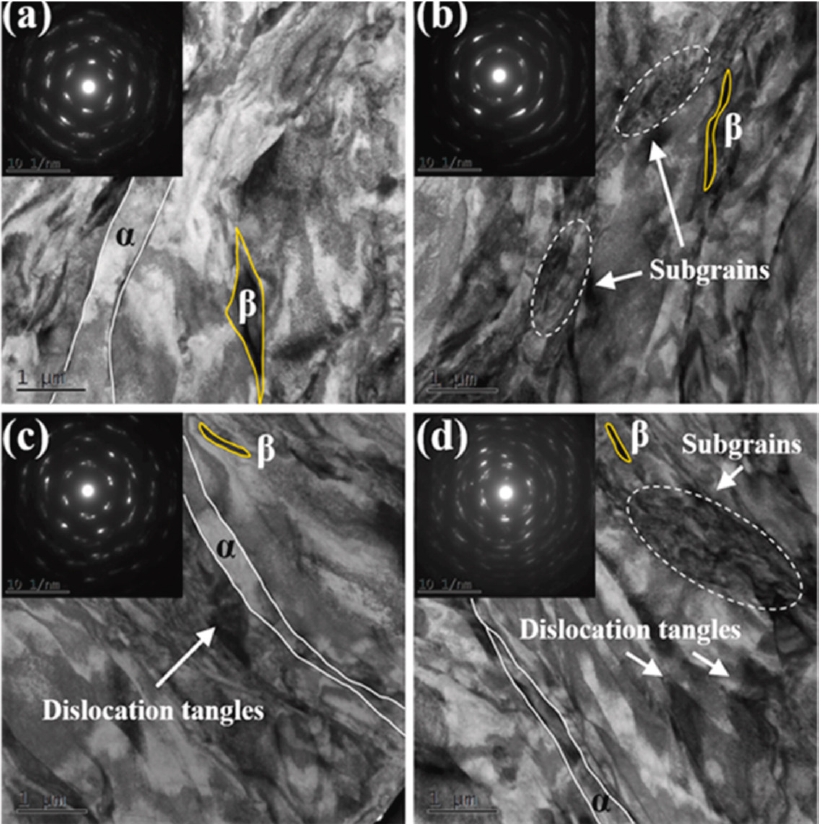

- Comparative Review of the Microstructural and Mechanical Properties of Ti-6Al-4V Fabricated via Wrought and Powder Metallurgy Processes

- Raj Narayan Hajra, Gargi Roy, An Seong Min, Hyunseok Lee, Jeoung Han Kim

- J Powder Mater. 2024;31(5):365-373. Published online October 31, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00213

- 2,836 View

- 66 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF - This review examines the microstructural and mechanical properties of a Ti-6Al-4V alloy produced by wrought processing and powder metallurgy (PM), specifically laser powder bed fusion (LPBF) and hot isostatic pressing. Wrought methods, such as forging and rolling, create equiaxed alpha (α) and beta (β) grain structures with balanced properties, which are ideal for fatigue resistance. In contrast, PM methods, particularly LPBF, often yield a martensitic α′ structure with high microhardness, enabling complex geometries but requiring post-processing to improve its properties and reduce stress. The study evaluated the effects of processing parameters on grain size, phase distribution, and material characteristics, guiding the choice of fabrication techniques for optimizing Ti-6Al-4V performance in aerospace, biomedical, and automotive applications. The analysis emphasizes tailored processing to meet advanced engineering demands.

-

Citations

Citations to this article as recorded by- Removal of Organic and Inorganic Contaminants from Titanium Turning Scrap via Alkali and Acid Two-Step Cleaning

Seong Min An, Raj Narayan Hajra, Chan Hee Park, Jin-Ho Yoon, Jinsung Rho, Chang-Min Yoon, Jeoung Han Kim

MATERIALS TRANSACTIONS.2025; 66(7): 855. CrossRef - Effect of oxygen content in feedstock powders on microstructure and mechanical properties of ELI Ti-6Al-4V fabricated via laser powder bed fusion

Woo Hyeok Kim, Sang Woo Kim, Raj Narayan Hajra, Gargi Roy, Jeoung Han Kim

Powder Metallurgy.2025; 68(4): 307. CrossRef

- Removal of Organic and Inorganic Contaminants from Titanium Turning Scrap via Alkali and Acid Two-Step Cleaning

- [English]

- Data-driven Approach to Explore the Contribution of Process Parameters for Laser Powder Bed Fusion of a Ti-6Al-4V Alloy

- Jeong Min Park, Jaimyun Jung, Seungyeon Lee, Haeum Park, Yeon Woo Kim, Ji-Hun Yu

- J Powder Mater. 2024;31(2):137-145. Published online April 30, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00038

- 4,733 View

- 118 Download

- 5 Citations

-

Abstract

Abstract

PDF

PDF - In order to predict the process window of laser powder bed fusion (LPBF) for printing metallic components, the calculation of volumetric energy density (VED) has been widely calculated for controlling process parameters. However, because it is assumed that the process parameters contribute equally to heat input, the VED still has limitation for predicting the process window of LPBF-processed materials. In this study, an explainable machine learning (xML) approach was adopted to predict and understand the contribution of each process parameter to defect evolution in Ti alloys in the LPBF process. Various ML models were trained, and the Shapley additive explanation method was adopted to quantify the importance of each process parameter. This study can offer effective guidelines for fine-tuning process parameters to fabricate high-quality products using LPBF.

-

Citations

Citations to this article as recorded by- Data-Driven analysis relates mechanical properties to pore morphology in laser powder bed fusion

Jaemin Wang, Seungyeon Lee, Yeon Woo Kim, Kyung Tae Kim, Jeong Min Park, Dierk Raabe

Acta Materialia.2026; 304: 121751. CrossRef - Effect of Support Structure on Residual Stress Distribution in Ti-6Al-4V Alloy Fabricated by Laser Powder Bed Fusion

Seungyeon Lee, Haeum Park, Min Jae Baek, Dong Jun Lee, Jae Wung Bae, Ji-Hun Yu, Jeong Min Park

Journal of Powder Materials.2025; 32(3): 244. CrossRef - Automated segmentation and analysis of microscopy images of laser powder bed fusion melt tracks

Aagam Shah, Reimar Weissbach, David A. Griggs, A. John Hart, Elif Ertekin, Sameh Tawfick

Journal of Manufacturing Processes.2025; 154: 61. CrossRef - Coefficient of Thermal Expansion of AlSi10Mg, 316L Stainless Steel and Ti6Al4V Alloys Made with Laser Powder Bed Fusion

Selami Emanet, Edem Honu, Kekeli Agbewornu, Evelyn Quansah, Congyuan Zeng, Patrick Mensah

Materials.2025; 18(19): 4468. CrossRef - Adaptive slicing for increased productivity of metal laser powder bed fusion

Lars Vanmunster, Louca R. Goossens, Laurent Sergeant, Brecht Van Hooreweder, Bey Vrancken

Additive Manufacturing.2025; 112: 105000. CrossRef

- Data-Driven analysis relates mechanical properties to pore morphology in laser powder bed fusion

- [Korean]

- Fabrication of Bi2Te2.5Se0.5 by Combining Oxide-reduction and Compressive-forming Process and Its Thermoelectric Properties

- Young Soo Lim, Gil-Geun Lee

- J Powder Mater. 2024;31(1):50-56. Published online February 28, 2024

- DOI: https://doi.org/10.4150/KPMI.2024.31.1.50

- 1,086 View

- 21 Download

- [Korean]

- Fabrication and Sintering Behavior Analysis of Molybdenum-tungsten Nanopowders by Pechini Process

- Suyeon Kim, Taehyun Kwon, Seulgi Kim, Dongju Lee

- J Powder Mater. 2023;30(5):436-441. Published online October 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.5.436

- 912 View

- 8 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF Molybdenum-tungsten (Mo-W) alloy sputtering targets are widely utilized in fields like electronics, nanotechnology, sensors, and as gate electrodes for TFT-LCDs, owing to their superior properties such as hightemperature stability, low thermal expansion coefficient, electrical conductivity, and corrosion resistance. To achieve optimal performance in application, these targets’ purity, relative density, and grain size of these targets must be carefully controlled. We utilized nanopowders, prepared via the Pechini method, to obtain uniform and fine powders, then carried out spark plasma sintering (SPS) to densify these powders. Our studies revealed that the sintered compacts made from these nanopowders exhibited outstanding features, such as a high relative density of more than 99%, consistent grain size of 3.43 μm, and shape, absence of preferred orientation.

-

Citations

Citations to this article as recorded by- Ultrafast Synthesis of Molybdenum Disulfide via Flashlamp Annealing

Chan Hyeon Yang, Jaehak Lee, Jung Hwan Park

Journal of Powder Materials.2025; 32(6): 509. CrossRef

- Ultrafast Synthesis of Molybdenum Disulfide via Flashlamp Annealing

- [Korean]

- Analysis of the Effects of Process Variables and Alloy Composition on the Relative density and Mechanical Properties of 3D Printed Aluminum Alloys

- Suwon Park, Jiyoon Yeo, Songyun Han, Hyunjoo Choi

- J Powder Mater. 2023;30(3):223-232. Published online June 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.3.223

- 3,065 View

- 16 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF Metal additive manufacturing (AM) has transformed conventional manufacturing processes by offering unprecedented opportunities for design innovation, reduced lead times, and cost-effective production. Aluminum alloy, a material used in metal 3D printing, is a representative lightweight structural material known for its high specific strength and corrosion resistance. Consequently, there is an increasing demand for 3D printed aluminum alloy components across industries, including aerospace, transportation, and consumer goods. To meet this demand, research on alloys and process conditions that satisfy the specific requirement of each industry is necessary. However, 3D printing processes exhibit different behaviors of alloy elements owing to rapid thermal dynamics, making it challenging to predict the microstructure and properties. In this study, we gathered published data on the relationship between alloy composition, processing conditions, and properties. Furthermore, we conducted a sensitivity analysis on the effects of the process variables on the density and hardness of aluminum alloys used in additive manufacturing.

-

Citations

Citations to this article as recorded by- Effect of Heat Treatment on Microstructure and Mechanical Properties of Al–Zn–Mg–Cu–Si Sintered Alloys with and Without High-energy Ball Milling

Junho Lee, Seonghyun Park, Sang-Hwa Lee, Seung Bae Son, Seok-Jae Lee, Jae-Gil Jung

journal of Korean Powder Metallurgy Institute.2023; 30(6): 470. CrossRef

- Effect of Heat Treatment on Microstructure and Mechanical Properties of Al–Zn–Mg–Cu–Si Sintered Alloys with and Without High-energy Ball Milling

- [Korean]

- A Study on Rinsing Effects of Sn Sensitization and Pd Activation Processes for Uniform Electroless Plating

- Seong-Jae Jeong, Mi-Se Chang, Jae-Won Jeong, Sang-Sun Yang, Young-Tae Kwon

- J Powder Mater. 2022;29(6):511-516. Published online December 1, 2022

- DOI: https://doi.org/10.4150/KPMI.2022.29.6.511

- 1,750 View

- 14 Download

-

Abstract

Abstract

PDF

PDF Electroless plating is widely utilized in engineering for the metallization of insulator substrates, including polymers, glass, and ceramics, without the need for the application of external potential. Homogeneous nucleation of metals requires the presence of Sn-Pd catalysts, which significantly reduce the activation energy of deposition. Therefore, rinsing conducted during Sn sensitization and Pd activation is a key variable for the formation of a uniform seed layer without the lack or excess of catalysts. Herein, we report the optimized rinsing process for the functionalization of Sn-Pd catalysts, which enables the uniform FeCo metallization of the glass fibers. Rinsing enables good deposition of the FeCo alloy because of the removal of excess catalysts from the glass fiber. Concurrently, excessive rinsing results in a complete removal of the Sn–Pd nucleus. Collectively, the comprehensive study of the proposed nanomaterial preparation and surface science show that the metallization of insulators is a promising technology for electronics, solar cells, catalysts, and mechanical parts.

- [English]

- Optimization of VIGA Process Parameters for Power Characteristics of Fe-Si-Al-P Soft Magnetic Alloy using Machine Learning

- Sung-Min Kim, Eun-Ji Cha, Do-Hun Kwon, Sung-Uk Hong, Yeon-Joo Lee, Seok-Jae Lee, Kee-Ahn Lee, Hwi-Jun Kim

- J Powder Mater. 2022;29(6):459-467. Published online December 1, 2022

- DOI: https://doi.org/10.4150/KPMI.2022.29.6.459

- 886 View

- 13 Download

-

Abstract

Abstract

PDF

PDF Soft magnetic powder materials are used throughout industries such as motors and power converters. When manufacturing Fe-based soft magnetic composites, the size and shape of the soft magnetic powder and the microstructure in the powder are closely related to the magnetic properties. In this study, Fe-Si-Al-P alloy powders were manufactured using various manufacturing process parameter sets, and the process parameters of the vacuum induction melt gas atomization process were set as melt temperature, atomization gas pressure, and gas flow rate. Process variable data that records are converted into 6 types of data for each powder recovery section. Process variable data that recorded minute changes were converted into 6 types of data and used as input variables. As output variables, a total of 6 types were designated by measuring the particle size, flowability, apparent density, and sphericity of the manufactured powders according to the process variable conditions. The sensitivity of the input and output variables was analyzed through the Pearson correlation coefficient, and a total of 6 powder characteristics were analyzed by artificial neural network model. The prediction results were compared with the results through linear regression analysis and response surface methodology, respectively.

- [Korean]

- Comparison of Properties with Different Sintering Process of 3Y-TZP/WC Composites

- Min-Soo Nam, Jae-Hyung Choi, Sahn Nahm, Seongwon Kim

- J Powder Mater. 2022;29(5):424-431. Published online October 1, 2022

- DOI: https://doi.org/10.4150/KPMI.2022.29.5.424

- 889 View

- 3 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF 3Y-TZP ceramics obtained by doping 3 mol.% of Y2O3 to ZrO2 to stabilize the phase transition are widely used in the engineering ceramic industry due to their excellent mechanical properties such as high strength, fracture toughness, and wear resistance. An additional increase in mechanical properties is possible by manufacturing a composite in which a high-hardness material such as oxide or carbide is added to the 3Y-TZP matrix. In this study, composite powder was prepared by dispersing a designated percentage of WC in the 3Y-TZP matrix, and the results were compared after manufacturing the composite using the different processes of spark plasma sintering and HP. The difference between the densification behavior and porosity with the process mechanism was investigated. The correlation between the process conditions and phase formation was examined based on the crystalline phase formation behavior. Changes to the microstructure according to the process conditions were compared using field-emission scanning electron microscopy. The toughness-strengthening mechanism of the composite with densification and phase formation was also investigated.

-

Citations

Citations to this article as recorded by- Phase Formation and Mechanical Property of YSZ‒30 vol.% WC Composite Ceramics Fabricated by Hot Pressing

Jin-Kwon Kim, Jae-Hyeong Choi, Nahm Sahn, Sung-Soo Ryu, Seongwon Kim

journal of Korean Powder Metallurgy Institute.2023; 30(5): 409. CrossRef

- Phase Formation and Mechanical Property of YSZ‒30 vol.% WC Composite Ceramics Fabricated by Hot Pressing

- [Korean]

- Effect of Process Stopping and Restarting on the Microstructure and Local Property of 316L Stainless Steel Manufactured by Selective Laser Melting Process

- Hyunjin Joo, Jeongmin Woo, Yongho Sohn, Kee-Ahn Lee

- J Powder Mater. 2022;29(1):1-7. Published online February 1, 2022

- DOI: https://doi.org/10.4150/KPMI.2022.29.1.1

- 780 View

- 7 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF This study investigates the effect of process stopping and restarting on the microstructure and local nanoindentation properties of 316L stainless steel manufactured via selective laser melting (SLM). We find that stopping the SLM process midway, exposing the substrate to air having an oxygen concentration of 22% or more for 12 h, and subsequently restarting the process, makes little difference to the density of the restarted area (~ 99.8%) as compared to the previously melted area of the substrate below. While the microstructure and pore distribution near the stop/restart area changes, this modified process does not induce the development of unusual features, such as an inhomogeneous microstructure or irregular pore distribution in the substrate. An analysis of the stiffness and hardness values of the nano-indented steel also reveals very little change at the joint of the stop/restart area. Further, we discuss the possible and effective follow-up actions of stopping and subsequently restarting the SLM process.

-

Citations

Citations to this article as recorded by- On the Fabrication of Functionally Graded Prototypes with Laser Powder Bed Fusion from Reused Ni-625 and 17-4 PH Stainless Steel Powder

Bharat Kalia, Rupinder Singh, B. S. Pabla

Journal of Materials Engineering and Performance.2025; 34(22): 27160. CrossRef - Additive Manufacturing of SS316L/IN718 Bimetallic Structure via Laser Powder Bed Fusion

Asif Mahmud, Nicolas Ayers, Thinh Huynh, Yongho Sohn

Materials.2023; 16(19): 6527. CrossRef

- On the Fabrication of Functionally Graded Prototypes with Laser Powder Bed Fusion from Reused Ni-625 and 17-4 PH Stainless Steel Powder

- [Korean]

- Additive Manufacturing Optimization of Directed Energy Deposition-Processed Ti-6Al-4V Alloy using Energy Density and Powder Deposition Density

- Yukyeong Lee, Eun Sung Kim, Se-Ho Chun, Jae Bok Seol, Hyokyung Sung, Jung Seok Oh, Hyoung Seop Kim, Taekyung Lee, Tae-Hyun Nam, Jung Gi Kim

- J Korean Powder Metall Inst. 2021;28(6):491-496. Published online December 1, 2021

- DOI: https://doi.org/10.4150/KPMI.2021.28.6.491

- 1,040 View

- 4 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF The process optimization of directed energy deposition (DED) has become imperative in the manufacture of reliable products. However, an energy-density-based approach without a sufficient powder feed rate hinders the attainment of an appropriate processing window for DED-processed materials. Optimizing the processing of DEDprocessed Ti-6Al- 4V alloys using energy per unit area (Eeff) and powder deposition density (PDDeff) as parameters helps overcome this problem in the present work. The experimental results show a lack of fusion, complete melting, and overmelting regions, which can be differentiated using energy per unit mass as a measure. Moreover, the optimized processing window (Eeff = 44~47 J/mm2 and PDDeff = 0.002~0.0025 g/mm2) is located within the complete melting region. This result shows that the Eeff and PDDeff-based processing optimization methodology is effective for estimating the properties of DED-processed materials.

-

Citations

Citations to this article as recorded by- Cryogenic Tensile Behavior of Ferrous Medium-entropy Alloy Additively Manufactured by Laser Powder Bed Fusion

Seungyeon Lee, Kyung Tae Kim, Ji-Hun Yu, Hyoung Seop Kim, Jae Wung Bae, Jeong Min Park

journal of Korean Powder Metallurgy Institute.2024; 31(1): 8. CrossRef

- Cryogenic Tensile Behavior of Ferrous Medium-entropy Alloy Additively Manufactured by Laser Powder Bed Fusion

- [Korean]

- Microstructure and High Temperature Mechanical Properties of Oxide Dispersion Strengthened Steels Manufactured by Combination Milling Process

- Jung-Uk Lee, Young-Kyun Kim, Jeoung Han Kim, Hwi-Jin Kim, Kee-Ahn Lee

- J Korean Powder Metall Inst. 2021;28(5):389-395. Published online October 1, 2021

- DOI: https://doi.org/10.4150/KPMI.2021.28.5.389

- 809 View

- 9 Download

-

Abstract

Abstract

PDF

PDF Oxide dispersion-strengthened (ODS) steel has excellent high-temperature properties, corrosion resistance, and oxidation resistance, and is expected to be applicable in various fields. Recently, various studies on mechanical alloying (MA) have been conducted for the dispersion of oxide particles in ODS steel with a high number density. In this study, ODS steel is manufactured by introducing a complex milling process in which planetary ball milling, cryogenic ball milling, and drum ball milling are sequentially performed, and the microstructure and high-temperature mechanical properties of the ODS steel are investigated. The microstructure observation revealed that the structure is stretched in the extrusion direction, even after the heat treatment. In addition, transmission electron microscopy (TEM) analysis confirmed the presence of oxide particles in the range of 5 to 10 nm. As a result of the room-temperature and high-temperature compression tests, the yield strengths were measured as 1430, 1388, 418, and 163 MPa at 25, 500, 700, and 900°C, respectively. Based on these results, the correlation between the microstructure and mechanical properties of ODS steel manufactured using the composite milling process is also discussed.

- [Korean]

- Current Status of Titanium Smelting Technology for Powder Metallurgy

- Ho-Sang Sohn

- J Korean Powder Metall Inst. 2021;28(2):164-172. Published online April 1, 2021

- DOI: https://doi.org/10.4150/KPMI.2021.28.2.164

- 823 View

- 8 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF Titanium is the ninth most abundant element in the Earth’s crust and is the fourth most abundant structural metal after aluminum, iron, and magnesium. It exhibits a higher specific strength than steel along with an excellent corrosion resistance, highlighting the promising potential of titanium as a structural metal. However, titanium is difficult to extract from its ore and is classified as a rare metal, despite its abundance. Therefore, the production of titanium is exceedingly low compared to that of common metals. Titanium is conventionally produced as a sponge by the Kroll process. For powder metallurgy (PM), hydrogenation-dehydrogenation (HDH) of the titanium sponge or gas atomization of the titanium bulk is required. Therefore, numerous studies have been conducted on smelting, which replaces the Kroll process and produces powder that can be used directly for PM. In this review, the Kroll process and new smelting technologies of titanium for PM, such as metallothermic, electrolytic, and hydrogen reduction of TiCl4 and TiO2 are discussed.

-

Citations

Citations to this article as recorded by- Enhancing corrosion resistance of Ti-based amorphous alloy powders via misch metal addition

Yeon Joo Lee, Hyokyung Sung, Jae Bok Seol, Kisub Cho, Hwi Jun Kim, Hyunjoo Choi

Powder Metallurgy.2025; 68(3): 230. CrossRef

- Enhancing corrosion resistance of Ti-based amorphous alloy powders via misch metal addition

- [Korean]

- Study on the Preparation of TiO2 3D Nanostructure for Photocatalyst by Wet Chemical Process

- Duk-Hee Lee, Jae-Ryang Park, Chan-Gi Lee, Kyoung-Tae Park, Kyung-Soo Park

- J Korean Powder Metall Inst. 2020;27(5):381-387. Published online October 1, 2020

- DOI: https://doi.org/10.4150/KPMI.2020.27.5.381

- 1,056 View

- 7 Download

-

Abstract

Abstract

PDF

PDF In this work, TiO2 3D nanostructures (TF30) were prepared via a facile wet chemical process using ammonium hexafluorotitanate. The synthesized 3D TiO2 nanostructures exhibited well-defined crystalline and hierarchical structures assembled from TiO2 nanorods with different thicknesses and diameters, which comprised numerous small beads. Moreover, the maximum specific surface area of TiO2 3D nanostructures was observed to be 191 m2g-1, with concentration of F ions on the surface being 2 at%. The TiO2 3D nanostructures were tested as photocatalysts under UV irradiation using Rhodamine B solution in order to determine their photocatalytic performance. The TiO2 3D nanostructures showed a higher photocatalytic activity than that of the other TiO2 samples, which was likely associated with the combined effects of a high crystallinity, unique features of the hierarchical structure, a high specific surface area, and the advantage of adsorbing F ions.

- [English]

- Multi-step Metals Additive Manufacturing Technologies

- Ji-Won Oh, Jinsu Park, Hanshin Choi

- J Korean Powder Metall Inst. 2020;27(3):256-267. Published online June 1, 2020

- DOI: https://doi.org/10.4150/KPMI.2020.27.3.256

- 1,644 View

- 8 Download

- 3 Citations

-

Abstract

Abstract

PDF

PDF Metal additive manufacturing (AM) technologies are classified into two groups according to the consolidation mechanisms and densification degrees of the as-built parts. Densified parts are obtained via a single-step process such as powder bed fusion, directed energy deposition, and sheet lamination AM technologies. Conversely, green bodies are consolidated with the aid of binder phases in multi-step processes such as binder jetting and material extrusion AM. Green-body part shapes are sustained by binder phases, which are removed for the debinding process. Chemical and/or thermal debinding processes are usually devised to enhance debinding kinetics. The pathways to final densification of the green parts are sintering and/or molten metal infiltration. With respect to innovation types, the multistep metal AM process allows conventional powder metallurgy manufacturing to be innovated continuously. Eliminating cost/time-consuming molds, enlarged 3D design freedom, and wide material selectivity create opportunities for the industrial adoption of multi-step AM technologies. In addition, knowledge of powders and powder metallurgy fuel advances of multi-step AM technologies. In the present study, multi-step AM technologies are briefly introduced from the viewpoint of the entire manufacturing lifecycle.

-

Citations

Citations to this article as recorded by- Potential and challenges for Powder Bed Fusion – Laser Beam (PBF-LB) in industrial ceramic additive manufacturing

Christian Berger, Gabriela Schimo-Aichhorn, Stefan Gronau, Franziska Saft, Sarah Seiringer, Uwe Scheithauer

Open Ceramics.2024; 18: 100614. CrossRef - Fabrication of Cu-Infiltrated Journal Bearing by Binder Jetting Additive Manufacturing

Jin Man Jang

Crystals.2024; 14(11): 912. CrossRef - SiC-Si composite part fabrication via SiC powder binder jetting additive manufacturing and molten-Si infiltration

Ji-Won Oh, Jinsu Park, Sahn Nahm, Hanshin Choi

International Journal of Refractory Metals and Hard Materials.2021; 101: 105686. CrossRef

- Potential and challenges for Powder Bed Fusion – Laser Beam (PBF-LB) in industrial ceramic additive manufacturing

- [Korean]

- Fabrication and Photocatalytic Activity of TiO2 Hollow Structures using One-pot Wet Chemical Process

- Duk-Hee Lee, Kyung-Soo Park, Jae-Ryang Park, Chan-Gi Lee

- J Korean Powder Metall Inst. 2020;27(2):132-138. Published online April 1, 2020

- DOI: https://doi.org/10.4150/KPMI.2020.27.2.132

- 546 View

- 4 Download

-

Abstract

Abstract

PDF

PDF A facile one-pot wet chemical process to prepare pure anatase TiO2 hollow structures using ammonium hexafluorotitanate as a precursor is developed. By defining the formic acid ratio, we fabricate TiO2 hollow structures containing fluorine on the surface. The TiO2 hollow sphere is composed of an anatase phase containing fluorine by various analytical techniques. A possible formation mechanism for the obtained hollow samples by self-transformation and Ostwald ripening is proposed. The TiO2 hollow structures containing fluorine exhibits 1.2 - 2.7 times higher performance than their counterparts in photocatalytic activity. The enhanced photocatalytic activity of the TiO2 hollow structures is attributed to the combined effects of high crystallinity, specific surface area (62 m2g-1), and the advantage of surface fluorine ions (at 8%) having strong electron-withdrawing ability of the surface ≡ Ti-F groups reduces the recombination of photogenerated electrons and holes.

- [Korean]

- Structural Characteristics, Microstructure and Mechanical Properties of Fe-Cr-Al Metallic Foam Fabricated by Powder Alloying Process

- Kyu-Sik Kim, Byeong-Hoon Kang, Man-Ho Park, Jung-Yeul Yun, Kee-Ahn Lee

- J Korean Powder Metall Inst. 2020;27(1):37-43. Published online February 1, 2020

- DOI: https://doi.org/10.4150/KPMI.2020.27.1.37

- 651 View

- 5 Download

-

Abstract

Abstract

PDF

PDF The Fe-22wt.%Cr-6wt.%Al foams were fabricated via the powder alloying process in this study. The structural characteristics, microstructure, and mechanical properties of Fe-Cr-Al foams with different average pore sizes were investigated. Result of the structural analysis shows that the average pore sizes were measured as 474 μm (450 foam) and 1220 μm (1200 foam). Regardless of the pore size, Fe-Cr-Al foams had a Weaire-Phelan bubble structure, and α-ferrite was the major constituent phase. Tensile and compressive tests were conducted with an initial strain rate of 10−3 /s. Tensile yield strengths were 3.4 MPa (450 foam) and 1.4 MPa (1200 foam). Note that the total elongation of 1200 foam was higher than that of 450 foam. Furthermore, their compressive yield strengths were 2.5 MPa (450 foam) and 1.1 MPa (1200 foam), respectively. Different compressive deformation behaviors according to the pore sizes of the Fe-Cr-Al foams were characterized: strain hardening for the 450 foam and constant flow stress after a slight stress drop for the 1200 foam. The effect of structural characteristics on the mechanical properties was also discussed.

- [Korean]

- Austenite Stability of Nanocrystalline FeMnNiC Alloy

- Seung-Jin Oh, Junhyub Jeon, In-Jin Shon, Seok-Jae Lee

- J Korean Powder Metall Inst. 2019;26(5):389-394. Published online October 1, 2019

- DOI: https://doi.org/10.4150/KPMI.2019.26.5.389

- 914 View

- 4 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF In the present study, we have investigated the effect of sintering process conditions on the stability of the austenite phase in the nanocrystalline Fe-5wt.%Mn-0.2wt.%C alloy. The stability and volume fraction of the austenite phase are the key factors that determine the mechanical properties of FeMnC alloys, because strain-induced austenitemartensite transformation occurs under the application of an external stress at room temperature. Nanocrystalline Fe-5wt.%Mn-0.2wt.%C samples are fabricated using the spark plasma sintering method. The stability of the austenite phase in the sintered samples is evaluated by X-ray diffraction analysis and hardness test. The volume fraction of austenite at room temperature increases as the sample is held for 10 min at the sintering temperature, because of carbon diffusion in austenite. Moreover, water quenching effectively prevents the formation of cementite during cooling, resulting in a higher volume fraction of austenite. Furthermore, it is found that the hardness is influenced by both the austenite carbon content and volume fraction.

-

Citations

Citations to this article as recorded by- Influence of Cobalt Content on Austenite Stability and Strain-Induced Martensite Transformation of Nanocrystalline Fe-7Mn Alloy Fabricated by Spark Plasma Sintering

Sungjin Kim, Seung Bae Son, Seok-Jae Lee

MATERIALS TRANSACTIONS.2025; 66(7): 811. CrossRef - Austenite Stability of Sintered Fe-based Alloy

Seunggyu Choi, Namhyuk Seo, Junhyub Jun, Seung Bae Son, Seok-Jae Lee

Journal of Korean Powder Metallurgy Institute.2020; 27(5): 414. CrossRef

- Influence of Cobalt Content on Austenite Stability and Strain-Induced Martensite Transformation of Nanocrystalline Fe-7Mn Alloy Fabricated by Spark Plasma Sintering

- [Korean]

- Property Evaluation of Tungsten-Carbide Hard Materials as a Function of Binder

- Ju-Hun Kim, Ik-Hyun Oh, Jeong-Han Lee, Sung-Kil Hong, Hyun-Kuk Park

- J Korean Powder Metall Inst. 2019;26(2):132-137. Published online April 1, 2019

- DOI: https://doi.org/10.4150/KPMI.2019.26.2.132

- 1,074 View

- 8 Download

- 3 Citations

-

Abstract

Abstract

PDF

PDF Tungsten carbide (WC) hard materials are used in various industries and possess a superior hardness compared to other hard materials. They have particularly high melting points, high strength, and abrasion resistance. Accordingly, tungsten carbide hard materials are used for wear-resistant tools, cutting tools, machining tools, and other tooling materials. In this study, the WC-5wt.%Co, Fe, Ni hard materials are densified using the horizontal ball milled WC-Co, WC-Fe, and WC-Ni powders by a spark plasma sintering process. The WC-5Co, WC-5Fe, and WC-5Ni hard materials are almost completely densified with a relative density of up to 99.6% after simultaneous application of a pressure of 60 MPa and an electric current for about 15 min without any significant change in the grain size. The average grain size of WC-5Co, WC-5Fe, and WC-5Ni that was produced through SPS was about 0.421, 0.779, and 0.429 μm, respectively. The hardness and fracture toughness of the dense WC-5Co, WC-5Fe, WC-5Ni hard materials were also investigated.

-

Citations

Citations to this article as recorded by- Enhancing Mechanical Properties via Grain Growth Suppression and High Densification in WC Compacts

Jong Min Gwak, Min Soo Park, Gook Hyun Ha, Nam Hyun Kang

Metals and Materials International.2025; 31(12): 3733. CrossRef - Synthesis of W2C by Spark Plasma Sintering of W-WC Powder Mixture and Its Etching Property

Gyu-Sang Oh, Sung-Min Lee, Sung-Soo Ryu

Journal of Korean Powder Metallurgy Institute.2020; 27(4): 293. CrossRef - Fabrication and Properties of Densified Tungsten by Magnetic Pulse Compaction and Spark Plasma Sintering

Eui Seon Lee, Jongmin Byun, Young-Keun Jeong, Sung-Tag Oh

Korean Journal of Materials Research.2020; 30(6): 321. CrossRef

- Enhancing Mechanical Properties via Grain Growth Suppression and High Densification in WC Compacts

- [Korean]

- Interaction of Solid Particles with the Solidifying Front in the Liquid-Particle Mixture

- Ho-Suk Lee, Kyu-Hee Lee, Sung-Tag Oh, Young Do Kim, Myung-Jin Suk

- J Korean Powder Metall Inst. 2018;25(4):336-339. Published online August 1, 2018

- DOI: https://doi.org/10.4150/KPMI.2018.25.4.336

- 1,046 View

- 2 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF A unique porous material with controlled pore characteristics can be fabricated by the freeze-drying process, which uses the slurry of organic material as the sublimable vehicle mixed with powders. The essential feature in this process is that during the solidification of the slurry, the dendrites of the organic material should repel the dispersed particles into the interdendritic region. In the present work, a model experiment is attempted using some transparent organic materials mixed with glass powders, which enable in-situ observation. The organic materials used are camphor-naphthalene mixture (hypo- and hypereutectic composition), salol, camphene, and pivalic acid. Among these materials, the constituent phases in camphor-naphthalene system, i.e. naphthalene plate, camphor dendrite, and camphornaphthalene eutectic exclusively repel the glass powders. This result suggests that the control of organic material composition in the binary system is useful for producing a porous body with the required pore structure.

-

Citations

Citations to this article as recorded by- Freeze Drying Process and Pore Structure Characteristics of Porous Cu with Various Sublimable Vehicles

Gyuhwi Lee, Sung-Tag Oh, Myung-Jin Suk, Young-Keun Jeong

Journal of Korean Powder Metallurgy Institute.2020; 27(3): 198. CrossRef

- Freeze Drying Process and Pore Structure Characteristics of Porous Cu with Various Sublimable Vehicles

- [Korean]

- Study on the Recovery Silver and Nanoparticles Synthesis from LTCC By-products of Lowly Concentrated Silver

- Soyeong Joo, Nak-Kyoon Ahn, Chan Gi Lee, Jin-Ho Yoon

- J Korean Powder Metall Inst. 2018;25(3):232-239. Published online June 1, 2018

- DOI: https://doi.org/10.4150/KPMI.2018.25.3.232

- 884 View

- 4 Download

-

Abstract

Abstract

PDF

PDF In this paper, the recovery and nanoparticle synthesis of Ag from low temperature co-fired ceramic (LTCC) by-products are studied. The effect of reaction behavior on Ag leaching conditions from the LTCC by-products is confirmed. The optimum leaching conditions are determined to be: 5 M HNO3, a reaction temperature of 75°C, and a pulp density of 50 g/L at 60 min. For the selective recovery of Ag, the [Cl]/[Ag] equivalence ratio experiment is performed using added HCl; most of the Ag (more than 99%) is recovered. The XRD and MP-AES results confirm that the powder is AgCl and that impurities are at less than 1%. Ag nanoparticles are synthesized using a chemical reduction process for recycling, NaBH4 and PVP are used as reducing agents and dispersion stabilizers. UV-vis and FE-SEM results show that AgCl powder is precipitated and that Ag nanoparticles are synthesized. Ag nanoparticles of 100% Ag are obtained under the chemical reaction conditions.

- [Korean]

- Effect of Milling Time and Addition of PCA on Austenite Stability of Fe-7%Mn Alloy

- Seung-Jin Oh, In-Jin Shon, Seok-Jae Lee

- J Korean Powder Metall Inst. 2018;25(2):126-131. Published online April 1, 2018

- DOI: https://doi.org/10.4150/KPMI.2018.25.2.126

- 777 View

- 9 Download

- 5 Citations

-

Abstract

Abstract

PDF

PDF In the present study, we investigate the effects of milling time and the addition of a process control agent (PCA) on the austenite stability of a nanocrystalline Fe-7%Mn alloy by XRD analysis and micrograph observation. Nanocrystalline Fe-7%Mn alloys samples are successfully fabricated by spark plasma sintering. The crystallite size of ball-milled powder and the volume fraction of austenite in the sintered sample are calculated using XRD analysis. Changes in the shape and structure of alloyed powder according to milling conditions are observed through FE-SEM. It is found that the crystallite size is reduced with increasing milling time and amount of PCA addition due to the variation in the balance between the cold-welding and fracturing processes. As a result, the austenite stability increased, resulting in an exceptionally high volume fraction of austenite retained at room temperature.

-

Citations

Citations to this article as recorded by- Effects of mechanical milling on microstructure and mechanical properties of CrMnFeCoNi high-entropy alloy fabricated via spark plasma sintering

Seonghyun Park, Sang-Hwa Lee, Eunjoo Shin, Seok-Jae Lee, Jae-Gil Jung

Journal of Materials Research and Technology.2025; 39: 4854. CrossRef - Effect of Cooling Rate on Microstructure and Hardness during Solution Treatment and Aging Process of Ti-6Al-4V Alloy for Aerospace Components

Seongji Seo, Hojoon Choi, Geeyoung Lee, Kee-Ahn Lee, Jeongho Han, Minsu Jung

Journal of Materials Engineering and Performance.2021; 30(5): 3406. CrossRef - Development of Fe-Mn-based Hybrid Materials Containing Nano-scale Oxides by a Powder Metallurgical Route

Jonggyu Jeon, Jungjoon Kim, Hyunjoo Choi

Journal of Korean Powder Metallurgy Institute.2020; 27(3): 203. CrossRef - Austenite Stability of Sintered Fe-based Alloy

Seunggyu Choi, Namhyuk Seo, Junhyub Jun, Seung Bae Son, Seok-Jae Lee

Journal of Korean Powder Metallurgy Institute.2020; 27(5): 414. CrossRef - Austenite Stability of Nanocrystalline FeMnNiC Alloy

Seung-Jin Oh, Junhyub Jeon, In-Jin Shon, Seok-Jae Lee

Journal of Korean Powder Metallurgy Institute.2019; 26(5): 389. CrossRef

- Effects of mechanical milling on microstructure and mechanical properties of CrMnFeCoNi high-entropy alloy fabricated via spark plasma sintering

- [Korean]

- Technology Trend of the additive Manufacturing (AM)

- Ji-Won Oh, Hyunwoong Na, Hanshin Choi

- J Korean Powder Metall Inst. 2017;24(6):494-507. Published online December 1, 2017

- DOI: https://doi.org/10.4150/KPMI.2017.24.6.494

- 1,924 View

- 11 Download

- 7 Citations

-

Abstract

Abstract

PDF

PDF A three-dimensional physical part can be fabricated from a three-dimensional digital model in a layer-wise manner via additive manufacturing (AM) technology, which is different from the conventional subtractive manufacturing technology. Numerous studies have been conducted to take advantage of the AM opportunities to penetrate bespoke custom product markets, functional engineering part markets, volatile low-volume markets, and spare part markets. Nevertheless, materials issues, machines issues, product issues, and qualification/certification issues still prevent the AM technology from being extensively adopted in industries. The present study briefly reviews the standard classification, technological structures, industrial applications, technological advances, and qualification/certification activities of the AM technology. The economics, productivity, quality, and reliability of the AM technology should be further improved to pass through the technology adoption lifecycle of innovation technology. The AM technology is continuously evolving through the introduction of PM materials, hybridization of AM and conventional manufacturing technologies, adoption of process diagnostics and control systems, and enhanced standardization of the whole lifecycle qualification and certification methodology.

-

Citations

Citations to this article as recorded by- Convolutional LSTM based melt-pool prediction from images of laser tool path strategy in laser powder bed fusion for additive manufacturing

Joung Min Park, Minho Choi, Jumyung Um

The International Journal of Advanced Manufacturing Technology.2024; 130(3-4): 1871. CrossRef - Color evaluation by thickness of interim restorative resin produced by digital light processing 3D printer

Wol Kang, Won-Gi Kim

Journal of Korean Acedemy of Dental Technology.2021; 43(3): 77. CrossRef - Optimization of Metal Powder Particle Size Distribution for Powder Bed Fusion Process via Simulation

Hwaseon Lee, Dae-Kyeom Kim, Young Il Kim, Jieun Nam, Yong Son, Taek-Soo Kim, Bin Lee

Journal of Korean Powder Metallurgy Institute.2020; 27(1): 44. CrossRef - Technology Trend of Additive Manufacturing Standardization

Hanshin Choi, Jinsu Park

Journal of Korean Powder Metallurgy Institute.2020; 27(5): 420. CrossRef - Multi-step Metals Additive Manufacturing Technologies

Ji-Won Oh, Jinsu Park, Hanshin Choi

Journal of Korean Powder Metallurgy Institute.2020; 27(3): 256. CrossRef - Anisotropy in Green Body Bending Strength due to Additive Direction in the Binder-Jetting Additive Manufacturing Process

Ji-Won Oh, Sahn Nahm, Byoungmoon Kim, Hanshin Choi

Korean Journal of Metals and Materials.2019; 57(4): 227. CrossRef - Effect of Porosity on Mechanical Anisotropy of 316L Austenitic Stainless Steel Additively Manufactured by Selective Laser Melting

Jeong Min Park, Jin Myoung Jeon, Jung Gi Kim, Yujin Seong, Sun Hong Park, Hyoung Seop Kim

Journal of Korean Powder Metallurgy Institute.2018; 25(6): 475. CrossRef

- Convolutional LSTM based melt-pool prediction from images of laser tool path strategy in laser powder bed fusion for additive manufacturing

- [Korean]

- Research Trends in Powder Materials for Solution-based Transparent Conducting Electrode

- Bon-Ryul Koo, Hyo-Jin Ahn

- J Korean Powder Metall Inst. 2017;24(2):153-163. Published online April 1, 2017

- DOI: https://doi.org/10.4150/KPMI.2017.24.2.153

- 827 View

- 3 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF Transparent conducting electrodes (TCEs) are attracting considerable attention as an important component for emerging optoelectronic applications such as liquid crystal displays, touch panels, and solar cells owing to their attractive combination of low resistivity (< 10-3 Ω cm) and high transparency (>80%) in the visible region. The solutionbased process has unique properties of an easy fabrication procedure, scalability, and low cost compared to the conventional vacuum-based process and may prove to be a useful process for fabricating TCEs for future optoelectronic applications demanding large scale and flexibility. In this paper, we focus on the introduction of a solution-based process for TCEs. In addition, we consider the powder materials used to fabricate solution-based TCEs and strategies to improve their transparent conducting properties.

-

Citations

Citations to this article as recorded by- Electrically conductive and anti-corrosive coating on copper foil assisted by polymer-nanocomposites embedded with graphene

Han Kim, Hyemin Lee, Hyo-Ryoung Lim, Hong-Baek Cho, Yong-Ho Choa

Applied Surface Science.2019; 476: 123. CrossRef

- Electrically conductive and anti-corrosive coating on copper foil assisted by polymer-nanocomposites embedded with graphene

- [Korean]

- Basic Study on the Recycling of Waste Tungsten Scraps by the Oxidation and Reduction Process

- Sang-Uk Kim, Ji-seok Yun, Tae-Wook Kim, Bong-Hwi Cho, In-Ho Kim, Sang-Mu Kim, Chang-Bin Song

- J Korean Powder Metall Inst. 2017;24(1):34-40. Published online February 1, 2017

- DOI: https://doi.org/10.4150/KPMI.2017.24.1.34

- 795 View

- 2 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF This study is carried out to obtain basic data regarding oxidation and reduction reactions, originated on the recycling of waste tungsten hard scraps by oxidation and reduction processes. First, it is estimated that the theoretical Gibbs free energy for the formation reaction of WO2 and WO3 are calculated as ΔG1,000K= -407.335 kJ/mol and ΔG1,000K = -585.679 kJ/mol, from the thermodynamics data reported by Ihsan Barin. In the experiments, the oxidation of pure tungsten rod by oxygen is carried out over a temperature range of 700-1,000°C for 1 h, and it is possible to conclude that the oxidation reaction can be represented by a relatively linear relationship. Second, the reduction of WO2 and WO3 powder by hydrogen is also calculated from the same thermodynamics data, and it can be found that it was difficult for the reduction reaction to occur at 1,027°C, in the case of WO2, but it can happen for temperatures higher than 1127°C. On the other hand, WO3 reduction reaction occurs at the relatively low temperature of 827oC. Based on these results, the reduction experiments are carried out at a temperature range of 500-1,000°C for 15 min to 4 h, in the case of WO3 powder, and it is possible to conclude that the reduction at 900°C for 2h is needed for a perfect reduction reaction.

-

Citations

Citations to this article as recorded by- A Basic Study on the Recycling of Wasted Cemented Carbide by the Zn Bath Process(Ⅰ)

Kyung-Sik Kim, In-Ho Kim, Chan-Gi Lee, Chang-Bin Song

Journal of the Korean Institute of Resources Recycling.2020; 29(6): 35. CrossRef

- A Basic Study on the Recycling of Wasted Cemented Carbide by the Zn Bath Process(Ⅰ)

- [Korean]

- Synthesis and Properties of InP/ZnS core/shell Nanoparticles with One-pot process

- So Yeong Joo, Myung Hwan Hong, Leeseung Kang, Tae Hyung Kim, Chan Gi Lee

- J Korean Powder Metall Inst. 2017;24(1):11-16. Published online February 1, 2017

- DOI: https://doi.org/10.4150/KPMI.2017.24.1.11

- 1,037 View

- 9 Download

-

Abstract

Abstract

PDF

PDF In this study, simple chemical synthesis of green emitting Cd-free InP/ZnS QDs is accomplished by reacting In, P, Zn, and S precursors by one-pot process. The particle size and the optical properties were tailored, by controlling various experimental conditions, including [In]/[MA] (MA: myristic acid) mole ratio, reaction temperature and reaction time. The results of ultraviolet–visible spectroscopy (UV-vis), and of photoluminescence (PL), reveal that the exciton emission of InP was improved by surface coating, with a layer of ZnS. We report the correlation between each experimental condition and the luminescent properties of InP/ZnS core/shell QDs. Transmission electron microscopy (TEM), and X-ray powder diffraction (XRD) techniques were used to characterize the as-synthesized QDs. In contrast to core nanoparticles, InP/ZnS core/shell treated with surface coating shows a clear ultraviolet peak. Besides this work, we need to study what clearly determines the shell kinetic growth mechanism of InP/ZnS core shell QDs.

- [Korean]

- Effect of Cu/Al powder mixing on Dy diffusion in Nd-Fe-B sintered magnets treated with a grain boundary diffusion process

- Min Woo Lee, Tae Suk Jang

- J Korean Powder Metall Inst. 2016;23(6):432-436. Published online December 1, 2016

- DOI: https://doi.org/10.4150/KPMI.2016.23.6.432

- 791 View

- 5 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF We investigate the microstructural and magnetic property changes of DyH2, Cu + DyH2, and Al + DyH2 diffusion-treated NdFeB sintered magnets with the post annealing (PA) temperature. The coercivity of all the diffusiontreated magnets increases with increasing heat treatment temperature except at 910°C, where it decreases slightly. Moreover, at 880°C, the coercivity increases by 3.8 kOe in Cu and 4.7 kOe in Al-mixed DyH2-coated magnets, whereas this increase is relatively low (3.0 kOe) in the magnet coated with only DyH2. Both Cu and Al have an almost similar effect on the coercivity improvement, particularly over the heat treatment temperature range of 790-880°C. The diffusivity and diffusion depth of Dy increases in those magnets that are treated with Cu or Al-mixed DyH2, mainly because of the comparatively easy diffusion path provided by Cu and Al owing to their solubility in the Nd-rich grain boundary phase. The formation of a highly anisotropic (Nd, Dy)2Fe14B phase layer, which acts as the shell in the core-shell-type structure so as to prevent the reverse domain movement, is the cause of enhanced coercivity of diffusion-treated Nd-Fe-B magnets.

-

Citations

Citations to this article as recorded by- Synthesize of Nd2Fe14B Powders from 1-D Nd2Fe14B Wires using Electrospinning Process

Nu Si A Eom, Su Noh, Muhammad Aneeq Haq, Bum Sung Kim

Journal of Korean Powder Metallurgy Institute.2019; 26(6): 477. CrossRef

- Synthesize of Nd2Fe14B Powders from 1-D Nd2Fe14B Wires using Electrospinning Process

- [Korean]

- Preparation of Ni(OH)2 Hollow Spheres by Solvent Displacement Crystallization Using Micro-Injection Device

- Seiki Kim, Kyungsoo Park, Kwang-Il Jung

- J Korean Powder Metall Inst. 2016;23(4):311-316. Published online August 1, 2016

- DOI: https://doi.org/10.4150/KPMI.2016.23.4.311

- 1,040 View

- 9 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF Ni(OH)2 hollow spheres have been prepared by solvent displacement crystallization using a micro-injection device, and the effect of process parameters such as concentration and the relative ratio of the injection speed of the precursor solution, which is an aqueous solution of NiSO4·6H2O, to isopropyl alcohol of displacement solvent have been investigated. The crystal phases after NaOH treatment are in the β-phase for all process parameters. A higher concentration of NiSO4·6H2O aqueous solution is injected by a micro-injection device and bigger Ni(OH)2 hollow spheres with a narrower particle size distribution are formed. The crystallinity and hardness of the as-obtained powder are so poor that hydrothermal treatment of the as-obtained Ni(OH)2 at 120°C for 24 h in distilled water is performed in order to greatly improve the crystallinity. It is thought that a relative ratio of the injection speed of NiSO4·6H2O to that of isopropyl alcohol of at least more than 1 is preferable to synthesize Ni(OH)2 hollow spheres. It is confirmed that this solution- based process is very effective in synthesizing ceramic hollow spheres by simple adjustment of the process parameters such as the concentration and the injection speed.

-

Citations

Citations to this article as recorded by- The Effects of Hexamethylenetetramine Concentration on the Structural and Electrochemical Performances of Ni(OH)2 Powder for Pseudocapacitor Applications

Dong Yeon Kim, Young-Min Jeong, Seong-Ho Baek, Injoon Son

Journal of Korean Powder Metallurgy Institute.2019; 26(3): 231. CrossRef

- The Effects of Hexamethylenetetramine Concentration on the Structural and Electrochemical Performances of Ni(OH)2 Powder for Pseudocapacitor Applications

- [Korean]

- Fabrication and Characterization of Ag Particles by Polyol Process and Wet Chemical Process

- Juyeon Yoo, Hyosung Jang, Kun-Jae Lee

- J Korean Powder Metall Inst. 2016;23(4):297-302. Published online August 1, 2016

- DOI: https://doi.org/10.4150/KPMI.2016.23.4.297

- 809 View

- 3 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF Ag nanoparticles are extensively studied and utilized due to their excellent catalysis, antibiosis and optical properties. They can be easily synthesized by chemical reduction methods and it is possible to prepare particles of uniform size and high purity. These methods are divided into vapor methods and liquid phase reduction methods. In the present study, Ag particles are prepared and analyzed through two chemical reduction methods using solvents containing a silver nitrate precursor. When Ag ions are reduced using a reductant in the aqueous solution, it is possible to control the Ag particle size by controlling the formic acid ratio. In addition, in the Polyol process, Ag nanoparticles prepared at various temperatures and reaction time conditions have multiple twinned and anisotropic structures, and the particle size variation can be confirmed using field emissions scanning electron microscopy and by analyzing the UV-vis spectrum.

-

Citations

Citations to this article as recorded by- Recovery and Synthesis of Silver Nanoparticles from Leaching Solution of LTCC Electrode By-Products

Juyeon Yoo, Yubin Kang, Jinju Park, Hojin Ryu, Jin-Ho Yoon, Kun-Jae Lee

Journal of Korean Powder Metallurgy Institute.2017; 24(4): 315. CrossRef

- Recovery and Synthesis of Silver Nanoparticles from Leaching Solution of LTCC Electrode By-Products

- [Korean]

- Mechanical Property Improvement of the H13 Tool Steel Sculptures Built by Metal 3D Printing Process via Optimum Conditions

- Jaecheol Yun, Jungho Choe, Haengna Lee, Ki-Bong Kim, Sangsun Yang, Dong-Yeol Yang, Yong-Jin Kim, Chang-Woo Lee, Ji-Hun Yu

- J Korean Powder Metall Inst. 2016;24(3):195-201. Published online June 1, 2016

- DOI: https://doi.org/10.4150/KPMI.2017.24.3.195

- 1,272 View

- 12 Download

- 9 Citations

-

Abstract

Abstract

PDF

PDF In this study, H13 tool steel sculptures are built by a metal 3D printing process at various laser scan speeds. The properties of commercial H13 tool steel powders are confirmed for the metal 3D printing process used: powder bed fusion (PBF), which is a selective laser melting (SLM) process. Commercial H13 powder has an excellent flowability of 16.68 s/50 g with a Hausner ratio of 1.25 and a density of 7.68 g/cm3. The sculptures are built with dimensions of 10 × 10 × 10 mm3 in size using commercial H13 tool steel powder. The density measured by the Archimedes method is 7.64 g/cm3, similar to the powder density of 7.68 g/cm3. The hardness is measured by Rockwell hardness equipment 5 times to obtain a mean value of 54.28 HRC. The optimum process conditions in order to build the sculptures are a laser power of 90 W, a layer thickness of 25 μm, an overlap of 30%, and a laser scan speed of 200 mm/s.

-

Citations

Citations to this article as recorded by- Enhancement of resistance to cracking under thermal cycling of EDM-treated H13 steel by shot peening with optimized intensity

Pengpeng Zuo, Zhiyang Dou, Huikai Yang, Haoyan Hou, Yafeng Zheng

Engineering Failure Analysis.2026; 187: 110622. CrossRef - A Study on Fabrication of PCD Boring Tool Body based on Metal 3D Printing Technology

Ho Min Son, Dong Gyu Kim, Min-Woo Sa

Journal of the Korean Society for Precision Engineering.2026; 43(2): 189. CrossRef - Spheroidization of Enamel Powders by Radio Frequency Plasma Treatment and Application to Additive Manufacturing

Ki-Bong Kim, Dong-Yeol Yang, Yong-Jin Kim, Jungho Choe, Ji-Na Kwak, Woo-Hyung Jung

Journal of Korean Powder Metallurgy Institute.2020; 27(5): 388. CrossRef - Microstructural effects on the tensile and fracture behavior of selective laser melted H13 tool steel under varying conditions

Jungsub Lee, Jungho Choe, Junhyeok Park, Ji-Hun Yu, Sangshik Kim, Im Doo Jung, Hyokyung Sung

Materials Characterization.2019; 155: 109817. CrossRef - Nano-mechanical Behavior of H13 Tool Steel Fabricated by a Selective Laser Melting Method

Van Luong Nguyen, Eun-ah Kim, Jaecheol Yun, Jungho Choe, Dong-yeol Yang, Hak-sung Lee, Chang-woo Lee, Ji-Hun Yu

Metallurgical and Materials Transactions A.2019; 50(2): 523. CrossRef - Correlation between Microstructure and Mechanical Properties of the Additive Manufactured H13 Tool Steel

Woojin An, Junhyeok Park, Jungsub Lee, Jungho Choe, Im Doo Jung, Ji-Hun Yu, Sangshik Kim, Hyokyung Sung

Korean Journal of Materials Research.2018; 28(11): 663. CrossRef - Evaluation of Strain-Rate Sensitivity of Selective Laser Melted H13 Tool Steel Using Nanoindentation Tests

Van Luong Nguyen, Eun-ah Kim, Seok-Rok Lee, Jaecheol Yun, Jungho Choe, Dong-yeol Yang, Hak-sung Lee, Chang-woo Lee, Ji-Hun Yu

Metals.2018; 8(8): 589. CrossRef - Comparison of Nano-Mechanical Behavior between Selective Laser Melted SKD61 and H13 Tool Steels

Jaecheol Yun, Van Luong Nguyen, Jungho Choe, Dong-Yeol Yang, Hak-Sung Lee, Sangsun Yang, Ji-Hun Yu

Metals.2018; 8(12): 1032. CrossRef - A study about sculpture characteristic of SKD61 tool steel fabricated by selective laser melting(SLM) process

Jaecheol Yun, Jungho Choe, Ki-Bong Kim, Sangsun Yang, Dong-Yeol Yang, Yong-Jin Kim, Chang-Woo Lee, Chang-Woo Lee

Journal of Korean Powder Metallurgy Institute.2018; 25(2): 137. CrossRef

- Enhancement of resistance to cracking under thermal cycling of EDM-treated H13 steel by shot peening with optimized intensity

- [English]

- Fabrication and Mechanical Characteristics of Bulk Nickel/Carbon Nanotube Nanocomposites via the Electrical Explosion of Wire in Liquid and Spark Plasma Sintering Method

- Thuyet-Nguyen Minh, Hai-Nguyen Hong, Won Joo Kim, Ho Yoon Kim, Jin-Chun Kim

- J Korean Powder Metall Inst. 2016;23(3):213-220. Published online June 1, 2016

- DOI: https://doi.org/10.4150/KPMI.2016.23.3.213

- 1,278 View

- 4 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF In this study, bulk nickel-carbon nanotube (CNT) nanocomposites are synthesized by a novel method which includes a combination of ultrasonication, electrical explosion of wire in liquid and spark plasma sintering. The mechanical characteristics of the bulk Ni-CNT composites synthesized with CNT contents of 0.7, 1, 3 and 5 wt.% are investigated. X-ray diffraction, optical microscopy and field emission scanning electron microscopy techniques are used to observe the different phases, morphologies and structures of the composite powders as well as the sintered samples. The obtained results reveal that the as-synthesized composite exhibits substantial enhancement in the microhardness and values more than 140 HV are observed. However an empirical reinforcement limit of 3 wt.% is determined for the CNT content, beyond which, there is no significant improvement in the mechanical properties.

-

Citations

Citations to this article as recorded by- Fabrication of nanocomposites by electric explosion of stainless steel capillaries filled with carbon nanotubes

Tao Jiang, Zhongyu Hou

Applied Surface Science.2020; 513: 145824. CrossRef - Effect of a nano-sized TiC particle addition on the flow-assisted corrosion resistance of SA 106B carbon steel

Jin-Ju Park, Eun-Kwang Park, Gyoung-Ja Lee, Chang-Kyu Rhee, Min-Ku Lee

Applied Surface Science.2017; 415: 143. CrossRef

- Fabrication of nanocomposites by electric explosion of stainless steel capillaries filled with carbon nanotubes

- [Korean]

- Fabrication and Microstructure/Properties of Bulk-type Tantalum Material by a Kinetic Spray Process

- Ji-Hye Lee, Ji-Won Kim, Kee-Ahn Lee

- J Korean Powder Metall Inst. 2016;23(1):8-14. Published online February 1, 2016

- DOI: https://doi.org/10.4150/KPMI.2016.23.1.8

- 747 View

- 2 Download

- 3 Citations

-

Abstract

Abstract

PDF

PDF A bulk-type Ta material is fabricated using the kinetic spray process and its microstructure and physical properties are investigated. Ta powder with an angular size in the range 9-37 μm (purity 99.95%) is sprayed on a Cu plate to form a coating layer. As a result, ~7 mm-sized bulk-type high-density material capable of being used as a sputter material is fabricated. In order to assess the physical properties of the thick coating layer at different locations, the coating material is observed at three different locations (surface, center, and interface). Furthermore, a vacuum heat treatment is applied to the coating material to reduce the variation of physical properties at different locations of the coating material and improve the density. OM, Vickers hardness test, SEM, XRD, and EBSD are implemented for analyzing the microstructure and physical properties. The fabricated Ta coating material produces porosity of 0.11~0.12%, hardness of 311~327 Hv, and minor variations at different locations. In addition, a decrease in the porosity and hardness is observed at different locations upon heat treatment.

-

Citations

Citations to this article as recorded by- Sintering Behavior and Microstructures of Tantalum and Tantalum-Tungsten Alloys Powders

Youngmoo Kim, Sung Ho Yang, Seong Lee, Sung Ho Lee, Joon-Woong Noh

Journal of Korean Powder Metallurgy Institute.2020; 27(5): 373. CrossRef - Manufacturing of Large-Scale Cold-Sprayed Ta Target Material and Its Sputtering Property

Gi-Su Ham, Dong-Yeol Wi, Jun-Mo Yang, Kee-Ahn Lee

Journal of Thermal Spray Technology.2019; 28(8): 1974. CrossRef - Mechanical properties of Mo-Nb-Si-B quaternary alloy fabricated by powder metallurgical method

Jong Min Byun, Su-Ryong Bang, Se Hoon Kim, Won June Choi, Young Do Kim

International Journal of Refractory Metals and Hard Materials.2017; 65: 14. CrossRef

- Sintering Behavior and Microstructures of Tantalum and Tantalum-Tungsten Alloys Powders

- [Korean]

- Characterization of Films Sputtered with the Cu-Ga Target Prepared by the Cold Spray Process

- Youngji Cho, Jung Ho Yoo, Jun-Mo Yang, Dong-Yong Park, Jong-Kyun Kim, Gang-Bo Choi, Jiho Chang

- J Korean Powder Metall Inst. 2016;23(1):21-25. Published online February 1, 2016

- DOI: https://doi.org/10.4150/KPMI.2016.23.1.21

- 559 View

- 1 Download

-

Abstract

Abstract

PDF

PDF The microstructural properties and electrical characteristics of sputtering films deposited with a Cu-Ga target are analyzed. The Cu-Ga target is prepared using the cold spray process and shows generally uniform composition distributions, as suggested by secondary ion mass spectrometer (SIMS) data. Characteristics of the sputtered Cu-Ga films are investigated at three positions (top, center and bottom) of the Cu-Ga target by X-ray diffraction (XRD), SIMS, 4-point probe and transmission electron microscopy (TEM) analysis methods. The results show that the Cu-Ga films are composed of hexagonal and unknown phases, and they have similar distributions of composition and resistivity at the top, center, and bottom regions of the Cu-Ga target. It demonstrates that these films have uniform properties regardless of the position on the Cu-Ga target. In conclusion, the cold spray process is expected to be a useful method for preparing sputter targets.

- [Korean]

- Effect of Sublimable Vehicle Compositions in the Camphor-Naphthalene System on the Pore Structure of Porous Cu-Ni

- Na-Yeon Kwon, Myung-Jin Suka, Sung-Tag Oh

- J Korean Powder Metall Inst. 2015;22(5):362-366. Published online October 1, 2015

- DOI: https://doi.org/10.4150/KPMI.2015.22.5.362

- 1,096 View

- 1 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF The effect of sublimable vehicle composition in the camphor-naphthalene system on the pore structure of porous Cu-Ni alloy is investigated. The CuO-NiO mixed slurries with hypoeutectic, eutectic and hypereutectic compositions are frozen into a mold at -25°C. Pores are generated by sublimation of the vehicles at room temperature. After hydrogen reduction at 300°C and sintering at 850°C for 1 h, the green body of CuO-NiO is completely converted to porous Cu-Ni alloy with various pore structures. The sintered samples show large pores which are aligned parallel to the sublimable vehicle growth direction. The pore size and porosity decrease with increase in powder content due to the degree of powder rearrangement in slurry. In the hypoeutectic composition slurry, small pores with dendritic morphology are observed in the sintered Cu-Ni, whereas the specimen of hypereutectic composition shows pore structure of plate shape. The change of pore structure is explained by growth behavior of primary camphor and naphthalene crystals during solidification of camphor-naphthalene alloys.

-

Citations

Citations to this article as recorded by- Freeze Drying Process and Pore Structure Characteristics of Porous Cu with Various Sublimable Vehicles

Gyuhwi Lee, Sung-Tag Oh, Myung-Jin Suk, Young-Keun Jeong

Journal of Korean Powder Metallurgy Institute.2020; 27(3): 198. CrossRef - Interaction of Solid Particles with the Solidifying Front in the Liquid-Particle Mixture

Ho-Suk Lee, Kyu-Hee Lee, Sung-Tag Oh, Young Do Kim, Myung-Jin Suk

Journal of Korean Powder Metallurgy Institute.2018; 25(4): 336. CrossRef

- Freeze Drying Process and Pore Structure Characteristics of Porous Cu with Various Sublimable Vehicles

- [Korean]

- Formation of Nano-oxides on Porous Metallic Glass Compacts using Hydrothermal Synthesis

- H. J. Park, Y. S. Kim, S. H. Hong, J. T. Kim, J. Y. Cho, W. H. Lee, K. B. Kim

- J Korean Powder Metall Inst. 2015;22(4):229-233. Published online August 1, 2015

- DOI: https://doi.org/10.4150/KPMI.2015.22.4.229

- 760 View

- 1 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF Porous metallic glass compact (PMGC) are developed by electro-discharge sintering (EDS) process of gas atomized Zr41.2Ti13.8Cu12.5Ni10Be22.5 metallic glass powder under of 0.2 kJ generated by a 450 μF capacitor being charged to 0.94 kV. Functional iron-oxides are formed and growth on the surface of PMGCs via hydrothermal synthesis. It is carried out at 150°C for 48hr with distilled water of 100 mL containing Fe ions of 0.18 g/L. Consequently, two types of iron oxides with different morphology which are disc-shaped Fe2O3 and needle-shaped Fe3O4 are successfully formed on the surface of the PMGCs. This finding suggests that PMGC witih hydrothermal technique can be attractive for the practical technology as a new area of structural and functional materials. And they provide a promising road map for using the metallic glasses as a potential functional application.

-

Citations

Citations to this article as recorded by- Enhanced wear resistivity of a Zr-based bulk metallic glass processed by high-pressure torsion under reciprocating dry conditions

Soo-Hyun Joo, Dong-Hai Pi, Jing Guo, Hidemi Kato, Sunghak Lee, Hyoung Seop Kim

Metals and Materials International.2016; 22(3): 383. CrossRef

- Enhanced wear resistivity of a Zr-based bulk metallic glass processed by high-pressure torsion under reciprocating dry conditions

- [English]

- Fabrication and Pore Characteristics of Cu Foam by Slurry Coating Process

- Dahee Park, Eun-Mi Jung, Sangsun Yang, Jung-Yeul Yun

- J Korean Powder Metall Inst. 2015;22(2):87-92. Published online April 1, 2015

- DOI: https://doi.org/10.4150/KPMI.2015.22.2.87

- 1,137 View

- 7 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF Metallic porous materials have many interesting combinations of physical and geometrical properties with very low specific weight or high gas permeability. In this study, highly porous Cu foam is successfully fabricated by a slurry coating process. The Cu foam is fabricated specifically by changing the coating amount and the type of polyurethane foam used as a template. The processing parameters and pore characteristics are observed to identify the key parameters of the slurry coating process and the optimized morphological properties of the Cu foam. The pore characteristics of Cu foam are investigated by scanning electron micrographs and micro-CT analyzer, and air permeability of the Cu foam is measured by capillary flow porometer. We confirmed that the characteristics of Cu foam can be easily controlled in the slurry coating process by changing the microstructure, porosity, pore size, strut thickness, and the cell size. It can be considered that the fabricated Cu foams show tremendous promise for industrial application.

-

Citations

Citations to this article as recorded by- Preparation and comparative evolution of mechanical behavior of Fe and Fe2O3 foams and their polymer composites

Vemoori Raju, Roy Johnson, Asit Kumar Khanra

Journal of Alloys and Compounds.2018; 750: 71. CrossRef

- Preparation and comparative evolution of mechanical behavior of Fe and Fe2O3 foams and their polymer composites

- [Korean]

- The Fabrication of Cobalt Nanopowder by Sonochemical Polyol Synthesis of Cobalt Hydroxide and Magnetic Separation Method

- Jong Min Byun, Myoung Hwan Choi, Chang Min Shim, Ji Young Kim, Young Do Kim

- J Korean Powder Metall Inst. 2015;22(1):39-45. Published online February 1, 2015

- DOI: https://doi.org/10.4150/KPMI.2015.22.1.39

- 815 View

- 2 Download

-

Abstract

Abstract

PDF