Search

- Page Path

- HOME > Search

- [English]

- A Self-Powered Cationic Microfiber-Based Triboelectric Air Filter for High-Speed Particulate Matter Removal and Smart Monitoring

- Tae-hyung Kim, Jin-Kyeom Kim

- J Powder Mater. 2025;32(6):481-491. Published online December 31, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00465

- 853 View

- 4 Download

-

Abstract

Abstract

PDF

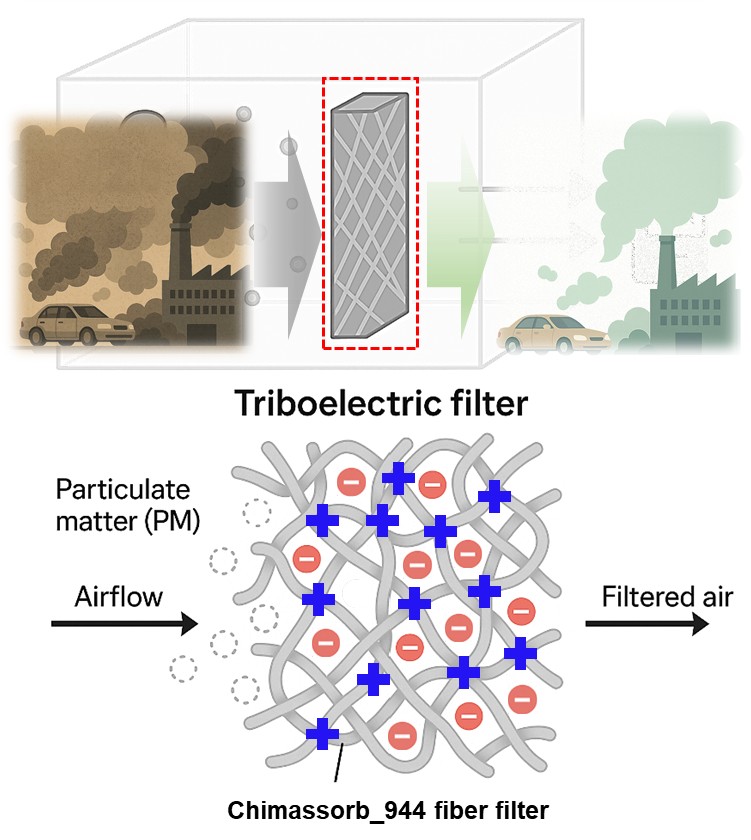

PDF - Particulate matter (PM) pollution demands air filters that combine high efficiency with low pressure drop. Here, we report a self-powered electrostatic filter based on an electrospun cationic microfiber web of Chimassorb 944 (C-fiber). The C-fiber functions as a triboelectric nanogenerator (TENG), generating a surface charge density of 85.8 85.8 μC/m2 when paired with polytetrafluoroethylene (PTFE), which creates a strong electrostatic field for capturing sub-micron particles, including the most penetrating particle size (MPPS). As a result, the triboelectrically charged C-fiber filter maintains >80% filtration efficiency at a high wind speed of 60 cm/s, far exceeding uncharged mechanical filters (<20%) while retaining low air resistance. Kelvin probe force microscopy (KPFM) visualizes the surface-potential change after particle capture, and the gradual decay of TENG output provides a built-in indicator of dust loading. This strategy offers a promising platform for next-generation smart air purification systems.

- [Korean]

- Enhanced H2S Gas Sensing Using ZnO Porous Nanorod Synthesized via a Rotational Hydrothermal Method

- Jimyeong Park, Changyu Kim, Minseo Kim, Jiyeon Shin, Jae-Hyoung Lee, Myung Sik Choi

- J Powder Mater. 2025;32(5):406-415. Published online October 31, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00262

- 431 View

- 9 Download

-

Abstract

Abstract

PDF

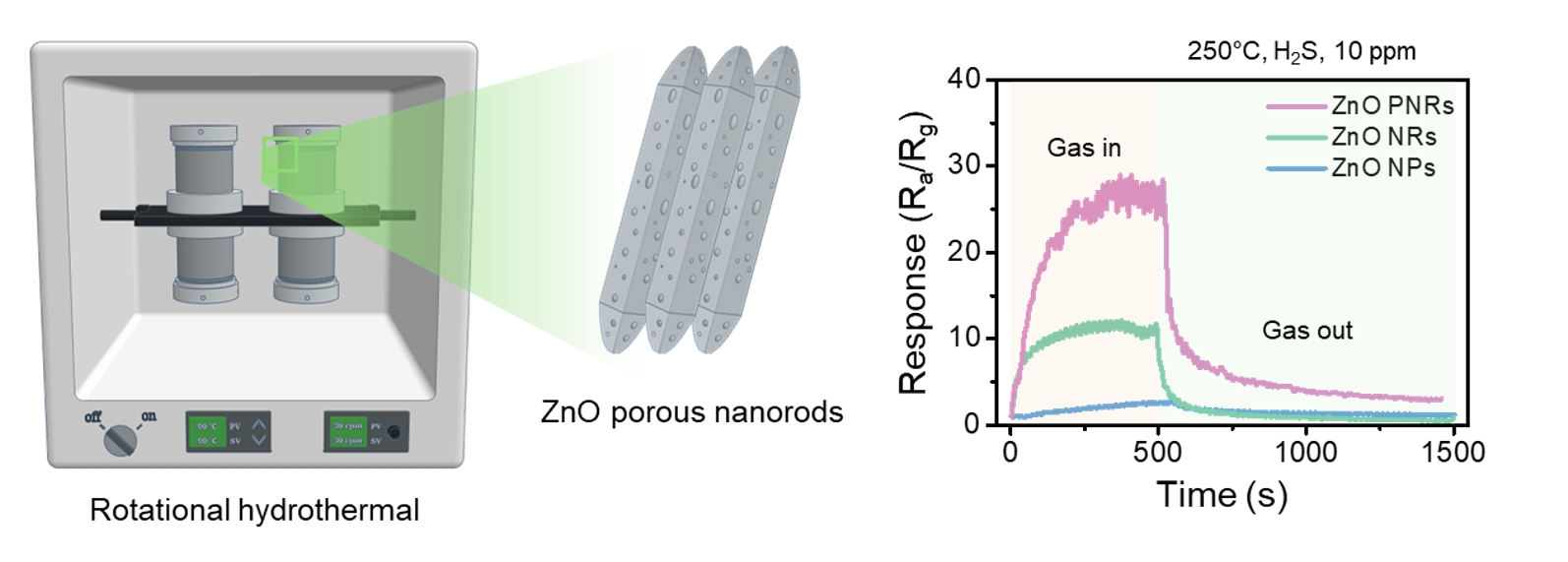

PDF - In this study, ZnO porous nanorods were synthesised using a rotational hydrothermal process, and their performance as hydrogen sulphide (H2S) gas sensors was analysed. Compared to commercial ZnO nanoparticles and conventionally hydrothermally synthesised ZnO nanorods, the ZnO porous nanorods exhibited a more uniform structure and improved crystal growth in the (002) plane, with surfaces rich in porosity and oxygen vacancies. These structural and chemical characteristics significantly improved the sensitivity toward H2S, showing high detection performance at 250°C across various concentrations of H2S gas. Additionally, the sensor demonstrated excellent selectivity against other gases such as C2H5OH, C6H6, C7H8, and NH3. This study indicated that the rotational hydrothermal process is an effective method for developing high-performance ZnO-based gas sensors and suggests its applicability to other metal oxide materials.

- [Korean]

- Optimized Process and Mechanical and Electrical Analysis of Polyimide/Pb(Zr,Ti)O3-Based Flexible Piezoelectric Composites

- Junki Lee, Sang-il Yoon, Hyunseung Kim, Chang Kyu Jeong

- J Powder Mater. 2025;32(1):16-22. Published online February 28, 2025

- DOI: https://doi.org/10.4150/jpm.2024.00444

- 977 View

- 30 Download

-

Abstract

Abstract

PDF

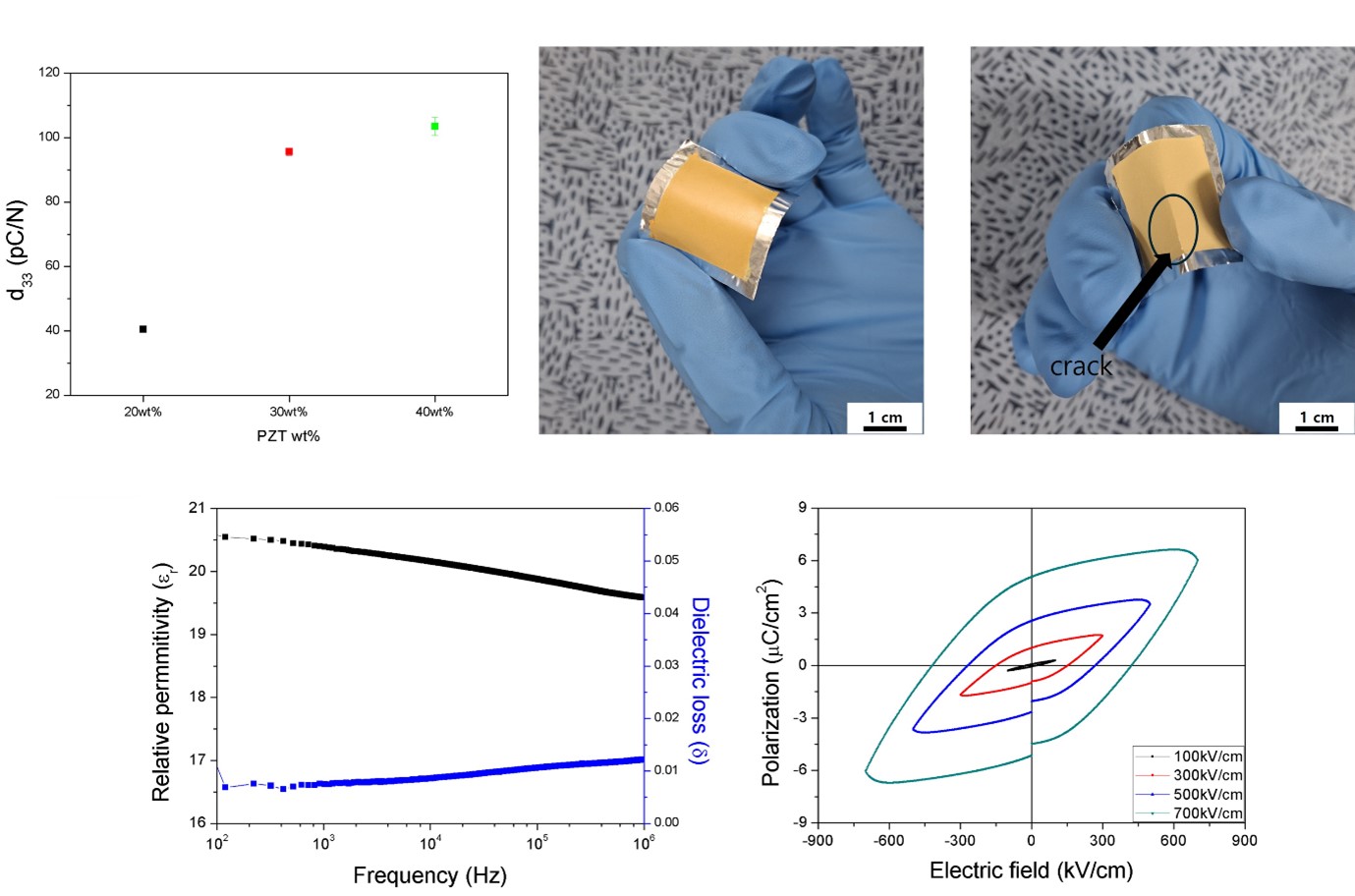

PDF - Piezoelectric composites have attracted significant research interest as sustainable power sources for electronic devices due to their high mechanical stability and electrical output characteristics. This study investigated the optimal processing conditions for fabricating a flexible piezoelectric energy harvester based on Pb(Zr,Ti)O₃ (PZT) powder and a polyimide (PI) matrix composite. Various parameters, including the optimal mixing ratio of PI/PZT, ultrasonic treatment, homogenization, vacuum oven, and UV/O₃ treatment, were optimized to achieve a uniform piezoelectric composite. A PZT content of 30 wt% and 20 minutes of homogenization were identified as the most effective conditions for increasing the uniformity of the composite. The optimized composite exhibited a high piezoelectric coefficient, a typical P-E hysteresis loop, and dielectric properties, exhibiting a voltage output that adjusts in response to variations in the applied touch force. This study provides foundational data for the uniform fabrication of flexible piezoelectric energy harvesters and next-generation miniaturized electronic devices.

- [Korean]

- Capacitance Enhancement and Evaluation of Gold-Deposited Carbon Nanotube Film Ion-Selective Electrode

- Do Youn Kim, Hanbyeol Son, Hyo-Ryoung Lim

- J Powder Mater. 2023;30(4):310-317. Published online August 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.4.310

- 964 View

- 7 Download

-

Abstract

Abstract

PDF

PDF Small-film-type ion sensors are garnering considerable interest in the fields of wearable healthcare and home-based monitoring systems. The performance of these sensors primarily relies on electrode capacitance, often employing nanocomposite materials composed of nano- and sub-micrometer particles. Traditional techniques for enhancing capacitance involve the creation of nanoparticles on film electrodes, which require cost-intensive and complex chemical synthesis processes, followed by additional coating optimization. In this study, we introduce a simple one-step electrochemical method for fabricating gold nanoparticles on a carbon nanotube (Au NP–CNT) electrode surface through cyclic voltammetry deposition. Furthermore, we assess the improvement in capacitance by distinguishing between the electrical double-layer capacitance and diffusion-controlled capacitance, thereby clarifying the principles underpinning the material design. The Au NP–CNT electrode maintains its stability and sensitivity for up to 50 d, signifying its potential for advanced ion sensing. Additionally, integration with a mobile wireless data system highlights the versatility of the sensor for health applications.

- [Korean]

- Recent Advances in Soft Magnetic Actuators and Sensors using Magnetic Particles

- Hyeonseo Song, Hajun Lee, Junghyo Kim, Jiyun Kim

- J Korean Powder Metall Inst. 2021;28(6):509-517. Published online December 1, 2021

- DOI: https://doi.org/10.4150/KPMI.2021.28.6.509

- 941 View

- 4 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF Smart materials capable of changing their characteristics in response to stimuli such as light, heat, pH, and electric and magnetic fields are promising for application to flexible electronics, soft robotics, and biomedicine. Compared with conventional rigid materials, these materials are typically composed of soft materials that improve the biocompatibility and allow for large and dynamic deformations in response to external environmental stimuli. Among them, smart magnetic materials are attracting immense attention owing to their fast response, remote actuation, and wide penetration range under various conditions. In this review, we report the material design and fabrication of smart magnetic materials. Furthermore, we focus on recent advances in their typical applications, namely, soft magnetic actuators, sensors for self-assembly, object manipulation, shape transformation, multimodal robot actuation, and tactile sensing.

-

Citations

Citations to this article as recorded by- Advanced Magnetic Actuation: Harnessing the Dynamics of Sm2Fe17–xCuxN3 Composites

Kangmo Koo, Young-Tae Kwon, Ji Young Park, Yong-Ho Choa

ACS Applied Materials & Interfaces.2024; 16(9): 11872. CrossRef

- Advanced Magnetic Actuation: Harnessing the Dynamics of Sm2Fe17–xCuxN3 Composites

- [Korean]

- Fluorescent Nanoparticles: Synthesis and Applications

- Y. K. Kim, B. K. Song, J. G. Lee, Y. K. Baek

- J Korean Powder Metall Inst. 2020;27(2):154-163. Published online April 1, 2020

- DOI: https://doi.org/10.4150/KPMI.2020.27.2.154

- 2,920 View

- 12 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF Fluorescent nanoparticles are characterized by their unique properties such as luminescence, optical transparency, and sensitivity to various chemical environments. For example, semiconductor nanocrystals (quantum dots), which are nanophosphors doped with transition metal or rare earth ions, can be classified as fluorescent nanoparticles. Tuning their optical and physico-chemical properties can be carried out by considering and taking advantage of nanoscale effects. For instance, quantum confinement causes a much higher fluorescence with nanoparticles than with their bulk counterparts. Recently, various types of fluorescent nanoparticles have been synthesized to extend their applications to other fields. In this study, State-of-the-art fluorescent nanoparticles are reviewed with emphasis on their analytical and anti-counterfeiting applications and synthesis processes. Moreover, the fundamental principles behind the exceptional properties of fluorescent nanoparticles are discussed.

-

Citations

Citations to this article as recorded by- Preparation and Analysis of High Functional Silicone Hydrogel Lens Containing Metal Oxide Nanoparticles by Photopolymerizaion

Ji-Won Heo, A-Young Sung

Korean Journal of Materials Research.2022; 32(4): 193. CrossRef

- Preparation and Analysis of High Functional Silicone Hydrogel Lens Containing Metal Oxide Nanoparticles by Photopolymerizaion

- [Korean]

- Additive Manufacturing for Sensor Integrated Components

- Im Doo Jung, Min Sik Lee, Young Jin Woo, Kyung Tae Kim, Ji-Hun Yu

- J Korean Powder Metall Inst. 2020;27(2):111-118. Published online April 1, 2020

- DOI: https://doi.org/10.4150/KPMI.2020.27.2.111

- 1,369 View

- 14 Download

-

Abstract

Abstract

PDF

PDF The convergence of artificial intelligence with smart factories or smart mechanical systems has been actively studied to maximize the efficiency and safety. Despite the high improvement of artificial neural networks, their application in the manufacturing industry has been difficult due to limitations in obtaining meaningful data from factories or mechanical systems. Accordingly, there have been active studies on manufacturing components with sensor integration allowing them to generate important data from themselves. Additive manufacturing enables the fabrication of a net shaped product with various materials including plastic, metal, or ceramic parts. With the principle of layer-bylayer adhesion of material, there has been active research to utilize this multi-step manufacturing process, such as changing the material at a certain step of adhesion or adding sensor components in the middle of the additive manufacturing process. Particularly for smart parts manufacturing, researchers have attempted to embed sensors or integrated circuit boards within a three-dimensional component during the additive manufacturing process. While most of the sensor embedding additive manufacturing was based on polymer material, there have also been studies on sensor integration within metal or ceramic materials. This study reviews the additive manufacturing technology for sensor integration into plastic, ceramic, and metal materials.

- [Korean]

- Fabrication and Characterization of Hexagonal Tungsten Oxide Nanopowders for High Performance Gas Sensing Application

- Jinsoo Park

- J Korean Powder Metall Inst. 2019;26(1):28-33. Published online February 1, 2019

- DOI: https://doi.org/10.4150/KPMI.2019.26.1.28

- 843 View

- 5 Download

-

Abstract

Abstract

PDF

PDF The gas sensor is essential to monitoring dangerous gases in our environment. Metal oxide (MO) gas sensors are primarily utilized for flammable, toxic and organic gases and O3 because of their high sensitivity, high response and high stability. Tungsten oxides (WO3) have versatile applications, particularly for gas sensor applications because of the wide bandgap and stability of WO3. Nanosize WO3 are synthesized using the hydrothermal method. Asprepared WO3 nanopowders are in the form of nanorods and nanorulers. The crystal structure is hexagonal tungsten bronze (MxWO3, x =< 0.33), characterized as a tunnel structure that accommodates alkali ions and the phase stabilizer. A gas detection test reveals that WO3 can detect acetone, butanol, ethanol, and gasoline. This is the first study to report this capability of WO3.

- [English]

- The Synthesis Method of Tin Dioxide Nanoparticles by Plasma-Assisted Electrolysis Process and Gas Sensing Property

- Tae Hyung Kim, Yoseb Song, Chan-Gi Lee, Yong-Ho Choa

- J Korean Powder Metall Inst. 2017;24(5):351-356. Published online October 1, 2017

- DOI: https://doi.org/10.4150/KPMI.2017.24.5.351

- 1,537 View

- 2 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF Tin dioxide nanoparticles are prepared using a newly developed synthesis method of plasma-assisted electrolysis. A high voltage is applied to the tin metal plate to apply a high pressure and temperature to the synthesized oxide layer on the metal surface, producing nanoparticles in a low concentration of sulfuric acid. The particle size, morphology, and size distribution is controlled by the concentration of electrolytes and frequency of the power supply. The as-prepared powder of tin dioxide nanoparticles is used to fabricate a gas sensor to investigate the potential application. The particle-based gas sensor exhibits a short response and recovery time. There is sensitivity to the reduction gas for the gas flowing at rates of 50, 250, and 500 ppm of H2S gas.

-

Citations

Citations to this article as recorded by- Effects of porosity and particle size on the gas sensing properties of SnO2 films

Min Ah Han, Hyun-Jong Kim, Hee Chul Lee, Jin-Seong Park, Ho-Nyun Lee

Applied Surface Science.2019; 481: 133. CrossRef

- Effects of porosity and particle size on the gas sensing properties of SnO2 films

TOP

KPMI

KPMI

First

First Prev

Prev