- [Korean]

- The Use of TiH2 to Refine Y2Ti2O7 in a Nano Mo-ODS Alloy

-

Yuncheol Ha, Chun Woong Park, Won Hee Lee, Jongmin Byun, Young Do Kim

-

J Powder Mater. 2024;31(5):399-405. Published online October 31, 2024

-

DOI: https://doi.org/10.4150/jpm.2024.00178

-

-

Abstract Abstract

PDF PDF

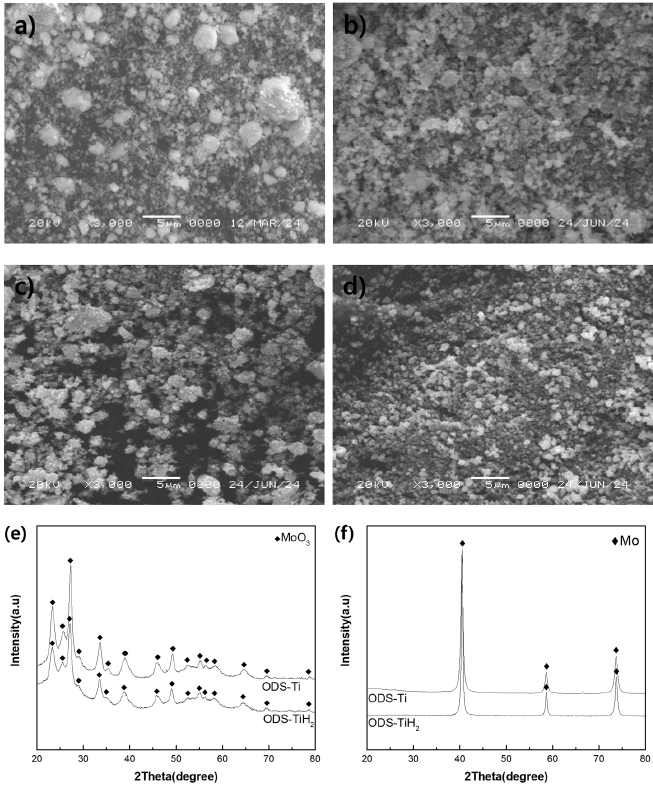

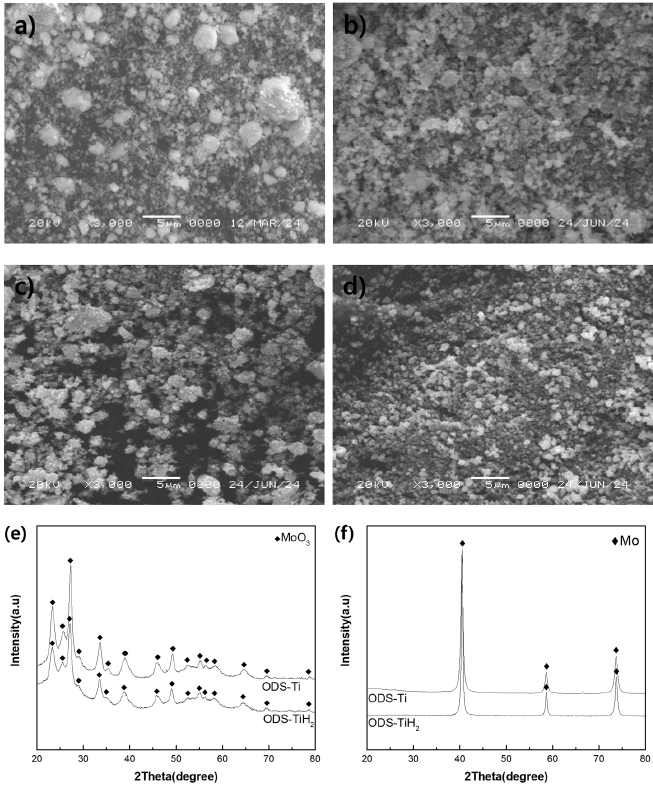

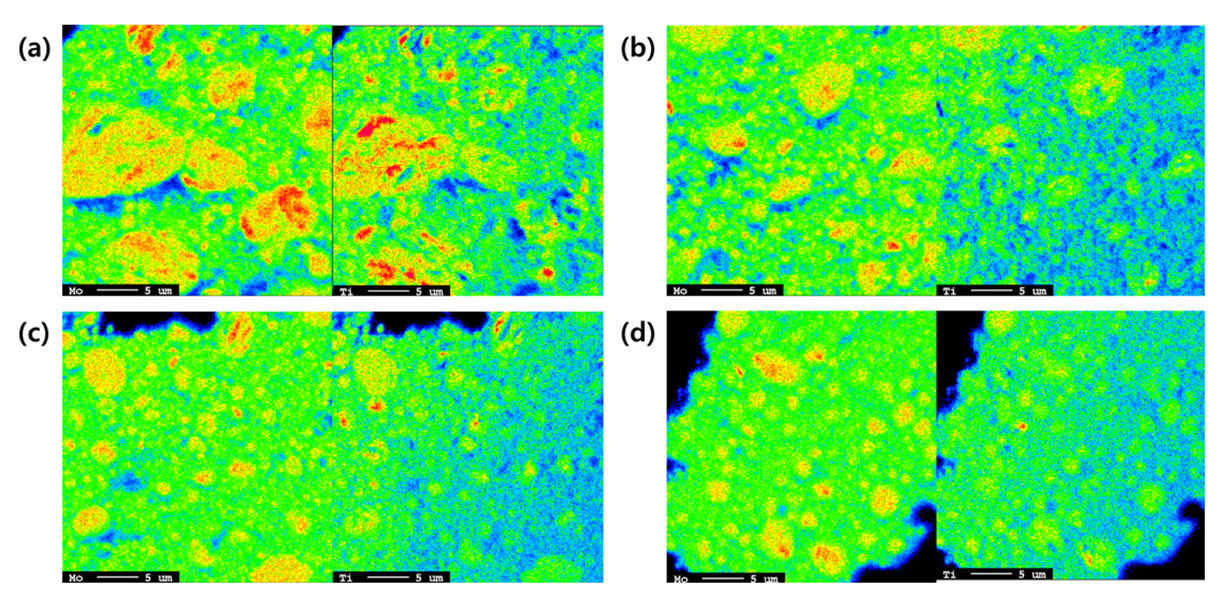

- Mo-ODS alloys have excellent mechanical properties, including an improved recrystallization temperature, greater strength due to dispersed oxides, and the ability to suppress grain growth at high temperatures. In ODS alloys, the dispersed Y2O3 and added Ti form Y-Ti-O complex oxides, producing finer particles than those in the initial Y2O3. The complex oxides increase high-temperature stability and improve the mechanical properties of the alloy. In particular, the use of TiH2 powder, which is more brittle than conventional Ti, can enable the distribution of finer oxides than is possible with conventional Ti powder during milling. Moreover, dehydrogenation leads to a more refined powder size in the reduction process. This study investigated the refinement of Y2Ti2O7 in a nano Mo-ODS alloy using TiH2. The alloy compositions were determined to be Mo-0.5Ti-0.5Y2O3 and Mo-1.0Ti-0.5Y2O3. The nano Mo-ODS alloys were fabricated using Ti and TiH2 to explore the effects of adding different forms of Ti. The sintered specimens were analyzed through X-ray diffraction for phase analysis, and the microstructure of the alloys was analyzed using scanning electron microscopy and transmission electron microscopy. Vickers hardness tests were conducted to determine the effect of the form of Ti added on the mechanical properties, and it was found that using TiH2 effectively improved the mechanical properties.

- [Korean]

- TiO2 Thin Film Coating on an Nb-Si–Based Superalloy via Atomic Layer Deposition

-

Ji Young Park, Su Min Eun, Jongmin Byun, Byung Joon Choi

-

J Powder Mater. 2024;31(3):255-262. Published online June 27, 2024

-

DOI: https://doi.org/10.4150/jpm.2024.00052

-

-

Abstract Abstract

PDF PDF

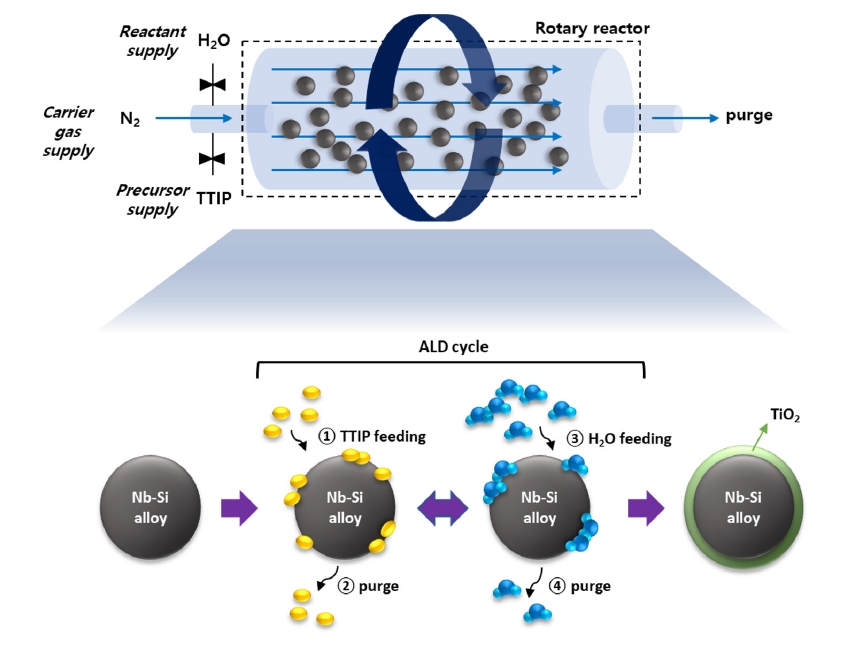

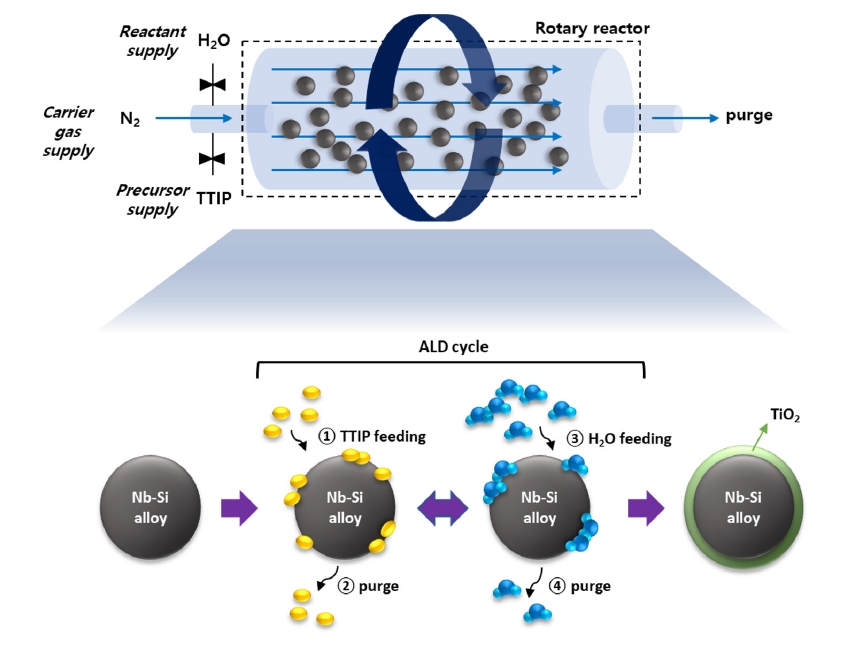

- Nano-oxide dispersion–strengthened (ODS) superalloys have attracted attention because of their outstanding mechanical reinforcement mechanism. Dispersed oxides increase the material’s strength by preventing grain growth and recrystallization, as well as increasing creep resistance. In this research, atomic layer deposition (ALD) was applied to synthesize an ODS alloy. It is useful to coat conformal thin films even on complex matrix shapes, such as nanorods or powders. We coated an Nb-Si–based superalloy with TiO2 thin film by using rotary-reactor type thermal ALD. TiO2 was grown by controlling the deposition recipe, reactor temperature, N2 flow rate, and rotor speed. We could confirm the formation of uniform TiO2 film on the surface of the superalloy. This process was successfully applied to the synthesis of an ODS alloy, which could be a new field of ALD applications.

- [Korean]

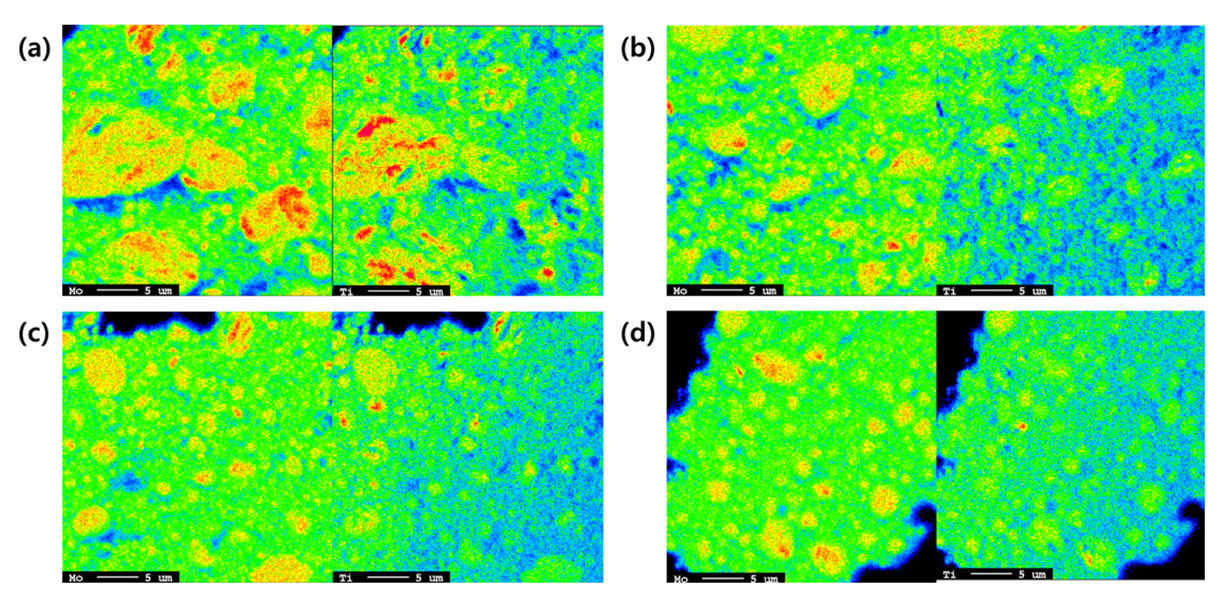

- Fabrication of Ti-Mo Core-shell Powder and Sintering Properties for Application as a Sputtering Target

-

Won Hee Lee, Chun Woong Park, Heeyeon Kim, Yuncheol Ha, Jongmin Byun, Young Do Kim

-

J Powder Mater. 2024;31(1):43-49. Published online February 28, 2024

-

DOI: https://doi.org/10.4150/KPMI.2024.31.1.43

-

-

PDF PDF

- [Korean]

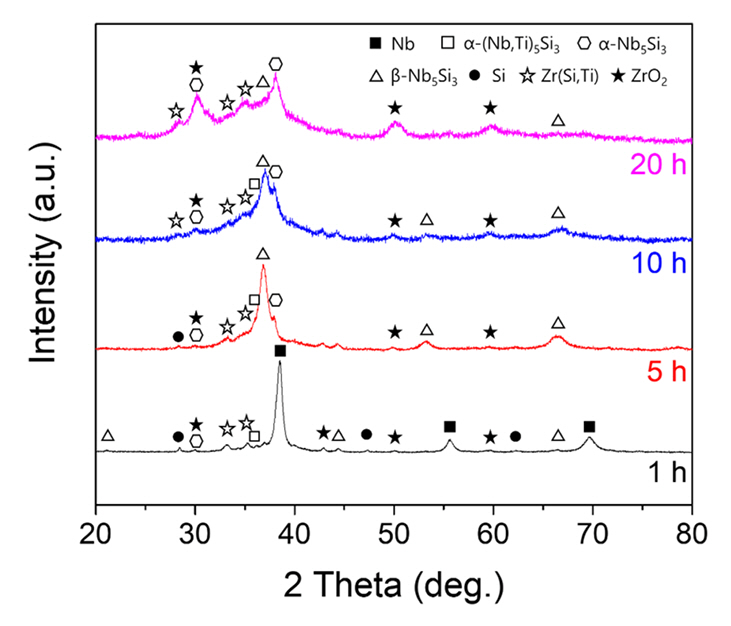

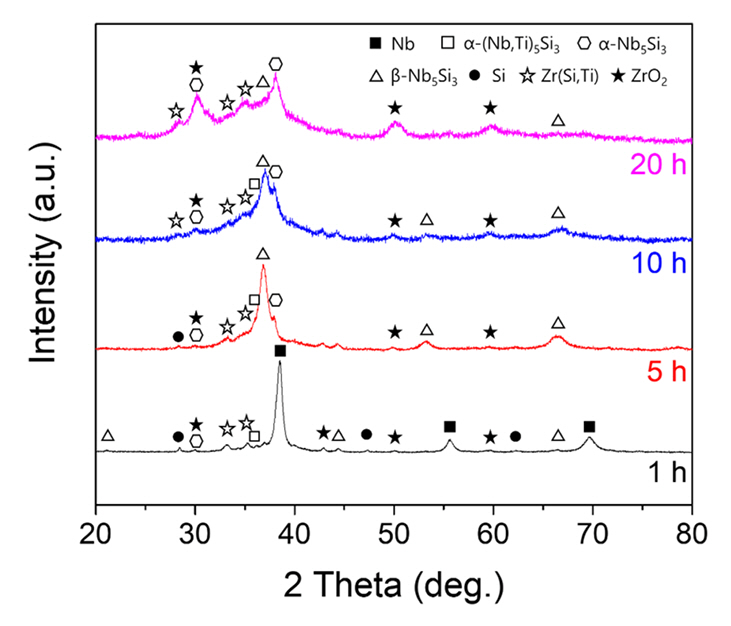

- Development of High-strength, High-temperature Nb-Si-Ti Alloys through Mechanical Alloying

-

Jung-Joon Kim, Sang-Min Yoon, Deok-Hyun Han, Jongmin Byun, Young-Kyun Kim

-

J Powder Mater. 2024;31(1):30-36. Published online February 28, 2024

-

DOI: https://doi.org/10.4150/KPMI.2024.31.1.30

-

-

2,138

View

-

51

Download

-

1

Citations

-

PDF PDF

-

Citations

Citations to this article as recorded by  - Review of “Integrated Computer-Aided Process Engineering Session in the 17th International Symposium on Novel and Nano Materials (ISNNM, 14–18 November 2022)”

Yeon-Joo Lee, Pil-Ryung Cha, Hyoung-Seop Kim, Hyun-Joo Choi

MATERIALS TRANSACTIONS.2025; 66(1): 144. CrossRef

- [English]

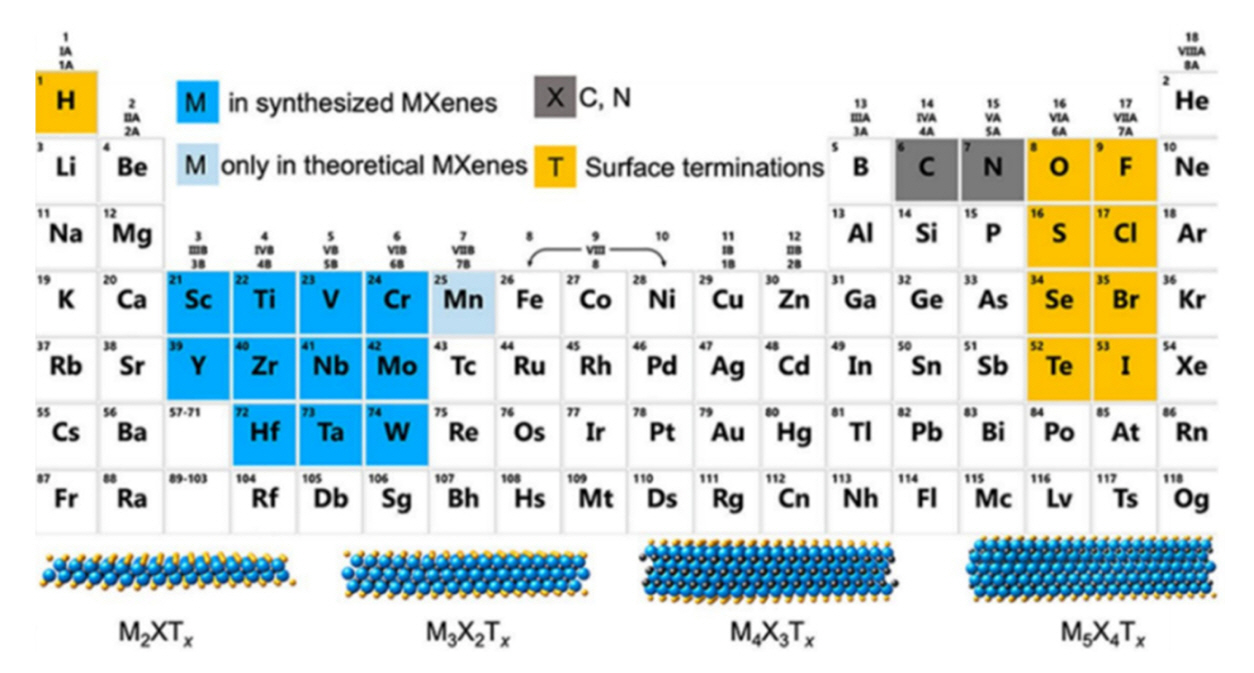

- Research Trends in Electromagnetic Shielding using MXene-based Composite Materials

-

Siyeon Kim, Jongmin Byun

-

J Powder Mater. 2024;31(1):57-76. Published online February 28, 2024

-

DOI: https://doi.org/10.4150/KPMI.2024.31.1.57

-

-

8,331

View

-

163

Download

-

4

Citations

-

Abstract Abstract

PDF PDF

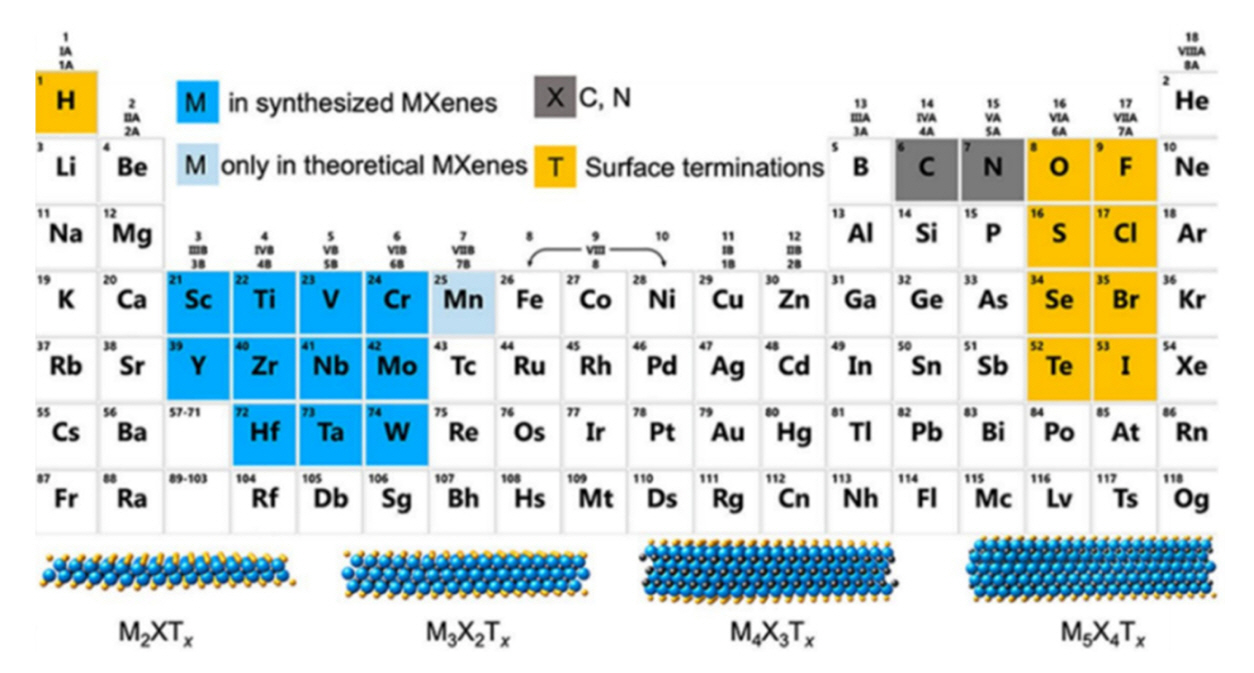

Recent advancements in electronic devices and wireless communication technologies, particularly the rise of 5G, have raised concerns about the escalating electromagnetic pollution and its potential adverse impacts on human health and electronics. As a result, the demand for effective electromagnetic interference (EMI) shielding materials has grown significantly. Traditional materials face limitations in providing optimal solutions owing to inadequacy and low performance due to small thickness. MXene-based composite materials have emerged as promising candidates in this context owing to their exceptional electrical properties, high conductivity, and superior EMI shielding efficiency across a broad frequency range. This review examines the recent developments and advantages of MXene-based composite materials in EMI shielding applications, emphasizing their potential to address the challenges posed by electromagnetic pollution and to foster advancements in modern electronics systems and vital technologies. -

Citations

Citations to this article as recorded by  - Designing dual phase hexaferrite (SrFe12O19) – Perovskite (La0.5Nd0.5FeO3) composites for enhanced electromagnetic wave absorption and band gap modulation

Pramod D. Mhase, Varsha C. Pujari, Santosh S. Jadhav, Abdullah G. Al-Sehemi, Sarah Alsobaie, Sunil M. Patange

Composites Communications.2025; 54: 102284. CrossRef - Microstructure tailoring of Nb-based MAX phase by low temperature synthesis with layer-structured Nb2C powder and molten salt method

Chaehyun Lim, Wonjune Choi, Jongmin Byun

Materials Characterization.2025; 225: 115106. CrossRef - Fabrication of MOF@MXene composites via surface modification of MXene under acidic conditions

Ji-Haeng Jeong, Woong-Ryeol Yu

Functional Composites and Structures.2025; 7(2): 025006. CrossRef - V2CTx MXene@ZIF-8 composite as an efficient adsorbent for Pb(II) removal from aqueous solution

Sarina Khojasteh Fard, Golshan Mazloom, Manoochehr Sobhani, Mohsen Tamtaji

Journal of Environmental Chemical Engineering.2025; 13(6): 120099. CrossRef

- [Korean]

- Machine Learning-based Data Analysis for Designing High-strength Nb-based Superalloys

-

Eunho Ma, Suwon Park, Hyunjoo Choi, Byoungchul Hwang, Jongmin Byun

-

J Powder Mater. 2023;30(3):217-222. Published online June 1, 2023

-

DOI: https://doi.org/10.4150/KPMI.2023.30.3.217

-

-

Abstract Abstract

PDF PDF

Machine learning-based data analysis approaches have been employed to overcome the limitations in accurately analyzing data and to predict the results of the design of Nb-based superalloys. In this study, a database containing the composition of the alloying elements and their room-temperature tensile strengths was prepared based on a previous study. After computing the correlation between the tensile strength at room temperature and the composition, a material science analysis was conducted on the elements with high correlation coefficients. These alloying elements were found to have a significant effect on the variation in the tensile strength of Nb-based alloys at room temperature. Through this process, a model was derived to predict the properties using four machine learning algorithms. The Bayesian ridge regression algorithm proved to be the optimal model when Y, Sc, W, Cr, Mo, Sn, and Ti were used as input features. This study demonstrates the successful application of machine learning techniques to effectively analyze data and predict outcomes, thereby providing valuable insights into the design of Nb-based superalloys.

- [Korean]

- Pressureless Sintering and Microstructure of Pure Tungsten Powders Prepared by Ultrasonic Spray Pyrolysis

-

Youn Ji Heo, Eui Seon Lee, Sung-Tag Oh, Jongmin Byun

-

J Powder Mater. 2022;29(3):247-251. Published online June 1, 2022

-

DOI: https://doi.org/10.4150/KPMI.2022.29.3.247

-

-

1,292

View

-

11

Download

-

2

Citations

-

Abstract Abstract

PDF PDF

This study demonstrates the effect of the compaction pressure on the microstructure and properties of pressureless-sintered W bodies. W powders are synthesized by ultrasonic spray pyrolysis and hydrogen reduction using ammonium metatungstate hydrate as a precursor. Microstructural investigation reveals that a spherical powder in the form of agglomerated nanosized W particles is successfully synthesized. The W powder synthesized by ultrasonic spray pyrolysis exhibits a relative density of approximately 94% regardless of the compaction pressure, whereas the commercial powder exhibits a relative density of 64% under the same sintering conditions. This change in the relative density of the sintered compact can be explained by the difference in the sizes of the raw powder and the densities of the compacted green body. The grain size increases as the compaction pressure increases, and the sintered compact uniaxially pressed to 50 MPa and then isostatically pressed to 300 MPa exhibits a size of 0.71 m. The Vickers hardness of the sintered W exhibits a high value of 4.7 GPa, mainly due to grain refinement. -

Citations

Citations to this article as recorded by  - Preparation of W-Ni-Cu Alloy Powder by Hydrogen Reduction of Metal Oxides

Youn Ji Heo, Eui Seon Lee, Ji Won Choi, Jongmin Byun, Sung-Tag Oh

Korean Journal of Metals and Materials.2024; 62(5): 334. CrossRef - Influence of the initial powder characteristic on the densified tungsten microstructure by spark plasma sintering and hot isostatic pressing

Ji Young Kim, Eui Seon Lee, Youn Ji Heo, Young-In Lee, Jongmin Byun, Sung-Tag Oh

Powder Metallurgy.2023; 66(5): 644. CrossRef

- [Korean]

- Rotation Speed Dependence of ZnO Coating Layer on SnSe powders by Rotary Atomic Layer Deposition Reactor

-

Myeong Jun Jung, Ye Jun Yun, Jongmin Byun, Byung Joon Choi

-

J Korean Powder Metall Inst. 2021;28(3):239-245. Published online June 1, 2021

-

DOI: https://doi.org/10.4150/KPMI.2021.28.3.239

-

-

642

View

-

2

Download

-

1

Citations

-

Abstract Abstract

PDF PDF

The SnSe single crystal shows an outstanding figure of merit (ZT) of 2.6 at 973 K; thus, it is considered to be a promising thermoelectric material. However, the mass production of SnSe single crystals is difficult, and their mechanical properties are poor. Alternatively, we can use polycrystalline SnSe powder, which has better mechanical properties. In this study, surface modification by atomic layer deposition (ALD) is chosen to increase the ZT value of SnSe polycrystalline powder. SnSe powder is ground by a ball mill. An ALD coating process using a rotary-type reactor is adopted. ZnO thin films are grown by 100 ALD cycles using diethylzinc and H2O as precursors at 100°C. ALD is performed at rotation speeds of 30, 40, 50, and 60 rpm to examine the effects of rotation speed on the thin film characteristics. The physical and chemical properties of ALD-coated SnSe powders are characterized by scanning and tunneling electron microscopy combined with energy-dispersive spectroscopy. The results reveal that a smooth oxygenrich ZnO layer is grown on SnSe at a rotation speed of 30 rpm. This result can be applied for the uniform coating of a ZnO layer on various powder materials. -

Citations

Citations to this article as recorded by  - Thermal Confinement and Filtering Effect of SnSe by Insertion of Atomic-Layer-Deposited ZnO Interfacial Layer

Myeong Jun Jung, Su Min Eun, Hogyoung Kim, Seong Keun Kim, Jongmin Byun, Byung Joon Choi

Korean Journal of Chemical Engineering.2025; 42(14): 3545. CrossRef

- [Korean]

- Research trends of MXenes as the Next-generation Two-dimensional Materials

-

Hojun Lee, Yejun Yun, Jinkwang Jang, Jongmin Byun

-

J Korean Powder Metall Inst. 2021;28(2):150-163. Published online April 1, 2021

-

DOI: https://doi.org/10.4150/KPMI.2021.28.2.150

-

-

3,543

View

-

106

Download

-

3

Citations

-

Abstract Abstract

PDF PDF

Interest in eco-friendly materials with high efficiencies is increasing significantly as science and technology undergo a paradigm shift toward environment-friendly and sustainable development. MXenes, a class of two-dimensional inorganic compounds, are generally defined as transition metal carbides or nitrides composed of few-atoms-thick layers with functional groups. Recently MXenes, because of their desirable electrical, thermal, and mechanical properties that emerge from conductive layered structures with tunable surface terminations, have garnered significant attention as promising candidates for energy storage applications (e.g., supercapacitors and electrode materials for Li-ion batteries), water purification, and gas sensors. In this review, we introduce MXenes and describe their properties and research trends by classifying them into two main categories: transition metal carbides and nitrides, including Ti-based MXenes, Mo-based MXenes, and Nb-based MXenes. -

Citations

Citations to this article as recorded by  - Next-generation brackish water treatment: Exploring dual-ion capacitive deionization

Yize Li, Jing He, He Liu, Chao Yan

Journal of Environmental Chemical Engineering.2025; 13(2): 116037. CrossRef - Microstructure tailoring of Nb-based MAX phase by low temperature synthesis with layer-structured Nb2C powder and molten salt method

Chaehyun Lim, Wonjune Choi, Jongmin Byun

Materials Characterization.2025; 225: 115106. CrossRef - Review on 2D MXene and graphene electrodes in capacitive deionization

Hammad Younes, Ding Lou, Md. Mahfuzur Rahman, Daniel Choi, Haiping Hong, Linda Zou

Environmental Technology & Innovation.2022; 28: 102858. CrossRef

- [Korean]

- Microstructure and Mechanical Property of Ti-Mn-Cu Alloys with Magnetic Pulsed Compaction

-

Ye Jun Yun, Chun Woong Park, Won June Choi, Jongmin Byun

-

J Korean Powder Metall Inst. 2021;28(1):20-24. Published online February 1, 2021

-

DOI: https://doi.org/10.4150/KPMI.2021.28.1.20

-

-

Abstract Abstract

PDF PDF

Ti-based alloys are widely used in biomaterials owing to their excellent biocompatibility. In this study, Ti- Mn-Cu alloys are prepared by high-energy ball milling, magnetic pulsed compaction, and pressureless sintering. The microstructure and microhardness of the Ti-Mn-Cu alloys with variation of the Cu addition and compaction pressure are analyzed. The correlation between the composition, compaction pressure, and density is investigated by measuring the green density and sintered density for samples with different compositions, subjected to various compaction pressures. For all compositions, it is confirmed that the green density increases proportionally as the compaction pressure increases, but the sintered density decreases owing to gas formation from the pyrolysis of TiH2 powders and reduction of oxides on the surface of the starting powders during the sintering process. In addition, an increase in the amount of Cu addition changes the volume fractions of the α-Ti and β-Ti phases, and the microstructure of the alloys with different compositions also changes. It is demonstrated that these changes in the phase volume fraction and microstructure are closely related to the mechanical properties of the Ti-Mn-Cu alloys.

- [Korean]

- Research Trends of High-entropy Alloys

-

Pureunsol Park, Ho Joon Lee, Youngjun Jo, Bonseung Gu, Won June Choi, Jongmin Byun

-

J Korean Powder Metall Inst. 2019;26(6):515-527. Published online December 1, 2019

-

DOI: https://doi.org/10.4150/KPMI.2019.26.6.515

-

-

5,702

View

-

44

Download

-

2

Citations

-

Abstract Abstract

PDF PDF

High-entropy alloys (HEAs) are generally defined as solid solutions containing at least 5 constituent elements with concentrations between 5 and 35 atomic percent without the formation of intermetallic compounds. Currently, HEAs receive great attention as promising candidate materials for extreme environments due to their potentially desirable properties that result from their unique structural properties. In this review paper, we aim to introduce HEAs and explain their properties and related research by classifying them into three main categories, namely, mechanical properties, thermal properties, and electrochemical properties. Due to the high demand for structural materials in extreme environments, the mechanical properties of HEAs including strength, hardness, ductility, fatigue, and wear resistance are mainly described. Thermal and electrochemical properties, essential for the application of these alloys as structural materials, are also described. -

Citations

Citations to this article as recorded by  - Composites of equiatomic Y, La, Ce, Nd, and Gd rare earth oxides: Chemical-shift effects and valence spectra

Jungsu Bin, Hyunbae Gee, Taesung Park, UiJun Go, Jeoung Han Kim, Youn-Seoung Lee

Current Applied Physics.2024; 59: 85. CrossRef - Sintering Behavior and Mechanical Property of Transition Metal Carbide-Based Cermets by Spark Plasma Sintering

Jeong-Han Lee, Hyun-Kuk Park, Sung-Kil Hong

Korean Journal of Materials Research.2022; 32(1): 44. CrossRef

- [Korean]

- Fabrication of Molybdenum Alloys with Improved Fracture Toughness through the Dispersion of Lanthanum Oxide

-

Won June Choi, Chun Woong Park, Jung Hyo Park, Young Do Kim, Jongmin Byun

-

J Korean Powder Metall Inst. 2019;26(3):208-213. Published online June 1, 2019

-

DOI: https://doi.org/10.4150/KPMI.2019.26.3.208

-

-

875

View

-

1

Download

-

2

Citations

-

Abstract Abstract

PDF PDF

In this study, lanthanum oxide (La2O3) dispersed molybdenum (Mo–La2O3) alloys are fabricated using lanthanum nitrate solution and nanosized Mo particles produced by hydrogen reduction of molybdenum oxide. The effect of La2O3 dispersion in a Mo matrix on the fracture toughness at room temperature is demonstrated through the formation behavior of La2O3 from the precursor and three-point bending test using a single-edge notched bend specimen. The relative density of the Mo–0.3La2O3 specimen sintered by pressureless sintering is approximately 99%, and La2O3 with a size of hundreds of nanometers is uniformly distributed in the Mo matrix. It is also confirmed that the fracture toughness is 19.46 MPa·m1/2, an improvement of approximately 40% over the fracture toughness of 13.50 MPa·m1/2 on a pure-Mo specimen without La2O3, and this difference in the fracture toughness occurs because of the changes in fracture mode of the Mo matrix caused by the dispersion of La2O3. -

Citations

Citations to this article as recorded by  - Sintering property of micro/nano core-shell molybdenum powder synthesized by mechanochemical process

Chun Woong Park, Heeyeon Kim, Won Hee Lee, Wonjune Choi, Jongmin Byun, Young Do Kim

International Journal of Refractory Metals and Hard Materials.2024; 119: 106532. CrossRef - Novel design of Mo-Si-B + La2O3 powder with multi-shell structure for ideal microstructure and enhanced mechanical property

Wonjune Choi, Chun Woong Park, Young Do Kim, Jongmin Byun

International Journal of Refractory Metals and Hard Materials.2024; 120: 106611. CrossRef

|