Search

- Page Path

- HOME > Search

- [Korean]

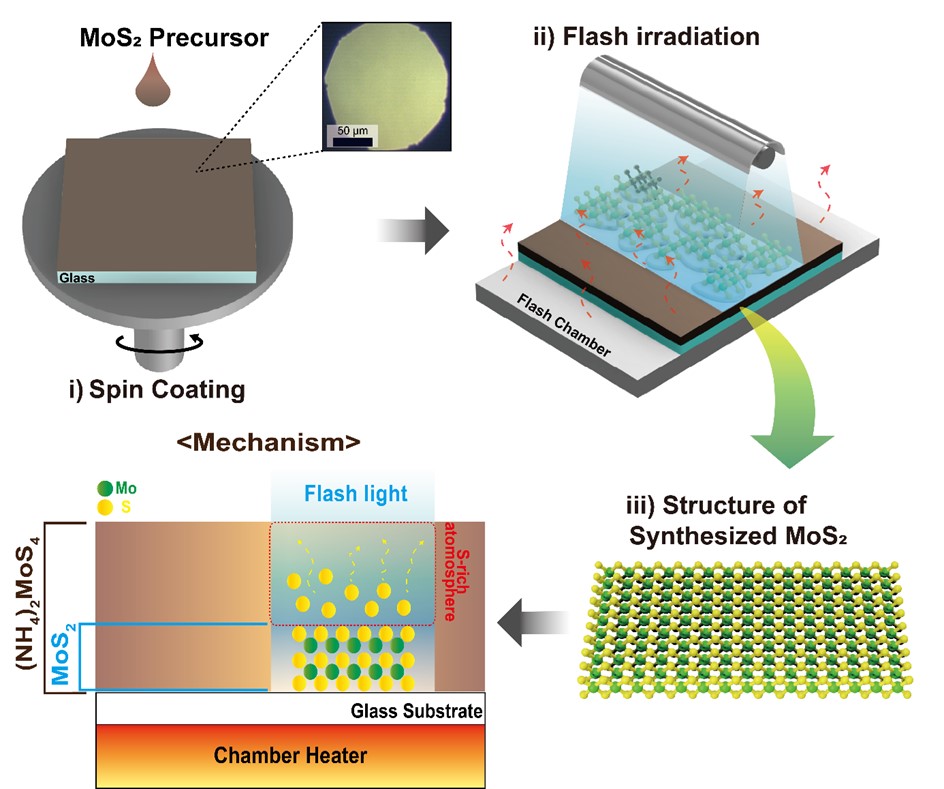

- Ultrafast Synthesis of Molybdenum Disulfide via Flashlamp Annealing

- Chan Hyeon Yang, Jaehak Lee, Jung Hwan Park

- J Powder Mater. 2025;32(6):509-516. Published online December 31, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00339

- 684 View

- 6 Download

-

Abstract

Abstract

PDF

PDF - This study presents the synthesis of molybdenum disulfide (MoS₂) using flashlamp annealing and provides a comprehensive investigation of its structural and physical properties. The proposed flash-induced approach enables rapid production of high-quality MoS₂, offering superior process efficiency compared to conventional synthesis techniques. The structural, electronic, and thermal characteristics of the synthesized MoS₂ were systematically examined using multiple analytical methods, with particular attention to how synthesis conditions influence layer structure, crystallinity, and defect density. The results indicate that MoS₂ produced through this method exhibits material properties suitable for high-performance electronic devices and energy storage applications. Moreover, this work demonstrates the potential of flash-induced synthesis for scalable and practical fabrication of MoS₂-based nanomaterials, thereby contributing to the broader advancement of transition metal dichalcogenide technologies across diverse nanotechnology applications.

- [Korean]

- A Study on Particle and Crystal Size Analysis of Lithium Lanthanum Titanate Powder Depending on Synthesis Methods (Sol-Gel & Solid-State reaction)

- Jeungjai Yun, Seung-Hwan Lee, So Hyun Baek, Yongbum Kwon, Yoseb Song, Bum Sung Kim, Bin Lee, Rhokyun Kwak, Da-Woon Jeong

- J Powder Mater. 2023;30(4):324-331. Published online August 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.4.324

- 1,405 View

- 15 Download

-

Abstract

Abstract

PDF

PDF Lithium (Li) is a key resource driving the rapid growth of the electric vehicle industry globally, with demand and prices continually on the rise. To address the limited reserves of major lithium sources such as rock and brine, research is underway on seawater Li extraction using electrodialysis and Li-ion selective membranes. Lithium lanthanum titanate (LLTO), an oxide solid electrolyte for all-solid-state batteries, is a promising Li-ion selective membrane. An important factor in enhancing its performance is employing the powder synthesis process. In this study, the LLTO powder is prepared using two synthesis methods: sol-gel reaction (SGR) and solid-state reaction (SSR). Additionally, the powder size and uniformity are compared, which are indices related to membrane performance. X-ray diffraction and scanning electron microscopy are employed for determining characterization, with crystallite size analysis through the full width at half maximum parameter for the powders prepared using the two synthetic methods. The findings reveal that the powder SGR-synthesized powder exhibits smaller and more uniform characteristics (0.68 times smaller crystal size) than its SSR counterpart. This discovery lays the groundwork for optimizing the powder manufacturing process of LLTO membranes, making them more suitable for various applications, including manufacturing high-performance membranes or mass production of membranes.

- [Korean]

- Effect of Acid Leaching Conditions on the Properties of Cr Powder Produced by Self-propagating High-temperature Synthesis

- YongKwan Lee, YeongWoo Cho, ShinYoung Choi, SungGue Heo, Ju Won, KyoungTae Park, MiHye Lee, JaeJin Sim

- J Powder Mater. 2023;30(3):233-241. Published online June 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.3.233

- 762 View

- 3 Download

-

Abstract

Abstract

PDF

PDF In this study, we evaluated the effects of acid leaching on the properties of Cr powder synthesized using self-propagating high-temperature synthesis (SHS). Cr powder was synthesized from a mixture of Cr2O3 and magnesium (Mg) powders using the SHS Process, and the byproducts after the reaction were removed using acid leaching. The properties of the recovered Cr powder were analyzed via X-ray diffraction (XRD), scanning electron microscopy (SEM), energy-dispersive X-ray spectroscopy (EDS), particle size analysis (PSA), and oxygen content analysis. The results show that perfect selective leaching of Cr is challenging because of various factors such as incomplete reaction, reaction kinetics, the presence of impurities, and incompatibility between the acid and metal mixture. Therefore, this study provides essential information on the properties under acidic conditions during the production of high-quality Cr powder using a self-propagating high-temperature synthesis method.

- [Korean]

- Recycling of Hardmetal Tool through Alkali Leaching Process and Fabrication Process of Nano-sized Tungsten Carbide Powder using Self-propagation High-temperature Synthesis

- Hee-Nam Kang, Dong Il Jeong, Young Il Kim, In Yeong Kim, Sang Cheol Park, Cheol Woo Nam, Seok-Jun Seo, Jin Yeong Lee, Bin Lee

- J Powder Mater. 2022;29(1):47-55. Published online February 1, 2022

- DOI: https://doi.org/10.4150/KPMI.2022.29.1.47

- 1,424 View

- 12 Download

-

Abstract

Abstract

PDF

PDF Tungsten carbide is widely used in carbide tools. However, its production process generates a significant number of end-of-life products and by-products. Therefore, it is necessary to develop efficient recycling methods and investigate the remanufacturing of tungsten carbide using recycled materials. Herein, we have recovered 99.9% of the tungsten in cemented carbide hard scrap as tungsten oxide via an alkali leaching process. Subsequently, using the recovered tungsten oxide as a starting material, tungsten carbide has been produced by employing a self-propagating high-temperature synthesis (SHS) method. SHS is advantageous as it reduces the reaction time and is energy-efficient. Tungsten carbide with a carbon content of 6.18 wt % and a particle size of 116 nm has been successfully synthesized by optimizing the SHS process parameters, pulverization, and mixing. In this study, a series of processes for the highefficiency recycling and quality improvement of tungsten-based materials have been developed.

- [Korean]

- Synthesis and Nucleation Behavior of MoO3 Nano Particles with Concentration of Precursors

- Seyoung Lee, Namhun Kwon, Jaeseok Roh, Kun-Jae Lee

- J Korean Powder Metall Inst. 2020;27(5):394-400. Published online October 1, 2020

- DOI: https://doi.org/10.4150/KPMI.2020.27.5.394

- 1,540 View

- 8 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF Molybdenum trioxide (MoO3) is used in various applications including sensors, photocatalysts, and batteries owing to its excellent ionic conductivity and thermal properties. It can also be used as a precursor in the hydrogen reduction process to obtain molybdenum metals. Control of the parameters governing the MoO3 synthesis process is extremely important because the size and shape of MoO3 in the reduction process affect the shape, size, and crystallization of Mo metal. In this study, we fabricated MoO3 nanoparticles using a solution combustion synthesis (SCS) method that utilizes an organic additive, thereby controlling their morphology. The nucleation behavior and particle morphology were confirmed using ultraviolet-visible spectroscopy (UV-vis) and field emission scanning electron microscopy (FE-SEM). The concentration of the precursor (ammonium heptamolybdate tetrahydrate) was adjusted to be 0.1, 0.2, and 0.4 M. Depending on this concentration, different nucleation rates were obtained, thereby resulting in different particle morphologies.

-

Citations

Citations to this article as recorded by- Characterization of Compacted and Pressureless Sintered Parts for Molybdenum Oxide Powder according to Hydrogen Reduction Temperature

Jong Hoon Lee, Kun-Jae Lee

Journal of Powder Materials.2024; 31(4): 336. CrossRef

- Characterization of Compacted and Pressureless Sintered Parts for Molybdenum Oxide Powder according to Hydrogen Reduction Temperature

- [Korean]

- Magnetic Properties of Micron Sized Fe3O4 Crystals Synthesized by Hydrothermal Methods

- Ki-Bum Lee, Chunghee Nam

- J Korean Powder Metall Inst. 2019;26(6):481-486. Published online December 1, 2019

- DOI: https://doi.org/10.4150/KPMI.2019.26.6.481

- 1,161 View

- 9 Download

-

Abstract

Abstract

PDF

PDF Iron oxides currently attract considerable attention due to their potential applications in the fields of lithiumion batteries, bio-medical sensors, and hyperthermia therapy materials. Magnetite (Fe3O4) is a particularly interesting research target due to its low cost, good biocompatibility, outstanding stability in physiological conditions. Hydrothermal synthesis is one of several liquid-phase synthesis methods with water or an aqueous solution under high pressure and high temperature. This paper reports the growth of magnetic Fe3O4 particles from iron powder (spherical, <10 μm) through an alkaline hydrothermal process under the following conditions: (1) Different KOH molar concentrations and (2) different synthesis time for each KOH molar concentrations. The optimal condition for the synthesis of Fe3O4 using Fe powders is hydrothermal oxidation with 6.25 M KOH for 48 h, resulting in 89.2 emu/g of saturation magnetization at room temperature. The structure and morphologies of the synthesized particles are characterized by X-ray diffraction (XRD, 2θ = 20°–80°) with Cu-kα radiation and field emission scanning electron microscopy (FE-SEM), respectively. The magnetic properties of magnetite samples are investigated using a vibrating sample magnetometer (VSM). The role of KOH in the formation of magnetite octahedron is observed.

- [Korean]

- Nanostructure Construction of SiO2@Au Core-Shell by In-situ Synthesis

- Mu-Jae Pyeon, Do Kyung Kim, Young-Keun Jeong

- J Korean Powder Metall Inst. 2018;25(5):420-425. Published online October 1, 2018

- DOI: https://doi.org/10.4150/KPMI.2018.25.5.420

- 934 View

- 6 Download

-

Abstract

Abstract

PDF

PDF Core-shell structured nanoparticles are garnering attention because these nanoparticles are expected to have a wide range of applications. The objective of the present study is to improve the coating efficiency of gold shell formed on the surface of silica nanoparticles for SiO2@Au core-shell structure. For the efficient coating of gold shell, we attempt an in-situ synthesis method such that the nuclei of the gold nanoparticles are generated and grown on the surface of silica nanoparticles. This method can effectively form a gold shell as compared to the conventional method of attaching gold nanoparticles to silica particles. It is considered possible to form a dense gold shell because the problems caused by electrostatic repulsion between the gold nanoparticles in the conventional method are eliminated.

- [Korean]

- Recent Developments in Synthesis of Colloidal Quantum Dots

- Jae-Yong Jung, Jong-Pal Hong, Young-Kuk Kim

- J Korean Powder Metall Inst. 2018;25(4):346-354. Published online August 1, 2018

- DOI: https://doi.org/10.4150/KPMI.2018.25.4.346

- 1,936 View

- 13 Download

-

Abstract

Abstract

PDF

PDF Over the last decade, the study of the synthesis of semiconductor colloidal quantum dots has progressed at a tremendous rate. Colloidal quantum dots, which possess unique spectral-luminescent characteristics, are of great interest in the development of novel materials and devices, which are promising for use in various fields. Several studies have been carried out on hot injection synthesis methods. However, these methods have been found to be unsuitable for large-capacity synthesis. Therefore, this review paper introduces synthesis methods other than the hot injection synthesis method, to synthesize quantum dots with excellent optical properties, through continuous synthesis and large capacity synthesis. In addition, examples of the application of synthesized colloid quantum dots in displays, solar cells, and bio industries are provided.

- [Korean]

- Pre-treatments of initial materials for controlling synthesized TaC characteristics in the SHS process

- Jae Jin Sim, Sang Hoon Choi, Ji Hwan Park, Il Kyu Park, Jae Hong Lim, Kyoung Tae Park

- J Korean Powder Metall Inst. 2018;25(3):251-256. Published online June 1, 2018

- DOI: https://doi.org/10.4150/KPMI.2018.25.3.251

- 991 View

- 5 Download

-

Abstract

Abstract

PDF

PDF We report the feasibility of TaC production via self-propagating high temperature synthesis, and the influence of the initial green compact density on the final composite particle size. Experiments are carried out from a minimum pressure of 0.3 MPa, the pressure at which the initial green body becomes self-standing, up to 3 MPa, the point at which no further combustion occurs. The green density of the pellets varies from 29.99% to 42.97%, as compared with the theoretical density. The increase in green density decreases the powder size of TaC, and the smallest particle size is observed with 1.5 MPa, at 10.36 μm. Phase analysis results confirm the presence of the TaC phase only. In the range of 0.3-0.5 MPa, traces of unreacted Ta and C residues are detected. However, results also show the presence of only C residue in the matrix within the pressure range of 0.6-3.0 MPa.

- [Korean]

- Synthesis and analysis CdSe/ZnS quantum dot with a Core/shell Continuous Synthesis System Using a Microfluidic Reactor

- Myung Hwan Hong, So Young Joo, Lee-Seung Kang, Chan Gi Lee

- J Korean Powder Metall Inst. 2018;25(2):132-136. Published online April 1, 2018

- DOI: https://doi.org/10.4150/KPMI.2018.25.2.132

- 1,932 View

- 10 Download

-

Abstract

Abstract

PDF

PDF Core/shell CdSe/ZnS quantum dots (QDs) are synthesized by a microfluidic reactor-assisted continuous reactor system. Photoluminescence and absorbance of synthesized CdSe/ZnS core/shell QDs are investigated by fluorescence spectrophotometry and online UV-Vis spectrometry. Three reaction conditions, namely; the shell coating reaction temperature, the shell coating reaction time, and the ZnS/CdSe precursor volume ratio, are combined in the synthesis process. The quantum yield of the synthesized CdSe QDs is determined for each condition. CdSe/ZnS QDs with a higher quantum yield are obtained compared to the discontinuous microfluidic reactor synthesis system. The maximum quantum efficiency is 98.3% when the reaction temperature, reaction time, and ZnS/CdSe ratio are 270°C, 10 s, and 0.05, respectively. Obtained results indicate that a continuous synthesis of the Core/shell CdSe/ZnS QDs with a high quantum efficiency could be achieved by isolating the reaction from the external environment.

- [English]

- Synthesis of Boron Nitride Nanotubes via inductively Coupled thermal Plasma process Catalyzed by Solid-state ammonium Chloride

- Mi Se Chang, Young Gyun Nam, Sangsun Yang, Kyung Tae Kim, Ji Hun Yu, Yong-Jin Kim, Jae Won Jeong

- J Korean Powder Metall Inst. 2018;25(2):120-125. Published online April 1, 2018

- DOI: https://doi.org/10.4150/KPMI.2017.25.2.120

- 683 View

- 7 Download

-

Abstract

Abstract

PDF

PDF Boron nitride nanotubes (BNNTs) are receiving great attention because of their unusual material properties, such as high thermal conductivity, mechanical strength, and electrical resistance. However, high-throughput and highefficiency synthesis of BNNTs has been hindered due to the high boiling point of boron (~ 4000°C) and weak interaction between boron and nitrogen. Although, hydrogen-catalyzed plasma synthesis has shown potential for scalable synthesis of BNNTs, the direct use of H2 gas as a precursor material is not strongly recommended, as it is extremely flammable. In the present study, BNNTs have been synthesized using radio-frequency inductively coupled thermal plasma (RF-ITP) catalyzed by solid-state ammonium chloride (NH4Cl), a safe catalyst materials for BNNT synthesis. Similar to BNNTs synthesized from h-BN (hexagonal boron nitride) + H2, successful fabrication of BNNTs synthesized from h-BN+NH4Cl is confirmed by their sheet-like properties, FE-SEM images, and XRD analysis. In addition, improved dispersion properties in aqueous solution are found in BNNTs synthesized from h-BN +NH4Cl.

- [English]

- The Synthesis and Photocatalytic activity of Carbon Nanotube-mixed TiO2 Nanotubes

- Chun Woong Park, Young Do Kim, Tohru Sekino, Se Hoon Kim

- J Korean Powder Metall Inst. 2017;24(4):279-284. Published online August 1, 2017

- DOI: https://doi.org/10.4150/KPMI.2017.24.4.279

- 1,543 View

- 11 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF The formation mechanism and photocatalytic properties of a multiwalled carbon nanotube (MWCNT)/TiO2- based nanotube (TNTs) composite are investigated. The CNT/TNT composite is synthesized via a solution chemical route. It is confirmed that this 1-D nanotube composite has a core-shell nanotubular structure, where the TNT surrounds the CNT core. The photocatalytic activity investigated based on the methylene blue degradation test is superior to that of with pure TNT. The CNTs play two important roles in enhancing the photocatalytic activity. One is to act as a template to form the core-shell structure while titanate nanosheets are converted into nanotubes. The other is to act as an electron reservoir that facilitates charge separation and electron transfer from the TNT, thus decreasing the electronhole recombination efficiency.

-

Citations

Citations to this article as recorded by- Carbon-based photocatalysis in organic transformation

Md Razu Ahmed, Yuta Nishina

Bulletin of the Chemical Society of Japan.2026;[Epub] CrossRef - Low-Dimensional Carbon and Titania Nanotube Composites via a Solution Chemical Process and Their Nanostructural and Electrical Properties for Electrochemical Devices

Sunghun Eom, Sung Hun Cho, Tomoyo Goto, Myoung Pyo Chun, Tohru Sekino

ACS Applied Nano Materials.2019; 2(10): 6230. CrossRef

- Carbon-based photocatalysis in organic transformation

- [Korean]

- Synthesis of Hexagonal Boron Nitride Nanocrystals and Their Application to Thermally Conductive Composites

- Jae-Yong Jung, Yang-Do Kim, Pyung-Woo Shin, Young-Kuk Kim

- J Korean Powder Metall Inst. 2016;23(6):414-419. Published online December 1, 2016

- DOI: https://doi.org/10.4150/KPMI.2016.23.6.414

- 1,503 View

- 20 Download

-

Abstract

Abstract

PDF

PDF Much attention has been paid to thermally conductive materials for efficient heat dissipation of electronic devices to maintain their functionality and to support lifetime span. Hexagonal boron nitride (h-BN), which has a high thermal conductivity, is one of the most suitable materials for thermally conductive composites. In this study, we synthesize h-BN nanocrystals by pyrolysis of cost-effective precursors, boric acid, and melamine. Through pyrolysis at 900°C and subsequent annealing at 1500°C, h-BN nanoparticles with diameters of ~80 nm are synthesized. We demonstrate that the addition of small amounts of Eu-containing salts during the preparation of melamine borate precursors significantly enhanced the crystallinity of h-BN. In particular, addition of Eu assists the growth of h-BN nanoplatelets with diameters up to ~200 nm. Polymer composites containing both spherical Al2O3 (70 vol%) and Eu-doped h-BN nanoparticles (4 vol%) show an enhanced thermal conductivity (λ ~ 1.72W/mK), which is larger than the thermal conductivity of polymer composites containing spherical Al2O3 (70 vol%) as the sole fillers (λ ~ 1.48W/mK).

- [Korean]

- Synthesis and analysis CdSe Quantum dot with a Microfluidic Reactor Using a Combinatorial Synthesis System

- Myung Hwan Hong, Duk-Hee Lee, Lee-Seung Kang, Chan Gi Lee, Bum-Sung Kim, Nam-Hoon Kim

- J Korean Powder Metall Inst. 2016;23(2):143-148. Published online April 1, 2016

- DOI: https://doi.org/10.4150/KPMI.2016.23.2.143

- 881 View

- 7 Download

-

Abstract

Abstract

PDF

PDF A microfluidic reactor with computer-controlled programmable isocratic pumps and online detectors is employed as a combinatorial synthesis system to synthesize and analyze materials for fabricating CdSe quantum dots for various applications. Four reaction condition parameters, namely, the reaction temperature, reaction time, Cd/Se compositional ratio, and precursor concentration, are combined in synthesis condition sets, and the size of the synthesized CdSe quantum dots is determined for each condition. The average time corresponding to each reaction condition for obtaining the ultraviolet–visible absorbance and photoluminescence spectra is approximately 10 min. Using the data from the combinatorial synthesis system, the effects of the reaction conditions on the synthesized CdSe quantum dots are determined. Further, the data is used to determine the relationships between the reaction conditions and the CdSe particle size. This method should aid in determining and selecting the optimal conditions for synthesizing nanoparticles for diverse applications.

- [Korean]

- Synthesis of Perforated Polygonal Cobalt Oxides using a Carbon Nanofiber Template

- Dong-Yo Sin, Geon-Hyoung An, Hyo-Jin Ahn

- J Korean Powder Metall Inst. 2015;22(5):350-355. Published online October 1, 2015

- DOI: https://doi.org/10.4150/KPMI.2015.22.5.350

- 831 View

- 3 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF Perforated polygonal cobalt oxide (CO3O4) is synthesized using electrospinning and a hydrothermal method followed by the removal of a carbon nanofiber (CNF) template. To investigate their formation mechanism, thermogravimetric analysis, field-emission scanning electron microscopy, transmission electron microscopy, X-ray diffraction, and Xray photoelectron spectroscopy are examined. To obtain the optimum condition of perforated polygonal CO3O4, we prepare three different weight ratios of the Co precursor and the CNF template: sample A (Co precursor:CNF template- 10:1), sample B (Co precursor:CNF template-3.2:1), and sample C (Co precursor:CNF template-2:1). Among them, sample A exhibits the perforated polygonal CO3O4 with a thin carbon layer (5.7-6.2 nm) owing to the removal of CNF template. However, sample B and sample C synthesized perforated round CO3O4 and destroyed CO3O4 powders, respectively, due to a decreased amount of Co precursor. The increased amount of the CNF template prevents the formation of polygonal CO3O4. For sample A, the optimized weight ratio of the Co precursor and CNF template may be related to the successful formation of perforated polygonal CO3O4. Thus, perforated polygonal CO3O4 can be applied to electrode materials of energy storage devices such as lithium ion batteries, supercapacitors, and fuel cells.

-

Citations

Citations to this article as recorded by- Synthesis of Nitrogen Doped Protein Based Carbon as Pt Catalysts Supports for Oxygen Reduction Reaction

Young-geun Lee, Geon-hyeong An, Hyo-Jin Ahn

Korean Journal of Materials Research.2018; 28(3): 182. CrossRef - Electrochemical Behavior of Well-dispersed Catalysts on Ruthenium Oxide Nanofiber Supports

Geon-Hyoung An, Hyo-Jin Ahn

Journal of Korean Powder Metallurgy Institute.2017; 24(2): 96. CrossRef

- Synthesis of Nitrogen Doped Protein Based Carbon as Pt Catalysts Supports for Oxygen Reduction Reaction

- [Korean]

- Spark Plasma Sintering of Fe-TiC Composite Powders

- Yong-Heui Lee, Xuan-Khoa Hyunh, Ji Soon Kim

- J Korean Powder Metall Inst. 2014;21(5):382-388. Published online October 1, 2014

- DOI: https://doi.org/10.4150/KPMI.2014.21.5.382

- 925 View

- 4 Download

- 3 Citations

-

Abstract

Abstract

PDF

PDF Fe-TiC composite powder was fabricated by high-energy milling of powder mixture of (Fe, TiC) and (FeO, TiH2, C) as starting materials, respectively. The latter one was heat-treated for reaction synthesis of TiC phase after milling. Both powders were spark-plasma sintered at various temperatures of 680-1070°C for 10 min. with sintering pressure of 70 MPa and the heating rate of 50°C/min. under vacuum of 0.133 Pa. Density and hardness of the sintered compact was investigated. Fe-TiC composite fabricated from (FeO, TiH2, C) as starting materials showed better sintered properties. It seems to be resulted from ultra-fine TiC particle size and its uniform distribution in Fe-matrix compared to the simply mixed (Fe, TiC) powder.

-

Citations

Citations to this article as recorded by- Comparative study of Ni-TaC composites via high-energy ball milling activation and spark plasma sintering: Reinforcement, densification, oxidation resistance, and mechanical property

Bum-Soon Park, Jeong-Han Lee, Jae-Cheol Park, Hyun-Kuk Park

Journal of Alloys and Compounds.2024; 984: 173900. CrossRef - Effect of TiC particle size on high temperature oxidation behavior of TiC reinforced stainless steel

Yeong-Hwan Lee, Sungmin Ko, Hyeonjae Park, Donghyun Lee, Sangmin Shin, Ilguk Jo, Sang-Bok Lee, Sang-Kwan Lee, Yangdo Kim, Seungchan Cho

Applied Surface Science.2019; 480: 951. CrossRef - Effect of TiC addition on surface oxidation behavior of SKD11 tool steel composites

Seungchan Cho, Ilguk Jo, Heebong Kim, Hyuk-Tae Kwon, Sang-Kwan Lee, Sang-Bok Lee

Applied Surface Science.2017; 415: 155. CrossRef

- Comparative study of Ni-TaC composites via high-energy ball milling activation and spark plasma sintering: Reinforcement, densification, oxidation resistance, and mechanical property

TOP

KPMI

KPMI

First

First Prev

Prev