Search

- Page Path

- HOME > Search

- [English]

- Epsilon Iron Oxide (ε-Fe2O3) as an Electromagnetic Functional Material: Properties, Synthesis, and Applications

- Ji Hyeong Jeong, Hwan Hee Kim, Jung-Goo Lee, Youn-Kyoung Baek

- J Powder Mater. 2024;31(6):465-479. Published online December 31, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00290

- 3,513 View

- 91 Download

- 3 Citations

-

Abstract

Abstract

PDF

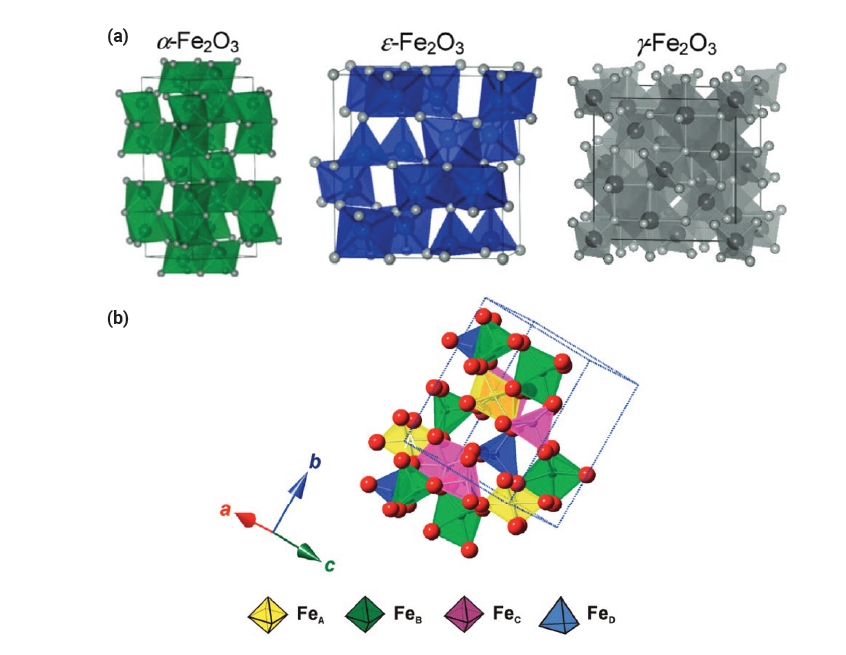

PDF - Iron oxide (ε-Fe₂O₃) is emerging as a promising electromagnetic material due to its unique magnetic and electronic properties. This review focuses on the intrinsic properties of ε-Fe₂O₃, particularly its high coercivity, comparable to that of rare-earth magnets, which is attributed to its significant magnetic anisotropy. These properties render it highly suitable for applications in millimeter wave absorption and high-density magnetic storage media. Furthermore, its semiconducting behavior offers potential applications in photocatalytic hydrogen production. The review also explores various synthesis methods for fabricating ε-Fe₂O₃ as nanoparticles or thin films, emphasizing the optimization of purity and stability. By exploring and harnessing the properties of ε-Fe₂O₃, this study aims to contribute to the advancement of next-generation electromagnetic materials with potential applications in 6G wireless telecommunications, spintronics, high-density data storage, and energy technologies.

-

Citations

Citations to this article as recorded by- A Comprehensive Review of GPR Data Analysis for Bridge Deck Evaluation: From Conventional Methods to Emerging Artificial Intelligence Approaches

Babak Enami Alamdari, Yu Tang, Danilo Erricolo, Lesley H. Sneed

Journal of Nondestructive Evaluation.2026;[Epub] CrossRef - Chemical Pressure Induced Strain Control of Magnetic Anisotropy in the Simple Perovskite ϵ-Fe2O3

Subir Roy, Gurleen K. Uppal, Alberto Acosta, Rachel Nickel, Charles A. Roberts, Johan van Lierop

Nano Letters.2026; 26(1): 34. CrossRef - Superparamagnetism of Baked Clays Containing Polymorphs of Iron Oxides: Experimental Study and Theoretical Modeling

Petr Kharitonskii, Andrei Krasilin, Nadezhda Belskaya, Svetlana Yanson, Nikita Bobrov, Andrey Ralin, Kamil Gareev, Nikita Zolotov, Dmitry Zaytsev, Elena Sergienko

Magnetochemistry.2025; 11(12): 103. CrossRef

- A Comprehensive Review of GPR Data Analysis for Bridge Deck Evaluation: From Conventional Methods to Emerging Artificial Intelligence Approaches

- [Korean]

- Size Control of Iron Oxide (Fe3O4) Nanoclusters according to Reaction Factors and Consequent Change in Their Magnetic Attraction

- Sanghoon Lee, Arim Byun, Jin-sil Choi

- J Powder Mater. 2023;30(4):297-304. Published online August 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.4.297

- 1,055 View

- 13 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF Iron oxide (Fe2O3) nanoclusters exhibit significant potential in the biomedical and pharmaceutical fields due to their strong magnetic properties, stability in solutions, and compatibility with living systems. They excel in magnetic separation processes, displaying high responsiveness to external magnetic fields. In contrast to conventional Fe2O3 nanoparticles that can aggregate in aqueous solutions due to their ferrimagnetic properties, these nanoclusters, composed of multiple nanoparticles, maintain their magnetic traits even when scaled to hundreds of nanometers. In this study, we develop a simple method using solvothermal synthesis to precisely control the size of nanoclusters. By adjusting precursor materials and reducing agents, we successfully control the particle sizes within the range of 90 to 420 nm. Our study not only enhances the understanding of nanocluster creation but also offers ways to improve their properties for applications such as magnetic separation. This is supported by our experimental results highlighting their size-dependent magnetic response in water. This study has the potential to advance both the knowledge and practical utilization of Fe2O3 nanoclusters in various applications.

-

Citations

Citations to this article as recorded by- Enzymatic properties of iron oxide nanoclusters and their application as a colorimetric glucose detection probe

Dahyun Bae, Minhee Kim, Jin-sil Choi

RSC Advances.2025; 15(6): 4573. CrossRef

- Enzymatic properties of iron oxide nanoclusters and their application as a colorimetric glucose detection probe

- [Korean]

- Effect of Substrate Pre-heating on Microstructure and Magnetic Properties of Nd-Fe-B Permanent Magnet Manufactured by L-PBF

- Yeon Woo Kim, Haeum Park, Tae-Hoon Kim, Kyung Tae Kim, Ji-Hun Yu, Yoon Suk Choi, Jeong Min Park

- J Powder Mater. 2023;30(2):116-122. Published online April 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.2.116

- 1,159 View

- 17 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF Because magnets fabricated using Nd-Fe-B exhibit excellent magnetic properties, this novel material is used in various high-tech industries. However, because of the brittleness and low formability of Nd-Fe-B magnets, the design freedom of shapes for improving the performance is limited based on conventional tooling and postprocessing. Laserpowder bed fusion (L-PBF), the most famous additive manufacturing (AM) technique, has recently emerged as a novel process for producing geometrically complex shapes of Nd-Fe-B parts owing to its high precision and good spatial resolution. However, because of the repeated thermal shock applied to the materials during L-PBF, it is difficult to fabricate a dense Nd-Fe-B magnet. In this study, a high-density (>96%) Nd-Fe-B magnet is successfully fabricated by minimizing the thermal residual stress caused by substrate heating during L-PBF.

-

Citations

Citations to this article as recorded by- Effect of Support Structure on Residual Stress Distribution in Ti-6Al-4V Alloy Fabricated by Laser Powder Bed Fusion

Seungyeon Lee, Haeum Park, Min Jae Baek, Dong Jun Lee, Jae Wung Bae, Ji-Hun Yu, Jeong Min Park

Journal of Powder Materials.2025; 32(3): 244. CrossRef - Linkage between process-induced microstructure and magnetic property of Nd-Fe-B permanent magnets additively manufactured by laser powder bed fusion

Yeon Woo Kim, Sujin Lee, Yoona Lee, Jae Bok Seol, Namhyun Kang, Yoon Suk Choi, Ji-Hun Yu, Jung-Goo Lee, Tae-Hoon Kim, Jeong Min Park

Materials & Design.2025; 259: 114929. CrossRef

- Effect of Support Structure on Residual Stress Distribution in Ti-6Al-4V Alloy Fabricated by Laser Powder Bed Fusion

- [Korean]

- Microstructure and Characteristics of Ag-SnO2-Bi2O3 Contact Materials by Powder Compaction

- Jin Kyu Lee

- J Powder Mater. 2022;29(1):41-46. Published online February 1, 2022

- DOI: https://doi.org/10.4150/KPMI.2022.29.1.41

- 541 View

- 5 Download

-

Abstract

Abstract

PDF

PDF In this study, we report the microstructure and characteristics of Ag-SnO2-Bi2O3 contact materials using a controlled milling process with a subsequent compaction process. Using magnetic pulsed compaction (MPC), the milled Ag-SnO2-Bi2O3 powders have been consolidated into bulk samples. The effects of the compaction conditions on the microstructure and characteristics have been investigated in detail. The nanoscale SnO2 phase and microscale Bi2O3 phase are well-distributed homogeneously in the Ag matrix after the consolidation process. The successful consolidation of Ag-SnO2-Bi2O3 contact materials was achieved by an MPC process with subsequent atmospheric sintering, after which the hardness and electrical conductivity of the Ag-SnO2-Bi2O3 contact materials were found to be 62–75 HV and 52–63% IACS, respectively, which is related to the interfacial stability between the Ag matrix, the SnO2 phase, and the Bi2O3 phase.

- [Korean]

- Recent Advances in Soft Magnetic Actuators and Sensors using Magnetic Particles

- Hyeonseo Song, Hajun Lee, Junghyo Kim, Jiyun Kim

- J Korean Powder Metall Inst. 2021;28(6):509-517. Published online December 1, 2021

- DOI: https://doi.org/10.4150/KPMI.2021.28.6.509

- 941 View

- 4 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF Smart materials capable of changing their characteristics in response to stimuli such as light, heat, pH, and electric and magnetic fields are promising for application to flexible electronics, soft robotics, and biomedicine. Compared with conventional rigid materials, these materials are typically composed of soft materials that improve the biocompatibility and allow for large and dynamic deformations in response to external environmental stimuli. Among them, smart magnetic materials are attracting immense attention owing to their fast response, remote actuation, and wide penetration range under various conditions. In this review, we report the material design and fabrication of smart magnetic materials. Furthermore, we focus on recent advances in their typical applications, namely, soft magnetic actuators, sensors for self-assembly, object manipulation, shape transformation, multimodal robot actuation, and tactile sensing.

-

Citations

Citations to this article as recorded by- Advanced Magnetic Actuation: Harnessing the Dynamics of Sm2Fe17–xCuxN3 Composites

Kangmo Koo, Young-Tae Kwon, Ji Young Park, Yong-Ho Choa

ACS Applied Materials & Interfaces.2024; 16(9): 11872. CrossRef

- Advanced Magnetic Actuation: Harnessing the Dynamics of Sm2Fe17–xCuxN3 Composites

- [Korean]

- Synthesis and Application of Magnetoplasmonic Nanoparticles

- Sejeong Park, Siyeong Hwang, Seonghwan Jung, Juyong Gwak, Jaebeom Lee

- J Korean Powder Metall Inst. 2021;28(5):429-434. Published online October 1, 2021

- DOI: https://doi.org/10.4150/KPMI.2021.28.5.429

- 738 View

- 9 Download

-

Abstract

Abstract

PDF

PDF Magnetic nanoparticles have a significant impact on the development of basic sciences and nanomedical, electronic, optical, and biotech industries. The development of magnetic structures with size homogeneity, magnetization, and particle dispersibility due to high-quality process development can broaden their utilization for separation analysis, structural color optics using surface modification, and energy/catalysts. In addition, magnetic nanoparticles simultaneously exhibit two properties: magnetic and plasmon resonance, which can be self-assembled and can improve signal sensitivity through plasmon resonance. This paper reports typical examples of the synthesis and properties of various magnetic nanoparticles, especially magnetoplasmonic nanoparticles developed in our laboratory over the past decade, and their optical, electrochemical, energy/catalytic, and bio-applications. In addition, the future value of magnetoplasmonic nanoparticles can be reevaluated by comparing them with that reported in the literature.

- [Korean]

- A Study on the Microstructure and Magnetic Properties of Fe83.2Si5.33-0.33

x B10.67-0.67x Px Cu0.8 Nanocrystalline Soft Magnetic Alloys with varying P Content - Hyun Ah Im, Kyoung-Hoon Bae, Yeong gyun Nam, Subong An, Sangsun Yang, Yong-Jin Kim, Jung Woo Lee, Jae Won Jeong

- J Korean Powder Metall Inst. 2021;28(4):293-300. Published online August 1, 2021

- DOI: https://doi.org/10.4150/KPMI.2021.28.4.293

- 883 View

- 11 Download

-

Abstract

Abstract

PDF

PDF We investigate the effect of phosphorous content on the microstructure and magnetic properties of Fe83.2Si5.33-0.33

x B10.67-0.67x Px Cu0.8 (x = 1–4 at.%) nanocrystalline soft magnetic alloys. The simultaneous addition of Cu and P to nanocrystalline alloys reportedly decreases the nanocrystalline size significantly, to 10–20 nm. In the P-containing nanocrystalline alloy, P atoms are distributed in an amorphous residual matrix, which suppresses grain growth, increases permeability, and decreases coercivity. In this study, nanocrystalline ribbons with a composition of Fe83.2Si5.33-0.33x B10.67- 0.67x Px Cu0.8 (x = 1–4 at.%) are fabricated by rapid quenching melt-spinning and thermal annealing. It is demonstrated that the addition of a small amount of P to the alloy improves the glass-forming ability and increases the resistance to undesirable Fex(B,P) crystallization. Among the alloys investigated in this work, an Fe83.2Si5B10P1Cu0.8 nanocrystalline ribbon annealed at 460°C exhibits excellent soft-magnetic properties including low coercivity, low core loss, and high saturation magnetization. The uniform nanocrystallization of the Fe83.2Si5B10P1Cu0.8 alloy is confirmed by high-resolution transmission electron microscopy analysis.

- [Korean]

- Development of Hybrid Insulating Coating for Fe-based Soft Magnetic Powder

- Jungjoon Kim, Sungyeom Kim, Youngkyun Kim, Taesuk Jang, Hwi-jun Kim, Youngjin Kim, Hyunjoo Choi

- J Korean Powder Metall Inst. 2021;28(3):233-238. Published online June 1, 2021

- DOI: https://doi.org/10.4150/KPMI.2021.28.3.233

- 625 View

- 6 Download

-

Abstract

Abstract

PDF

PDF Iron-based amorphous powder attracts increasing attention because of its excellent soft magnetic properties and low iron loss at high frequencies. The development of an insulating layer on the surface of the amorphous soft magnetic powder is important for minimizing the eddy current loss and enhancing the energy efficiency of highfrequency devices by further increasing the electrical resistivity of the cores. In this study, a hybrid insulating coating layer is investigated to compensate for the limitations of monolithic organic or inorganic coating layers. Fe2O3 nanoparticles are added to the flexible silicon-based epoxy layer to prevent magnetic dilution; in addition TiO2 nanoparticles are added to enhance the mechanical durability of the coating layer. In the hybrid coating layer with optimal composition, the decrease in magnetic permeability and saturation magnetization is suppressed.

- [Korean]

- Microstructure and Mechanical Property of Ti-Mn-Cu Alloys with Magnetic Pulsed Compaction

- Ye Jun Yun, Chun Woong Park, Won June Choi, Jongmin Byun

- J Korean Powder Metall Inst. 2021;28(1):20-24. Published online February 1, 2021

- DOI: https://doi.org/10.4150/KPMI.2021.28.1.20

- 825 View

- 6 Download

-

Abstract

Abstract

PDF

PDF Ti-based alloys are widely used in biomaterials owing to their excellent biocompatibility. In this study, Ti- Mn-Cu alloys are prepared by high-energy ball milling, magnetic pulsed compaction, and pressureless sintering. The microstructure and microhardness of the Ti-Mn-Cu alloys with variation of the Cu addition and compaction pressure are analyzed. The correlation between the composition, compaction pressure, and density is investigated by measuring the green density and sintered density for samples with different compositions, subjected to various compaction pressures. For all compositions, it is confirmed that the green density increases proportionally as the compaction pressure increases, but the sintered density decreases owing to gas formation from the pyrolysis of TiH2 powders and reduction of oxides on the surface of the starting powders during the sintering process. In addition, an increase in the amount of Cu addition changes the volume fractions of the α-Ti and β-Ti phases, and the microstructure of the alloys with different compositions also changes. It is demonstrated that these changes in the phase volume fraction and microstructure are closely related to the mechanical properties of the Ti-Mn-Cu alloys.

- [Korean]

- Synthesize of Nd2Fe14B Powders from 1-D Nd2Fe14B Wires using Electrospinning Process

- Nu Si A Eom, Su Noh, Muhammad Aneeq Haq, Bum Sung Kim

- J Korean Powder Metall Inst. 2019;26(6):477-480. Published online December 1, 2019

- DOI: https://doi.org/10.4150/KPMI.2019.26.6.477

- 896 View

- 1 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF Magnetic 0-D Nd2Fe14B powders are successfully fabricated using 1-D Nd2Fe14B nanowire formed by an efficient and facile electrospinning process approach. The synthesized Nd-Fe-B fibers and powders are investigated for their microstructural, crystallographic, and magnetic properties according to a series of subsequent heat treatments. Each heat-treatment process leads to the removal of organic impurities and the formation of the respective oxides/composites of Nd, Fe, and B, resulting in the formation of Nd2Fe14B powders. Nd-Fe-B fibers exhibit the following magnetic properties: The coercivity (Hci) of 3260 Oe, a maximum magnetization at 3T of 109.44 emu/g, and a magnetization remanence (Mr) of 44.11 emu/g. This process easily mass produces hard magnetic Nd2Fe14B powders using a 1-D synthesis process and can be extended to the experimental design of other magnetic materials.

-

Citations

Citations to this article as recorded by- Nd2Fe14B/FeCo Core–Shell Nanoparticle Synthesis Using Galvanic Substitution Based Electroless Plating

Muhammad Aneeq Haq, Han-Saem Lee, Mi Hye Lee, Da-Woon Jeong, Eom Nu Si A, Bin Lee, Yoseb Song, Bum Sung Kim

Coatings.2022; 12(3): 389. CrossRef

- Nd2Fe14B/FeCo Core–Shell Nanoparticle Synthesis Using Galvanic Substitution Based Electroless Plating

- [Korean]

- Synthesis of the Multifunctional Core/Intermediate/Shell Nanoparticles: Tunable Magnetic and Photoluminescence Properties

- Mun-Kyoung Kim, Seyun Kim, Kyoung-Seok Moon, Weon Ho Shin, Hyung Mo Jeong

- J Korean Powder Metall Inst. 2019;26(6):463-470. Published online December 1, 2019

- DOI: https://doi.org/10.4150/KPMI.2019.26.6.463

- 752 View

- 3 Download

-

Abstract

Abstract

PDF

PDF Fe3O4/SiO2/YVO4:Eu3+ multifunctional nanoparticles are successfully synthesized by facile stepwise sol-gel processes. The multifunctional nanoparticles show a spherical shape with narrow size distribution (approximately 40 nm) and the phosphor shells are well crystallized. The Eu3+ shows strong photoluminescence (red emission at 619 nm, absorbance at 290 nm) due to an effective energy transfer from the vanadate group to Eu. Core-shell structured multifunctional nanoparticles have superparamagnetic properties at 300 K. Furthermore, the core-shell nanoparticles have a quick response time for the external magnetic field. These results suggest that the photoluminescence and magnetic properties could be easily tuned by either varying the number of coating processes or changing the phosphor elements. The nanoparticles may have potential applications for appropriate fields such as laser systems, optical amplifiers, security systems, and drug delivery materials.

- [English]

- Magnetically Driven Assemblies of γ-Fe3O4 Nanoparticles into Well-Ordered Permanent Structures

- Myunghwan Byun

- J Korean Powder Metall Inst. 2017;24(3):229-234. Published online June 1, 2017

- DOI: https://doi.org/10.4150/KPMI.2017.24.3.229

- 857 View

- 1 Download

-

Abstract

Abstract

PDF

PDF We report on a simple and robust route to the spontaneous assembly of well-ordered magnetic nanoparticle superstructures by irreversible evaporation of a sessile single droplet of a mixture of a ferrofluid (FF) and a nonmagnetic fluid (NF). The resulting assembled superstructures are seen to form well-packed, vertically arranged columns with diameters of 5~0.7 μm, interparticle spacings of 9~2 μm, and heights of 1.3~3 μm. The assembled superstructures are strongly dependent on both the magnitude of magnetic field and the mixing ratio of the mixture. As the magnitude of the externally applied magnetic field and the mixing ratio of the mixture increase gradually, the size and interspacing of the magnetic nanoparticle aggregations decrease. Without an externally applied magnetic field, featureless patterns are observed for the γ-Fe3O4 nanoparticle aggregations. The proposed approach may lead to a versatile, cost-effective, fast, and scalable fabrication process based on the field-induced self-assembly of magnetic nanoparticles.

- [Korean]

- Investigation on Fe-Hf-B-Nb-P-C Soft Magnetic Powders Prepared by High-Pressure Gas Atomization

- Jae Won Jeong, Dong-Yeol Yang, Ki Bong Kim, Junhong Lee, Young Ja Kim, Tae-Soo Lim, Sangsun Yang, Min Ha Lee, Hwi Jun Kim, Yong-Jin Kim

- J Korean Powder Metall Inst. 2016;23(5):391-396. Published online October 1, 2016

- DOI: https://doi.org/10.4150/KPMI.2016.23.5.391

- 830 View

- 1 Download

- 3 Citations

-

Abstract

Abstract

PDF

PDF In this study, ultra-fine soft-magnetic micro-powders are prepared by high-pressure gas atomization of an Fe-based alloy, Fe-Hf-B-Nb-P-C. Spherical powders are successfully obtained by disintegration of the alloy melts under high-pressure He or N2 gas. The mean particle diameter of the obtained powders is 25.7 μm and 42.1 μm for He and N2 gas, respectively. Their crystallographic structure is confirmed to be amorphous throughout the interior when the particle diameter is less than 45 μm. The prepared powders show excellent soft magnetic properties with a saturation magnetization of 164.5 emu/g and a coercivity of 9.0 Oe. Finally, a toroidal core is fabricated for measuring the magnetic permeability, and a μr of up to 78.5 is obtained. It is strongly believed that soft magnetic powders prepared by gas atomization will be beneficial in the fabrication of high-performance devices, including inductors and motors.

-

Citations

Citations to this article as recorded by- Optimization of Densification Behavior of a Soft Magnetic Powder by Discrete Element Method and Machine Learning

Jungjoon Kim, Dongchan Min, Suwon Park, Junhyub Jeon, Seok-Jae Lee, Youngkyun Kim, Hwi-Jun Kim, Youngjin Kim, Hyunjoo Choi

MATERIALS TRANSACTIONS.2022; 63(10): 1304. CrossRef - Optimizing the magnetic properties of Fe-based amorphous powder by adjusting atomic structures from vitrification at different temperatures

Song-Yi Kim, Hye-Ryeong Oh, Hyeon-Ah Kim, A-Young Lee, Hwi-Jun Kim, Sang-Sun Yang, Yong-Jin Kim, Hyun-Joo Choi, Il-Hyun Kim, Hyun-Gil Kim, Jürgen Eckert, Jong-Ryoul Kim, Min-Ha Lee

Journal of Applied Physics.2019;[Epub] CrossRef - Soft magnetic properties of Fe-based amorphous/nanocrystalline hybrid materials

Yeonjoo Lee, Jonggyu Jeon, Seungjin Nam, Teasuk Jang, Hwijun Kim, Minwoo Lee, Yongjin Kim, Dongyeol Yang, Kyeongsik Min, Hyunjoo Choi

Powder Technology.2018; 339: 440. CrossRef

- Optimization of Densification Behavior of a Soft Magnetic Powder by Discrete Element Method and Machine Learning

- [Korean]

- Influence of Sintering Temperature on Magnetic Properties of Ni-Zn-Cu Ferrites Used for Mangetic Shielding in NFC

- Yo-Han Ryu, Sung-Soo Kim

- J Korean Powder Metall Inst. 2016;23(2):132-135. Published online April 1, 2016

- DOI: https://doi.org/10.4150/KPMI.2016.23.2.132

- 513 View

- 2 Download

-

Abstract

Abstract

PDF

PDF This study investigates the influence of sintering temperature on the magnetic properties and frequency dispersion of the complex permeability of Ni–Zn–Cu ferrites used for magnetic shielding in near-field communication (NFC) systems. Sintered specimens of (Ni0.7Zn0.3)0.96Cu0.04Fe2O4 are prepared by conventional ceramic processing. The complex permeability is measured by an RF impedance analyzer in the range of 1 MHz to 1.8 GHz. The real and imaginary parts of the complex permeability depend sensitively on the sintering temperature, which is closely related to the microstructure, including grain size and pore distribution. In particular, internal pores within grains produced by rapid grain growth decrease the permeability and increase the magnetic loss at the operating frequency of NFC (13.56 MHz). At the optimized sintering temperature (1225-1250°C), the highest permeability and lowest magnetic loss can be obtained.

- [Korean]

- Electromagnetic Wave Shielding Effect of Nano-powder Dispersed Epoxy Resin Composite

- Jun-Young Han, Chul-Hee Lee, Min-Gyu Choi, Soon-Jik Hong, Joong-Hark Park, Dong-Jin Lee

- J Korean Powder Metall Inst. 2015;22(4):234-239. Published online August 1, 2015

- DOI: https://doi.org/10.4150/KPMI.2015.22.4.234

- 575 View

- 2 Download

-

Abstract

Abstract

PDF

PDF Electronic products are a major part of evolving industry and human life style; however most of them are known to emit electromagnetic waves that have severe health hazards. Therefore, different materials and fabrication techniques are understudy to control or limit transfer of such waves to human body. In this study, nanocomposite powder is dispersed into epoxy resin and shielding effects such as absorption, reflection, penetration and multiple reflections are investigated. In addition, nano size powder (Ni, Fe2O3, Fe-85Ni, C-Ni) is fabricated by pulsed wire evaporation method and dispersed manually into epoxy. Characterization techniques such as X-ray diffraction, Scanning electron microscopy and Transmission electron microscopy are used to investigate the phase analysis, size and shape as well as dispersion trend of a nano powder on epoxy matrix. Shielding effect is measured by standard test method to investigate the electromagnetic shielding effectiveness of planar materials, ASTM D4935. At lower frequency, sample consisting nano-powder of Fe-85%Wt Ni shows better electromagnetic shielding effect compared to only epoxy, only Ni, Fe2O3 and C-Ni samples.

- [Korean]

- Synthesis and Characterization of Nickel Nanowires by an Anodic Aluminum Oxide Template-Based Electrodeposition

- Hyo-Ryoung Lim, Yong-Ho Choa, Young-In Lee

- J Korean Powder Metall Inst. 2015;22(3):216-220. Published online June 1, 2015

- DOI: https://doi.org/10.4150/KPMI.2015.22.3.216

- 755 View

- 2 Download

-

Abstract

Abstract

PDF

PDF Vertically oriented nickel nanowire arrays with a different diameter and length are synthesized in porous anodic aluminium oxide templates by an electrodeposition method. The pore diameters of the templates are adjusted by controlling the anodization conditions and then they are utilized as templates to grow nickel nanowire arrays. The nickel nanowires have the average diameters of approximately 25 and 260 nm and the crystal structure, morphology and microstructure of the nanowires are systematically investigated using XRD, FE-SEM and TEM analysis. The nickel nanowire arrays show a magnetic anisotropy with the easy axis parallel to the nanowires and the coercivity and remanence enhance with decreasing a wire diameter and increasing a wire length.

- [Korean]

- The Fabrication of Cobalt Nanopowder by Sonochemical Polyol Synthesis of Cobalt Hydroxide and Magnetic Separation Method

- Jong Min Byun, Myoung Hwan Choi, Chang Min Shim, Ji Young Kim, Young Do Kim

- J Korean Powder Metall Inst. 2015;22(1):39-45. Published online February 1, 2015

- DOI: https://doi.org/10.4150/KPMI.2015.22.1.39

- 815 View

- 2 Download

-

Abstract

Abstract

PDF

PDF In this study, cobalt nanopowder is fabricated by sonochemical polyol synthesis and magnetic separation method. First, sonochemical polyol synthesis is carried out at 220°C for up to 120 minutes in diethylene glycol (C4H10O3). As a result, when sonochemical polyol synthesis is performed for 50 minutes, most of the cobalt precursor (Co(OH)2) is reduced to spherical cobalt nanopowder of approximately 100 nm. In particular, aggregation and growth of cobalt particles are effectively suppressed as compared to common polyol synthesis. Furthermore, in order to obtain finer cobalt nanopowder, magnetic separation method using magnetic property of cobalt is introduced at an early reduction stage of sonochemical polyol synthesis when cobalt and cobalt precursor coexist. Finally, spherical cobalt nanopowder having an average particle size of 22 nm is successfully separated.

- [Korean]

- High-frequency Magnetic Properties of Ni-Zn-Co Ferrites Used for Mangetic Shielding in NFC

- Yo-Han Ryu, Sung-Soo Kim

- J Korean Powder Metall Inst. 2014;21(6):429-433. Published online December 1, 2014

- DOI: https://doi.org/10.4150/KPMI.2014.21.6.429

- 646 View

- 1 Download

-

Abstract

Abstract

PDF

PDF This study investigated the magnetic properties and frequency dispersion of complex permeability of Ni-Zn-Co ferrites used for magnetic shielding in near field communication (NFC) system. The sintered specimens of (Ni0.7Zn0.3)1-xCoxFe2O4 composition were prepared by the conventional ceramic processing. The coercive force and saturation magnetization were measured by vibrating sample magnetometer. The complex permeability was measured by RF impedance analyzer in the range of 1 MHz~1.8 GHz. The coercive force increased and saturation magnetization decreased with increasing the Co substitution. The real and imaginary parts of complex permeability decreased and the resonance frequency increased with Co substitution, which was attributed to the increase in crystal anisotropy field and reduction in saturation magnetization. The effect of Co substitution could be found in reducing the magnetic loss to nearly zero at the operating frequency of NFC (13.56 MHz).

- [English]

- Spark Plasma Sintering Behaviors of M-type Barium Hexaferrite Nano Powders

- Im Doo Jung, Youngmoo Kim, Yang-Ki Hong, Seong Jin Park

- J Korean Powder Metall Inst. 2014;21(4):256-259. Published online August 1, 2014

- DOI: https://doi.org/10.4150/KPMI.2014.21.4.256

- 1,101 View

- 7 Download

- 5 Citations

-

Abstract

Abstract

PDF

PDF A magnetic powder, M-type barium hexaferrite (BaFe12O19), was consolidated with the spark plasma sintering process. Three different holding temperatures, 850°C, 875°C and 900°C were applied to the spark plasma sintering process with the same holding times, heating rates and compaction pressure of 30 MPa. The relative density was measured simultaneously with spark plasma sintering and the convergent relative density after cooling was found to be proportional to the holding temperature. The full relative density was obtained at 900°C and the total sintering time was only 33.3 min, which was much less than the conventional furnace sintering method. The higher holding temperature also led to the higher saturation magnetic moment (σs) and the higher coercivity (Hc) in the vibrating sample magnetometer measurement. The saturation magnetic moment (σs) and the coercivity (Hc) obtained at 900°C were 56.3 emu/g and 541.5 Oe for each.

-

Citations

Citations to this article as recorded by- Effect of microwave sintering on density, microstructural and magnetic properties of pure strontium hexaferrite at low temperatures and heating rate

Wail M. Matran, Mazli Mustapha, Mohd Faizairi Nor, Faizal Mustapha, Fahd Saeed Alakbari, Gamal Al-shawesh, Mohammed Bawahab

Heliyon.2024; 10(20): e38766. CrossRef - A study of crystalline – texture and anisotropic properties of hexagonal BaFe12O19 sintered by in-situ magnetic-anisotropy spark plasma sintering (MASPS)

Haetham G. Mohammed, Thar Mohammed Badri Albarody, Husam Kareem Mohsin Al-Jothery, Mazli Mustapha, N.M Sultan

Journal of Magnetism and Magnetic Materials.2022; 553: 169268. CrossRef - Process Optimization of In Situ Magnetic-Anisotropy Spark Plasma Sintering of M-Type-Based Barium Hexaferrite BaFe12O19

Haetham Mohammed, Thar Albarody, Susilawati Susilawati, Scott Gohery, Aris Doyan, Saiful Prayogi, Muhammad Bilad, Reza Alebrahim, Anwar Saeed

Materials.2021; 14(10): 2650. CrossRef - Self-Consolidation and Surface Modification of Mechanical Alloyed Ti-25.0 at.% Al Powder Mixture by Using an Electro-Discharge Technique

S.Y. Chang, H.S. Jang, Y.H. Yoon, Y.H. Kim, J.Y. Kim, Y.K. Lee, W.H. Lee

Archives of Metallurgy and Materials.2017; 62(2): 1293. CrossRef - Plastic deformation and microstructural evolution during the shock consolidation of ultrafine copper powders

Dong-Hyun Ahn, Wooyeol Kim, Minju Kang, Lee Ju Park, Sunghak Lee, Hyoung Seop Kim

Materials Science and Engineering: A.2015; 625: 230. CrossRef

- Effect of microwave sintering on density, microstructural and magnetic properties of pure strontium hexaferrite at low temperatures and heating rate

TOP

KPMI

KPMI

First

First Prev

Prev