Search

- Page Path

- HOME > Search

- [Korean]

- Preparation of Porous W-Cu by Freeze Casting of Tert-butyl Alcohol Slurry Mixed with WO3-CuO Powder

- Youngmin Kim, Ji Young Kim, Minju Son, Wonyong Kwon, Eui Seon Lee, Sung-Tag Oh

- J Powder Mater. 2025;32(6):466-471. Published online December 31, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00437

- 713 View

- 9 Download

-

Abstract

Abstract

PDF

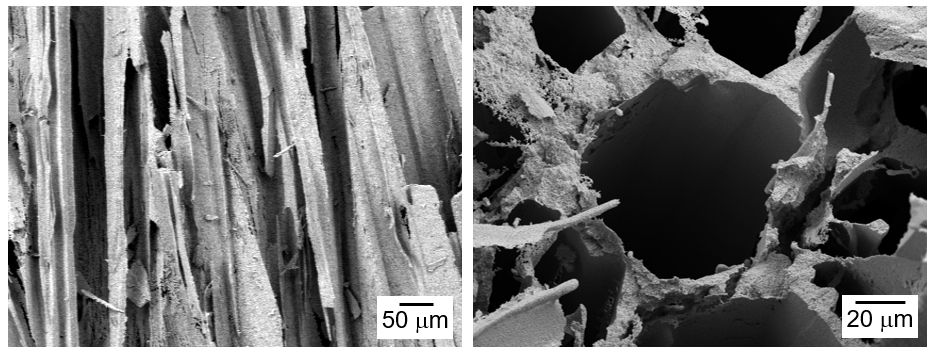

PDF - The influence of process conditions on the microstructure of porous W-Cu, fabricated by freeze casting using tert-butyl alcohol as the freezing agent, was investigated. The slurries containing 10 vol% of WO3-CuO powder were prepared by milling with a small amount of citric acid and polyethylene glycol as dispersants. The slurries with dispersion stability were frozen in a mold with the lower part cooled to -25°C, followed by sublimation in a vacuum to remove the freezing agent. The sintered W-1 vol% Cu in a hydrogen atmosphere exhibited aligned pores with the size of 50 μm, which were generated by sublimation of directionally solidified tert-butyl alcohol crystals. In the cross-section of the specimen, hexagonal pores corresponding to the crystal structure of tert-butyl alcohol was observed. Microstructure analysis of the struts revealed that Cu was distributed non-uniformly due to the mutual insolubility and low wettability of the W-Cu system.

- [Korean]

- Microstructure and Mechanical Properties of AA3003 Tube for Heat Exchanger Processed by Floating Plug Drawing

- Hyeon-Jun Heo, Sung Jun Oh, Seong-Hee Lee

- J Powder Mater. 2025;32(6):459-465. Published online December 31, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00346

- 710 View

- 8 Download

-

Abstract

Abstract

PDF

PDF - An AA3003 tube was severely deformed by cold floating plug drawing, and then annealed at temperatures from 210 to 460℃. The as drawn Al tube exhibited a typical deformation structure in which the grains were greatly elongated along the drawing direction. The hardness increased with increasing the reduction of cross-sectional area (RA), became 68Hv after RA= 99%. Up to 310℃, the Al tube still mainly exhibited a deformed structure. While complete recrystallization occurred at temperatures above 360℃. The hardness decreased with increasing the annealing temperature, and it became 33Hv after annealing at 410℃. Both the tensile and yield strengths also decreased with increasing the annealing temperature, but the decrease was larger in yield strength than in tensile strength. The elongation increased with increasing the annealing temperature. The changes in the strength and the elongation with the annealing temperature were the largest at 360℃, in which the complete recrystallization occurred.

- [Korean]

- Optimization of Mechanical Properties in WC–Mo₂C–Co Cemented Carbides via Dual Hard-Phase Based Heterogeneous Microstructure Design

- Jinwoo Seok, Jong Tae Kim, Juree Jung, SongYi Kim, Bin Lee, Junhee Han, Leeseung Kang

- J Powder Mater. 2025;32(5):428-436. Published online October 31, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00297

- 530 View

- 15 Download

-

Abstract

Abstract

PDF

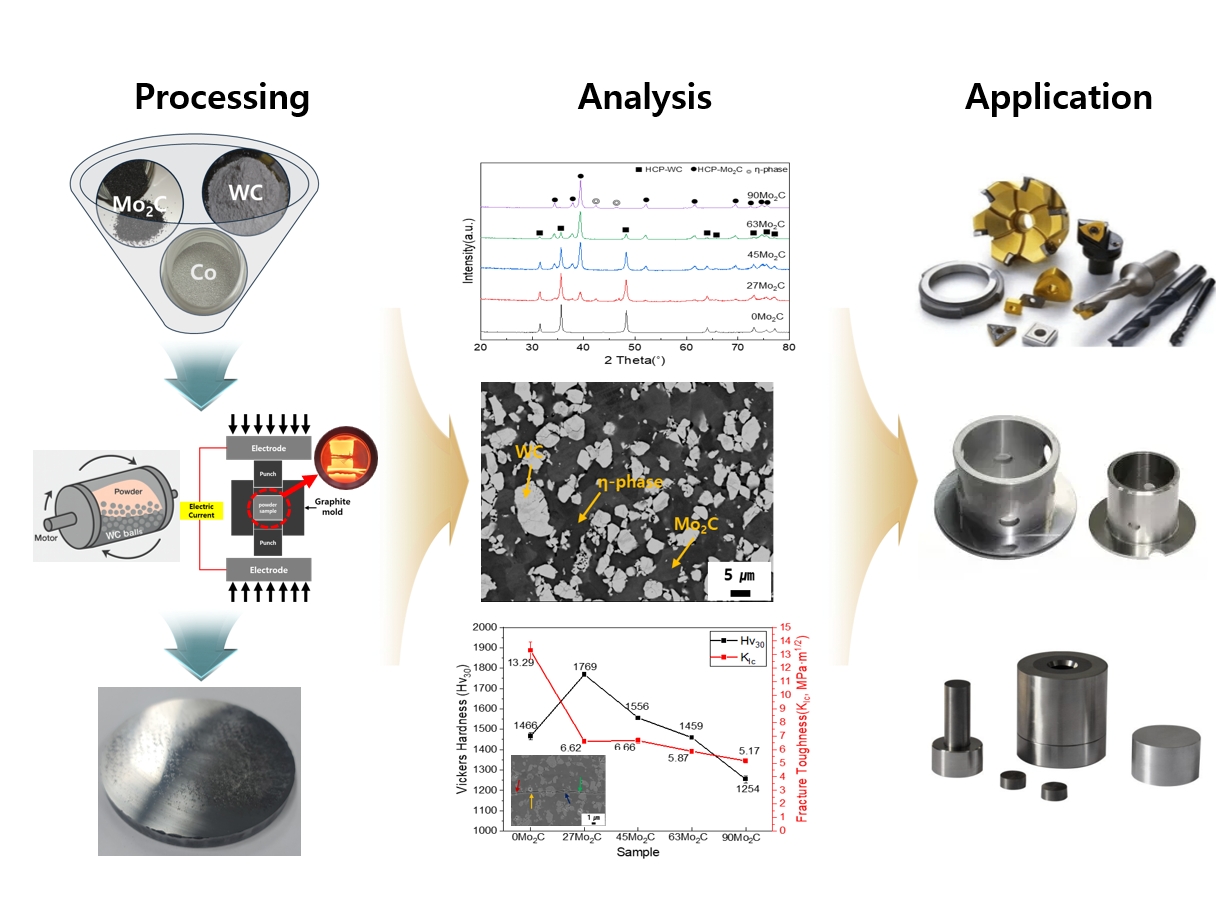

PDF - WC–Mo₂C–Co cemented carbides were fabricated to investigate the effects of Mo₂C addition on microstructure and mechanical properties. Dual hard-phase design using WC and Mo₂C was employed to optimize the balance between hardness and toughness. Spark plasma sintering (SPS) was conducted at various temperatures after ball milling, and 1300 °C for 5 min was identified as the optimized sintering condition, achieving complete densification and phase stability. The addition of Mo₂C refined the microstructure by suppressing abnormal WC grain growth through preferential dissolution of Mo₂C into the Co binder. Hardness increased up to 1769 Hv30 due to grain refinement and solid-solution strengthening, while promoted η-phase formation and reduced fracture toughness.The 27Mo₂C composition exhibited the most balanced combination of hardness and toughness. These results demonstrate that controlled Mo₂C addition enables dual hard-phase strengthening and microstructure optimization in WC–Mo₂C–Co carbides for advanced cutting and forming applications.

- [Korean]

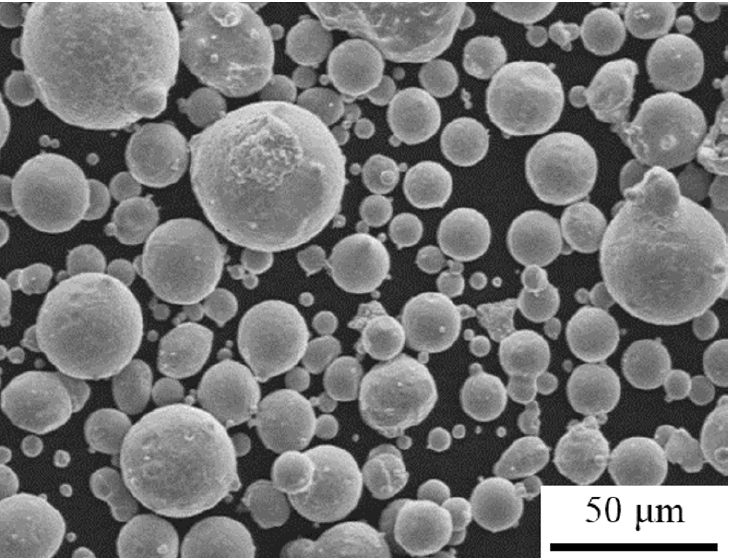

- The Manufacturing Process of Clean Ni-Cr-Co-Based Superalloy Powder Using a Plasma Rotating Electrode

- Kyu-Sik Kim, Dae Woong Kim, Yeontae Kim, Jung Hyo Park

- J Powder Mater. 2025;32(3):222-231. Published online June 30, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00171

- 784 View

- 23 Download

-

Abstract

Abstract

PDF

PDF - Ni-based superalloys are widely used for critical components in aerospace, defense, industrial power generation systems, and other applications. Clean superalloy powders and manufacturing processes, such as compaction and hot isostatic pressing, are essential for producing superalloy discs used in turbine engines, which operate under cyclic rotating loads and high-temperature conditions. In this study, the plasma rotating electrode process (PREP), one of the most promising methods for producing clean metallic powders, is employed to fabricate Ni-based superalloy powders. PREP leads to a larger powder size and narrower distribution compared to powders produced by vacuum induction melt gas atomization. An important finding is that highly spheroidized powders almost free of satellites, fractured, and deformed particles can be obtained by PREP, with significantly low oxygen content (approximately 50 ppm). Additionally, large grain size and surface inclusions should be further controlled during the PREP process to produce high-quality powder metallurgy parts.

- [Korean]

- Effect of Building Orientation on Tensile Properties of Hastelloy X alloy Manufactured by Laser Powder Bed Fusion

- Seong-June Youn, GooWon Noh, Seok Su Sohn, Young-Sang Na, Young-Kyun Kim

- J Powder Mater. 2025;32(2):131-137. Published online April 30, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00080

- 1,139 View

- 32 Download

-

Abstract

Abstract

PDF

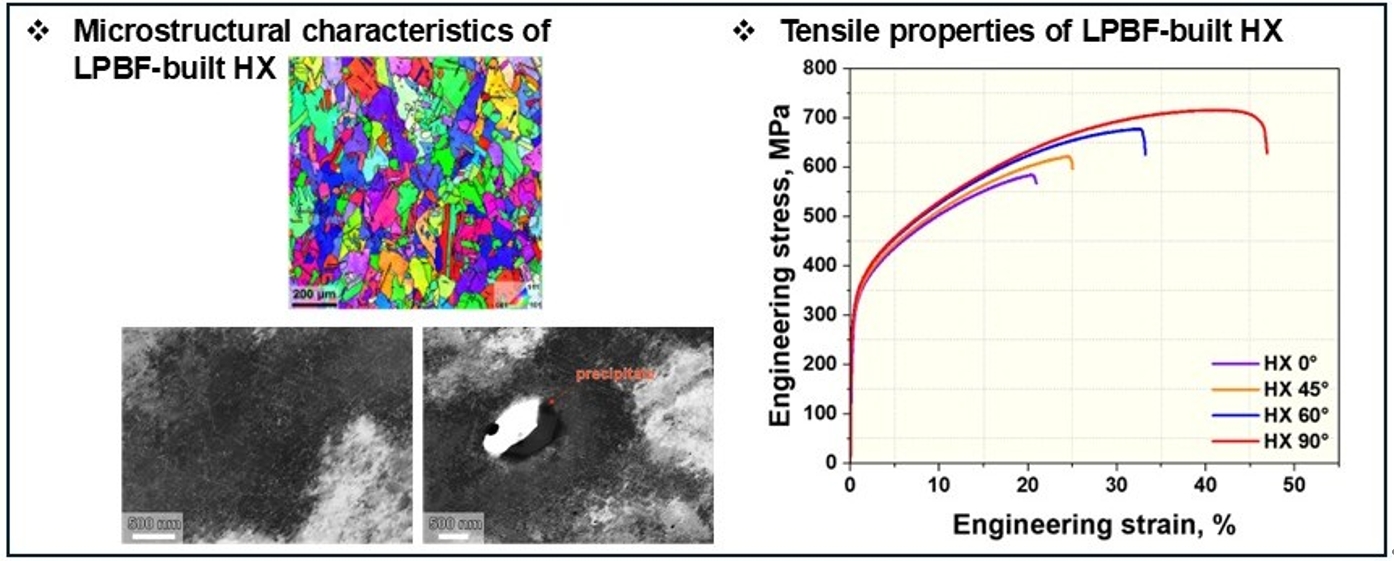

PDF - In this study, the effect of build orientation on the mechanical properties of Hastelloy X fabricated by laser powder bed fusion (LPBF) process was investigated. Initial microstructural analysis revealed an equiaxed grain structure with random crystallographic orientation and annealing twins. Intragranular precipitates identified as Cr-rich M23C6 and Mo-rich M6C carbides were observed, along with a dense dislocation network and localized dislocation accumulation around the carbides. Mechanical testing showed negligible variation in yield strength with respect to build orientation; however, both ultimate tensile strength and elongation exhibited a clear increasing trend with higher build angles. Notably, the specimen built at 90° exhibited approximately 22% higher tensile strength and more than twice the elongation compared to the 0° specimen.

- [English]

- Ultra-Low-Temperature (4.2 K) Tensile Properties and Deformation Mechanism of Stainless Steel 304L Manufactured by Laser Powder Bed Fusion

- Seung-Min Jeon, Young-Sang Na, Young-Kyun Kim

- J Powder Mater. 2025;32(2):95-103. Published online April 30, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00066

- 1,927 View

- 57 Download

- 3 Citations

-

Abstract

Abstract

PDF

PDF - This study investigated the ultra-low-temperature (4.2 K) tensile properties and deformation mechanisms of stainless steel 304L manufactured via laser powder bed fusion (LPBF). The tensile properties of LPBF 304L were compared to those of conventional 304L to assess its suitability for cryogenic applications. The results revealed that LPBF 304L exhibited a significantly higher yield strength but lower ultimate tensile strength and elongation than conventional 304L at 4.2 K. The temperature dependence of the yield strength also favored LPBF 304L. Microstructural analysis demonstrated that LPBF 304L features a high density of dislocation cells and nano-inclusions, contributing to its greater strength. Furthermore, strain-induced martensitic transformation was observed as a key deformation mechanism at cryogenic temperatures, where austenite transformed into both hexagonal-closed packed (HCP) and body-centered cubic (BCC) martensite. Notably, BCC martensite nucleation occurred within a single HCP band. These findings provide critical insights into the mechanical behavior of LPBF 304L at cryogenic temperatures and its potential for applications in extreme environments.

-

Citations

Citations to this article as recorded by- Extremely low-temperature tensile behavior of 316L stainless steel additively manufactured by laser powder bed fusion

Haeum Park, Heechan Jung, Min Young Sung, Young-Kyun Kim, Jaimyun Jung, Yoona Lee, Namhyun Kang, Kyung Tae Kim, Young-Sang Na, Seok Su Sohn, Jeong Min Park

Materials Science and Engineering: A.2026; 950: 149460. CrossRef - Twinning- and transformation-induced high cryogenic strength and ductility of the CoCrFeNi high-entropy alloy: Experiment and MD simulation

Yuze Wu, Zhide Li, Charlie Kong, M.W. Fu, Hailiang Yu

International Journal of Plasticity.2026; 196: 104553. CrossRef - Understanding the unique appearance behavior of shear bands during tensile deformation of α-brass at 4.2 K

Seon-Keun Oh, Sang-Hun Shim, Young-Kyun Kim, Young-Sang Na

Materials Science and Engineering: A.2025; 945: 148989. CrossRef

- Extremely low-temperature tensile behavior of 316L stainless steel additively manufactured by laser powder bed fusion

- [English]

- A Review of Recent Developments in CoCrFeMnNi High-Entropy Alloys Processed by Powder Metallurgy

- Cheenepalli Nagarjuna, Sheetal Kumar Dewangan, Hansung Lee, Eunhyo Song, K. Raja Rao, Byungmin Ahn

- J Powder Mater. 2025;32(2):145-164. Published online April 30, 2025

- DOI: https://doi.org/10.4150/jpm.2024.00430

- 4,526 View

- 118 Download

- 4 Citations

-

Abstract

Abstract

PDF

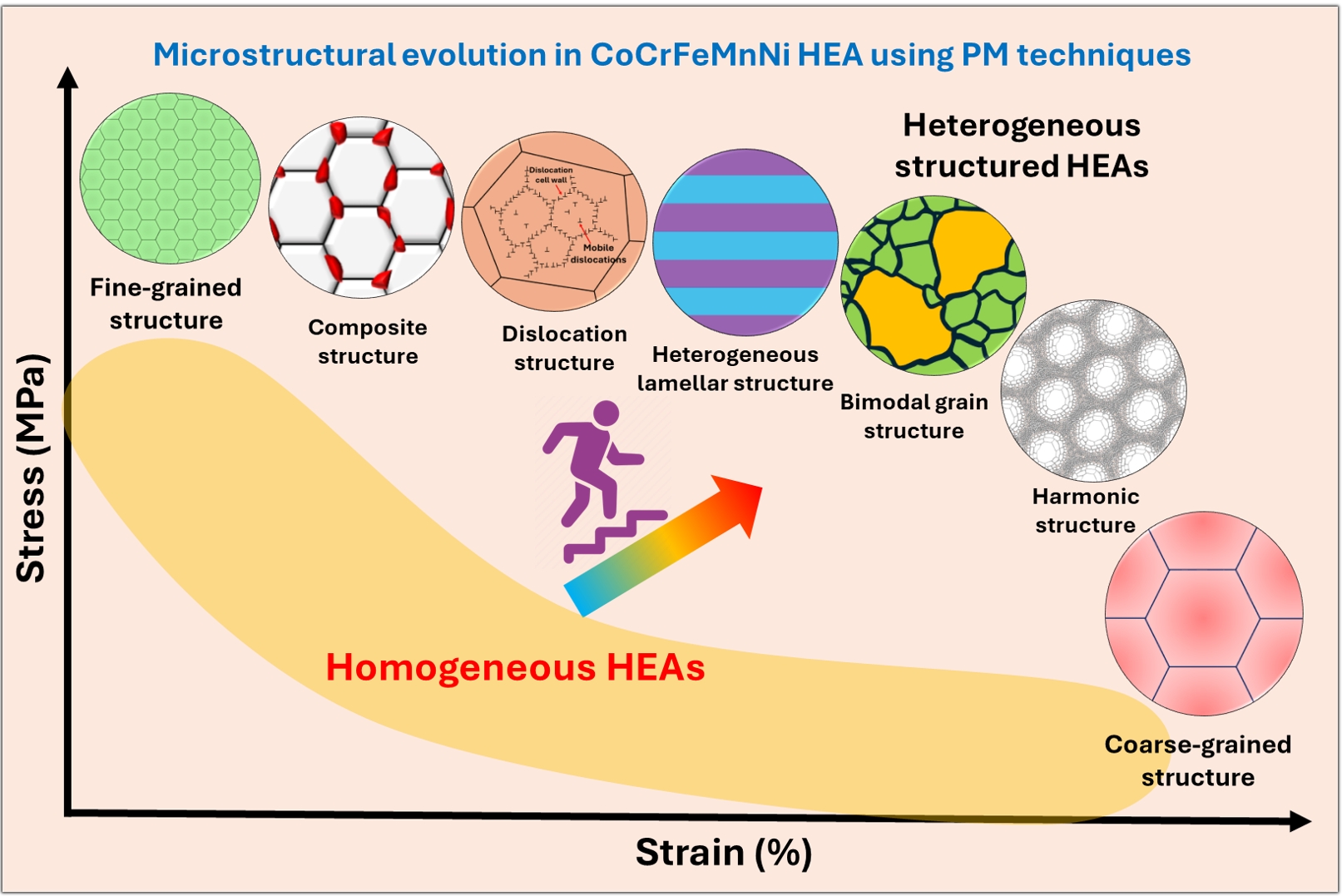

PDF - In recent years, high-entropy alloys (HEAs) have attracted considerable attention in materials engineering due to their unique phase stability and mechanical properties compared to conventional alloys. Since the inception of HEAs, CoCrFeMnNi alloys have been widely investigated due to their outstanding strength and fracture toughness at cryogenic temperatures. However, their lower yield strength at room temperature limits their structural applications. The mechanical properties of HEAs are greatly influenced by their processing methods and microstructural features. Unlike traditional melting techniques, powder metallurgy (PM) provides a unique opportunity to produce HEAs with nanocrystalline structures and uniform compositions. The current review explores recent advances in optimizing the microstructural characteristics in CoCrFeMnNi HEAs by using PM techniques to improve mechanical performance. The most promising strategies include grain refinement, dispersion strengthening, and the development of heterogeneous microstructures (e.g., harmonic, bimodal, and multi-metal lamellar structures). Thermomechanical treatments along with additive manufacturing techniques are also summarized. Additionally, the review addresses current challenges and suggests future research directions for designing advanced HEAs through PM techniques.

-

Citations

Citations to this article as recorded by- Effect of annealing temperature on thermal expansion and cryogenic mechanical properties of low-thermal-expansion Co22.2Cr6.2Fe48.8Ni17.8Cu5.0 medium-entropy alloy

Wooyoung Lee, Munsu Choi, Sungwook Kim, Dae-Kyeom Kim, Myungsuk Song, Taek-Soo Kim, Jungwan Lee, Hyoung Seop Kim, Hyunjoo Choi, Soo-Hyun Joo

Materials Science and Engineering: A.2026; 954: 149811. CrossRef - Structural and mechanical characteristics of high-entropy CoCrFeMnNi alloys manufactured by vacuum induction melting

V. K. Drobyshev, I. A. Panchenko, S. V. Konovalov, E. M. Zapolskaya

Russian Physics Journal.2026;[Epub] CrossRef - Sustainable powder metallurgy route to Densify oxide-derived CoCrFeNi high-entropy alloy

Taehyeob Im, Minjong Kim, Gertrude Mugwe Mongella, Nelson Bayi, Caroline Sunyong Lee

Materials Today Sustainability.2026; 34: 101330. CrossRef - Thermodynamic and Electronic Descriptor-Driven Machine Learning for Phase Prediction in High-Entropy Alloys: Experimental Validation

Nguyen Lam Khoa, Nguyen Duy Khanh, Hoang Thi Ngoc Quyen, Nguyen Thi Hoang, Oanh, Le Hong Thang, Nguyen Hoa Khiem, Nguyen Hoang Viet

Journal of Powder Materials.2025; 32(3): 191. CrossRef

- Effect of annealing temperature on thermal expansion and cryogenic mechanical properties of low-thermal-expansion Co22.2Cr6.2Fe48.8Ni17.8Cu5.0 medium-entropy alloy

- [Korean]

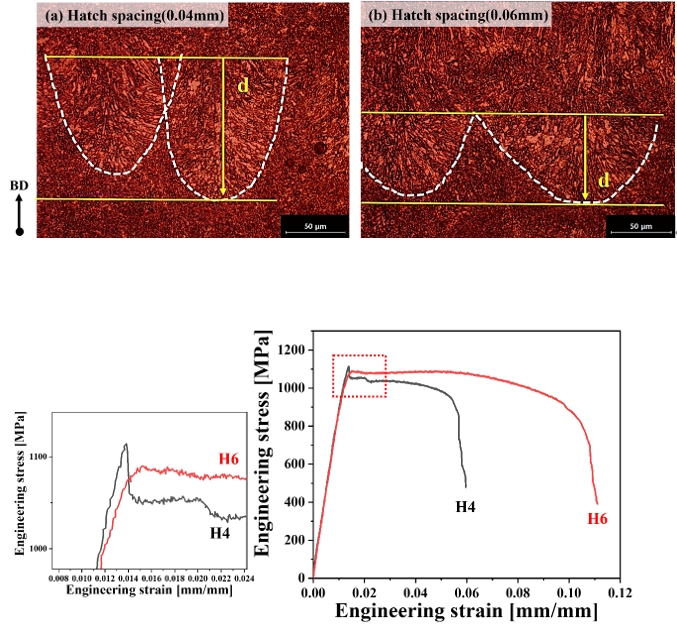

- Effect of Hatch Spacing on the Microstructure and Mechanical Properties of SA508 Gr.3 Steel Fabricated by Laser Powder Bed Fusion

- Yuanjiu Huang, Ho Jin Ryu, Kee-Ahn Lee

- J Powder Mater. 2025;32(1):50-58. Published online February 28, 2025

- DOI: https://doi.org/10.4150/jpm.2024.00479

- 1,167 View

- 27 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF - This study investigated the effect of the hatch spacing parameter on the microstructure and mechanical properties of SA508 Gr.3 steel manufactured by laser powder bed fusion (L-PBF) for a nuclear pressure vessel. Materials were prepared with varying hatch spacing (0.04 mm [H4] and 0.06 mm [H6]). The H4 exhibited finer and more uniformly distributed grains, while the H6 showed less porosity and a lower defect fraction. The yield strength of the H4 material was higher than that of the H6 material, but there was a smaller difference between the materials in tensile strength. The measured elongation was 5.65% for the H4 material and 10.41% for the H6 material, showing a significantly higher value for H6. An explanation for this is that although the H4 material had a microstructure of small and uniform grains, it contained larger and more numerous pore defects than the H6 material, facilitating stress concentration and the initiation of microcracks.

-

Citations

Citations to this article as recorded by- Extremely low temperature mechanical behavior of in-situ oxide containing 304L stainless steel fabricated by laser powder bed fusion

Kwangtae Son, Seung-Min Jeon, Brian K. Paul, Young-Sang Na, Kijoon Lee, Young-Kyun Kim

Journal of Materials Science & Technology.2025; 234: 319. CrossRef

- Extremely low temperature mechanical behavior of in-situ oxide containing 304L stainless steel fabricated by laser powder bed fusion

- [Korean]

- Effect of Sintering Conditions on the Microstructure of an FeCrMnNiCo High-Entropy Alloy

- Seonghyun Park, Sang-Hwa Lee, Junho Lee, Seok-Jae Lee, Jae-Gil Jung

- J Powder Mater. 2024;31(5):406-413. Published online October 31, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00185

- 1,292 View

- 40 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF - We investigated the microstructure of an FeCrMnNiCo alloy fabricated by spark plasma sintering under different sintering temperatures (1000–1100°C) and times (1–600 s). All sintered alloys consisted of a single face-centered cubic phase. As the sintering time or temperature increased, the grains of the sintered alloys became partially coarse. The formation of Cr7C3 carbide occurred on the surface of the sintered alloys due to carbon diffusion from the graphite crucible. The depth of the layer containing Cr7C3 carbides increased to ~110 μm under severe sintering conditions (1100°C, 60 s). A molten zone was observed on the surface of the alloys sintered at higher temperatures (>1060°C) due to severe carbon diffusion that reduced the melting point of the alloy. The porosity of the sintered alloys decreased with increasing time at 1000°C, but increased at higher temperatures above 1060°C due to melting-induced porosity formation.

-

Citations

Citations to this article as recorded by- Fabrication and Alloying Behavior of Ultra-Lightweight AlTiCrVMg High-Entropy Alloy via Al-Mg Mutual Solubility and Sintering Control

Eunhyo Song, Hansung Lee, Byungmin Ahn

Journal of Powder Materials.2025; 32(3): 254. CrossRef - Microstructure and mechanical properties of oxide-dispersion-strengthened CrMnFeCoNiC0.2O0.2 high-entropy alloy fabricated by mechanical alloying and spark plasma sintering

Sang-Hwa Lee, Seonghyun Park, Ka Ram Lim, Seok-Jae Lee, Jae-Gil Jung

Materials Science and Engineering: A.2025; 947: 149284. CrossRef

- Fabrication and Alloying Behavior of Ultra-Lightweight AlTiCrVMg High-Entropy Alloy via Al-Mg Mutual Solubility and Sintering Control

- [Korean]

- Preparation and Microstructural Characteristics of Ti Nanopowder by Ball Milling and Dehydrogenation of TiH2 Powder

- Ji Young Kim, Eui Seon Lee, Ji Won Choi, Youngmin Kim, Sung-Tag Oh

- J Powder Mater. 2024;31(4):324-328. Published online August 30, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00199

- 1,170 View

- 17 Download

-

Abstract

Abstract

PDF

PDF - This study analyzed the influence of ball size and process control agents on the refinement and dehydrogenation behavior of TiH2 powder. Powders milled using ZrO2 balls with diameters of 0.1 mm, 0.3 mm, and 0.3+0.5+1 mm exhibited a bimodal particle size distribution, of which the first mode had the smallest size of 0.23 μm for the 0.3 mm balls. Using ethanol and/or stearic acid as process control agents was effective in particle refinement. Thermogravimetric analysis showed that dehydrogenation of the milled powder started at a relatively low temperature compared to the raw powder, which is interpreted to have resulted from a decrease in particle size and an increase in defects. The dehydrogenation kinetics of the TiH2 powder were evaluated by the magnitude of peak shift with heating rates using thermogravimetric analysis. The activation energy of the dehydrogenation reaction, calculated from the slope of the Kissinger plot, was measured to be 228.6 kJ/mol for the raw powder and 194.5 kJ/mol for the milled powder. TEM analysis revealed that both the milled and dehydrogenated powders showed an angular shape with a size of about 200 nm.

- [English]

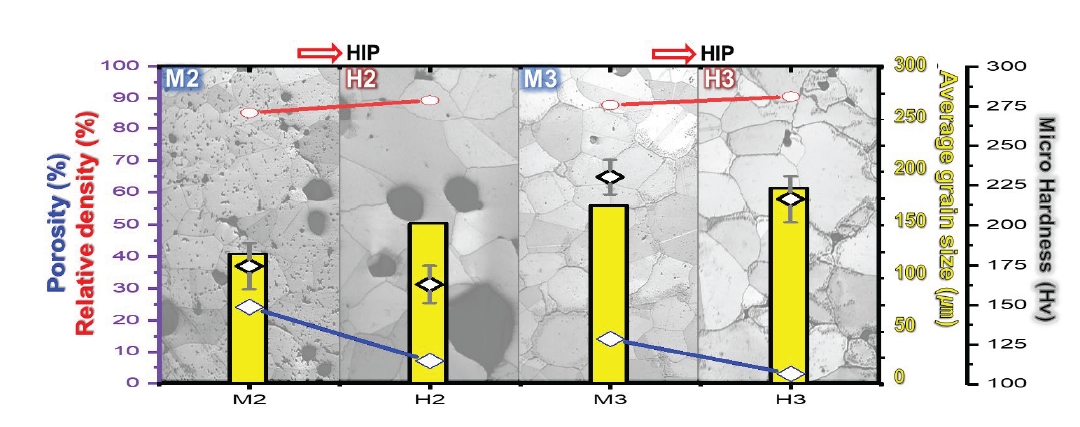

- Characterization of the Manufacturing Process and Mechanical Properties of CoCrFeMnNi High-Entropy Alloys via Metal Injection Molding and Hot Isostatic Pressing

- Eun Seong Kim, Jae Man Park, Do Won Lee, Hyojeong Ha, Jungho Choe, Jaemin Wang, Seong Jin Park, Byeong-Joo Lee, Hyoung Seop Kim

- J Powder Mater. 2024;31(3):243-254. Published online June 27, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00059

- 2,235 View

- 56 Download

-

Abstract

Abstract

PDF

PDF - High-entropy alloys (HEAs) have been reported to have better properties than conventional materials; however, they are more expensive due to the high cost of their main components. Therefore, research is needed to reduce manufacturing costs. In this study, CoCrFeMnNi HEAs were prepared using metal injection molding (MIM), which is a powder metallurgy process that involves less material waste than machining process. Although the MIM-processed samples were in the face-centered cubic (FCC) phase, porosity remained after sintering at 1200°C, 1250°C, and 1275°C. In this study, the hot isostatic pressing (HIP) process, which considers both temperature (1150°C) and pressure (150 MPa), was adopted to improve the quality of the MIM samples. Although the hardness of the HIP-treated samples decreased slightly and the Mn composition was significantly reduced, the process effectively eliminated many pores that remained after the 1275°C MIM process. The HIP process can improve the quality of the alloy.

- [English]

- The Effect of TiO2 Addition on Low-temperature Sintering Behaviors in a SnO2-CoO-CuO System

- Jae-Sang Lee, Kyung-Sik Oh, Yeong-Kyeun Paek

- J Powder Mater. 2024;31(2):146-151. Published online April 30, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00024

- 1,190 View

- 18 Download

-

Abstract

Abstract

PDF

PDF - Pure SnO2 has proven very difficult to densify. This poor densification can be useful for the fabrication of SnO2 with a porous microstructure, which is used in electronic devices such as gas sensors. Most electronic devices based on SnO2 have a porous microstructure, with a porosity of > 40%. In pure SnO2, a high sintering temperature of approximately 1300C is required to obtain > 40% porosity. In an attempt to reduce the required sintering temperature, the present study investigated the low-temperature sinterability of a current system. With the addition of TiO2, the compositions of the samples were Sn1-xTixO2-CoO(0.3wt%)-CuO(2wt%) in the range of x ≤ 0.04. Compared to the samples without added TiO2, densification was shown to be improved when the samples were sintered at 950C. The dominant mass transport mechanism appears to be grain-boundary diffusion during heat treatment at 950C.

- [Korean]

- Effect of Ball Milling Conditions on the Microstructure and Dehydrogenation Behavior of TiH2 Powder

- Ji Young Kim, Eui Seon Lee, Ji Won Choi, Youngmin Kim, Sung-Tag Oh

- J Powder Mater. 2024;31(2):132-136. Published online April 30, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00001

- 2,185 View

- 38 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF - This study investigated the effects of revolution speed and ball size in planetary milling on the microstructure and dehydrogenation behavior of TiH2 powder. The particle size analysis showed that the large particles present in the raw powder were effectively refined as the revolution speed increased, and when milled at 500 rpm, the median particle size was 1.47 m. Milling with a mixture of balls of two or three sizes was more effective in refining the raw powder than milling with balls of a single size. A mixture of 3-mm and 5-mm-diameter balls was the optimal condition for particle refinement, and the measured median particle size was 0.71 m. The dependence of particle size on revolution speed and ball size was explained by changes in input energy and the number of contact points of the balls. In the milled powder, the endothermic peak measured using differential thermal analysis was observed at a relatively low temperature. This finding was interpreted as the activation of a dehydrogenation reaction, mainly due to the increase in the specific surface area and the concentration of lattice defects.

-

Citations

Citations to this article as recorded by- Preparation and Microstructural Characteristics of Ti Nanopowder by Ball Milling and Dehydrogenation of TiH2 Powder

Ji Young Kim, Eui Seon Lee, Ji Won Choi, Youngmin Kim, Sung-Tag Oh

Journal of Powder Materials.2024; 31(4): 324. CrossRef

- Preparation and Microstructural Characteristics of Ti Nanopowder by Ball Milling and Dehydrogenation of TiH2 Powder

- [Korean]

- Evaluation of Microstructures and Mechanical Properties of Ni-Y2O3 Sintered Alloys Based on the Powder Preparation Methods

- Gun-Woo Jung, Ji-Ho Cha, Min-Seo Jang, Minsuk Oh, Jeshin Park

- J Powder Mater. 2023;30(6):484-492. Published online December 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.6.484

- 1,097 View

- 15 Download

-

Abstract

Abstract

PDF

PDF In this study, Ni-Y2O3 powder was prepared by alloying recomposition oxidation sintering (AROS), solution combustion synthesis (SCS), and conventional mechanical alloying (MA). The microstructure and mechanical properties of the alloys were investigated by spark plasma sintering (SPS). Among the Ni-Y2O3 powders synthesized by the three methods, the AROS powder had approximately 5 nm of Y2O3 crystals uniformly distributed within the Ni particles, whereas the SCS powder contained a mixture of Ni and Y2O3 nanoparticles, and the MA powder formed small Y2O3 crystals on the surface of large Ni particles by milling the mixture of Ni and Y2O3. The average grain size of Y2O3 in the sintered alloys was approximately 15 nm, with the AROS sinter having the smallest, followed by the SCS sinter at 18 nm, and the MA sinter at 22 nm. The yield strength (YS) of the SCS- and MA-sintered alloys were 1511 and 1688 MPa, respectively, which are lower than the YS value of 1697 MPa for the AROS-sintered alloys. The AROS alloy exhibited improved strength compared to the alloys fabricated by SCS and conventional MA methods, primarily because of the increased strengthening from the finer Y2O3 particles and Ni grains.

- [Korean]

- Effect of Heat Treatment on Microstructure and Mechanical Properties of Al–Zn–Mg–Cu–Si Sintered Alloys with and Without High-energy Ball Milling

- Junho Lee, Seonghyun Park, Sang-Hwa Lee, Seung Bae Son, Seok-Jae Lee, Jae-Gil Jung

- J Powder Mater. 2023;30(6):470-477. Published online December 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.6.470

- 2,784 View

- 32 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF The effects of annealing on the microstructure and mechanical properties of Al–Zn–Mg–Cu–Si alloys fabricated by high-energy ball milling (HEBM) and spark plasma sintering (SPS) were investigated. The HEBM-free sintered alloy primarily contained Mg2Si, Q-AlCuMgSi, and Si phases. Meanwhile, the HEBM-sintered alloy contains Mg-free Si and θ-Al2Cu phases due to the formation of MgO, which causes Mg depletion in the Al matrix. Annealing without and with HEBM at 500°C causes partial dissolution and coarsening of the Q-AlCuMgSi and Mg2Si phases in the alloy and dissolution of the θ-Al2Cu phase in the alloy, respectively. In both alloys, a thermally stable α-AlFeSi phase was formed after long-term heat treatment. The grain size of the sintered alloys with and without HEBM increased from 0.5 to 1.0 μm and from 2.9 to 6.3 μm, respectively. The hardness of the sintered alloy increases after annealing for 1 h but decreases significantly after 24 h of annealing. Extending the annealing time to 168 h improved the hardness of the alloy without HEBM but had little effect on the alloy with HEBM. The relationship between the microstructural factors and the hardness of the sintered and annealed alloys is discussed.

-

Citations

Citations to this article as recorded by- Microstructural evolution and thermal stability of Al–Zn–Mg–Cu–Si–Zr alloy fabricated via spark plasma sintering

Junho Lee, Seonghyun Park, Sang-Hwa Lee, Seung Bae Son, Hanjung Kwon, Seok-Jae Lee, Jae-Gil Jung

Journal of Materials Research and Technology.2024; 31: 205. CrossRef

- Microstructural evolution and thermal stability of Al–Zn–Mg–Cu–Si–Zr alloy fabricated via spark plasma sintering

- [Korean]

- Effect of Chelating Agent on Li1.5Al0.5Ti1.5(PO4)3 Particles by Sol-gel Method and Densification

- SungJoon Ryu, Seul Ki Choi, Jong Ho Won, MinHo Yang

- J Powder Mater. 2023;30(5):394-401. Published online October 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.5.394

- 1,775 View

- 48 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF Li1.5Al0.5Ti1.5(PO4)3 (LATP) is considered to be one of the promising solid-state electrolytes owing to its excellent chemical and thermal stability, wide potential range (~5.0 V), and high ionic conductivity (~10-4 S/cm). LATP powders are typically prepared via the sol-gel method by adding and mixing nitrate or alkoxide precursors with chelating agents. Here, the thermal properties, crystallinity, density, particle size, and distribution of LATP powders based on chelating agents (citric acid, acetylacetone, EDTA) are compared to find the optimal conditions for densely sintered LATP with high purity. In addition, the three types of LATP powders are utilized to prepare sintered solid electrolytes and observe the microstructure changes during the sintering process. The pyrolysis onset temperature and crystallization temperature of the powder samples are in the order AC-LATP > CA-LATP > ED-LATP, and the LATP powder utilizing citric acid exhibits the highest purity, as no secondary phase other than LiTi2PO4 phase is observed. LATP with citric acid and acetylacetone has a value close to the theoretical density (2.8 g/cm3) after sintering. In comparison, LATP with EDTA has a low sintered density (2.2 g/cm3) because of the generation of many pores after sintering.

-

Citations

Citations to this article as recorded by- Uniform lithium deposition using Cu teepee structures for anode-free lithium metal batteries

Seo Yun Jung, Jaehun Han, Seul Ki Choi, Se Youn Cho, Jong Ho Won, Jaewon Choi, Minho Yang

Chemical Engineering Journal.2025; 522: 167302. CrossRef

- Uniform lithium deposition using Cu teepee structures for anode-free lithium metal batteries

- [Korean]

- Controlling Particle Size of Recycled Copper Oxide Powder for Copper Thermite Welding Characteristics

- Hansung Lee, Minsu Kim, Byungmin Ahn

- J Powder Mater. 2023;30(4):332-338. Published online August 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.4.332

- 922 View

- 9 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF Thermite welding is an exceptional process that does not require additional energy supplies, resulting in welded joints that exhibit mechanical properties and conductivity equivalent to those of the parent materials. The global adoption of thermite welding is growing across various industries. However, in Korea, limited research is being conducted on the core technology of thermite welding. Currently, domestic production of thermite powder in Korea involves recycling copper oxide (CuO). Unfortunately, controlling the particle size of waste CuO poses challenges, leading to the unwanted formation of pores and cracks during thermite welding. In this study, we investigate the influence of powder particle size on thermite welding in the production of Cu-thermite powder using waste CuO. We conduct the ball milling process for 0.5–24 h using recycled CuO. The evolution of the powder shape and size is analyzed using particle size analysis and scanning electron microscopy (SEM). Furthermore, we examine the thermal reaction characteristics through differential scanning calorimetry. Additionally, the microstructures of the welded samples are observed using optical microscopy and SEM to evaluate the impact of powder particle size on weldability. Lastly, hardness measurements are performed to assess the strengths of the welded materials.

-

Citations

Citations to this article as recorded by- Friction Welding of Casted SCM440 and Sintered F-05-140 Dissimilar Steels and Their Joint Properties under Various Welding Conditions

Jisung Lee, Hansung Lee, Eunhyo Song, Byungmin Ahn

Journal of Powder Materials.2024; 31(5): 414. CrossRef

- Friction Welding of Casted SCM440 and Sintered F-05-140 Dissimilar Steels and Their Joint Properties under Various Welding Conditions

- [Korean]

- Exploration of Aluminum Alloy using Multi-feeder 3D Additive Manufacturing-based Combinatorial Experiment

- Suwon Park, Yongwook Song, Jiyoon Yeo, Songyun Han, Hyunjoo Choi

- J Powder Mater. 2023;30(3):255-261. Published online June 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.3.255

- 1,590 View

- 8 Download

- 3 Citations

-

Abstract

Abstract

PDF

PDF Aluminum alloys are widely utilized in diverse industries, such as automobiles, aerospace, and architecture, owing to their high specific strength and resistance to oxidation. However, to meet the increasing demands of the industry, it is necessary to design new aluminum alloys with excellent properties. Thus, a new method is required to efficiently test additively manufactured aluminum alloys with various compositions within a short period during the alloy design process. In this study, a combinatory approach using a direct energy deposition system for metal 3D printing process with a dual feeder was employed. Two types of aluminum alloy powders, namely Al6061 and Al-12Cu, were utilized for the combinatory test conducted through 3D printing. Twelve types of Al-Si-Cu-Mg alloys were manufactured during this combinatory test, and the relationship between their microstructures and properties was investigated.

-

Citations

Citations to this article as recorded by- Trends in Materials Modeling and Computation for Metal Additive Manufacturing

Seoyeon Jeon, Hyunjoo Choi

journal of Korean Powder Metallurgy Institute.2024; 31(3): 213. CrossRef - Microstructural Effects on the Mechanical Properties of Ti-6Al-4V Fabricated by Direct Energy Deposition

Juho Kim, Seoyeon Jeon, Hwajin Park, Taeyoel Kim, Hyunjoo Choi

Journal of Powder Materials.2024; 31(4): 302. CrossRef - Combinatorial Experiment for Al-6061 and Al-12Si alloy Based on Directed Energy Deposition (DED) Process

Seoyeon Jeon, Suwon Park, Yongwook Song, Jiwon Park, Hyunyoung Park, Boram Lee, Hyunjoo Choi

journal of Korean Powder Metallurgy Institute.2023; 30(6): 463. CrossRef

- Trends in Materials Modeling and Computation for Metal Additive Manufacturing

- [Korean]

- Effect of WC Particle Size on the Microstructure, Mechanical and Electrical Properties of Ag/WC Sintered Electrical Contact Material

- Soobin Kim, So-Yeon Park, Jong-Bin Lim, Soon Ho Kwon, Kee-Ahn Lee

- J Powder Mater. 2023;30(3):242-248. Published online June 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.3.242

- 954 View

- 4 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF The Ag/WC electrical contacts were prepared via powder metallurgy using 60 wt% Ag, 40 wt% WC, and small amounts of Co3O4 with varying WC particle sizes. After the fabrication of the contact materials, microstructure observations confirmed that WC-1 had an average grain size (AGS) of 0.27 μm, and WC-2 had an AGS of 0.35 μm. The Ag matrix in WC-1 formed fine grains, whereas a significantly larger and continuous growth of the Ag matrix was observed in WC-2. This indicates the different flow behaviors of liquid Ag during the sintering process owing to the different WC sizes. The electrical conductivities of WC-1 and WC-2 were 47.8% and 60.4%, respectively, and had a significant influence on the Ag matrix. In particular, WC-2 exhibited extremely high electrical conductivity owing to its large and continuous Ag-grain matrix. The yield strengths of WC-1 and WC-2 after compression tests were 349.9 MPa and 280.7 MPa, respectively. The high yield strength of WC-1 can be attributed to the Hall–Petch effect, whereas the low yield strength of WC-2 can be explained by the high fraction of high-angle boundaries (HAB) between the WC grains. Furthermore, the relationships between the microstructure, electrical/mechanical properties, and deformation mechanisms were evaluated.

-

Citations

Citations to this article as recorded by- Enhanced Epoxy Composites Reinforced by 3D-Aligned Aluminum Borate Nanowhiskers

Hyunseung Song, Kiho Song, Haejin Hwang, Changui Ahn

Materials.2024; 17(19): 4727. CrossRef

- Enhanced Epoxy Composites Reinforced by 3D-Aligned Aluminum Borate Nanowhiskers

- [Korean]

- Effect of Bulk Shape on Mechanical Properties of Ti-6Al-4V Alloy Manufactured by Laser Powder Bed Fusion

- Haeum Park, Yeon Woo Kim, Seungyeon Lee, Kyung Tae Kim, Ji-Hun Yu, Jung Gi Kim, Jeong Min Park

- J Powder Mater. 2023;30(2):140-145. Published online April 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.2.140

- 2,492 View

- 33 Download

- 6 Citations

-

Abstract

Abstract

PDF

PDF Although the Ti–6Al–4V alloy has been used in the aircraft industry owing to its excellent mechanical properties and low density, the low formability of the alloy hinders broadening its applications. Recently, laser-powder bed fusion (L-PBF) has become a novel process for overcoming the limitations of the alloy (i.e., low formability), owing to the high degree of design freedom for the geometry of products having outstanding performance used in hightech applications. In this study, to investigate the effect of bulk shape on the microstructure and mechanical properties of L-PBFed Ti-6Al-4V alloys, two types of samples are fabricated using L-PBF: thick and thin samples. The thick sample exhibits lower strength and higher ductility than the thin sample owing to the larger grain size and lower residual dislocation density of the thick sample because of the heat input during the L-PBF process.

-

Citations

Citations to this article as recorded by- Effect of Support Structure on Residual Stress Distribution in Ti-6Al-4V Alloy Fabricated by Laser Powder Bed Fusion

Seungyeon Lee, Haeum Park, Min Jae Baek, Dong Jun Lee, Jae Wung Bae, Ji-Hun Yu, Jeong Min Park

Journal of Powder Materials.2025; 32(3): 244. CrossRef - Cryogenic Tensile Behavior of Ferrous Medium-entropy Alloy Additively Manufactured by Laser Powder Bed Fusion

Seungyeon Lee, Kyung Tae Kim, Ji-Hun Yu, Hyoung Seop Kim, Jae Wung Bae, Jeong Min Park

journal of Korean Powder Metallurgy Institute.2024; 31(1): 8. CrossRef - Microstructural Evolution and Mechanical Properties of Ti-6Al-4V Alloy through Selective Laser Melting: Comprehensive Study on the Effect of Hot Isostatic Pressing (HIP)

Gargi Roy, Raj Narayan Hajra, Woo Hyeok Kim, Jongwon Lee, Sangwoo Kim, Jeoung Han Kim

journal of Korean Powder Metallurgy Institute.2024; 31(1): 1. CrossRef - Data-driven Approach to Explore the Contribution of Process Parameters for Laser Powder Bed Fusion of a Ti-6Al-4V Alloy

Jeong Min Park, Jaimyun Jung, Seungyeon Lee, Haeum Park, Yeon Woo Kim, Ji-Hun Yu

journal of Korean Powder Metallurgy Institute.2024; 31(2): 137. CrossRef - A Parametric Study on the L-PBF Process of an AlSi10Mg Alloy for High-Speed Productivity of Automotive Prototype Parts

Yeonha Chang, Hyomoon Joo, Wanghyun Yong, Yeongcheol Jo, Seongjin Kim, Hanjae Kim, Yeon Woo Kim, Kyung Tae Kim, Jeong Min Park

Journal of Powder Materials.2024; 31(5): 390. CrossRef - High-speed manufacturing-driven strength-ductility improvement of H13 tool steel fabricated by selective laser melting

Yeon Woo Kim, Haeum Park, Young Seong Eom, Dong Gill Ahn, Kyung Tae Kim, Ji-hun Yu, Yoon Suk Choi, Jeong Min Park

Powder Metallurgy.2023; 66(5): 582. CrossRef

- Effect of Support Structure on Residual Stress Distribution in Ti-6Al-4V Alloy Fabricated by Laser Powder Bed Fusion

- [Korean]

- Effect of Substrate Pre-heating on Microstructure and Magnetic Properties of Nd-Fe-B Permanent Magnet Manufactured by L-PBF

- Yeon Woo Kim, Haeum Park, Tae-Hoon Kim, Kyung Tae Kim, Ji-Hun Yu, Yoon Suk Choi, Jeong Min Park

- J Powder Mater. 2023;30(2):116-122. Published online April 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.2.116

- 1,159 View

- 17 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF Because magnets fabricated using Nd-Fe-B exhibit excellent magnetic properties, this novel material is used in various high-tech industries. However, because of the brittleness and low formability of Nd-Fe-B magnets, the design freedom of shapes for improving the performance is limited based on conventional tooling and postprocessing. Laserpowder bed fusion (L-PBF), the most famous additive manufacturing (AM) technique, has recently emerged as a novel process for producing geometrically complex shapes of Nd-Fe-B parts owing to its high precision and good spatial resolution. However, because of the repeated thermal shock applied to the materials during L-PBF, it is difficult to fabricate a dense Nd-Fe-B magnet. In this study, a high-density (>96%) Nd-Fe-B magnet is successfully fabricated by minimizing the thermal residual stress caused by substrate heating during L-PBF.

-

Citations

Citations to this article as recorded by- Effect of Support Structure on Residual Stress Distribution in Ti-6Al-4V Alloy Fabricated by Laser Powder Bed Fusion

Seungyeon Lee, Haeum Park, Min Jae Baek, Dong Jun Lee, Jae Wung Bae, Ji-Hun Yu, Jeong Min Park

Journal of Powder Materials.2025; 32(3): 244. CrossRef - Linkage between process-induced microstructure and magnetic property of Nd-Fe-B permanent magnets additively manufactured by laser powder bed fusion

Yeon Woo Kim, Sujin Lee, Yoona Lee, Jae Bok Seol, Namhyun Kang, Yoon Suk Choi, Ji-Hun Yu, Jung-Goo Lee, Tae-Hoon Kim, Jeong Min Park

Materials & Design.2025; 259: 114929. CrossRef

- Effect of Support Structure on Residual Stress Distribution in Ti-6Al-4V Alloy Fabricated by Laser Powder Bed Fusion

- [English]

- Investigation on Microstructure and Flowability of Gas Atomized Heat-resistant KHR45A Alloy Powders for Additive Manufacturing

- Geonwoo Baek, Mohsen Saboktakin Rizi, Yeeun Lee, SungJae Jo, Joo-Hyun Choi, Soon-Jik Hong

- J Powder Mater. 2023;30(1):13-21. Published online February 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.1.13

- 2,573 View

- 766 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF In additive manufacturing, the flowability of feedstock particles determines the quality of the parts that are affected by different parameters, including the chemistry and morphology of the powders and particle size distribution. In this study, the microstructures and flowabilities of gas-atomized heat-resistant alloys for additive manufacturing applications are investigated. A KHR45A alloy powder with a composition of Fe-30Cr-40Mn-1.8Nb (wt.%) is fabricated using gas atomization process. The microstructure and effect of powder chemistry and morphology on the flow behavior are investigated by scanning electron microscopy (SEM), X-ray diffraction (XRD), X-ray photoelectron spectroscopy (XPS), and revolution powder analysis. The results reveal the formation of spherical particles composed of single-phase FCC dendritic structures after gas atomization. SEM observations show variations in the microstructures of the powder particles with different size distributions. Elemental distribution maps, line scans, and high-resolution XPS results indicate the presence of a Si-rich oxide accompanied by Fe, Cr, and Nb metal oxides in the outer layer of the powders. The flowability behavior is found to be induced by the particle size distribution, which can be attributed to the interparticle interactions and friction of particles with different sizes.

-

Citations

Citations to this article as recorded by- Engineering heterogeneous microstructure for enhancing mechanical properties of multicomponent alloys via powder metallurgy route

Min Woo Shin, Sung-Jae Jo, Sourabh Kumar Soni, Ji-Woon Lee, Jongun Moon, Hyoung Seop Kim, Soon-Jik Hong

Materials Science and Engineering: A.2025; 941: 148599. CrossRef - Al-based amorphous coatings by warm spraying: Numerical simulation and experimental validation

Deming Wang, Nianchu Wu, Peng Cao

Journal of Alloys and Compounds.2024; 1008: 176674. CrossRef

- Engineering heterogeneous microstructure for enhancing mechanical properties of multicomponent alloys via powder metallurgy route

- [Korean]

- Evaluation of Mechanical Properties and Microstructure Depending on Sintering Heating Rate of IN 939W Alloy

- Junhyub Jeon, Junho Lee, Namhyuk Seo, Seung Bae Son, Jae-Gil Jung, Seok-Jae Lee

- J Powder Mater. 2022;29(5):399-410. Published online October 1, 2022

- DOI: https://doi.org/10.4150/KPMI.2022.29.5.399

- 1,682 View

- 31 Download

-

Abstract

Abstract

PDF

PDF Changes in the mechanical properties and microstructure of an IN 939 W alloy according to the sintering heating rate were evaluated. IN 939 W alloy samples were fabricated by spark plasma sintering. The phase fraction, number density, and mean radius of the IN 939W alloy were calculated using a thermodynamic calculation. A universal testing machine and micro-Vickers hardness tester were employed to confirm the mechanical properties of the IN 939W alloy. X-ray diffraction, optical microscopy, field-emission scanning electron microscopy, Cs-corrected-field emission transmission electron microscopy, and energy dispersive X-ray spectrometry were used to evaluate the microstructure of the alloy. The rapid sintering heating rate resulted in a slightly dispersed γ' phase and chromium oxide. It also suppressed the precipitation of the η phase. These helped to reinforce the mechanical properties.

- [Korean]

- Gradient Microstructure and Mechanical Properties of Fe-6%Mn Alloy by Different Sized Powder Stacking

- Namhyuk Seo, Junho Lee, Woocheol Shin, Junhyub Jeon, Jungbin Park, Seung Bae Son, Jae-Gil Jung, Seok-Jae Lee

- J Powder Mater. 2022;29(5):382-389. Published online October 1, 2022

- DOI: https://doi.org/10.4150/KPMI.2022.29.5.382

- 750 View

- 10 Download

-

Abstract

Abstract

PDF

PDF A typical trade-off relationship exists between strength and elongation in face-centered cubic metals. Studies have recently been conducted to enhance strength without ductility reduction through surface-treatment-based ultrasonic nanocrystalline surface modification (UNSM), which creates a gradient microstructure in which grains become smaller from the inside to the surface. The transformation-induced plasticity effect in Fe-Mn alloys results in excellent strength and ductility due to their high work-hardening rate. This rate is achieved through strain-induced martensitic transformation when an alloy is plastically deformed. In this study, Fe-6%Mn powders with different sizes were prepared by high-energy ball milling and sintered through spark plasma sintering to produce Fe-6%Mn samples. A gradient microstructure was obtained by stacking the different-sized powders to achieve similar effects as those derived from UNSM. A compressive test was performed to investigate the mechanical properties, including the yielding behavior. The deformed microstructure was observed through electron backscatter diffraction to determine the effects of gradient plastic deformation.

- [English]

- The Effect of SnO2 Addition on Sintering Behaviors in a Titanium Oxide-Copper Oxide System

- Ju-Won Lee, Kyung-Sik Oh, Tai-Joo Chung, Yeong-Kyeun Paek

- J Powder Mater. 2022;29(5):357-362. Published online October 1, 2022

- DOI: https://doi.org/10.4150/KPMI.2022.29.5.357

- 829 View

- 4 Download

-

Abstract

Abstract

PDF

PDF The low-temperature sinterability of TiO2-CuO systems was investigated using a solid solution of SnO2. Sample powders were prepared through conventional ball milling of mixed raw powders. With the SnO2 content, the compositions of the samples were Ti1-xSnxO2-CuO(2 wt.%) in the range of x ≤ 0.08. Compared with the samples without SnO2 addition, the densification was enhanced when the samples were sintered at 900°C. The dominant mass transport mechanism seemed to be grain-boundary diffusion during heat treatment at 900°C, where active grain-boundary diffusion was responsible for the improved densification. The rapid grain growth featured by activated sintering was also obstructed with the addition of SnO2. This suggested that both CuO as an activator and SnO2 dopant synergistically reduced the sintering temperature of TiO2.

- [Korean]

- Effect of Post Heat Treatment on the Microstructure and Mechanical Properties of BCuP-5 Filler Metal Coating Layers Fabricated by High Velocity Oxygen Fuel Thermal Spray Process on Ag Substrate

- So-Yeon Park, Seong-June Youn, Jae-Sung Park, Kee-Ahn Lee

- J Powder Mater. 2022;29(4):283-290. Published online August 1, 2022

- DOI: https://doi.org/10.4150/KPMI.2022.29.4.283

- 1,169 View

- 2 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF A Cu-15Ag-5P filler metal (BCuP-5) is fabricated on a Ag substrate using a high-velocity oxygen fuel (HVOF) thermal spray process, followed by post-heat treatment (300°C for 1 h and 400°C for 1 h) of the HVOF coating layers to control its microstructure and mechanical properties. Additionally, the microstructure and mechanical properties are evaluated according to the post-heat treatment conditions. The porosity of the heat-treated coating layers are significantly reduced to less than half those of the as-sprayed coating layer, and the pore shape changes to a spherical shape. The constituent phases of the coating layers are Cu, Ag, and Cu-Ag-Cu3P eutectic, which is identical to the initial powder feedstock. A more uniform microstructure is obtained as the heat-treatment temperature increases. The hardness of the coating layer is 154.6 Hv (as-sprayed), 161.2 Hv (300°C for 1 h), and 167.0 Hv (400°C for 1 h), which increases with increasing heat-treatment temperature, and is 2.35 times higher than that of the conventional cast alloy. As a result of the pull-out test, loss or separation of the coating layer rarely occurs in the heat-treated coating layer.

-

Citations

Citations to this article as recorded by- Evaluation and Prediction of Mechanical Properties According to Welding Methods of Ni 825/A516-70N Clad Plates

Cheolhong Hwang, Jeongseok Oh, Jini Park, Myungwoo Joe, Sunhwan Kim, Kyunghoon Yoo, Sungwoong Kim, Youngjoo Kim, Sangyeob Lee, Joonsik Park

Korean Journal of Metals and Materials.2024; 62(11): 844. CrossRef

- Evaluation and Prediction of Mechanical Properties According to Welding Methods of Ni 825/A516-70N Clad Plates

- [Korean]

- Pressureless Sintering and Microstructure of Pure Tungsten Powders Prepared by Ultrasonic Spray Pyrolysis

- Youn Ji Heo, Eui Seon Lee, Sung-Tag Oh, Jongmin Byun

- J Powder Mater. 2022;29(3):247-251. Published online June 1, 2022

- DOI: https://doi.org/10.4150/KPMI.2022.29.3.247

- 1,285 View

- 11 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF This study demonstrates the effect of the compaction pressure on the microstructure and properties of pressureless-sintered W bodies. W powders are synthesized by ultrasonic spray pyrolysis and hydrogen reduction using ammonium metatungstate hydrate as a precursor. Microstructural investigation reveals that a spherical powder in the form of agglomerated nanosized W particles is successfully synthesized. The W powder synthesized by ultrasonic spray pyrolysis exhibits a relative density of approximately 94% regardless of the compaction pressure, whereas the commercial powder exhibits a relative density of 64% under the same sintering conditions. This change in the relative density of the sintered compact can be explained by the difference in the sizes of the raw powder and the densities of the compacted green body. The grain size increases as the compaction pressure increases, and the sintered compact uniaxially pressed to 50 MPa and then isostatically pressed to 300 MPa exhibits a size of 0.71 m. The Vickers hardness of the sintered W exhibits a high value of 4.7 GPa, mainly due to grain refinement.

-

Citations

Citations to this article as recorded by- Preparation of W-Ni-Cu Alloy Powder by Hydrogen Reduction of Metal Oxides

Youn Ji Heo, Eui Seon Lee, Ji Won Choi, Jongmin Byun, Sung-Tag Oh

Korean Journal of Metals and Materials.2024; 62(5): 334. CrossRef - Influence of the initial powder characteristic on the densified tungsten microstructure by spark plasma sintering and hot isostatic pressing

Ji Young Kim, Eui Seon Lee, Youn Ji Heo, Young-In Lee, Jongmin Byun, Sung-Tag Oh

Powder Metallurgy.2023; 66(5): 644. CrossRef

- Preparation of W-Ni-Cu Alloy Powder by Hydrogen Reduction of Metal Oxides

- [Korean]

- Fabrication, Microstructure and Adhesion Properties of BCuP-5 Filler Metal/Ag Plate Clad Material by Using High Velocity Oxygen Fuel Thermal Spray Process

- Yeun A Joo, Yong-Hoon Cho, Jae-Sung Park, Kee-Ahn Lee

- J Powder Mater. 2022;29(3):226-232. Published online June 1, 2022

- DOI: https://doi.org/10.4150/KPMI.2022.29.3.226

- 936 View

- 3 Download

-

Abstract

Abstract

PDF

PDF In this study, a new manufacturing process for a multilayer-clad electrical contact material is suggested. A thin and dense BCuP-5 (Cu-15Ag-5P filler metal) coating layer is fabricated on a Ag plate using a high-velocity oxygen-fuel (HVOF) process. Subsequently, the microstructure and bonding properties of the HVOF BCuP-5 coating layer are evaluated. The thickness of the HVOF BCuP-5 coating layer is determined as 34.8 μm, and the surface fluctuation is measured as approximately 3.2 μm. The microstructure of the coating layer is composed of Cu, Ag, and Cu-Ag-Cu3P ternary eutectic phases, similar to the initial BCuP-5 powder feedstock. The average hardness of the coating layer is 154.6 HV, which is confirmed to be higher than that of the conventional BCuP-5 alloy. The pull-off strength of the Ag/BCup-5 layer is determined as 21.6 MPa. Thus, the possibility of manufacturing a multilayer-clad electrical contact material using the HVOF process is also discussed.

- [Korean]

- Microstructure and Mechanical Properties of CoCrFeMnNi-type High-entropy Alloy Fabricated by Selective Laser Melting: A Review

- Jeong Min Park

- J Powder Mater. 2022;29(2):132-151. Published online April 1, 2022

- DOI: https://doi.org/10.4150/KPMI.2022.29.2.132

- 2,617 View

- 37 Download

- 7 Citations

-

Abstract

Abstract

PDF

PDF The CoCrFeMnNi high-entropy alloy (HEA), which is the most widely known HEA with a single facecentered cubic structure, has attracted significant academic attention over the past decade owing to its outstanding multifunctional performance. Recent studies have suggested that CoCrFeMnNi-type HEAs exhibit excellent printability for selective laser melting (SLM) under a wide range of process conditions. Moreover, it has been suggested that SLM can not only provide great topological freedom of design but also exhibit excellent mechanical properties by overcoming the strength–ductility trade-off via producing a hierarchical heterogeneous microstructure. In this regard, the SLM-processed CoCrFeMnNi HEA has been extensively studied to comprehensively understand the mechanisms of microstructural evolution and resulting changes in mechanical properties. In this review, recent studies on CoCrFeMnNi-type HEAs produced using SLM are discussed with respect to process-induced microstructural evolution and the relationship between hierarchical heterogeneous microstructure and mechanical properties.

-

Citations

Citations to this article as recorded by- Thermodynamic and Electronic Descriptor-Driven Machine Learning for Phase Prediction in High-Entropy Alloys: Experimental Validation

Nguyen Lam Khoa, Nguyen Duy Khanh, Hoang Thi Ngoc Quyen, Nguyen Thi Hoang, Oanh, Le Hong Thang, Nguyen Hoa Khiem, Nguyen Hoang Viet

Journal of Powder Materials.2025; 32(3): 191. CrossRef - Investigation of effects of process parameters on microstructure and fracture toughness of SLM CoCrFeMnNi

Joseph Agyapong, Diego Mateos, Aleksander Czekanski, Solomon Boakye-Yiadom

Journal of Alloys and Compounds.2024; 987: 173998. CrossRef - Cryogenic Tensile Behavior of Ferrous Medium-entropy Alloy Additively Manufactured by Laser Powder Bed Fusion

Seungyeon Lee, Kyung Tae Kim, Ji-Hun Yu, Hyoung Seop Kim, Jae Wung Bae, Jeong Min Park

journal of Korean Powder Metallurgy Institute.2024; 31(1): 8. CrossRef - Data-driven Approach to Explore the Contribution of Process Parameters for Laser Powder Bed Fusion of a Ti-6Al-4V Alloy

Jeong Min Park, Jaimyun Jung, Seungyeon Lee, Haeum Park, Yeon Woo Kim, Ji-Hun Yu

journal of Korean Powder Metallurgy Institute.2024; 31(2): 137. CrossRef - Cryogenic tensile behavior of carbon-doped CoCrFeMnNi high-entropy alloys additively manufactured by laser powder bed fusion

Haeum Park, Hyeonseok Kwon, Kyung Tae Kim, Ji-Hun Yu, Jungho Choe, Hyokyung Sung, Hyoung Seop Kim, Jung Gi Kim, Jeong Min Park

Additive Manufacturing.2024; 86: 104223. CrossRef - Microstructural evolution and high strain rate deformation response of SLM-printed CoCrFeMnNi after annealing and deep-cryogenic treatment

Joseph Agyapong, Aleksander Czekanski, Solomon Boakye Yiadom

Materials Characterization.2024; 218: 114506. CrossRef - High-speed manufacturing-driven strength-ductility improvement of H13 tool steel fabricated by selective laser melting

Yeon Woo Kim, Haeum Park, Young Seong Eom, Dong Gill Ahn, Kyung Tae Kim, Ji-hun Yu, Yoon Suk Choi, Jeong Min Park

Powder Metallurgy.2023; 66(5): 582. CrossRef

- Thermodynamic and Electronic Descriptor-Driven Machine Learning for Phase Prediction in High-Entropy Alloys: Experimental Validation

- [Korean]

- Grain Shape and Grain Growth Behavior in the (K0.5Na0.5)NbO3-CaZrO3 System

- Chul-Lee Lee, Kyoung-Seok Moon

- J Powder Mater. 2022;29(2):110-117. Published online April 1, 2022

- DOI: https://doi.org/10.4150/KPMI.2022.29.2.110

- 476 View

- 3 Download

-

Abstract

Abstract

PDF

PDF The grain growth behavior in the (1-x)K0.5Na0.5NbO3-

x CaZrO3 (KNNCZ-x) system is studied as a function of the amount of CZ and grain shape. The (1-x)K0.5Na0.5NbO3-x CaZrO3 (KNNCZ-x) powders are synthesized using a conventional solid-state reaction method. A single orthorhombic phase is observed atx = 0 – 0.03. However, rhombohedral and orthorhombic phases are observed atx = 0.05. The grain growth behavior changes from abnormal grain growth to the suppression of grain growth as the amount of CaZrO3 (CZ) increases. With increasing CZ content, grains become more faceted, and the step-free energy increases. Therefore, the critical growth driving force increases. The grain size distribution broadens with increasing sintering time in KNNCZ-0.05. As a result, some large grains with a driving force larger than the critical driving force for growth exhibit abnormal grain growth behavior during sintering. Therefore, CZ changes the grain growth behavior and microstructure of KNN. Grain growth at the faceted interface of the KNNCZ system occurs via two-dimensional nucleation and growth.

- [Korean]

- Preparation and Refinement Behavior of (Hf-Ti-Ta-Zr-Nb)C High-Entropy Carbide Powders by Ultra High Energy Ball Milling Process

- Junwoo Song, Junhee Han, Song-Yi Kim, Jinwoo Seok, Hyoseop Kim

- J Powder Mater. 2022;29(1):34-40. Published online February 1, 2022

- DOI: https://doi.org/10.4150/KPMI.2022.29.1.34

- 1,369 View

- 3 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF Recently, high-entropy carbides have attracted considerable attention owing to their excellent physical and chemical properties such as high hardness, fracture toughness, and conductivity. However, as an emerging class of novel materials, the synthesis methods, performance, and applications of high-entropy carbides have ample scope for further development. In this study, equiatomic (Hf-Ti-Ta-Zr-Nb)C high-entropy carbide powders have been prepared by an ultrahigh- energy ball-milling (UHEBM) process with different milling times (1, 5, 15, 30, and 60 min). Further, their refinement behavior and high-entropy synthesis potential have been investigated. With an increase in the milling time, the particle size rapidly reduces (under sub-micrometer size) and homogeneous mixing of the prepared powder is observed. The distortions in the crystal lattice, which occur as a result of the refinement process and the multicomponent effect, are found to improve the sintering, thereby notably enhancing the formation of a single-phase solid solution (high-entropy). Herein, we present a procedure for the bulk synthesis of highly pure, dense, and uniform FCC single-phase (

Fm3m crystal structure) (Hf-Ti-Ta-Zr-Nb)C high-entropy carbide using a milling time of 60 min and a sintering temperature of 1,600°C.-

Citations

Citations to this article as recorded by- Controlling Particle Size of Recycled Copper Oxide Powder for Copper Thermite Welding Characteristics

Hansung Lee, Minsu Kim, Byungmin Ahn

journal of Korean Powder Metallurgy Institute.2023; 30(4): 332. CrossRef

- Controlling Particle Size of Recycled Copper Oxide Powder for Copper Thermite Welding Characteristics

- [Korean]

- The Effects of TiC Content on Microstructure of Modified A6013-3wt.%Si Alloy Powder Compact

- Hyo-Sang Yoo, Yong-Ho Kim, Hyeon-Taek Son

- J Powder Mater. 2022;29(1):28-33. Published online February 1, 2022

- DOI: https://doi.org/10.4150/KPMI.2022.29.1.28

- 940 View

- 5 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF Aluminum-based powders have attracted attention as key materials for 3D printing owing to their low density, high specific strength, high corrosion resistance, and formability. This study describes the effects of TiC addition on the microstructure of the A6013 alloy. The alloy powder was successfully prepared by gas atomization and further densified using an extrusion process. We have carried out energy dispersive X-ray spectrometry (EDS) and electron backscatter diffraction (EBSD) using scanning electron microscopy (SEM) in order to investigate the effect of TiC addition on the microstructure and texture evolution of the A6013 alloy. The atomized A6013-xTiC alloy powder is fine and spherical, with an initial powder size distribution of approximately 73 μm which decreases to 12.5, 13.9, 10.8, and 10.0 μm with increments in the amount of TiC.

-

Citations

Citations to this article as recorded by- Influence of Curing Agent Amount on Properties of Dynamic Vulcanized Phenyl Silicone Rubber-SEBS-SBS System

Chunxu Zhao, Bobing He, Xian Chen

Polymers.2022; 14(24): 5443. CrossRef

- Influence of Curing Agent Amount on Properties of Dynamic Vulcanized Phenyl Silicone Rubber-SEBS-SBS System

- [Korean]

- A Study on Powder Size Dependence of Additive Manufactured AlCrFeNi HEA on Its Microstructure and Mechanical Properties

- Jong Woo Choi, Hae Jin Park, Gyeol Chan Kang, Min Seob Jung, Ki Tae Oh, Sung Hwan Hong, Hyun Gil Kim, Ki Buem Kim

- J Powder Mater. 2022;29(1):22-27. Published online February 1, 2022

- DOI: https://doi.org/10.4150/KPMI.2022.29.1.22

- 793 View

- 4 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF Conventionally, metal materials are produced by subtractive manufacturing followed by melting. However, there has been an increasing interest in additive manufacturing, especially metal 3D printing technology, which is relatively inexpensive because of the absence of complicated processing steps. In this study, we focus on the effect of varying powder size on the synthesis quality, and suggest optimum process conditions for the preparation of AlCrFeNi high-entropy alloy powder. The SEM image of the as-fabricated specimens show countless, fine, as-synthesized powders. Furthermore, we have examined the phase and microstructure before and after 3D printing, and found that there are no noticeable changes in the phase or microstructure. However, it was determined that the larger the powder size, the better the Vickers hardness of the material. This study sheds light on the optimization of process conditions in the metal 3D printing field.

-

Citations

Citations to this article as recorded by- Fabrication and Alloying Behavior of Ultra-Lightweight AlTiCrVMg High-Entropy Alloy via Al-Mg Mutual Solubility and Sintering Control

Eunhyo Song, Hansung Lee, Byungmin Ahn

Journal of Powder Materials.2025; 32(3): 254. CrossRef

- Fabrication and Alloying Behavior of Ultra-Lightweight AlTiCrVMg High-Entropy Alloy via Al-Mg Mutual Solubility and Sintering Control

- [Korean]

- Microstructural Analysis of STS316L Samples Manufactured by Powder Bed Fusion and Post-heat Treatments

- S. Y. Song, D. W. Lee, D. V. Cong, J. W. Kim, S. M. Lee, S. H. Joo, J. C. Kim

- J Powder Mater. 2022;29(1):14-21. Published online February 1, 2022

- DOI: https://doi.org/10.4150/KPMI.2022.29.1.14

- 1,094 View

- 10 Download

- 3 Citations

-

Abstract

Abstract

PDF

PDF In the powder bed fusion (PBF) process, a 3D shape is formed by the continuous stacking of very fine powder layers using computer-aided design (CAD) modeling data, following which laser irradiation can be used to fuse the layers forming the desired product. In this method, the main process parameters for manufacturing the desired 3D products are laser power, laser speed, powder form, powder size, laminated thickness, and laser diameter. Stainless steel (STS) 316L exhibits excellent strength at high temperatures, and is also corrosion resistant. Due to this, it is widely used in various additive manufacturing processes, and in the production of corrosion-resistant components with complicated shapes. In this study, rectangular specimens have been manufactured using STS 316L powder via the PBF process. Further, the effect of heat treatment at 800 °C on the microstructure and hardness has been investigated.

-

Citations

Citations to this article as recorded by- Effect of Phase Composition on Microstructure and Mechanical Properties of Biomedical Ti-15Nb-5Sn Alloy Prepared by Material Extrusion Additive Manufacturing

Jin-hwan Lim, Gyeong-ho Kang, Shuanglei Li, Tae-hyun Nam

Journal of Materials Engineering and Performance.2025;[Epub] CrossRef - Effect of thermal debinding conditions on microstructure and mechanical properties of a biomedical Ti-15Nb-5Sn alloy prepared by material extrusion additive manufacturing (MEAM) process

Jin-hwan Lim, Soo-yeong Kim, Tae-gyun Gu, Shuanglei Li, Tae-hyun Nam

Journal of Alloys and Compounds.2025; 1044: 184366. CrossRef - In vitro Evaluation of Cytotoxicity and Cell Viability of Ultra-high Molecular Weight Polyethylene for 3D-printed Artificial Joint Manufacturing

Seung-Lim Yoo, Da-Been Lee, Min-Gyu Park, Junyeong Lim, Chanwoo Sim, Taeho Yoon, Youngmin Seo, Dae-Wui Yoon

Biomedical Science Letters.2024; 30(4): 291. CrossRef

- Effect of Phase Composition on Microstructure and Mechanical Properties of Biomedical Ti-15Nb-5Sn Alloy Prepared by Material Extrusion Additive Manufacturing

- [Korean]

- Effect of Process Stopping and Restarting on the Microstructure and Local Property of 316L Stainless Steel Manufactured by Selective Laser Melting Process

- Hyunjin Joo, Jeongmin Woo, Yongho Sohn, Kee-Ahn Lee

- J Powder Mater. 2022;29(1):1-7. Published online February 1, 2022

- DOI: https://doi.org/10.4150/KPMI.2022.29.1.1

- 780 View

- 7 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF This study investigates the effect of process stopping and restarting on the microstructure and local nanoindentation properties of 316L stainless steel manufactured via selective laser melting (SLM). We find that stopping the SLM process midway, exposing the substrate to air having an oxygen concentration of 22% or more for 12 h, and subsequently restarting the process, makes little difference to the density of the restarted area (~ 99.8%) as compared to the previously melted area of the substrate below. While the microstructure and pore distribution near the stop/restart area changes, this modified process does not induce the development of unusual features, such as an inhomogeneous microstructure or irregular pore distribution in the substrate. An analysis of the stiffness and hardness values of the nano-indented steel also reveals very little change at the joint of the stop/restart area. Further, we discuss the possible and effective follow-up actions of stopping and subsequently restarting the SLM process.

-

Citations

Citations to this article as recorded by- On the Fabrication of Functionally Graded Prototypes with Laser Powder Bed Fusion from Reused Ni-625 and 17-4 PH Stainless Steel Powder

Bharat Kalia, Rupinder Singh, B. S. Pabla

Journal of Materials Engineering and Performance.2025; 34(22): 27160. CrossRef - Additive Manufacturing of SS316L/IN718 Bimetallic Structure via Laser Powder Bed Fusion

Asif Mahmud, Nicolas Ayers, Thinh Huynh, Yongho Sohn

Materials.2023; 16(19): 6527. CrossRef

- On the Fabrication of Functionally Graded Prototypes with Laser Powder Bed Fusion from Reused Ni-625 and 17-4 PH Stainless Steel Powder

- [Korean]

- Microstructures and Mechanical Properties of Ti-20Mo-0.5EB Composites

- Suhyun Bae, Wonki Jeong, Se-Eun Shin

- J Korean Powder Metall Inst. 2021;28(5):403-409. Published online October 1, 2021

- DOI: https://doi.org/10.4150/KPMI.2021.28.5.403

- 650 View

- 8 Download

-

Abstract

Abstract

PDF

PDF In this study, Ti-Mo-EB composites are prepared by ball milling and spark plasma sintering (SPS) to obtain a low elastic modulus and high strength and to evaluate the microstructure and mechanical properties as a function of the process conditions. As the milling time and sintering temperature increased, Mo, as a β-Ti stabilizing element, diffused, and the microstructure of β-Ti increased. In addition, the size of the observed phase was small, so the modulus and hardness of α-Ti and β-Ti were measured using nanoindentation equipment. In both phases, as the milling time and sintering temperature increased, the modulus of elasticity decreased, and the hardness increased. After 12 h of milling, the specimen sintered at 1000°C showed the lowest values of modulus of elasticity of 117.52 and 101.46 GPa for α-Ti and β-Ti, respectively, confirming that the values are lower compared to the that in previously reported studies.

- [Korean]

- Microstructure and High Temperature Mechanical Properties of Oxide Dispersion Strengthened Steels Manufactured by Combination Milling Process

- Jung-Uk Lee, Young-Kyun Kim, Jeoung Han Kim, Hwi-Jin Kim, Kee-Ahn Lee

- J Korean Powder Metall Inst. 2021;28(5):389-395. Published online October 1, 2021

- DOI: https://doi.org/10.4150/KPMI.2021.28.5.389

- 809 View

- 9 Download

-

Abstract

Abstract

PDF

PDF Oxide dispersion-strengthened (ODS) steel has excellent high-temperature properties, corrosion resistance, and oxidation resistance, and is expected to be applicable in various fields. Recently, various studies on mechanical alloying (MA) have been conducted for the dispersion of oxide particles in ODS steel with a high number density. In this study, ODS steel is manufactured by introducing a complex milling process in which planetary ball milling, cryogenic ball milling, and drum ball milling are sequentially performed, and the microstructure and high-temperature mechanical properties of the ODS steel are investigated. The microstructure observation revealed that the structure is stretched in the extrusion direction, even after the heat treatment. In addition, transmission electron microscopy (TEM) analysis confirmed the presence of oxide particles in the range of 5 to 10 nm. As a result of the room-temperature and high-temperature compression tests, the yield strengths were measured as 1430, 1388, 418, and 163 MPa at 25, 500, 700, and 900°C, respectively. Based on these results, the correlation between the microstructure and mechanical properties of ODS steel manufactured using the composite milling process is also discussed.

- [Korean]

- Effect of Spray Angle the on Microstructure and Mechanical Properties of Y2O3 Coating Layer Manufactured by Atmospheric Plasma Spray Process

- Yu-Jin Hwang, Kyoung-Wook Kim, Ho-Young Lee, Sik-Chol Kwon, Kee Ahn Lee

- J Korean Powder Metall Inst. 2021;28(4):310-316. Published online August 1, 2021

- DOI: https://doi.org/10.4150/KPMI.2021.28.4.310

- 1,497 View

- 35 Download

- 5 Citations

-

Abstract

Abstract

PDF

PDF The effects of different spray angles (90°, 85°, 80°) on the microstructure and mechanical properties of a Y2O3 coating layer prepared using the atmospheric plasma spray (APS) process were studied. The powders employed in this study had a spherical shape and included a cubic Y2O3 phase. The APS coating layer exhibited the same phase as the powders. Thickness values of the coating layers were 90°: 203.7 ± 8.5 μm, 85°: 196.4 ± 9.6 μm, and 80°: 208.8 ± 10.2 μm, and it was confirmed that the effect of the spray angle on the thickness was insignificant. The porosities were measured as 90°: 3.9 ± 0.85%, 85°: 11.4 ± 2.3%, and 80°: 12.7 ± 0.5%, and the surface roughness values were 90°: 5.9 ± 0.3 μm, 85°: 8.5 ± 1.1 μm, and 80°: 8.5 ± 0.4 μm. As the spray angle decreased, the porosity increased, but the surface roughness did not show a significant difference. Vickers hardness measurements revealed values of 90°: 369.2 ± 22.3, 85°: 315.8 ± 31.4, and 80°: 267.1 ± 45.1 HV. It was found that under the condition of a 90° angle with the lowest porosity exhibited the best hardness value. Based on the aforementioned results, an improved method for the APS Y2O3 coating layer was also discussed.

-

Citations

Citations to this article as recorded by- The Effect of In Situ Laser-Assisted Plasma Spraying on the Plasma Etching Resistance of Yttrium Oxide Coating

Xutao Zhao, Tian Xie, Panpan Zhang, Zhehe Yao, Qunli Zhang, Jiake Deng, Yongfeng Sui, Jianhua Yao

Coatings.2024; 14(11): 1427. CrossRef - Investigation of contamination particles generation and surface chemical reactions on Al2O3, Y2O3, and YF3 coatings in F-based plasma

Jongho So, Minjoong Kim, Hyuksung Kwon, Seonjeong Maeng, Eunmi Choi, Chin-Wook Chung, Ju-Young Yun

Applied Surface Science.2023; 629: 157367. CrossRef - Cleaning Effect of Atmospheric-Plasma-Sprayed Y2O3 Coating Using Piranha Solution Based on Contamination Particle Measurement

Hyuksung Kwon, Minjoong Kim, Jongho So, Seonjeong Maeng, Jae-Soo Shin, Ju-Young Yun

Coatings.2023; 13(3): 653. CrossRef - The effect of powder particle size on the corrosion behavior of atmospheric plasma spray-Y2O3 coating: Unraveling the corrosion mechanism by fluorine-based plasma

Minjoong Kim, Eunmi Choi, Dongjin Lee, Jungpil Seo, Tae-Sun Back, Jongho So, Ju-Young Yun, Song-Moon Suh

Applied Surface Science.2022; 606: 154958. CrossRef - The Effect of Powder Particle Size on the Corrosion Behavior of Atmospheric Plasma Spray-Y2o3 Coating: Unraveling the Corrosion Mechanism by Fluorine-Based Plasma

Minjoong Kim, Eunmi Choi, Dongjin Lee, Jungpil Seo, Tae Sun Back, Jongho So, Ju-Young Yun, Song-Moon Suh

SSRN Electronic Journal .2022;[Epub] CrossRef

- The Effect of In Situ Laser-Assisted Plasma Spraying on the Plasma Etching Resistance of Yttrium Oxide Coating

- [Korean]

- A Study on the Microstructure and Magnetic Properties of Fe83.2Si5.33-0.33

x B10.67-0.67x Px Cu0.8 Nanocrystalline Soft Magnetic Alloys with varying P Content - Hyun Ah Im, Kyoung-Hoon Bae, Yeong gyun Nam, Subong An, Sangsun Yang, Yong-Jin Kim, Jung Woo Lee, Jae Won Jeong

- J Korean Powder Metall Inst. 2021;28(4):293-300. Published online August 1, 2021

- DOI: https://doi.org/10.4150/KPMI.2021.28.4.293

- 883 View

- 11 Download

-

Abstract

Abstract

PDF

PDF We investigate the effect of phosphorous content on the microstructure and magnetic properties of Fe83.2Si5.33-0.33

x B10.67-0.67x Px Cu0.8 (x = 1–4 at.%) nanocrystalline soft magnetic alloys. The simultaneous addition of Cu and P to nanocrystalline alloys reportedly decreases the nanocrystalline size significantly, to 10–20 nm. In the P-containing nanocrystalline alloy, P atoms are distributed in an amorphous residual matrix, which suppresses grain growth, increases permeability, and decreases coercivity. In this study, nanocrystalline ribbons with a composition of Fe83.2Si5.33-0.33x B10.67- 0.67x Px Cu0.8 (x = 1–4 at.%) are fabricated by rapid quenching melt-spinning and thermal annealing. It is demonstrated that the addition of a small amount of P to the alloy improves the glass-forming ability and increases the resistance to undesirable Fex(B,P) crystallization. Among the alloys investigated in this work, an Fe83.2Si5B10P1Cu0.8 nanocrystalline ribbon annealed at 460°C exhibits excellent soft-magnetic properties including low coercivity, low core loss, and high saturation magnetization. The uniform nanocrystallization of the Fe83.2Si5B10P1Cu0.8 alloy is confirmed by high-resolution transmission electron microscopy analysis.

- [Korean]

- Influence of Si-rich Phase Morphologies on Mechanical Properties of AlSi10Mg Alloys p rocessed by S elective L aser M elting a nd P ost-Heat Treatment

- Jung-woo Nam, Yeong Seong Eom, Kyung Tae Kim, Injoon Son

- J Korean Powder Metall Inst. 2021;28(2):134-142. Published online April 1, 2021

- DOI: https://doi.org/10.4150/KPMI.2021.28.2.134

- 740 View

- 0 Download

- 2 Citations

-

Abstract

Abstract

PDF