Search

- Page Path

- HOME > Search

- [Korean]

- Preparation of Porous W-Cu by Freeze Casting of Tert-butyl Alcohol Slurry Mixed with WO3-CuO Powder

- Youngmin Kim, Ji Young Kim, Minju Son, Wonyong Kwon, Eui Seon Lee, Sung-Tag Oh

- J Powder Mater. 2025;32(6):466-471. Published online December 31, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00437

- 599 View

- 6 Download

-

Abstract

Abstract

PDF

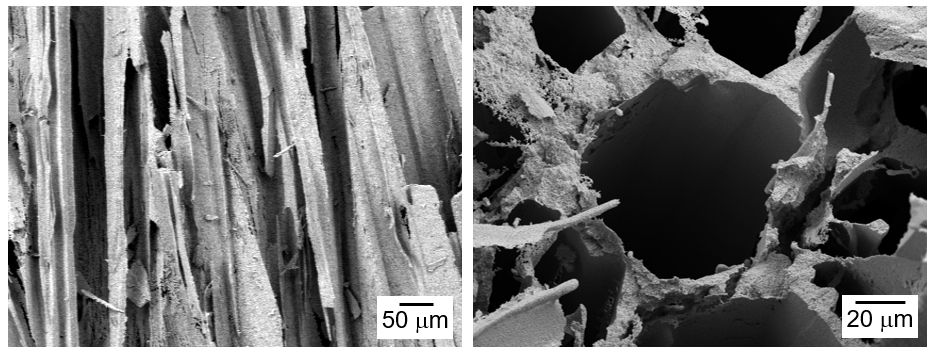

PDF - The influence of process conditions on the microstructure of porous W-Cu, fabricated by freeze casting using tert-butyl alcohol as the freezing agent, was investigated. The slurries containing 10 vol% of WO3-CuO powder were prepared by milling with a small amount of citric acid and polyethylene glycol as dispersants. The slurries with dispersion stability were frozen in a mold with the lower part cooled to -25°C, followed by sublimation in a vacuum to remove the freezing agent. The sintered W-1 vol% Cu in a hydrogen atmosphere exhibited aligned pores with the size of 50 μm, which were generated by sublimation of directionally solidified tert-butyl alcohol crystals. In the cross-section of the specimen, hexagonal pores corresponding to the crystal structure of tert-butyl alcohol was observed. Microstructure analysis of the struts revealed that Cu was distributed non-uniformly due to the mutual insolubility and low wettability of the W-Cu system.

- [Korean]

- Fabrication of Porous Tungsten by Freeze Casting and Vacuum Drying of WO3/Tert-butyl Alcohol Slurry

- Youn Ji Heo, Eui Seon Lee, Sung-Tag Oh, Young-Keun Jeong

- J Powder Mater. 2022;29(2):118-122. Published online April 1, 2022

- DOI: https://doi.org/10.4150/KPMI.2022.29.2.118

- 890 View

- 11 Download

- 3 Citations

-

Abstract

Abstract

PDF

PDF The synthesis of porous W by freeze-casting and vacuum drying is investigated. Ball-milled WO3 powders and tert-butyl alcohol were used as the starting materials. The tert-butyl alcohol slurry is frozen at –25°C and dried under vacuum at –25 and –10°C. The dried bodies are hydrogen-reduced at 800°C and sintered at 1000°C. The XRD analysis shows that WO3 is completely reduced to W without any reaction phases. SEM observations reveal that the struts and pores aligned in the tert-butyl alcohol growth direction, and the change in the powder content and drying temperature affects the pore structure. Furthermore, the struts of the porous body fabricated under vacuum are thinner than those fabricated under atmospheric pressure. This behavior is explained by the growth mechanism of tert-butyl alcohol and rearrangement of the powders during solidification. These results suggest that the pore structure of a porous body can be controlled by the powder content, drying temperature, and pressure.

-

Citations

Citations to this article as recorded by-

Fabrication of porous W by freeze-casting and hydrogen reduction of camphene-based WO

3

suspension

Ji Won Choi, Youngmin Kim, Ji Young Kim, Eui Seon Lee, Sung-Tag Oh

Powder Metallurgy.2025; 68(3): 283. CrossRef - Preparation of Porous W-Cu by Freeze Casting of Tert-butyl Alcohol Slurry Mixed with WO3-CuO Powder

Youngmin Kim, Ji Young Kim, Minju Son, Wonyong Kwon, Eui Seon Lee, Sung-Tag Oh

Journal of Powder Materials.2025; 32(6): 466. CrossRef - Fabrication of Porous TiO2 with Aligned Pores Using Tert-Butyl Alcohol Based Freeze Casting

Eui Seon Lee, Sung-Tag Oh

Korean Journal of Metals and Materials.2024; 62(12): 929. CrossRef

-

Fabrication of porous W by freeze-casting and hydrogen reduction of camphene-based WO

3

suspension

- [Korean]

- Effect of Freeze Drying Condition of WO3/Tert-Butyl Alcohol Slurry on the Microstructural Characteristics of Porous Body

- Eui Seon Lee, Youn Ji Heo, Myung-Jin Suk, Sung-Tag Oh

- J Korean Powder Metall Inst. 2021;28(4):331-335. Published online August 1, 2021

- DOI: https://doi.org/10.4150/KPMI.2021.28.4.331

- 573 View

- 2 Download

-

Abstract

Abstract

PDF

PDF The effects of drying temperature on the microstructure of porous W fabricated by the freeze-casting process of tert-butyl alcohol slurry with WO3 powder was investigated. Green bodies were hydrogen-reduced at 800°C for 1 h and sintered at 1000°C for 6 h. X-ray diffraction analysis revealed that WO3 powders were completely converted to W without any reaction phases by hydrogen reduction. The sintered body showed pores aligned in the direction of tertbutyl alcohol growth, and the porosity and pore size decreased as the amount of WO3 increased from 5 to 10v ol%. As the drying temperature of the frozen body increased from -25°C to -10°C, the pore size and thickness of the struts increased. The change in microstructural characteristics based on the amount of powder added and the drying temperature was explained by the growth behavior of the freezing agent and the degree of rearrangement of the solid powder during the solidification of the slurry.

- [Korean]

- Effect of Tert-Butyl Alcohol Template on the Pore Structure of Porous Tungsten in Freeze Drying Process

- Eui Seon Lee, Youn Ji Heo, Yun Taek Ko, Jin Gyeong Park, Yong-Ho Choa, Sung-Tag Oh

- J Korean Powder Metall Inst. 2021;28(3):216-220. Published online June 1, 2021

- DOI: https://doi.org/10.4150/KPMI.2021.28.3.216

- 667 View

- 4 Download

-

Abstract

Abstract

PDF

PDF The effect of tert-butyl alcohol (TBA) as a freezing solvent on the pore structure of a porous tungsten body prepared by freeze-drying is analyzed. TBA slurries with a WO3 content of 10 vol% are prepared by mixing with a small amount of dispersant and binder at 30°C. The slurries are frozen at -25°C, and pores are formed in the frozen specimens by the sublimation of TBA during drying in air. After hydrogen reduction at 800°C and sintering at 1000°C, the green body of WO3 is completely converted to porous W with various pore structures. Directional pores from the center of the specimen to the outside are observed in the sintered bodies because of the columnar growth of TBA. A decrease in pore directionality and porosity is observed in the specimens prepared by long-duration drying and sintering. The change in pore structure is explained by the growth of the freezing solvent and densification.

- [Korean]

- Freeze Drying Process and Pore Structure Characteristics of Porous Cu with Various Sublimable Vehicles

- Gyuhwi Lee, Sung-Tag Oh, Myung-Jin Suk, Young-Keun Jeong

- J Korean Powder Metall Inst. 2020;27(3):198-202. Published online June 1, 2020

- DOI: https://doi.org/10.4150/KPMI.2020.27.3.198

- 693 View

- 1 Download

-

Abstract

Abstract

PDF

PDF The effect of sublimable vehicles on the pore structure of Cu fabricated by freeze drying is investigated. The 5 vol% CuO-dispersed slurries with camphene and various camphor-naphthalene compositions are frozen in a Teflon mold at -25°C, followed by sublimation at room temperature. After hydrogen reduction at 300°C and sintering at 600 °C, the green bodies of CuO are completely converted to Cu with various pore structures. The sintered samples prepared using CuO/camphene slurries show large pores that are aligned parallel to the sublimable vehicle growth direction. In addition, a dense microstructure is observed in the bottom section of the specimen where the solidification heat was released, owing to the difference in the solidification behavior of the camphene crystals. The porous Cu shows different pore structures, such as dendritic, rod-like, and plate shaped, depending on the composition of the camphornaphthalene system. The change in pore structure is explained by the crystal growth behavior of primary camphor and eutectic and primary naphthalene.

- [Korean]

- Synthesis of Porous Cu-Co using Freeze Drying Process of Camphene Slurry with Oxide Composite Powders

- Gyuhwi Lee, Ju-Yeon Han, Sung-Tag Oh

- J Korean Powder Metall Inst. 2020;27(3):193-197. Published online June 1, 2020

- DOI: https://doi.org/10.4150/KPMI.2020.27.3.193

- 697 View

- 3 Download

-

Abstract

Abstract

PDF

PDF Porous Cu-14 wt% Co with aligned pores is produced by a freeze drying and sintering process. Unidirectional freezing of camphene slurry with CuO-Co3O4 powders is conducted, and pores in the frozen specimens are generated by sublimation of the camphene crystals. The dried bodies are hydrogen-reduced at 500°C and sintered at 800°C for 1 h. The reduction behavior of the CuO-Co3O4 powder mixture is analyzed using a temperature-programmed reduction method in an Ar-10% H2 atmosphere. The sintered bodies show large and aligned parallel pores in the camphene growth direction. In addition, small pores are distributed around the internal walls of the large pores. The size and fraction of the pores decrease as the amount of solid powder added to the slurry increases. The change in pore characteristics according to the amount of the mixed powder is interpreted to be due to the rearrangement and accumulation behavior of the solid particles in the freezing process of the slurry.

- [Korean]

- Fabrication of Macro-porous Carbon Foams from Spherical Phenolic Resin Powder and Furfuryl Alcohol by Casting Molding

- Hyeondeok Jeong, Seiki Kim

- J Korean Powder Metall Inst. 2019;26(6):502-507. Published online December 1, 2019

- DOI: https://doi.org/10.4150/KPMI.2019.26.6.502

- 525 View

- 1 Download

-

Abstract

Abstract

PDF

PDF Macro-porous carbon foams are fabricated using cured spherical phenolic resin particles as a matrix and furfuryl alcohol as a binder through a simple casting molding. Different sizes of the phenolic resin particles from 100–450 μm are used to control the pore size and structure. Ethylene glycol is additionally added as a pore-forming agent and oxalic acid is used as an initiator for polymerization of furfuryl alcohol. The polymerization is performed in two steps; at 80°C and 200°C in an ambient atmosphere. The carbonization of the cured body is performed under Nitrogen gas flow (0.8 L/min) at 800°C for 1 h. Shrinkage rate and residual carbon content are measured by size and weight change after carbonization. The pore structures are observed by both electron and optical microscope and compared with the porosity results achieved by the Archimedes method. The porosity is similar regardless of the size of the phenolic resin particles. On the other hand, the pore size increases in proportion to the phenol resin size, which indicates that the pore structure can be controlled by changing the raw material particle size.

- [Korean]

- Fabrication of Porous Ni by Freeze Drying and Hydrogen Reduction of NiO/Camphene Slurry

- Jae-Hun Jeong, Sung-Tag Oh, Chang-Yong Hyun

- J Korean Powder Metall Inst. 2019;26(1):6-10. Published online February 1, 2019

- DOI: https://doi.org/10.4150/KPMI.2019.26.1.6

- 886 View

- 2 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF In this study, freeze drying of a porous Ni with unidirectionally aligned pore channels is accomplished by using a NiO powder and camphene. Camphene slurries with NiO content of 5 and 10 vol% are prepared by mixing them with a small amount of dispersant at 50°C. Freezing of a slurry is performed at -25°C while the growth direction of the camphene is unidirectionally controlled. Pores are generated subsequently by sublimation of the camphene during drying in air for 48 h. The green bodies are hydrogen-reduced at 400°C and then sintered at 800°C and 900°C for 1 h. X-ray diffraction analysis reveals that the NiO powder is completely converted to the Ni phase without any reaction phases. The sintered samples show large pores that align parallel pores in the camphene growth direction as well as small pores in the internal walls of large pores. The size of large and small pores decreases with increasing powder content from 5 to 10 vol%. The influence of powder content on the pore structure is explained by the degree of powder rearrangement in slurry and the accumulation behavior of powders in the interdendritic spaces of solidified camphene.

-

Citations

Citations to this article as recorded by- Synthesis of Porous Cu-Co using Freeze Drying Process of Camphene Slurry with Oxide Composite Powders

Gyuhwi Lee, Ju-Yeon Han, Sung-Tag Oh

Journal of Korean Powder Metallurgy Institute.2020; 27(3): 193. CrossRef

- Synthesis of Porous Cu-Co using Freeze Drying Process of Camphene Slurry with Oxide Composite Powders

- [Korean]

- Fabrication of Porous Mo-Cu by Freeze Drying and Hydrogen Reduction of Metal Oxide Powders

- Hyunji Kang, Ju-Yeon Han, Sung-Tag Oh

- J Korean Powder Metall Inst. 2019;26(1):1-5. Published online February 1, 2019

- DOI: https://doi.org/10.4150/KPMI.2019.26.1.1

- 940 View

- 3 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF In this study, porous Mo-5 wt% Cu with unidirectionally aligned pores is prepared by freeze drying of camphene slurry with MoO3-CuO powders. Unidirectional freezing of camphene slurry with dispersion stability is conducted at -25°C, and pores in the frozen specimens are generated by sublimation of the camphene crystals. The green bodies are hydrogen-reduced at 750°C and sintered at 1000°C for 1 h. X-ray diffraction analysis reveals that MoO3-CuO composite powders are completely converted to a Mo-and-Cu phase without any reaction phases by hydrogen reduction. The sintered bodies with the Mo-Cu phase show large and aligned parallel pores to the camphene growth direction as well as small pores in the internal walls of large pores. The pore size and porosity decrease with increasing composite powder content from 5 to 10 vol%. The change of pore characteristics is explained by the degree of powder rearrangement in slurry and the accumulation behavior of powders in the interdendritic spaces of solidified camphene.

-

Citations

Citations to this article as recorded by- Characteristic Evaluation of WC Hard Materials According to Ni Content Variation by a Pulsed Current Activated Sintering Process

Hyun-Kuk Park

Korean Journal of Materials Research.2020; 30(12): 672. CrossRef - Effect of α-lath size on the mechanical properties of Ti–6Al–4V using core time hydrogen heat treatment

Gye-Hoon Cho, Jung-Min Oh, Hanjung Kwon, Jae-Won Lim

Materials Science and Technology.2020; 36(7): 858. CrossRef

- Characteristic Evaluation of WC Hard Materials According to Ni Content Variation by a Pulsed Current Activated Sintering Process

- [Korean]

- Fabrication of Al2O3 Dispersed Porous Cu by Freeze Drying of CuO-Al2O3/Camphene Slurry

- Hyunji Kang, Doh-Hyung Riu, Sung-Tag Oh

- J Korean Powder Metall Inst. 2018;25(1):25-29. Published online February 1, 2018

- DOI: https://doi.org/10.4150/KPMI.2018.25.1.25

- 587 View

- 2 Download

-

Abstract

Abstract

PDF

PDF Porous Cu with a dispersion of nanoscale Al2O3 particles is fabricated by freeze-drying CuO-Al2O3/camphene slurry and sintering. Camphene slurries with CuO-Al2O3 contents of 5 and 10 vol% are unidirectionally frozen at -30°C, and pores are generated in the frozen specimens by camphene sublimation during air drying. The green bodies are sintered for 1 h at 700°C and 800°C in H2 atmosphere. The sintered samples show large pores of 100 μm in average size aligned parallel to the camphene growth direction. The internal walls of the large pores feature relatively small pores of ~10 μm in size. The size of the large pores decreases with increasing CuO-Al2O3 content by the changing degree of powder rearrangement in the slurry. The size of the small pores decreases with increasing sintering temperature. Microstructural analysis reveals that 100-nm Al2O3 particles are homogeneously dispersed in the Cu matrix. These results suggest that a porous composite body with aligned large pores could be fabricated by a freeze-drying and H2 reducing process.

- [Korean]

- Effect of Freezing and Sintering Condition of CuO-SnO2/Camphene Slurries on the Pore Structure of Porous Cu-Sn

- Joo-Hyung Kim, Sung-Tag Oh, Chang-Yong Hyun

- J Korean Powder Metall Inst. 2016;23(1):49-53. Published online February 1, 2016

- DOI: https://doi.org/10.4150/KPMI.2016.23.1.49

- 678 View

- 1 Download

- 3 Citations

-

Abstract

Abstract

PDF

PDF The present study demonstrates the effect of freezing conditions on the pore structure of porous Cu-10 wt.% Sn prepared by freeze drying of CuO-SnO2/camphene slurry. Mixtures of CuO and SnO2 powders are prepared by ball milling for 10 h. Camphene slurries with 10 vol.% of CuO-SnO2 are unidirectionally frozen in a mold maintained at a temperature of -30°C for 1 and 24 h, respectively. Pores are generated by the sublimation of camphene at room temperature. After hydrogen reduction and sintering at 650°C for 2 h, the green body of the CuO-SnO2 is completely converted into porous Cu-Sn alloy. Microstructural observation reveals that the sintered samples have large pores which are aligned parallel to the camphene growth direction. The size of the large pores increases from 150 to 300 μm with an increase in the holding time. Also, the internal walls of the large pores contain relatively small pores whose size increases with the holding time. The change in pore structure is explained by the growth behavior of the camphene crystals and rearrangement of the solid particles during the freezing process.

-

Citations

Citations to this article as recorded by- Fabrication of Porous Ni by Freeze Drying and Hydrogen Reduction of NiO/Camphene Slurry

Jae-Hun Jeong, Sung-Tag Oh, Chang-Yong Hyun

Journal of Korean Powder Metallurgy Institute.2019; 26(1): 6. CrossRef - Fabrication of Al2O3 Dispersed Porous Cu by Freeze Drying of CuO-Al2O3/Camphene Slurry

Hyunji Kang, Doh-Hyung Riu, Sung-Tag Oh

journal of Korean Powder Metallurgy Institute.2018; 25(1): 25. CrossRef - Porous W-Ni Alloys Synthesized from Camphene/WO3-NiO Slurry by Freeze Drying and Heat Treatment in Hydrogen Atmosphere

Sung Hyun Park, Seong-Min Park, So-Jeong Park, Bo-Yeong Park, Sung-Tag Oh

Korean Journal of Materials Research.2018; 28(2): 108. CrossRef

- Fabrication of Porous Ni by Freeze Drying and Hydrogen Reduction of NiO/Camphene Slurry

- [Korean]

- Effect of Sublimable Vehicle Compositions in the Camphor-Naphthalene System on the Pore Structure of Porous Cu-Ni

- Na-Yeon Kwon, Myung-Jin Suka, Sung-Tag Oh

- J Korean Powder Metall Inst. 2015;22(5):362-366. Published online October 1, 2015

- DOI: https://doi.org/10.4150/KPMI.2015.22.5.362

- 1,038 View

- 1 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF The effect of sublimable vehicle composition in the camphor-naphthalene system on the pore structure of porous Cu-Ni alloy is investigated. The CuO-NiO mixed slurries with hypoeutectic, eutectic and hypereutectic compositions are frozen into a mold at -25°C. Pores are generated by sublimation of the vehicles at room temperature. After hydrogen reduction at 300°C and sintering at 850°C for 1 h, the green body of CuO-NiO is completely converted to porous Cu-Ni alloy with various pore structures. The sintered samples show large pores which are aligned parallel to the sublimable vehicle growth direction. The pore size and porosity decrease with increase in powder content due to the degree of powder rearrangement in slurry. In the hypoeutectic composition slurry, small pores with dendritic morphology are observed in the sintered Cu-Ni, whereas the specimen of hypereutectic composition shows pore structure of plate shape. The change of pore structure is explained by growth behavior of primary camphor and naphthalene crystals during solidification of camphor-naphthalene alloys.

-

Citations

Citations to this article as recorded by- Freeze Drying Process and Pore Structure Characteristics of Porous Cu with Various Sublimable Vehicles

Gyuhwi Lee, Sung-Tag Oh, Myung-Jin Suk, Young-Keun Jeong

Journal of Korean Powder Metallurgy Institute.2020; 27(3): 198. CrossRef - Interaction of Solid Particles with the Solidifying Front in the Liquid-Particle Mixture

Ho-Suk Lee, Kyu-Hee Lee, Sung-Tag Oh, Young Do Kim, Myung-Jin Suk

Journal of Korean Powder Metallurgy Institute.2018; 25(4): 336. CrossRef

- Freeze Drying Process and Pore Structure Characteristics of Porous Cu with Various Sublimable Vehicles

- [Korean]

- Fabrication of Porous W by Heat Treatment of Pore Forming Agent of PMMA and WO3 Powder Compacts

- Ki Cheol Jeon, Young Do Kim, Myung-Jin Suk, Sung-Tag Oh

- J Korean Powder Metall Inst. 2015;22(2):129-133. Published online April 1, 2015

- DOI: https://doi.org/10.4150/KPMI.2015.22.2.129

- 1,493 View

- 7 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF Porous W with controlled pore structure was fabricated by thermal decomposition and hydrogen reduction process of PMMA beads and WO3 powder compacts. The PMMA sizes of 8 and 50 μm were used as pore forming agent for fabricating the porous W. The WO3 powder compacts with 20 and 70 vol% PMMA were prepared by uniaxial pressing and sintered for 2 h at 1200°C in hydrogen atmosphere. TGA analysis revealed that the PMMA was decomposed at about 400°C and WO3 was reduced to metallic W at 800°C. Large pores in the sintered specimens were formed by thermal decomposition of spherical PMMA, and their size was increased with increase in PMMA size and the amount of PMMA addition. Also the pore shape was changed from spherical to irregular form with increasing PMMA contents due to the agglomeration of PMMA in the powder mixing process.

-

Citations

Citations to this article as recorded by- Synthesis of Porous Silica Particles Using Sodium Silicate Precursor for Water-Repellent Surfaces

Young-Sang Cho, Nahee Ku, Young-Seok Kim

JOURNAL OF CHEMICAL ENGINEERING OF JAPAN.2019; 52(2): 194. CrossRef

- Synthesis of Porous Silica Particles Using Sodium Silicate Precursor for Water-Repellent Surfaces

- [English]

- Processing Methods for the Preparation of Porous Ceramics

- Rizwan Ahmad, Jang-Hoon Ha, In-Hyuck Song

- J Korean Powder Metall Inst. 2014;21(5):389-398. Published online October 1, 2014

- DOI: https://doi.org/10.4150/KPMI.2014.21.5.389

- 3,830 View

- 115 Download

- 22 Citations

-

Abstract

Abstract

PDF

PDF Macroporous ceramics with tailored pore size and shape could be used for well-established and emerging applications, such as molten metal filtration, biomaterial, catalysis, thermal insulation, hot gas filtration and diesel particulate filters. In these applications, unique properties of porous materials were required which could be achieved through the incorporation of macro-pores into ceramics. In this article, we reviewed the main processing techniques which can be used for the fabrication of macroporous ceramics with tailored microstructure. Partial sintering, replica templates, sacrificial fugutives, and direct foaming techniques was described here and compared in terms of micro-structures and mechanical properties that could be achieved. The main focus was given to the direct foaming technique which was simple and versatile approach that allowed the fabrication of macro-porous ceramics with tailored features and properties.

-

Citations

Citations to this article as recorded by- Contribution of microscale stochastic truss models to investigate the macroscale elasticity constants of porous ceramics

Thierry Canet, Gilles Dusserre, Thierry Cutard

European Journal of Mechanics - A/Solids.2025; 111: 105561. CrossRef - Synthesis and properties of high alumina cement-based porous composites in the ZrO2-CaO-Al2O3 system

Yesica L. Bruni, María F. Hernández, Susana Conconi, Gustavo Suárez

Ceramics International.2025; 51(23): 39794. CrossRef - Morphology and phase analysis of cordierite ceramic foams with Ag nanoparticles

J. Kupková, G. Kratošová, K. Čech Barabaszová, G. Simha Martynková

IOP Conference Series: Materials Science and Engineering.2025; 1337(1): 012004. CrossRef - Organic waste-derived pore formers for macroporous ceramics fabrication: A review on synthesis, durability properties and potential applications

T.T. Dele-Afolabi, M.A. Azmah Hanim, A.A. Oyekanmi, M.N.M. Ansari, Surajudeen Sikiru, O.J. Ojo-Kupoluyi

Materials Today Sustainability.2024; 27: 100824. CrossRef - Chemistry and Physics of Wet Foam Stability for Porous Ceramics: A Review

Kamrun Nahar Fatema, Md Rokon Ud Dowla Biswas, Jung Gyu Park, Ik Jin Kim

Micro.2024; 4(4): 552. CrossRef - Investigating mass transfer coefficients in lean methane combustion reaction through the morphological and geometric analysis of structured open cell foam catalysts

Carmen W. Moncada Quintero, Hernan G. Mazzei, Marion Servel, Frédéric Augier, Yacine Haroun, Jean-François Joly, Stefania Specchia

Chemical Engineering Science.2023; 281: 119138. CrossRef - Composite PLGA–Nanobioceramic Coating on Moxifloxacin-Loaded Akermanite 3D Porous Scaffolds for Bone Tissue Regeneration

Georgia K. Pouroutzidou, Lambrini Papadopoulou, Maria Lazaridou, Konstantinos Tsachouridis, Chrysanthi Papoulia, Dimitra Patsiaoura, Ioannis Tsamesidis, Konstantinos Chrissafis, George Vourlias, Konstantinos M. Paraskevopoulos, Antonios D. Anastasiou, Dim

Pharmaceutics.2023; 15(3): 819. CrossRef - Development of high strength large open porosity alumina ceramics using the sacrificial phase route: The role of the sacrificial phase fineness

Julian Alzukaimi, Rafi Jabrah

Ceramics International.2023; 49(2): 2923. CrossRef - Sustainable nanocomposite porous absorbent and membrane sieves: Definition, classification, history, properties, synthesis, applications, and future prospects

Sameer Ahmad, Weqar Ahmad Siddiqi, Sharif Ahmad

Journal of Environmental Chemical Engineering.2023; 11(2): 109367. CrossRef - Processing and characterization of porous composites based on CaAl4O7/CaZrO3

Yesica L. Bruni, María S. Conconi, María F. Hernández, Gustavo Suárez

Ceramics International.2023; 49(23): 37630. CrossRef - Trace addition of cellulose nanofiber in gel-casting system for structurally controlled porous ceramics towards superior thermal-insulating property

Yunzi Xin, Takashi Shirai

Journal of the Ceramic Society of Japan.2022; 130(5): 355. CrossRef - State-of-the-art review of fabrication, application, and mechanical properties of functionally graded porous nanocomposite materials

Ismail Barbaros, Yongmin Yang, Babak Safaei, Zhicheng Yang, Zhaoye Qin, Mohammed Asmael

Nanotechnology Reviews.2022; 11(1): 321. CrossRef - A review of petroleum emulsification types, formation factors, and demulsification methods

Ahmed Abdulrazzaq Hadi, Ali Abdulkhabeer Ali

Materials Today: Proceedings.2022; 53: 273. CrossRef - SLURRY OPTIMISATION FOR FAST FREEZE-DRYING OF POROUS ALUMINA

Kritkaew Somton

Ceramics - Silikaty.2021; : 368. CrossRef - Recycling food, agricultural, and industrial wastes as pore-forming agents for sustainable porous ceramic production: A review

Siti Zuliana Salleh, Afiqah Awang Kechik, Abdul Hafidz Yusoff, Mustaffa Ali Azhar Taib, Maryana Mohamad Nor, Mardawani Mohamad, Tse Guan Tan, Arlina Ali, Mohamad Najmi Masri, Julie Juliewatty Mohamed, Siti Koriah Zakaria, Jia Geng Boon, Faisal Budiman, Pa

Journal of Cleaner Production.2021; 306: 127264. CrossRef - Novel noble-metal-free ceramic filter with controlled pore structure for environmental cleaning

Yunzi Xin, Sohei Nakagawa, Harumitsu Nishikawa, Takashi Shirai

Ceramics International.2021; 47(8): 11819. CrossRef - Fabrication of porous titania sheet via tape casting: Microstructure and water permeability study

Saber Ghannadi, Hossein Abdizadeh, Alireza Babaei

Ceramics International.2020; 46(7): 8689. CrossRef - Farklı Bağlayıcı ve Sinterleme Katkılarının SiC Seramik Prefom Mikroyapısı Üzerine Etkisi

Ebru Yılmaz, Fatih Çalışkan

Academic Perspective Procedia.2019; 2(3): 1309. CrossRef - The preparation and characterization of porous alumina ceramics using an eco‐friendly pore‐forming agent

Julian Alzukaimi, Rafi Jabrah

International Journal of Applied Ceramic Technology.2019; 16(2): 820. CrossRef - Wet Foam Stability from Colloidal Suspension to Porous Ceramics: A Review

Ik Jin Kim, Jung Gyu Park, Young Han Han, Suk Young Kim, James F. Shackelford

Journal of the Korean Ceramic Society.2019; 56(3): 211. CrossRef - Processing of porous alumina by foaming method-effect of foaming agent, solid loading and binder

Soumya Devavarapu, Paritosh Chaudhuri, Aroh Shrivastava, Santanu Bhattacharyya

Ceramics International.2019; 45(9): 12264. CrossRef - Macroporous flexible polyvinyl alcohol lithium adsorbent foam composite prepared via surfactant blending and cryo-desiccation

Grace M. Nisola, Lawrence A. Limjuco, Eleazer L. Vivas, Chosel P. Lawagon, Myoung Jun Park, Ho Kyong Shon, Neha Mittal, In Wook Nah, Hern Kim, Wook-Jin Chung

Chemical Engineering Journal.2015; 280: 536. CrossRef

- Contribution of microscale stochastic truss models to investigate the macroscale elasticity constants of porous ceramics

- [Korean]

- Effect of Solidification Condition of Sublimable Vehicles on the Pore Characteristics in Freeze Drying Process

- Myung-Jin Suk, Ji Soon Kim, Sung-Tag Oh

- J Korean Powder Metall Inst. 2014;21(5):366-370. Published online October 1, 2014

- DOI: https://doi.org/10.4150/KPMI.2014.21.5.366

- 722 View

- 1 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF The present study demonstrates the effect of solidification condition on the pore structure in freeze drying process using the slurries of CuO/sublimable vehicles. Camphene and Camphor-45 wt% naphthalene based slurries with 14 vol% CuO powder were frozen into a mold at -25°C, followed by sublimation at room temperature. The green bodies were hydrogen-reduced and sintered at 500°C for 1 h. The porous Cu specimen, frozen the CuO/camphene slurry into the heated mold of the upper part, showed large pores with unidirectional pore channels and small pores in their internal wall. Also, it was observed that the size of large pores was decreasing near the bottom part of specimen. The change of pore structure depending on the freezing condition was explained by the nucleation behavior of camphene crystals and rearrangement of solid powders during solidification. In case of porous Cu prepared from CuO/Camphornaphthalene system, the pore structure exhibited plate shape as a replica of the original structure of crystallized vehicles with hypereutectic composition.

-

Citations

Citations to this article as recorded by- Interaction of Solid Particles with the Solidifying Front in the Liquid-Particle Mixture

Ho-Suk Lee, Kyu-Hee Lee, Sung-Tag Oh, Young Do Kim, Myung-Jin Suk

Journal of Korean Powder Metallurgy Institute.2018; 25(4): 336. CrossRef - Fabrication of Ti Porous body with Improved Specific Surface Area by Synthesis of CNTs

Hye Rim Choi, Jong Min Byun, Myung-Jin Suk, Sung-Tag Oh, Young Do Kim

Journal of Korean Powder Metallurgy Institute.2016; 23(3): 235. CrossRef

- Interaction of Solid Particles with the Solidifying Front in the Liquid-Particle Mixture

- [Korean]

- Fabrication of Porous Cu-Ni by Freeze Drying and Hydrogen Reduction of CuO-NiO Powder Mixture

- Han Gil Seo, Sung-Tag Oh

- J Korean Powder Metall Inst. 2014;21(1):34-38. Published online February 1, 2014

- DOI: https://doi.org/10.4150/KPMI.2014.21.1.34

- 846 View

- 0 Download

- 3 Citations

-

Abstract

Abstract

PDF

PDF Cu-Ni alloys with unidirectionally aligned pores were prepared by freeze-drying process of CuO-NiO/camphene slurry. Camphene slurries with dispersion stability by the addition of oligomeric polyester were frozen at -25°C, and pores in the frozen specimens were generated by sublimation of the camphene during drying in air. The green bodies were hydrogen-reduced at 300°C and sintered at 850°C for 1 h. X-ray diffraction analysis revealed that CuO-NiO composite powders were completely converted to Cu-Ni alloy without any reaction phases by hydrogen reduction. The sintered samples showed large and aligned parallel pores to the camphene growth direction, and small pores in the internal wall of large pores. The pore size and porosity decreased with increase in CuO-NiO content from 5 to 10 vol%. The change of pore characteristics was explained by the degree of powder rearrangement in slurry and the accumulation behavior of powders in the interdendritic spaces of solidified camphene.

-

Citations

Citations to this article as recorded by- Enhancement in electrical conductivity of pastes containing submicron Ag-coated Cu filler with palmitic acid surface modification

Eun Byeol Choi, Jong-Hyun Lee

Applied Surface Science.2017; 415: 67. CrossRef - Investigation for Microstructure and Hardness of Welded Zone of Cu-Ni Alloy using W92-Ni-Fe Sintering Tool

Tae-Jin Yoon, Sang-Won Park, Myung-Chang Kang, Joong-Suk Noh, Sung-Wook Chung, Chung-Yun Kang

Journal of Korean Powder Metallurgy Institute.2015; 22(3): 181. CrossRef - Controlling Structural and Electrical Properties of Pt Nanopowder-Dispersed SiO2Film

Jae Ho Lee, In Joo Shin, Sung Woo Lee, Hyeong Cheol Kim, Byung Joon Choi

Journal of Korean Powder Metallurgy Institute.2014; 21(5): 355. CrossRef

- Enhancement in electrical conductivity of pastes containing submicron Ag-coated Cu filler with palmitic acid surface modification

TOP

KPMI

KPMI

First

First Prev

Prev