Search

- Page Path

- HOME > Search

- [English]

- Laser Processing of an Al0.1CoCrFeNi High Entropy Alloy + Cu Composite Powders via Laser Powder Bed Fusion

- Kwangtae Son, Ji-Woon Lee, Soon-Jik Hong, Somayeh Pasebani

- J Powder Mater. 2025;32(4):277-287. Published online August 29, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00101

- 1,115 View

- 25 Download

-

Abstract

Abstract

PDF

PDF - This study examined process–structure relationships in laser powder bed fusion of Al₀.₁CoCrFeNi + Cu composites, focusing on densification, elemental distribution, and solidification cracking. Mechanically mixed Al₀.₁CoCrFeNi and Cu powders were processed across a range of laser powers (100–250 W) and scan speeds (200–800 mm/s). Increased volumetric energy density (VED) improved densification, with a plateau near 200 J/mm³ yielding ~96% relative density; however, this value was still below application-grade thresholds. At low VED, insufficient thermal input and short melt pool residence times promoted Cu segregation, while higher VED facilitated improved elemental mixing. Elemental mapping showed partial co-segregation of Ni with Cu at low energies. Solidification cracks were observed across all processing conditions. In high VED regimes, cracking exhibited a minimal correlation with segregation behavior and was primarily attributed to steep thermal gradients, solidification shrinkage, and residual stress accumulation. In contrast, at low VED, pronounced Cu segregation appeared to exacerbate cracking through localized thermal and mechanical mismatch.

- [English]

- Thermodynamic and Electronic Descriptor-Driven Machine Learning for Phase Prediction in High-Entropy Alloys: Experimental Validation

- Nguyen Lam Khoa, Nguyen Duy Khanh, Hoang Thi Ngoc Quyen, Nguyen Thi Hoang Oanh, , Le Hong Thang, Nguyen Hoa Khiem, Nguyen Hoang Viet

- J Powder Mater. 2025;32(3):191-201. Published online June 30, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00143

- 2,436 View

- 79 Download

- 3 Citations

-

Abstract

Abstract

PDF

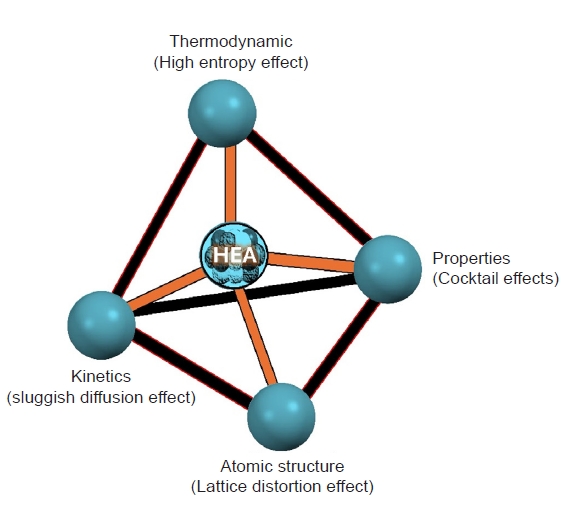

PDF - High-entropy alloys (HEAs) exhibit complex phase formation behavior, challenging conventional predictive methods. This study presents a machine learning (ML) framework for phase prediction in HEAs, using a curated dataset of 648 experimentally characterized compositions and features derived from thermodynamic and electronic descriptors. Three classifiers—random forest, gradient boosting, and CatBoost—were trained and validated through cross-validation and testing. Gradient boosting achieved the highest accuracy, and valence electron concentration (VEC), atomic size mismatch (δ), and enthalpy of mixing (ΔHmix) were identified as the most influential features. The model predictions were experimentally verified using a non-equiatomic Al₃₀Cu₁₇.₅Fe₁₇.₅Cr₁₇.₅Mn₁₇.₅ alloy and the equiatomic Cantor alloy (CoCrFeMnNi), both of which showed strong agreement with predicted phase structures. The results demonstrate that combining physically informed feature engineering with ML enables accurate and generalizable phase prediction, supporting accelerated HEA design.

-

Citations

Citations to this article as recorded by- Effect of annealing temperature on thermal expansion and cryogenic mechanical properties of low-thermal-expansion Co22.2Cr6.2Fe48.8Ni17.8Cu5.0 medium-entropy alloy

Wooyoung Lee, Munsu Choi, Sungwook Kim, Dae-Kyeom Kim, Myungsuk Song, Taek-Soo Kim, Jungwan Lee, Hyoung Seop Kim, Hyunjoo Choi, Soo-Hyun Joo

Materials Science and Engineering: A.2026; 954: 149811. CrossRef - Preparation and Arc Erosion Behavior of Cu-Based Contact Materials Reinforced with High Entropy Particles CuCrNiCoFe

Jiacheng Tong, Jun Wang, Huimin Zhang, Haoran Liu, Youchang Sun, Zhiguo Li, Wenyi Zhang, Zhe Wang, Yanli Chang, Zhao Yuan, Henry Hu

Metallurgical and Materials Transactions B.2025; 56(5): 5948. CrossRef - Recent progresses on high entropy alloy development using machine learning: A review

Abhishek Kumar, Nilay Krishna Mukhopadhyay, Thakur Prasad Yadav

Computational Materials Today.2025; 8: 100038. CrossRef

- Effect of annealing temperature on thermal expansion and cryogenic mechanical properties of low-thermal-expansion Co22.2Cr6.2Fe48.8Ni17.8Cu5.0 medium-entropy alloy

- [Korean]

- Fabrication and Alloying Behavior of Ultra-Lightweight AlTiCrVMg High-Entropy Alloy via Al-Mg Mutual Solubility and Sintering Control

- Eunhyo Song, Hansung Lee, Byungmin Ahn

- J Powder Mater. 2025;32(3):254-261. Published online June 12, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00059

- 666 View

- 23 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF - High-entropy alloys (HEAs) incorporating low-melting-point elements (Mg and Al) and high-melting-point elements (Ti, Cr, and V) were fabricated via mechanical alloying and spark plasma sintering. Sintering temperatures were varied to investigate phase behavior and microstructural evolution. X-ray diffraction was used to identify phase structures, scanning electron microscopy to analyze microstructures, X-ray fluorescence to determine elemental composition, and a gas pycnometer to measure density. Micro-Vickers hardness testing was conducted to evaluate mechanical properties. Mechanical-alloyed HEAs exhibited a body-centered cubic (BCC) phase and lamellar structures with element-enriched regions. Sintering introduced additional BCC and Laves phases, while higher temperatures promoted Mg liquid-phase sintering, increasing density and hardness. This study highlights the effects of sintering on HEAs containing elements with differing melting points to optimize their properties.

-

Citations

Citations to this article as recorded by- Effect of annealing temperature on thermal expansion and cryogenic mechanical properties of low-thermal-expansion Co22.2Cr6.2Fe48.8Ni17.8Cu5.0 medium-entropy alloy

Wooyoung Lee, Munsu Choi, Sungwook Kim, Dae-Kyeom Kim, Myungsuk Song, Taek-Soo Kim, Jungwan Lee, Hyoung Seop Kim, Hyunjoo Choi, Soo-Hyun Joo

Materials Science and Engineering: A.2026; 954: 149811. CrossRef

- Effect of annealing temperature on thermal expansion and cryogenic mechanical properties of low-thermal-expansion Co22.2Cr6.2Fe48.8Ni17.8Cu5.0 medium-entropy alloy

- [English]

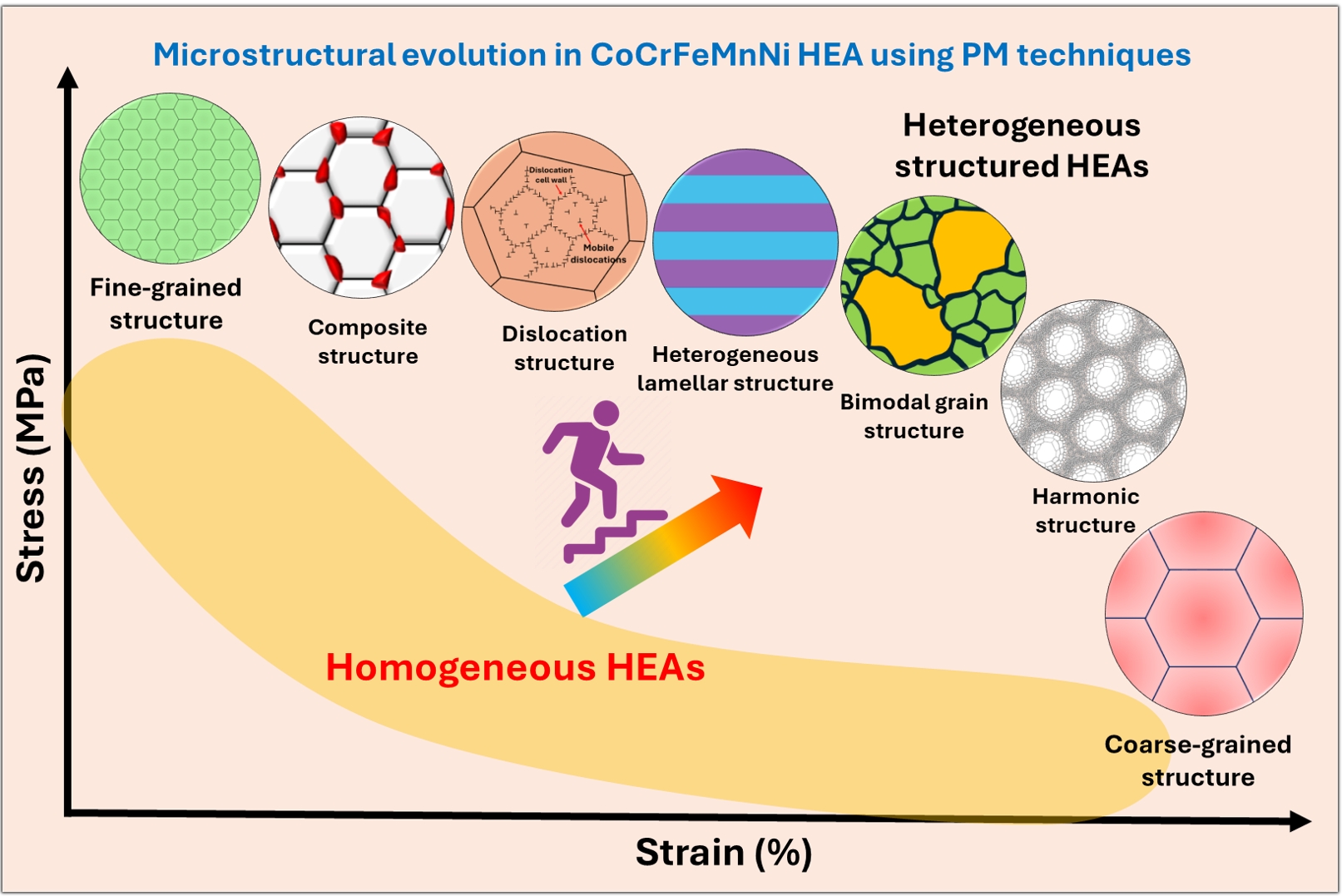

- A Review of Recent Developments in CoCrFeMnNi High-Entropy Alloys Processed by Powder Metallurgy

- Cheenepalli Nagarjuna, Sheetal Kumar Dewangan, Hansung Lee, Eunhyo Song, K. Raja Rao, Byungmin Ahn

- J Powder Mater. 2025;32(2):145-164. Published online April 30, 2025

- DOI: https://doi.org/10.4150/jpm.2024.00430

- 4,526 View

- 118 Download

- 4 Citations

-

Abstract

Abstract

PDF

PDF - In recent years, high-entropy alloys (HEAs) have attracted considerable attention in materials engineering due to their unique phase stability and mechanical properties compared to conventional alloys. Since the inception of HEAs, CoCrFeMnNi alloys have been widely investigated due to their outstanding strength and fracture toughness at cryogenic temperatures. However, their lower yield strength at room temperature limits their structural applications. The mechanical properties of HEAs are greatly influenced by their processing methods and microstructural features. Unlike traditional melting techniques, powder metallurgy (PM) provides a unique opportunity to produce HEAs with nanocrystalline structures and uniform compositions. The current review explores recent advances in optimizing the microstructural characteristics in CoCrFeMnNi HEAs by using PM techniques to improve mechanical performance. The most promising strategies include grain refinement, dispersion strengthening, and the development of heterogeneous microstructures (e.g., harmonic, bimodal, and multi-metal lamellar structures). Thermomechanical treatments along with additive manufacturing techniques are also summarized. Additionally, the review addresses current challenges and suggests future research directions for designing advanced HEAs through PM techniques.

-

Citations

Citations to this article as recorded by- Effect of annealing temperature on thermal expansion and cryogenic mechanical properties of low-thermal-expansion Co22.2Cr6.2Fe48.8Ni17.8Cu5.0 medium-entropy alloy

Wooyoung Lee, Munsu Choi, Sungwook Kim, Dae-Kyeom Kim, Myungsuk Song, Taek-Soo Kim, Jungwan Lee, Hyoung Seop Kim, Hyunjoo Choi, Soo-Hyun Joo

Materials Science and Engineering: A.2026; 954: 149811. CrossRef - Structural and mechanical characteristics of high-entropy CoCrFeMnNi alloys manufactured by vacuum induction melting

V. K. Drobyshev, I. A. Panchenko, S. V. Konovalov, E. M. Zapolskaya

Russian Physics Journal.2026;[Epub] CrossRef - Sustainable powder metallurgy route to Densify oxide-derived CoCrFeNi high-entropy alloy

Taehyeob Im, Minjong Kim, Gertrude Mugwe Mongella, Nelson Bayi, Caroline Sunyong Lee

Materials Today Sustainability.2026; 34: 101330. CrossRef - Thermodynamic and Electronic Descriptor-Driven Machine Learning for Phase Prediction in High-Entropy Alloys: Experimental Validation

Nguyen Lam Khoa, Nguyen Duy Khanh, Hoang Thi Ngoc Quyen, Nguyen Thi Hoang, Oanh, Le Hong Thang, Nguyen Hoa Khiem, Nguyen Hoang Viet

Journal of Powder Materials.2025; 32(3): 191. CrossRef

- Effect of annealing temperature on thermal expansion and cryogenic mechanical properties of low-thermal-expansion Co22.2Cr6.2Fe48.8Ni17.8Cu5.0 medium-entropy alloy

- [English]

- Advances in Powder Metallurgy for High-Entropy Alloys

- Sheetal Kumar Dewangan, Cheenepalli Nagarjuna, Hansung Lee, K. Raja Rao, Man Mohan, Reliance Jain, Byungmin Ahn

- J Powder Mater. 2024;31(6):480-492. Published online December 31, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00297

- 5,026 View

- 169 Download

- 5 Citations

-

Abstract

Abstract

PDF

PDF - High-entropy alloys (HEAs) represent a revolutionary class of materials characterized by their multi-principal element compositions and exceptional mechanical properties. Powder metallurgy, a versatile and cost-effective manufacturing process, offers significant advantages for the development of HEAs, including precise control over their composition, microstructure, and mechanical properties. This review explores innovative approaches integrating powder metallurgy techniques in the synthesis and optimization of HEAs. Key advances in powder production, sintering methods, and additive manufacturing are examined, highlighting their roles in improving the performance, advancement, and applicability of HEAs. The review also discusses the mechanical properties, potential industrial applications, and future trends in the field, providing a comprehensive overview of the current state and future prospects of HEA development using powder metallurgy.

-

Citations

Citations to this article as recorded by- Effect of Pressure and Temperature on the Microstructure and Vickers Microhardness of the CoCrFeMnNiAl1.5 Alloy During Conventional Sintering and High-Frequency Induction Sintering

Leonardo Baylón García, José Manuel Mendoza Duarte, Ivanovich Estrada Guel, Audel Santos Beltrán, Hansel Manuel Medrano Prieto, Gustavo Rodríguez Cabriales, Enrique Rocha Rangel, José Luis Hernández Rivera, Roberto Martínez Sánchez, Alfredo Martínez Garcí

Coatings.2026; 16(3): 275. CrossRef - Sustainable powder metallurgy route to Densify oxide-derived CoCrFeNi high-entropy alloy

Taehyeob Im, Minjong Kim, Gertrude Mugwe Mongella, Nelson Bayi, Caroline Sunyong Lee

Materials Today Sustainability.2026; 34: 101330. CrossRef - Fabrication and Alloying Behavior of Ultra-Lightweight AlTiCrVMg High-Entropy Alloy via Al-Mg Mutual Solubility and Sintering Control

Eunhyo Song, Hansung Lee, Byungmin Ahn

Journal of Powder Materials.2025; 32(3): 254. CrossRef - Thermodynamic and Electronic Descriptor-Driven Machine Learning for Phase Prediction in High-Entropy Alloys: Experimental Validation

Nguyen Lam Khoa, Nguyen Duy Khanh, Hoang Thi Ngoc Quyen, Nguyen Thi Hoang, Oanh, Le Hong Thang, Nguyen Hoa Khiem, Nguyen Hoang Viet

Journal of Powder Materials.2025; 32(3): 191. CrossRef - Latest Advancements and Mechanistic Insights into High-Entropy Alloys: Design, Properties and Applications

Anthoula Poulia, Alexander E. Karantzalis

Materials.2025; 18(24): 5616. CrossRef

- Effect of Pressure and Temperature on the Microstructure and Vickers Microhardness of the CoCrFeMnNiAl1.5 Alloy During Conventional Sintering and High-Frequency Induction Sintering

- [English]

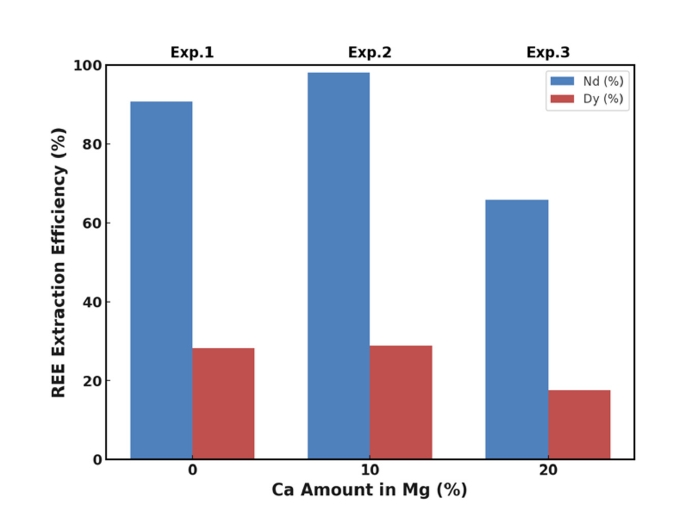

- Effect of Calcium Addition on the High-Temperature Recovery of Nd and Dy from Nd-Fe-B Scrap Using Mg-Based Extractants

- Hyoseop Kim

- J Powder Mater. 2024;31(6):493-499. Published online December 31, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00283

- 1,694 View

- 18 Download

-

Abstract

Abstract

PDF

PDF - This study investigated whether calcium (Ca) addition improved the recovery of neodymium (Nd) and dysprosium (Dy) from Nd-Fe-B magnet scrap using magnesium (Mg)-based liquid metal extraction (LME). Traditional LME processes are limited to temperatures up to 850 °C due to oxidation issues, reducing the efficiency of rare earth element (REE) recovery, especially for Dy. By adding 10 wt.% Ca to Mg and increasing the processing temperature to 1,000 °C, we achieved nearly 100% Nd and approximately 38% Dy recovery, compared to 91% and 28%, respectively, with pure Mg at 850 °C. However, excessive Ca addition (20 wt.%) decreased the recovery efficiency due to the formation of stable intermetallic compounds. These results highlight the critical role of Ca in optimizing REE recycling from Nd-Fe-B magnet scrap.

- [English]

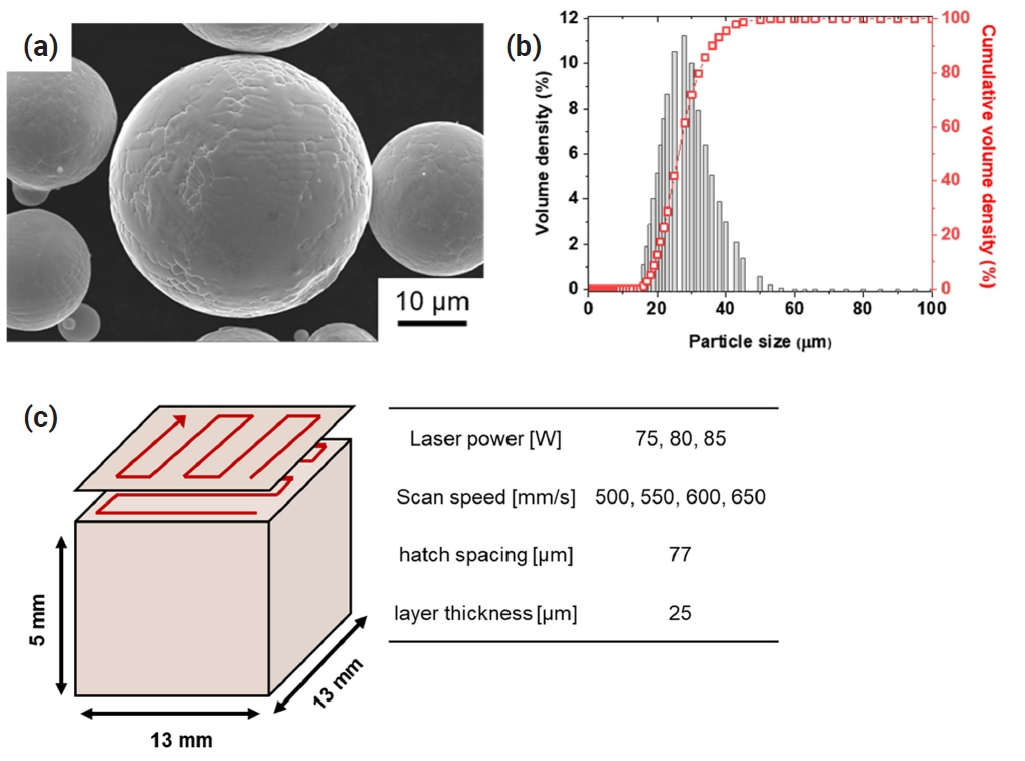

- Hot-Cracking Behaviors in (CoNi)85Mo15 Medium-Entropy Alloys Manufactured via Powder Bed Fusion

- Seungjin Nam, Heechan Jung, Haeum Park, Chahee Jung, Jeong Min Park, Hyoung Seop Kim, Seok Su Sohn

- J Powder Mater. 2024;31(6):537-545. Published online December 31, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00262

- 1,413 View

- 27 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF - Additive manufacturing makes it possible to improve the mechanical properties of alloys through segregation engineering of specific alloying elements into the dislocation cell structure. In this study, we investigated the mechanical and microstructural characteristics of CoNi-based medium-entropy alloys (MEAs), including the refractory alloying element Mo with a large atomic radius, manufactured via laser-powder bed fusion (L-PBF). In an analysis of the printability depending on the processing parameters, we achieved a high compressive yield strength up to 653 MPa in L-PBF for (CoNi)85Mo15 MEAs. However, severe residual stress remained at high-angle grain boundaries, and a brittle µ phase was precipitated at Mo-segregated dislocation cells. These resulted in hot-cracking behaviors in (CoNi)85Mo15 MEAs during L-PBF. These findings highlight the need for further research to adjust the Mo content and processing techniques to mitigate cracking behaviors in L-PBF-manufactured (CoNi)85Mo15 MEAs.

-

Citations

Citations to this article as recorded by- Effect of Support Structure on Residual Stress Distribution in Ti-6Al-4V Alloy Fabricated by Laser Powder Bed Fusion

Seungyeon Lee, Haeum Park, Min Jae Baek, Dong Jun Lee, Jae Wung Bae, Ji-Hun Yu, Jeong Min Park

Journal of Powder Materials.2025; 32(3): 244. CrossRef

- Effect of Support Structure on Residual Stress Distribution in Ti-6Al-4V Alloy Fabricated by Laser Powder Bed Fusion

- [Korean]

- Effect of Sintering Conditions on the Microstructure of an FeCrMnNiCo High-Entropy Alloy

- Seonghyun Park, Sang-Hwa Lee, Junho Lee, Seok-Jae Lee, Jae-Gil Jung

- J Powder Mater. 2024;31(5):406-413. Published online October 31, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00185

- 1,292 View

- 40 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF - We investigated the microstructure of an FeCrMnNiCo alloy fabricated by spark plasma sintering under different sintering temperatures (1000–1100°C) and times (1–600 s). All sintered alloys consisted of a single face-centered cubic phase. As the sintering time or temperature increased, the grains of the sintered alloys became partially coarse. The formation of Cr7C3 carbide occurred on the surface of the sintered alloys due to carbon diffusion from the graphite crucible. The depth of the layer containing Cr7C3 carbides increased to ~110 μm under severe sintering conditions (1100°C, 60 s). A molten zone was observed on the surface of the alloys sintered at higher temperatures (>1060°C) due to severe carbon diffusion that reduced the melting point of the alloy. The porosity of the sintered alloys decreased with increasing time at 1000°C, but increased at higher temperatures above 1060°C due to melting-induced porosity formation.

-

Citations

Citations to this article as recorded by- Fabrication and Alloying Behavior of Ultra-Lightweight AlTiCrVMg High-Entropy Alloy via Al-Mg Mutual Solubility and Sintering Control

Eunhyo Song, Hansung Lee, Byungmin Ahn

Journal of Powder Materials.2025; 32(3): 254. CrossRef - Microstructure and mechanical properties of oxide-dispersion-strengthened CrMnFeCoNiC0.2O0.2 high-entropy alloy fabricated by mechanical alloying and spark plasma sintering

Sang-Hwa Lee, Seonghyun Park, Ka Ram Lim, Seok-Jae Lee, Jae-Gil Jung

Materials Science and Engineering: A.2025; 947: 149284. CrossRef

- Fabrication and Alloying Behavior of Ultra-Lightweight AlTiCrVMg High-Entropy Alloy via Al-Mg Mutual Solubility and Sintering Control

- [English]

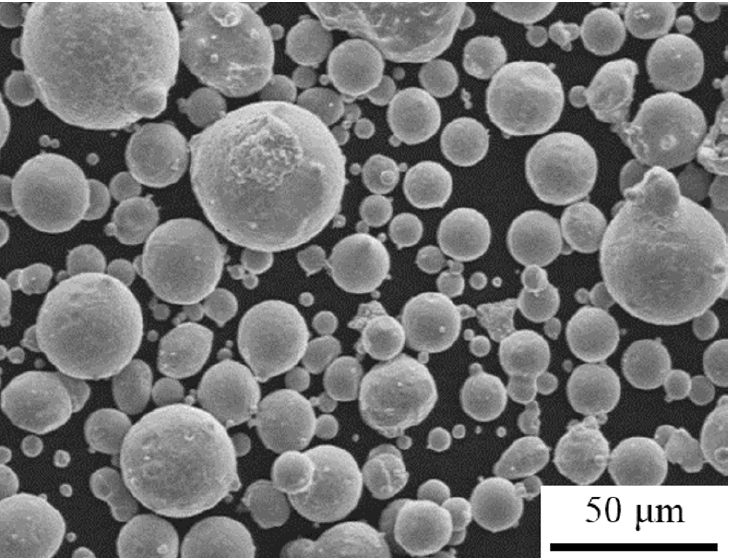

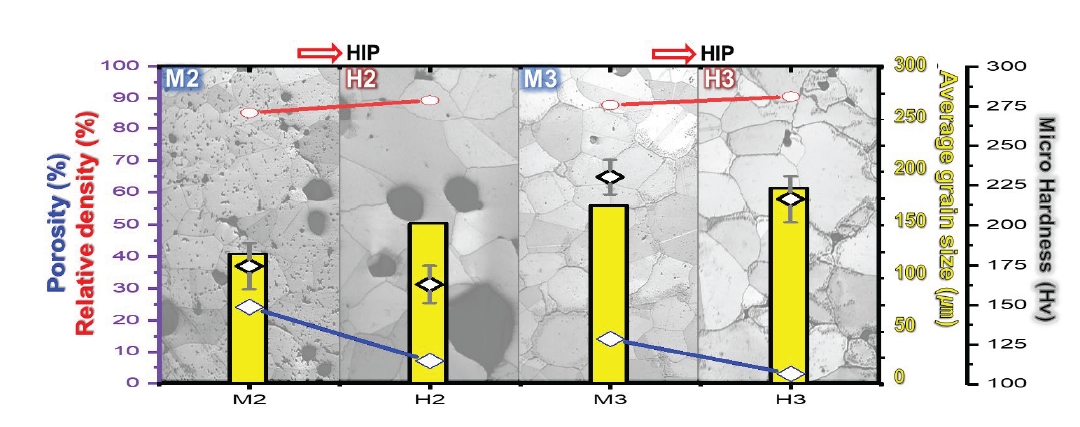

- Characterization of the Manufacturing Process and Mechanical Properties of CoCrFeMnNi High-Entropy Alloys via Metal Injection Molding and Hot Isostatic Pressing

- Eun Seong Kim, Jae Man Park, Do Won Lee, Hyojeong Ha, Jungho Choe, Jaemin Wang, Seong Jin Park, Byeong-Joo Lee, Hyoung Seop Kim

- J Powder Mater. 2024;31(3):243-254. Published online June 27, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00059

- 2,235 View

- 56 Download

-

Abstract

Abstract

PDF

PDF - High-entropy alloys (HEAs) have been reported to have better properties than conventional materials; however, they are more expensive due to the high cost of their main components. Therefore, research is needed to reduce manufacturing costs. In this study, CoCrFeMnNi HEAs were prepared using metal injection molding (MIM), which is a powder metallurgy process that involves less material waste than machining process. Although the MIM-processed samples were in the face-centered cubic (FCC) phase, porosity remained after sintering at 1200°C, 1250°C, and 1275°C. In this study, the hot isostatic pressing (HIP) process, which considers both temperature (1150°C) and pressure (150 MPa), was adopted to improve the quality of the MIM samples. Although the hardness of the HIP-treated samples decreased slightly and the Mn composition was significantly reduced, the process effectively eliminated many pores that remained after the 1275°C MIM process. The HIP process can improve the quality of the alloy.

- [Korean]

- Combinatorial Experiment for Al-6061 and Al-12Si alloy Based on Directed Energy Deposition (DED) Process

- Seoyeon Jeon, Suwon Park, Yongwook Song, Jiwon Park, Hyunyoung Park, Boram Lee, Hyunjoo Choi

- J Powder Mater. 2023;30(6):463-469. Published online December 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.6.463

- 2,055 View

- 45 Download

- 4 Citations

-

Abstract

Abstract

PDF

PDF Aluminum alloys, known for their high strength-to-weight ratios and impressive electrical and thermal conductivities, are extensively used in numerous engineering sectors, such as aerospace, automotive, and construction. Recently, significant efforts have been made to develop novel aluminum alloys specifically tailored for additive manufacturing. These new alloys aim to provide an optimal balance between mechanical properties and thermal/ electrical conductivities. In this study, nine combinatorial samples with various alloy compositions were fabricated using direct energy deposition (DED) additive manufacturing by adjusting the feeding speeds of Al6061 alloy and Al-12Si alloy powders. The effects of the alloying elements on the microstructure, electrical conductivity, and hardness were investigated. Generally, as the Si and Cu contents decreased, electrical conductivity increased and hardness decreased, exhibiting trade-off characteristics. However, electrical conductivity and hardness showed an optimal combination when the Si content was adjusted to below 4.5 wt%, which can sufficiently suppress the grain boundary segregation of the α- Si precipitates, and the Cu content was controlled to induce the formation of Al2Cu precipitates.

-

Citations

Citations to this article as recorded by- Development of Aluminum Alloys for Additive Manufacturing Using Machine Learning

Sungbin An, Juyeon Han, Seoyeon Jeon, Dowon Kim, Jae Bok Seol, Hyunjoo Choi

Journal of Powder Materials.2025; 32(3): 202. CrossRef - Trends in Materials Modeling and Computation for Metal Additive Manufacturing

Seoyeon Jeon, Hyunjoo Choi

journal of Korean Powder Metallurgy Institute.2024; 31(3): 213. CrossRef - The Challenges and Advances in Recycling/Re-Using Powder for Metal 3D Printing: A Comprehensive Review

Alex Lanzutti, Elia Marin

Metals.2024; 14(8): 886. CrossRef - Microstructural Effects on the Mechanical Properties of Ti-6Al-4V Fabricated by Direct Energy Deposition

Juho Kim, Seoyeon Jeon, Hwajin Park, Taeyoel Kim, Hyunjoo Choi

Journal of Powder Materials.2024; 31(4): 302. CrossRef

- Development of Aluminum Alloys for Additive Manufacturing Using Machine Learning

- [Korean]

- Exploration of Aluminum Alloy using Multi-feeder 3D Additive Manufacturing-based Combinatorial Experiment

- Suwon Park, Yongwook Song, Jiyoon Yeo, Songyun Han, Hyunjoo Choi

- J Powder Mater. 2023;30(3):255-261. Published online June 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.3.255

- 1,590 View

- 8 Download

- 3 Citations

-

Abstract

Abstract

PDF

PDF Aluminum alloys are widely utilized in diverse industries, such as automobiles, aerospace, and architecture, owing to their high specific strength and resistance to oxidation. However, to meet the increasing demands of the industry, it is necessary to design new aluminum alloys with excellent properties. Thus, a new method is required to efficiently test additively manufactured aluminum alloys with various compositions within a short period during the alloy design process. In this study, a combinatory approach using a direct energy deposition system for metal 3D printing process with a dual feeder was employed. Two types of aluminum alloy powders, namely Al6061 and Al-12Cu, were utilized for the combinatory test conducted through 3D printing. Twelve types of Al-Si-Cu-Mg alloys were manufactured during this combinatory test, and the relationship between their microstructures and properties was investigated.

-

Citations

Citations to this article as recorded by- Trends in Materials Modeling and Computation for Metal Additive Manufacturing

Seoyeon Jeon, Hyunjoo Choi

journal of Korean Powder Metallurgy Institute.2024; 31(3): 213. CrossRef - Microstructural Effects on the Mechanical Properties of Ti-6Al-4V Fabricated by Direct Energy Deposition

Juho Kim, Seoyeon Jeon, Hwajin Park, Taeyoel Kim, Hyunjoo Choi

Journal of Powder Materials.2024; 31(4): 302. CrossRef - Combinatorial Experiment for Al-6061 and Al-12Si alloy Based on Directed Energy Deposition (DED) Process

Seoyeon Jeon, Suwon Park, Yongwook Song, Jiwon Park, Hyunyoung Park, Boram Lee, Hyunjoo Choi

journal of Korean Powder Metallurgy Institute.2023; 30(6): 463. CrossRef

- Trends in Materials Modeling and Computation for Metal Additive Manufacturing

- [English]

- Fabrication of Equiatomic CoCrFeMnNi High-Entropy Alloy by Metal Injection Molding Process Using Coarse-Sized Powders

- Eun Seong Kim, Jae Man Park, Ji Sun Lee, Jungho Choe, Soung Yeoul Ahn, Sang Guk Jeong, Do Won Lee, Seong Jin Park, Hyoung Seop Kim

- J Powder Mater. 2023;30(1):1-6. Published online February 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.1.1

- 1,794 View

- 33 Download

- 3 Citations

-

Abstract

Abstract

PDF

PDF High-entropy alloys (HEAs) are attracting attention because of their excellent properties and functions; however, they are relatively expensive compared with commercial alloys. Therefore, various efforts have been made to reduce the cost of raw materials. In this study, MIM is attempted using coarse equiatomic CoCrFeMnNi HEA powders. The mixing ratio (powder:binder) for HEA feedstock preparation is explored using torque rheometer. The block-shaped green parts are fabricated through a metal injection molding process using feedstock. The thermal debinding conditions are explored by thermogravimetric analysis, and solvent and thermal debinding are performed. It is densified under various sintering conditions considering the melting point of the HEA. The final product, which contains a small amount of non-FCC phase, is manufactured at a sintering temperature of 1250°C.

-

Citations

Citations to this article as recorded by- Development of 3D interconnected nanoporous TiZrHfNbTaNi high-entropy alloy via liquid metal dealloying and subsequent synthesis of (TiZrHfNbTaNi)O high-entropy oxide

Jae Hyuk Lee, Soo Vin Ha, Jihye Seong, Akira Takeuchi, Ruirui Song, Hidemi Kato, Soo-Hyun Joo

Journal of Materials Research and Technology.2025; 35: 5204. CrossRef - Development of 3D interconnected heterogeneous high-entropy alloy composites with enhanced multifunctionality via liquid metal dealloying

Munsu Choi, Gang Hee Gu, Jongun Moon, Jae Wung Bae, Hidemi Kato, Seung Zeon Han, Hyoung Seop Kim, Yongseok Choi, Soo-Hyun Joo

Journal of Materials Research and Technology.2025; 37: 5672. CrossRef - Characterization of the Manufacturing Process and Mechanical Properties of CoCrFeMnNi High-Entropy Alloys via Metal Injection Molding and Hot Isostatic Pressing

Eun Seong Kim, Jae Man Park, Do Won Lee, Hyojeong Ha, Jungho Choe, Jaemin Wang, Seong Jin Park, Byeong-Joo Lee, Hyoung Seop Kim

journal of Korean Powder Metallurgy Institute.2024; 31(3): 243. CrossRef

- Development of 3D interconnected nanoporous TiZrHfNbTaNi high-entropy alloy via liquid metal dealloying and subsequent synthesis of (TiZrHfNbTaNi)O high-entropy oxide

- [Korean]

- 3D-printing-based Combinatorial Experiment for Al-Si-Cu-Mg Alloys

- Yongwook Song, Jungjoon Kim, Suwon Park, Hyunjoo Choi

- J Powder Mater. 2022;29(3):233-239. Published online June 1, 2022

- DOI: https://doi.org/10.4150/KPMI.2022.29.3.233

- 696 View

- 1 Download

-

Abstract

Abstract

PDF

PDF Aluminum alloys are extensively employed in several industries, such as automobile, aerospace, and architecture, owing to their high specific strength and electrical and thermal conductivities. However, to meet the rising industrial demands, aluminum alloys must be designed with both excellent mechanical and thermal properties. Computer-aided alloy design is emerging as a technique for developing novel alloys to overcome these trade-off properties. Thus, the development of a new experimental method for designing alloys with high-throughput confirmation is gaining focus. A new approach that rapidly manufactures aluminum alloys with different compositions is required in the alloy design process. This study proposes a combined approach to rapidly investigate the relationship between the microstructure and properties of aluminum alloys using a direct energy deposition system with a dual-nozzle metal 3D printing process. Two types of aluminum alloy powders (Al-4.99Si-1.05Cu-0.47Mg and Al-7Mg) are employed for the 3D printing-based combined method. Nine types of Al-Si-Cu-Mg alloys are manufactured using the combined method, and the relationship between their microstructures and properties is examined.

- [Korean]

- Interfacial Reaction between Spark Plasma Sintered High-entropy Alloys and Cast Aluminum

- Min-Sang Kim, Hansol Son, Cha Hee Jung, Juyeon Han, Jung Joon Kim, Young-Do Kim, Hyunjoo Choi, Se Hoon Kim

- J Powder Mater. 2022;29(3):213-218. Published online June 1, 2022

- DOI: https://doi.org/10.4150/KPMI.2022.29.3.213

- 890 View

- 5 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF This study investigates the interfacial reaction between powder-metallurgy high-entropy alloys (HEAs) and cast aluminum. HEA pellets are produced by the spark plasma sintering of Al0.5CoCrCu0.5FeNi HEA powder. These sintered pellets are then placed in molten Al, and the phases formed at the interface between the HEA pellets and cast Al are analyzed. First, Kirkendall voids are observed due to the difference in the diffusion rates between the liquid Al and solid HEA phases. In addition, although Co, Fe, and Ni atoms, which have low mixing enthalpies with Al, diffuse toward Al, Cu atoms, which have a high mixing enthalpy with Al, tend to form Al–Cu intermetallic compounds. These results provide guidelines for designing Al matrix composites containing high-entropy phases.

-

Citations

Citations to this article as recorded by- Simultaneous enhancement of strength and ductility of Al matrix composites enabled by submicron-sized high-entropy alloy phases

Chahee Jung, Seungin Nam, Hansol Son, Juyeon Han, Jaewon Jeong, Hyokyung Sung, Hyoung Seop Kim, Seok Su Sohn, Hyunjoo Choi

Journal of Materials Research and Technology.2024; 33: 1470. CrossRef

- Simultaneous enhancement of strength and ductility of Al matrix composites enabled by submicron-sized high-entropy alloy phases

- [Korean]

- Microstructure and Mechanical Properties of CoCrFeMnNi-type High-entropy Alloy Fabricated by Selective Laser Melting: A Review

- Jeong Min Park

- J Powder Mater. 2022;29(2):132-151. Published online April 1, 2022

- DOI: https://doi.org/10.4150/KPMI.2022.29.2.132

- 2,617 View

- 37 Download

- 7 Citations

-

Abstract

Abstract

PDF

PDF The CoCrFeMnNi high-entropy alloy (HEA), which is the most widely known HEA with a single facecentered cubic structure, has attracted significant academic attention over the past decade owing to its outstanding multifunctional performance. Recent studies have suggested that CoCrFeMnNi-type HEAs exhibit excellent printability for selective laser melting (SLM) under a wide range of process conditions. Moreover, it has been suggested that SLM can not only provide great topological freedom of design but also exhibit excellent mechanical properties by overcoming the strength–ductility trade-off via producing a hierarchical heterogeneous microstructure. In this regard, the SLM-processed CoCrFeMnNi HEA has been extensively studied to comprehensively understand the mechanisms of microstructural evolution and resulting changes in mechanical properties. In this review, recent studies on CoCrFeMnNi-type HEAs produced using SLM are discussed with respect to process-induced microstructural evolution and the relationship between hierarchical heterogeneous microstructure and mechanical properties.

-

Citations

Citations to this article as recorded by- Thermodynamic and Electronic Descriptor-Driven Machine Learning for Phase Prediction in High-Entropy Alloys: Experimental Validation

Nguyen Lam Khoa, Nguyen Duy Khanh, Hoang Thi Ngoc Quyen, Nguyen Thi Hoang, Oanh, Le Hong Thang, Nguyen Hoa Khiem, Nguyen Hoang Viet

Journal of Powder Materials.2025; 32(3): 191. CrossRef - Investigation of effects of process parameters on microstructure and fracture toughness of SLM CoCrFeMnNi

Joseph Agyapong, Diego Mateos, Aleksander Czekanski, Solomon Boakye-Yiadom

Journal of Alloys and Compounds.2024; 987: 173998. CrossRef - Cryogenic Tensile Behavior of Ferrous Medium-entropy Alloy Additively Manufactured by Laser Powder Bed Fusion

Seungyeon Lee, Kyung Tae Kim, Ji-Hun Yu, Hyoung Seop Kim, Jae Wung Bae, Jeong Min Park

journal of Korean Powder Metallurgy Institute.2024; 31(1): 8. CrossRef - Data-driven Approach to Explore the Contribution of Process Parameters for Laser Powder Bed Fusion of a Ti-6Al-4V Alloy

Jeong Min Park, Jaimyun Jung, Seungyeon Lee, Haeum Park, Yeon Woo Kim, Ji-Hun Yu

journal of Korean Powder Metallurgy Institute.2024; 31(2): 137. CrossRef - Cryogenic tensile behavior of carbon-doped CoCrFeMnNi high-entropy alloys additively manufactured by laser powder bed fusion

Haeum Park, Hyeonseok Kwon, Kyung Tae Kim, Ji-Hun Yu, Jungho Choe, Hyokyung Sung, Hyoung Seop Kim, Jung Gi Kim, Jeong Min Park

Additive Manufacturing.2024; 86: 104223. CrossRef - Microstructural evolution and high strain rate deformation response of SLM-printed CoCrFeMnNi after annealing and deep-cryogenic treatment

Joseph Agyapong, Aleksander Czekanski, Solomon Boakye Yiadom

Materials Characterization.2024; 218: 114506. CrossRef - High-speed manufacturing-driven strength-ductility improvement of H13 tool steel fabricated by selective laser melting

Yeon Woo Kim, Haeum Park, Young Seong Eom, Dong Gill Ahn, Kyung Tae Kim, Ji-hun Yu, Yoon Suk Choi, Jeong Min Park

Powder Metallurgy.2023; 66(5): 582. CrossRef

- Thermodynamic and Electronic Descriptor-Driven Machine Learning for Phase Prediction in High-Entropy Alloys: Experimental Validation

- [Korean]

- Effect of Sintering Condition on Tensile Strength of Fe-based Non-equiatomic High Entropy Alloy

- Namhyuk Seo, Junhyub Jeon, Gwanghun Kim, Jungbin Park, Seung Bae Son, Seok-Jae Lee

- J Korean Powder Metall Inst. 2021;28(3):221-226. Published online June 1, 2021

- DOI: https://doi.org/10.4150/KPMI.2021.28.3.221

- 985 View

- 8 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF We fabricate the non-equiatomic high-entropy alloy (NE-HEA) Fe49.5Mn30Co10Cr10C0.5 (at.%) using spark plasma sintering under various sintering conditions. Each elemental pure powder is milled by high-energy ball milling to prepare NE-HEA powder. The microstructure and mechanical properties of the sintered samples are investigated using various methods. We use the X-ray diffraction (XRD) method to investigate the microstructural characteristics. Quantitative phase analysis is performed by direct comparison of the XRD results. A tensile test is used to compare the mechanical properties of small samples. Next, electron backscatter diffraction analysis is performed to analyze the phase fraction, and the results are compared to those of XRD analysis. By combining different sintering durations and temperature conditions, we attempt to identify suitable spark plasma sintering conditions that yield mechanical properties comparable with previously reported values. The samples sintered at 900 and 1000°C with no holding time have a tensile strength of over 1000 MPa.

-

Citations

Citations to this article as recorded by- Fabrication and Alloying Behavior of Ultra-Lightweight AlTiCrVMg High-Entropy Alloy via Al-Mg Mutual Solubility and Sintering Control

Eunhyo Song, Hansung Lee, Byungmin Ahn

Journal of Powder Materials.2025; 32(3): 254. CrossRef

- Fabrication and Alloying Behavior of Ultra-Lightweight AlTiCrVMg High-Entropy Alloy via Al-Mg Mutual Solubility and Sintering Control

- [Korean]

- Effect of Sintering Additive and Composition on Cutting Performance of SiAlON

- Jae-Hyeong Choi, Sung-Min Lee, Sahn Nahm, Seongwon Kim

- J Korean Powder Metall Inst. 2019;26(5):415-420. Published online October 1, 2019

- DOI: https://doi.org/10.4150/KPMI.2019.26.5.415

- 549 View

- 5 Download

-

Abstract

Abstract

PDF

PDF SiAlON ceramics are used as ceramic cutting tools for heat-resistant super alloys (HRSAs) due to their excellent fracture toughness and thermal properties. They are manufactured from nitride and oxide raw materials. Mixtures of nitrides and oxides are densified via liquid phase sintering by using gas pressure sintering. Rare earth oxides, when used as sintering additives, affect the color and mechanical properties of SiAlON. Moreover, these sintering additives influence the cutting performance. In this study, we have prepared Ybm/3Si12-(m+n)Alm+nOnN16-n (m = 0.5; n = 0.5, 1.0) ceramics and manufactured SiAlON ceramics, which resulted in different colors. In addition, the characteristics of the sintered SiAlON ceramics such as fracture toughness and microstructure have been investigated and results of the cutting test have been analyzed.

- [Korean]

- Research Trends of the Mo-Si-B Alloys as Next Generation Ultra-high-temperature Alloys

- Won June Choi, Chun Woong Park, Jung Hyo Park, Young Do Kim, Jong Min Byun

- J Korean Powder Metall Inst. 2019;26(2):156-165. Published online April 1, 2019

- DOI: https://doi.org/10.4150/KPMI.2019.26.2.156

- 1,508 View

- 26 Download

- 4 Citations

-

Abstract

Abstract

PDF

PDF Over the last decade, the next generation’s ultra-high-temperature materials as an alternative to Nickel-based superalloys have been highlighted. Ultra-high-temperature materials based on refractory metals are one of several potential candidates. In particular, molybdenum alloys with small amounts of silicon and boron (Mo-Si-B alloys) have superior properties at high temperature. However, research related to Mo-Si-B alloys were mainly conducted by several developed countries but garnered little interest in Korea. Therefore, in this review paper, we introduce the development history of Mo-Si-B alloys briefly and discuss the properties, particularly the mechanical and oxidation properties of Mo-Si-B alloys. We also introduce the latest research trends of Mo-Si-B alloys based on the research paper. Finally, for domestic research related to this field, we explain why Mo-Si-B alloys should be developed and suggest the potential directions for Mo-Si-B alloys research.

-

Citations

Citations to this article as recorded by- Thermal Stability and Weight Reduction of Al0.75V2.82CrZr Refractory High Entropy Alloy Prepared Via Mechanical Alloying

Minsu Kim, Hansung Lee, Byungmin Ahn

journal of Korean Powder Metallurgy Institute.2023; 30(6): 478. CrossRef - Preparation and Structure of Chromium Coatings Doped with Diamond Nanoparticles Deposited Directly on a Monolithic Composite of Molybdenum and Aluminum

V. P. Petkov, M. K. Aleksandrova, R. V. Valov, V. P. Korzhov, V. M. Kiiko, I. S. Zheltyakova

Protection of Metals and Physical Chemistry of Surfaces.2023; 59(3): 396. CrossRef - A Review of Mo-Si Intermetallic Compounds as Ultrahigh-Temperature Materials

Liang Jiang, Bin Zheng, Changsong Wu, Pengxiang Li, Tong Xue, Jiandong Wu, Fenglan Han, Yuhong Chen

Processes.2022; 10(9): 1772. CrossRef - Heat-Resistant Molybdenum Borosilicate Alloys Hardened with Titanium Carbides: Mo–Si–B–TiC (Survey)

I. L. Svetlov, O. G. Ospennikova, M. I. Karpov, Yu. V. Artemenko

Inorganic Materials: Applied Research.2021; 12(4): 866. CrossRef

- Thermal Stability and Weight Reduction of Al0.75V2.82CrZr Refractory High Entropy Alloy Prepared Via Mechanical Alloying

- [Korean]

- Reflectance Characteristics of Al-Si based Alloys according to Powder Size and Composition

- Gwang Mook Choi, Hong Jun Chae

- J Korean Powder Metall Inst. 2019;26(1):22-27. Published online February 1, 2019

- DOI: https://doi.org/10.4150/KPMI.2019.26.1.22

- 834 View

- 1 Download

-

Abstract

Abstract

PDF

PDF In this study, the effects of powder size and composition on the reflectance of Al-Si based alloys are presented. First, the reflectance of Al-Si bulk and powder are analyzed to confirm the effect of powder size. Results show that the bulk has a higher reflectance than that of powder because the bulk has lower surface defects. In addition, the larger the particle size, the higher is the reflectance because the interparticle space decreases. Second, the effect of composition on the reflectance by the changing composition of Al-Si-Mg is confirmed. Consequently, the reflectance of the alloy decreases with the addition of Si and Mg because dendrite Si and Mg2Si are formed, and these have lower reflectance than pure Al. Finally, the reflectance of the alloy is due to the scattering of free electrons, which is closely related to electrical conductivity. Measurements of the electrical conductivity based on the composition of the Al-Si-Mg alloy confirm the same tendency as the reflectance.

- [Korean]

- New Co10Fe10Mn35Ni35Zn10 high-entropy alloy Fabricated by Powder Metallurgy

- Dami Yim, Hyung Keun Park, Antonio Joao Seco Ferreira Tapia, Byeong-Joo Lee, Hyoung Seop Kim

- J Korean Powder Metall Inst. 2018;25(3):208-212. Published online June 1, 2018

- DOI: https://doi.org/10.4150/KPMI.2018.25.3.208

- 1,037 View

- 5 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF In this paper, a new Co10Fe10Mn35Ni35Zn10 high entropy alloy (HEA) is identified as a strong candidate for the single face-centered cubic (FCC) structure screened using the upgraded TCFE2000 thermodynamic CALPHAD database. The Co10Fe10Mn35Ni35Zn10 HEA is fabricated using the mechanical (MA) procedure and pressure-less sintering method. The Co10Fe10Mn35Ni35Zn10 HEA, which consists of elements with a large difference in melting point and atomic size, is successfully fabricated using powder metallurgy techniques. The MA behavior, microstructure, and mechanical properties of the Co10Fe10Mn35Ni35Zn10 HEA are systematically studied to understand the MA behavior and develop advanced techniques for fabricating HEA products. After MA, a single FCC phase is found. After sintering at 900°C, the microstructure has an FCC single phase with an average grain size of 18 μm. Finally, the Co10Fe10Mn35Ni35Zn10 HEA has a compressive yield strength of 302 MPa.

-

Citations

Citations to this article as recorded by- Composites of equiatomic Y, La, Ce, Nd, and Gd rare earth oxides: Chemical-shift effects and valence spectra

Jungsu Bin, Hyunbae Gee, Taesung Park, UiJun Go, Jeoung Han Kim, Youn-Seoung Lee

Current Applied Physics.2024; 59: 85. CrossRef - Fabrication, microstructure and mechanical property of a novel Nb-rich refractory high-entropy alloy strengthened by in-situ formation of dispersoids

Byungchul Kang, Taeyeong Kong, Ahmad Raza, Ho Jin Ryu, Soon Hyung Hong

International Journal of Refractory Metals and Hard Materials.2019; 81: 15. CrossRef

- Composites of equiatomic Y, La, Ce, Nd, and Gd rare earth oxides: Chemical-shift effects and valence spectra

- [Korean]

- The Microstructure and Mechanical Properties of Y2O3-Dispersed Fe-C and Fe-CNT Sintered Steels

- Jin Young Lim, Jung-Ho Ahn

- J Korean Powder Metall Inst. 2017;24(4):298-301. Published online August 1, 2017

- DOI: https://doi.org/10.4150/KPMI.2017.24.4.298

- 626 View

- 1 Download

-

Abstract

Abstract

PDF

PDF In the present work, we use multiwall carbon nanotubes (MWCNT) as the starting material for the fabrication of sintered carbon steel. A comparison is made with conventionally sintered carbon steel, where graphite is used as the starting material. Milling is performed using a horizontal mill sintered in a vacuum furnace. We analyze the grain size, number of pores, X-ray diffraction patterns, and microstructure. Changes in the physical properties are determined by using the Archimedes method and Vickers hardness measurements. The result shows that the use of MWCNTs instead of graphite significantly reduces the size and volume of the pores as well as the grain size after sintering. The addition of Y2O3.to the Fe-MWCNT samples further inhibits the growth of grains.

- [English]

- Investigation of Spark Plasma Sintering Temperature on Microstructure and Thermoelectric Properties of p-type Bi-Sb-Te alloys

- Jin-Koo Han, Dong-won Shin, Babu Madavali, Soon-Jik Hong

- J Korean Powder Metall Inst. 2017;24(2):115-121. Published online April 1, 2017

- DOI: https://doi.org/10.4150/KPMI.2017.24.2.115

- 1,380 View

- 4 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF In this work, p-type Bi−Sb−Te alloys powders are prepared using gas atomization, a mass production powder preparation method involving rapid solidification. To study the effect of the sintering temperature on the microstructure and thermoelectric properties, gas-atomized powders are consolidated at different temperatures (623, 703, and 743 K) using spark plasma sintering. The crystal structures of the gas-atomized powders and sintered bulks are identified using an X-ray diffraction technique. Texture analysis by electron backscatter diffraction reveals that the grains are randomly oriented in the entire matrix, and no preferred orientation in any unique direction is observed. The hardness values decrease with increasing sintering temperature owing to a decrease in grain size. The conductivity increases gradually with increasing sintering temperature, whereas the Seebeck coefficient decreases owing to increases in the carrier mobility with grain size. The lowest thermal conductivity is obtained for the bulk sintered at a low temperature (603 K), mainly because of its fine-grained microstructure. A peak ZT of 1.06 is achieved for the sample sintered at 703 K owing to its moderate electrical conductivity and sustainable thermal conductivity.

-

Citations

Citations to this article as recorded by- Influence of the SPS heating rate on the optical and mechanical properties of Y2O3-MgO nanocomposites

Seok-Min Yong

Journal of Ceramic Processing Research.2019; 20(1): 59. CrossRef

- Influence of the SPS heating rate on the optical and mechanical properties of Y2O3-MgO nanocomposites

- [English]

- Investigation of Ball Size Effect on Microstructure and Thermoelectric Properties of

p -type BiSbTe by Mechanical Alloying - May Likha Lwin, Sang-min Yoon, Babu Madavali, Chul-Hee Lee, Soon-Jik Hong

- J Korean Powder Metall Inst. 2016;23(2):120-125. Published online April 1, 2016

- DOI: https://doi.org/10.4150/KPMI.2016.23.2.120

- 1,467 View

- 5 Download

- 4 Citations

-

Abstract

Abstract

PDF

PDF P -type ternary Bi0.5Sb1.5Te3 alloys are fabricated via mechanical alloying (MA) and spark plasma sintering (SPS). Different ball sizes are used in the MA process, and their effect on the microstructure; hardness, and thermoelectric properties of thep -type BiSbTe alloys are investigated. The phases of milled powders and bulks are identified using an X-ray diffraction technique. The morphology of milled powders and fracture surface of compacted samples are examined using scanning electron microscopy. The morphology, phase, and grain structures of the samples are not altered by the use of different ball sizes in the MA process. Measurements of the thermoelectric (TE) transport properties including the electrical conductivity, Seebeck coefficient, and power factor are measured at temperatures of 300- 400 K for samples treated by SPS. The TE properties do not depend on the ball size used in the MA process.-

Citations

Citations to this article as recorded by- Investigation of Spark Plasma Sintering Temperature on Microstructure and Thermoelectric Properties of p-type Bi-Sb-Te alloys

Jin-Koo Han, Dong-won Shin, Babu Madavali, Soon-Jik Hong

Journal of Korean Powder Metallurgy Institute.2017; 24(2): 115. CrossRef - Flexible Thermoelectric Device Using Thick Films for Energy Harvesting from the Human Body

Han Ki Cho, Da Hye Kim, Hye Sun Sin, Churl-Hee Cho, Seungwoo Han

Journal of the Korean Ceramic Society.2017; 54(6): 518. CrossRef - Investigation of the Microstructure and Thermoelectric Properties of P-Type BiSbTe Alloys by Usage of Different Revolutions Per Minute (RPM) During Mechanical Milling

S.-M. Yoon, B. Madavali, Y.-N. Yoon, S.-J. Hong

Archives of Metallurgy and Materials.2017; 62(2): 1167. CrossRef - Mechanical and thermoelectric properties of Bi2−xSbxTe3 prepared by using encapsulated melting and hot pressing

Woo-Jin Jung, Il-Ho Kim

Journal of the Korean Physical Society.2016; 69(8): 1328. CrossRef

- Investigation of Spark Plasma Sintering Temperature on Microstructure and Thermoelectric Properties of p-type Bi-Sb-Te alloys

- [English]

- Advanced PM Processes for Medical Technologies

- Frank Petzoldt, Vera Friederici, Philipp Imgrund, Claus Aumund-Kopp

- J Korean Powder Metall Inst. 2014;21(1):1-6. Published online February 1, 2014

- DOI: https://doi.org/10.4150/KPMI.2014.21.1.1

- 1,202 View

- 5 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF Medical technologies are gaining in importance because of scientific and technical progress in medicine and the increasing average lifetime of people. This has opened up a huge market for medical devices, where complex-shaped metallic parts made from biocompatible materials are in great demand. Today many of these components are already being manufactured by powder metallurgy technologies. This includes mass production of standard products and also customized components. In this paper some aspects related to metal injection molding of Ti and its alloys as well as modifications of microstructure and surface finish were discussed. The process chain of additive manufacturing (AM) was described and the current state of the art of AM processes like Selective Laser Melting and electron beam melting for medical applications was presented.

-

Citations

Citations to this article as recorded by- Enhancing corrosion resistance of Ti-based amorphous alloy powders via misch metal addition

Yeon Joo Lee, Hyokyung Sung, Jae Bok Seol, Kisub Cho, Hwi Jun Kim, Hyunjoo Choi

Powder Metallurgy.2025; 68(3): 230. CrossRef - Spontaneous Formation of Titanium Nitride on the Surface of a Ti Rod Induced by Electro-Discharge-Heat-Treatment in an N2 Atmosphere

W.H. Lee, Y.H. Yoon, Y.H. Kim, Y.K. Lee, J.Y. Kim, S.Y. Chang

Archives of Metallurgy and Materials.2017; 62(2): 1281. CrossRef

- Enhancing corrosion resistance of Ti-based amorphous alloy powders via misch metal addition

TOP

KPMI

KPMI

First

First Prev

Prev