Search

- Page Path

- HOME > Search

- [English]

- Enhancing the Dispersion Stability of Exfoliated MoS2 Nanoflakes for Na⁺ Intercalation

- Jae Min Sung, Dong-Won Kyung, Ammad Ali, Kee-Ryung Park, Mi Hye Lee, Da-Woon Jeong, Bum Sung Kim, Haejin Hwang, Leeseung Kang, Yoseb Song

- J Powder Mater. 2025;32(5):390-398. Published online October 31, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00255

- 280 View

- 5 Download

-

Abstract

Abstract

PDF

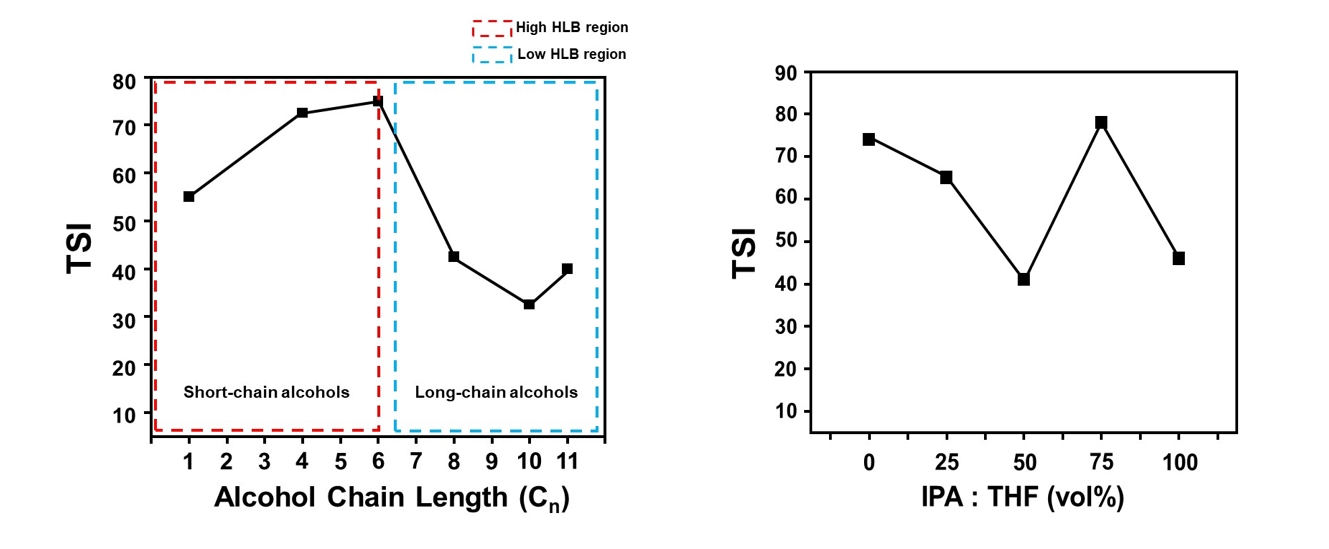

PDF - This study investigated the dispersion stability of exfoliated MoS₂ nanoflakes in various organic solvents and binary mixtures using a Turbiscan optical analyzer. Sedimentation behavior was quantitatively evaluated via transmittance variation (ΔT), backscattering variation (ΔBS), and the Turbiscan stability index (TSI). Alcohol-based solvents were categorized by hydrophilic-lipophilic balance values. Long-chain alcohols, such as 1-undecanol, showed increased stability due to high viscosity and strong hydrophobic affinity with MoS2 basal planes, while short-chain alcohols exhibited poor stabilization. Binary mixtures of isopropanol (IPA) and tetrahydrofuran (THF) were also assessed, with the 5:5 volume ratio showing the best stability profile, including the lowest TSI and minimal ΔT and ΔBS values. This improvement is attributed to synergistic interactions, as IPA stabilizes hydrophilic edge sites, while THF engages with hydrophobic basal surfaces. These findings highlight the importance of balancing physicochemical properties when selecting solvents to improve MoS2 dispersion for structural modification and electrocatalytic applications.

- [English]

- Effect of the Cross-rolling Process on the Microstructures and Mechanical Properties of 9Cr-1W ODS Steel

- Bu-An Kim, Sanghoon Noh

- J Powder Mater. 2025;32(1):37-42. Published online February 28, 2025

- DOI: https://doi.org/10.4150/jpm.2024.00332

- 848 View

- 25 Download

-

Abstract

Abstract

PDF

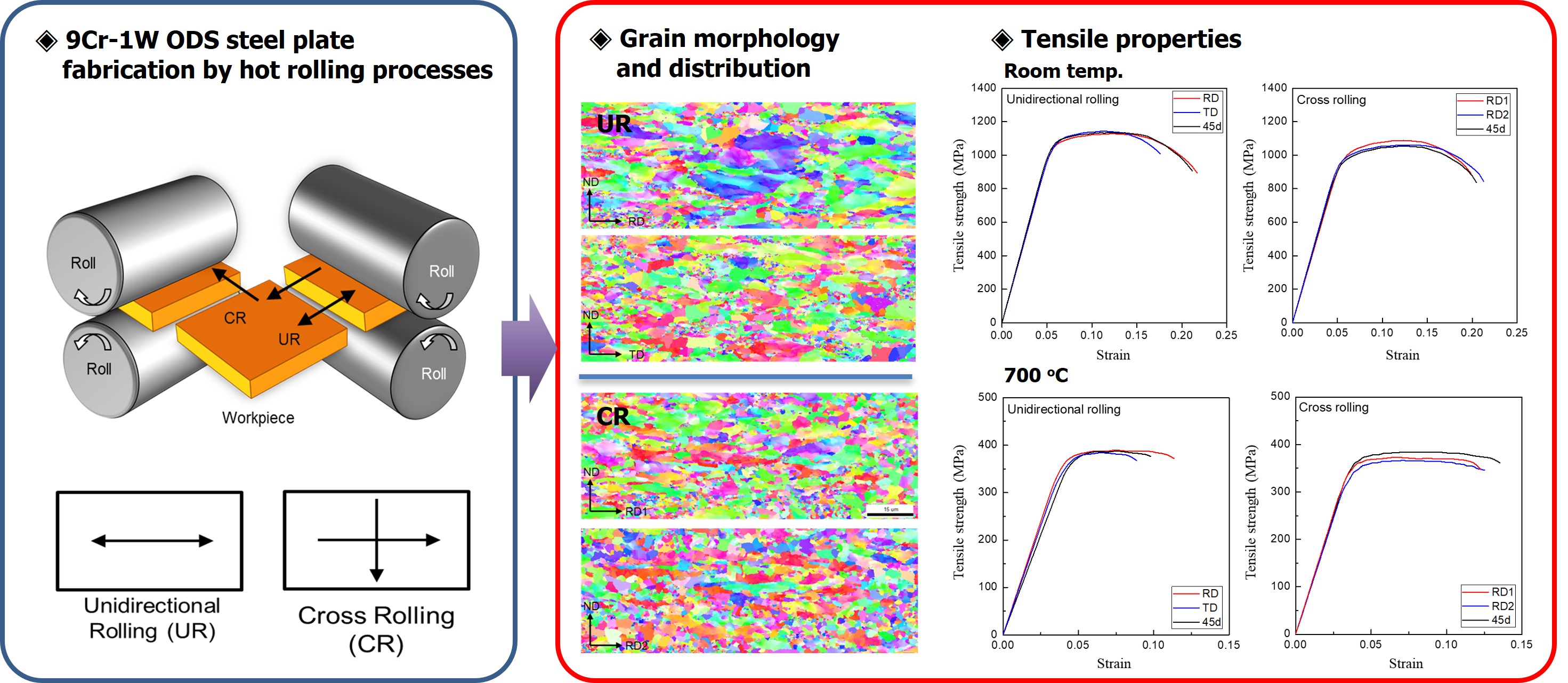

PDF - This study employed a cross-rolling process to fabricate oxide dispersion strengthened (ODS) steel plates and investigated their microstructures and mechanical properties. The 9Cr-1W ODS ferritic steel was fabricated using mechanical alloying and hot isostatic pressing. The hot cross-rolling process produced thick ODS ferritic steel plates with a well-extended rectangular shape. The working direction greatly affected the grain structure and crystal texture of the ODS ferritic steel. Cross-rolled plates showed fine micro-grains with random crystal orientation, while unidirectionally rolled plates exhibited a strong orientation with larger, elongated grains. Transmission electron microscopy revealed a uniform distribution of nano-oxide particles in both rolling methods, with no major differences. Tensile tests of the ODS ferritic steel plates showed that the unidirectional rolled plates had anisotropic elongation, while cross-rolled plates exhibited isotropic behavior with uniform elongation. Cross-rolling produced finer, more uniform grains, reducing anisotropy and improving mechanical properties, making it ideal for manufacturing wide ODS steel components.

- [Korean]

- Comparison and Characterization of Silodosin-loaded Solid Dispersions Prepared by Various Solid Dispersion Preparation Methods

- Su Man Lee, Da Young Song, Kyeong Soo Kim

- J Powder Mater. 2024;31(3):263-271. Published online June 27, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00143

- 1,467 View

- 36 Download

-

Abstract

Abstract

PDF

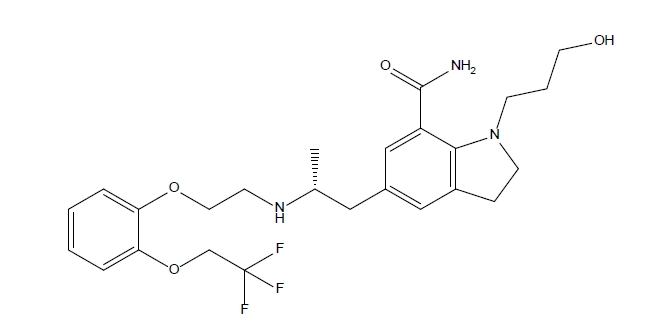

PDF - This study focused on improving the solubility of silodosin, a drug poorly soluble in water, by utilizing solid dispersions. Three types of dispersions were examined and compared against the drug powder: surface-attached (SA), solvent-wetted (SW), and solvent-evaporated (SE). Polyvinyl alcohol (PVA) was identified as the most effective polymer in enhancing solubility. These dispersions were prepared using spray-drying techniques with silodosin and PVA as the polymer, employing solvents such as water, ethanol, and a water-acetone mix. The physicochemical properties and solubility of the dispersions were evaluated. The surface-attached dispersions featured the polymer on a crystalline drug surface, the solvent-wetted dispersions had the amorphous drug on the polymer, and the solvent-evaporated dispersions produced nearly round particles with both components amorphous. Testing revealed that the order of improved solubility was: solvent-evaporated, solvent-wetted, and surface-attached. The results demonstrated that the preparation method of the solid dispersions significantly impacted their physicochemical properties and solubility enhancement.

- [Korean]

- TiO2 Thin Film Coating on an Nb-Si–Based Superalloy via Atomic Layer Deposition

- Ji Young Park, Su Min Eun, Jongmin Byun, Byung Joon Choi

- J Powder Mater. 2024;31(3):255-262. Published online June 27, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00052

- 1,917 View

- 49 Download

-

Abstract

Abstract

PDF

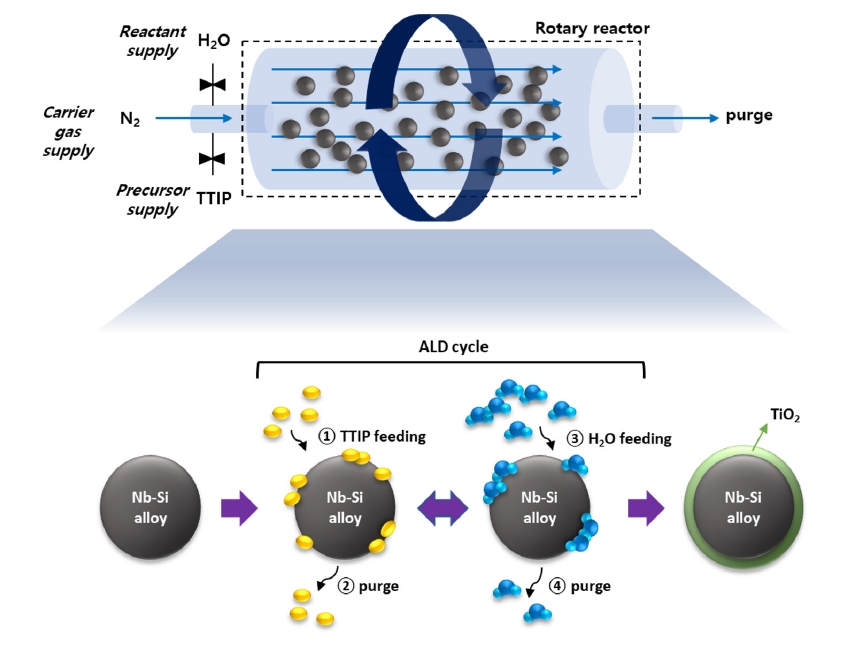

PDF - Nano-oxide dispersion–strengthened (ODS) superalloys have attracted attention because of their outstanding mechanical reinforcement mechanism. Dispersed oxides increase the material’s strength by preventing grain growth and recrystallization, as well as increasing creep resistance. In this research, atomic layer deposition (ALD) was applied to synthesize an ODS alloy. It is useful to coat conformal thin films even on complex matrix shapes, such as nanorods or powders. We coated an Nb-Si–based superalloy with TiO2 thin film by using rotary-reactor type thermal ALD. TiO2 was grown by controlling the deposition recipe, reactor temperature, N2 flow rate, and rotor speed. We could confirm the formation of uniform TiO2 film on the surface of the superalloy. This process was successfully applied to the synthesis of an ODS alloy, which could be a new field of ALD applications.

- [Korean]

- Evaluation of Microstructures and Mechanical Properties of Ni-Y2O3 Sintered Alloys Based on the Powder Preparation Methods

- Gun-Woo Jung, Ji-Ho Cha, Min-Seo Jang, Minsuk Oh, Jeshin Park

- J Powder Mater. 2023;30(6):484-492. Published online December 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.6.484

- 979 View

- 14 Download

-

Abstract

Abstract

PDF

PDF In this study, Ni-Y2O3 powder was prepared by alloying recomposition oxidation sintering (AROS), solution combustion synthesis (SCS), and conventional mechanical alloying (MA). The microstructure and mechanical properties of the alloys were investigated by spark plasma sintering (SPS). Among the Ni-Y2O3 powders synthesized by the three methods, the AROS powder had approximately 5 nm of Y2O3 crystals uniformly distributed within the Ni particles, whereas the SCS powder contained a mixture of Ni and Y2O3 nanoparticles, and the MA powder formed small Y2O3 crystals on the surface of large Ni particles by milling the mixture of Ni and Y2O3. The average grain size of Y2O3 in the sintered alloys was approximately 15 nm, with the AROS sinter having the smallest, followed by the SCS sinter at 18 nm, and the MA sinter at 22 nm. The yield strength (YS) of the SCS- and MA-sintered alloys were 1511 and 1688 MPa, respectively, which are lower than the YS value of 1697 MPa for the AROS-sintered alloys. The AROS alloy exhibited improved strength compared to the alloys fabricated by SCS and conventional MA methods, primarily because of the increased strengthening from the finer Y2O3 particles and Ni grains.

- [Korean]

- Microstructure and High Temperature Mechanical Properties of Oxide Dispersion Strengthened Steels Manufactured by Combination Milling Process

- Jung-Uk Lee, Young-Kyun Kim, Jeoung Han Kim, Hwi-Jin Kim, Kee-Ahn Lee

- J Korean Powder Metall Inst. 2021;28(5):389-395. Published online October 1, 2021

- DOI: https://doi.org/10.4150/KPMI.2021.28.5.389

- 747 View

- 9 Download

-

Abstract

Abstract

PDF

PDF Oxide dispersion-strengthened (ODS) steel has excellent high-temperature properties, corrosion resistance, and oxidation resistance, and is expected to be applicable in various fields. Recently, various studies on mechanical alloying (MA) have been conducted for the dispersion of oxide particles in ODS steel with a high number density. In this study, ODS steel is manufactured by introducing a complex milling process in which planetary ball milling, cryogenic ball milling, and drum ball milling are sequentially performed, and the microstructure and high-temperature mechanical properties of the ODS steel are investigated. The microstructure observation revealed that the structure is stretched in the extrusion direction, even after the heat treatment. In addition, transmission electron microscopy (TEM) analysis confirmed the presence of oxide particles in the range of 5 to 10 nm. As a result of the room-temperature and high-temperature compression tests, the yield strengths were measured as 1430, 1388, 418, and 163 MPa at 25, 500, 700, and 900°C, respectively. Based on these results, the correlation between the microstructure and mechanical properties of ODS steel manufactured using the composite milling process is also discussed.

- [Korean]

- Evolution on Microstructures and Tensile Properties of 10Cr-1Mo ODS Steel with Different Lengths of Mechanical Alloying Process Times

- Sanghoon Noh, Tae Kyu Kim

- J Korean Powder Metall Inst. 2021;28(5):375-380. Published online October 1, 2021

- DOI: https://doi.org/10.4150/KPMI.2021.28.5.375

- 806 View

- 6 Download

-

Abstract

Abstract

PDF

PDF In this study, we investigate the effect of the duration of mechanical alloying on the microstructures and mechanical properties of ODS ferritic/martensitic steel. The Fe(bal.)-10Cr-1Mo pre-alloyed powder and Y2O3 powder are mechanically alloyed for the different mechanical alloying duration (0 to 40 h) and then constantly fabricated using a uniaxial hot pressing process. Upon increasing the mechanical alloying time, the average powder diameter and crystallite size increased dramatically. In the initial stages within 5 h of mechanical alloying, inhomogeneous grain morphology is observed along with coarsened carbide and oxide distributions; thus, precipitate phases are temporarily observed between the two powders because of insufficient collision energy to get fragmented. After 40 h of the MA process, however, fine martensitic grains and uniformly distributed oxide particles are observed. This led to a favorable tensile strength and elongation at room temperature and 650°C.

- [Korean]

- Effect of Cobalt Contents on the Microstructure and Charpy Impact Properties of Ferritic/martensitic Oxide Dispersion Strengthened Steel

- Daehyun Kwon, Sanghoon Noh, Jung Gu Lee

- J Korean Powder Metall Inst. 2020;27(4):311-317. Published online August 1, 2020

- DOI: https://doi.org/10.4150/KPMI.2020.27.4.311

- 816 View

- 4 Download

-

Abstract

Abstract

PDF

PDF In this study, the effects of Co content on the microstructure and Charpy impact properties of Fe-Cr-W ferritic/martensitic oxide dispersion strengthened (F/M ODS) steels are investigated. F/M ODS steels with 0–5 wt% Co are fabricated by mechanical alloying, followed by hot isostatic pressing, hot-rolling, and normalizing/tempering heat treatment. All the steels commonly exhibit two-phase microstructures consisting of ferrite and tempered martensite. The volume fraction of ferrite increases with the increase in the Co content, since the Co element considerably lowers the hardenability of the F/M ODS steel. Despite the lowest volume fraction of tempered martensite, the F/M ODS steel with 5 wt% Co shows the highest micro-Vickers hardness, owing to the solid solution-hardening effect of the alloyed Co. The high hardness of the steel improves the resistance to fracture initiation, thereby resulting in the enhanced fracture initiation energy in a Charpy impact test at – 40°C. Furthermore, the addition of Co suppresses the formation of coarse oxide inclusions in the F/M ODS steel, while simultaneously providing a high resistance to fracture propagation. Owing to these combined effects of Co, the Charpy impact energy of the F/M ODS steel increases gradually with the increase in the Co content.

- [Korean]

- Effect of Surfactant on the Dispersion Stability of Slurry for Semiconductor Silicon CMP

- Hye Won Yun, Doyeon Kim, Do Hyung Han, Dong Wan Kim, Woo-Byoung Kim

- J Korean Powder Metall Inst. 2018;25(5):395-401. Published online October 1, 2018

- DOI: https://doi.org/10.4150/KPMI.2018.25.5.395

- 1,989 View

- 42 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF The improvement of dispersion stability for the primary polishing slurry in a CMP process is achieved to prevent defects produced by agglomeration of the slurry. The dispersion properties are analyzed according to the physical characteristics of each silica sol sample. Further, the difference in the dispersion stability is confirmed as the surfactant content. The dispersibility results measured by Zeta potential suggest that the dispersion properties depend on the content and size of the abrasive in the primary polishing slurry. Moreover, the optimum ratio for high dispersion stability is confirmed as the addition content of the surfactant. Based on the aforementioned results, the long-term stability of each slurry is analyzed. Turbiscan analysis demonstrates that the agglomeration occurs depending on the increasing amount of surfactant. As a result, we demonstrate that the increased particle size and the decreased content of silica improve the dispersion stability and long-term stability.

-

Citations

Citations to this article as recorded by- Surface Defect Properties of Prime, Test-Grade Silicon Wafers

Seung-Hwan Oh, Hyeonmin Yim, Donghee Lee, Dong Hyeok Seo, Won Jin Kim, Ryun Na Kim, Woo-Byoung Kim

Korean Journal of Materials Research.2022; 32(9): 396. CrossRef

- Surface Defect Properties of Prime, Test-Grade Silicon Wafers

- [Korean]

- Microstructure and Mechanical Properties of Oxide Dispersion Strengthened alloy Based on Commercially Pure Titanium

- Taesung Park, Jeoung Han Kim

- J Korean Powder Metall Inst. 2018;25(4):327-330. Published online August 1, 2018

- DOI: https://doi.org/10.4150/KPMI.2018.25.4.327

- 869 View

- 8 Download

- 4 Citations

-

Abstract

Abstract

PDF

PDF This study is conducted as a preliminary research to verify the feasibility of Ti-based Oxide dispersion strengthened (ODS) alloy. Pure-Ti powder is mixed with Y2O3 powder and subsequently, mechanically alloyed at -150°C. The Ti-based ODS powder is hot-isostatically pressed and subsequently hot-rolled for recrystallization. The microstructure consists of elongated grains and Y excess fine particles. The oxide particle size is larger than that of the typical Febased ODS steel. Tensile test shows that the tensile ductility is approximately 25%, while the strength is significantly higher than that of pure Ti. The high-temperature hardness of the Ti-ODS alloy is also significantly higher than that of pure Ti at all temperatures, while being lower than that of Ti-6Al-4V. The dimple structure is well developed, and no evidence of cleavage fracture surface is observed in the fracture surface of the tensile specimen.

-

Citations

Citations to this article as recorded by- Additive manufacturing of Ti-6Al-4V based oxide dispersion strengthened alloy using in-situ oxide-dispersed powders and bound metal deposition

Woo Hyeok Kim, Raj Narayan Hajra, Hyung-Ki Park, Jung-Yeul Yun, Jeoung Han Kim

Journal of Alloys and Compounds.2026; 1050: 185574. CrossRef - Experimental and Numerical Evaluation of Rockwell Hardness at High Temperatures

NamSeok Lee

Journal of the Korean Society of Manufacturing Technology Engineers.2025; 34(3): 165. CrossRef - Spheroidization of Pure-vanadium Powder using Radio Frequency Thermal Plasma Process

Nana Kwabena Adomako, Seungmin Yang, Min Gyu Lee, N. S. Reddy, Jeoung-Han Kim

Journal of Korean Powder Metallurgy Institute.2019; 26(4): 305. CrossRef - Microstructure and Mechanical Properties of Friction-Welded Alloy 718 and SNCRW Stainless Steel After Post-Weld Heat-Treatment

Jeoung Han Kim, Nam-Yong Kim, Yu Sik Kong, Nho Kwang Park

Journal of Welding and Joining.2019; 37(4): 313. CrossRef

- Additive manufacturing of Ti-6Al-4V based oxide dispersion strengthened alloy using in-situ oxide-dispersed powders and bound metal deposition

- [Korean]

- Microstructure and Wear Properties of Oxide Dispersion Strengthened Steel Powder Added Steel-Based Composite Material for Automotive Part

- Young-Kyun Kim, Jong-Kwan Park, Kee-Ahn Lee

- J Korean Powder Metall Inst. 2018;25(1):36-42. Published online February 1, 2018

- DOI: https://doi.org/10.4150/KPMI.2018.25.1.36

- 749 View

- 4 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF In order to expand the application of oxide dispersion-strengthened (ODS) steel, a composite material is manufactured by adding mechanically alloyed ODS steel powder to conventional steel and investigated in terms of microstructure and wear properties. For comparison, a commercial automobile part material is also tested. Initial microstructural observations confirm that the composite material with added ODS steel contains i) a pearlitic Fe matrix area and ii) an area with Cr-based carbides and ODS steel particles in the form of a Fe-Fe3C structure. In the commercial material, various hard Co-, Fe-Mo-, and Cr-based particles are present in a pearlitic Fe matrix. Wear testing using the VSR engine simulation wear test confirms that the seatface widths of the composite material with added ODS steel and the commercial material are increased by 24% and 47%, respectively, with wear depths of 0.05 mm and 0.1 mm, respectively. The ODS steel-added composite material shows better wear resistance. Post-wear-testing surface and cross-sectional observations show that particles in the commercial material easily fall off, while the ODS steel-added material has an even, smooth wear surface.

-

Citations

Citations to this article as recorded by- First principles determination of formation of a Cr shell on the interface between Y–Ti–O nanoparticles and a ferritic steel matrix

Ki-Ha Hong, Jae Bok Seol, Jeoung Han Kim

Applied Surface Science.2019; 481: 69. CrossRef - Thermal Properties and Microstructural Changes of Fe-Co System Valve Seat Alloy by High Densification Process

In-Shup Ahn, Dong-Kyu Park, Kwang-Bok Ahn, Seoung-Mok Shin

Journal of Korean Powder Metallurgy Institute.2019; 26(2): 112. CrossRef

- First principles determination of formation of a Cr shell on the interface between Y–Ti–O nanoparticles and a ferritic steel matrix

- [Korean]

- Fabrication of Al2O3 Dispersed Porous Cu by Freeze Drying of CuO-Al2O3/Camphene Slurry

- Hyunji Kang, Doh-Hyung Riu, Sung-Tag Oh

- J Korean Powder Metall Inst. 2018;25(1):25-29. Published online February 1, 2018

- DOI: https://doi.org/10.4150/KPMI.2018.25.1.25

- 553 View

- 2 Download

-

Abstract

Abstract

PDF

PDF Porous Cu with a dispersion of nanoscale Al2O3 particles is fabricated by freeze-drying CuO-Al2O3/camphene slurry and sintering. Camphene slurries with CuO-Al2O3 contents of 5 and 10 vol% are unidirectionally frozen at -30°C, and pores are generated in the frozen specimens by camphene sublimation during air drying. The green bodies are sintered for 1 h at 700°C and 800°C in H2 atmosphere. The sintered samples show large pores of 100 μm in average size aligned parallel to the camphene growth direction. The internal walls of the large pores feature relatively small pores of ~10 μm in size. The size of the large pores decreases with increasing CuO-Al2O3 content by the changing degree of powder rearrangement in the slurry. The size of the small pores decreases with increasing sintering temperature. Microstructural analysis reveals that 100-nm Al2O3 particles are homogeneously dispersed in the Cu matrix. These results suggest that a porous composite body with aligned large pores could be fabricated by a freeze-drying and H2 reducing process.

- [English]

- Dispersion Behavior and Size Analysis of Thermally Purified High Pressure-high Temperature Synthesized Nanodiamond Particles

- Hansang Kwon, Jehong Park, Marc Leparoux

- J Korean Powder Metall Inst. 2017;24(3):216-222. Published online June 1, 2017

- DOI: https://doi.org/10.4150/KPMI.2017.24.3.216

- 1,137 View

- 3 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF Synthesized monocrystalline nanodiamond (nD) particles are heat-treated at various temperatures to produce highly structured diamond crystals. The heat-treated nDs show different weight loss ratios during thermogravimetric analysis. The crystallinities of the heat-treated nDs are analyzed using Raman spectroscopy. The average particle sizes of the heat-treated nDs are measured by a dynamic light scattering (DLS) system and direct imaging observation methods. Moreover, individual dispersion behaviors of the heat-treated nD particles are investigated based on ultrasonic dispersion methods. The average particle sizes of the dispersed nDs according to the two different measurement methods show very similar size distributions. Thus, it is possible to produce highly crystallized nD powder particles by a heattreatment process, and the nD particles are relatively easy to disperse individually without any dispersant. The heattreated nDs can lead to potential applications such as in nanocomposites, quantum dots, and biomedical materials.

-

Citations

Citations to this article as recorded by- Two extreme crystal size scales of diamonds, large single crystal and nanocrystal diamonds: Synthesis, properties and their mutual transformation

Yang Wang, Wei-hua Wang, Shi-lin Yang, Guo-yang Shu, Bing Dai, Jia-qi Zhu

New Carbon Materials.2021; 36(3): 512. CrossRef

- Two extreme crystal size scales of diamonds, large single crystal and nanocrystal diamonds: Synthesis, properties and their mutual transformation

- [Korean]

- High Temperature Oxidation Behavior of Fe-14Cr Ferritic Oxide Dispersion Strengthened Steels Manufactured by Mechanical Alloying Process

- Young-Kyun Kim, Jong-Kwan Park, Hwi-Jun Kim, Man-Sik Kong, Kee-Ahn Lee

- J Korean Powder Metall Inst. 2017;24(2):133-140. Published online April 1, 2017

- DOI: https://doi.org/10.4150/KPMI.2017.24.2.133

- 594 View

- 5 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF This study investigates the oxidation properties of Fe-14Cr ferritic oxide-dispersion-strengthened (ODS) steel at various high temperatures (900, 1000, and 1100°C for 24 h). The initial microstructure shows that no clear structural change occurs even under high-temperature heat treatment, and the average measured grain size is 0.4 and 1.1 μm for the as-fabricated and heat-treated specimens, respectively. Y–Ti–O nanoclusters 10–50 nm in size are observed. High-temperature oxidation results show that the weight increases by 0.27 and 0.29 mg/cm2 for the asfabricated and heat-treated (900°C) specimens, and by 0.47 and 0.50 mg/cm2 for the as-fabricated and heat-treated (1000°C) specimens, respectively. Further, after 24 h oxidation tests, the weight increases by 56.50 and 100.60 mg/cm2 for the as-fabricated and heat-treated (1100°C) specimens, respectively; the latter increase is approximately 100 times higher than that at 1000°C. Observation of the surface after the oxidation test shows that Cr2O3 is the main oxide on a specimen tested at 1000°C, whereas Fe2O3 and Fe3O4 phases also form on a specimen tested at 1100°C, where the weight increases rapidly. The high-temperature oxidation behavior of Fe-14Cr ODS steel is confirmed to be dominated by changes in the Cr2O3 layer and generation of Fe-based oxides through evaporation.

-

Citations

Citations to this article as recorded by- Microstructure and Wear Properties of Oxide Dispersion Strengthened Steel Powder Added Steel-Based Composite Material for Automotive Part

Young-Kyun Kim, Jong-Kwan Park, Kee-Ahn Lee

journal of Korean Powder Metallurgy Institute.2018; 25(1): 36. CrossRef

- Microstructure and Wear Properties of Oxide Dispersion Strengthened Steel Powder Added Steel-Based Composite Material for Automotive Part

- [Korean]

- Fabrication of Porous Polytetrafluoroethylene thin Film from Powder Dispersion-solution for Energy Nanogenerator Applications

- Il-Kyu Park

- J Korean Powder Metall Inst. 2017;24(2):102-107. Published online April 1, 2017

- DOI: https://doi.org/10.4150/KPMI.2017.24.2.102

- 973 View

- 13 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF Porous polytetrafluoroethylene (PTFE) thin films are fabricated by spin-coating using a dispersion solution containing PTFE powders, and their crystalline properties are investigated after thermal annealing at various temperatures ranging from 300 to 500°C. Before thermal annealing, the film is densely packed and consists of many granular particles 200-300 nm in diameter. However, after thermal annealing, the film contains many voids and fibrous grains on the surface. In addition, the film thickness decreases after thermal annealing owing to evaporation of the surfactant, binder, and solvent composing the PTFE dispersion solution. The film thickness is systematically controlled from 2 to 6.5 μm by decreasing the spin speed from 1,500 to 500 rpm. A triboelectric nanogenerator is fabricated by spin-coating PTFE thin films onto polished Cu foils, where they act as an active layer to convert mechanical energy to electrical energy. A triboelectric nanogenerator consisting of a PTFE layer and Al metal foil pair shows typical output characteristics, exhibiting positive and negative peaks during applied strain and relief cycles due to charging and discharging of electrical charge carriers. Further, the voltage and current outputs increase with increasing strain cycle owing to accumulation of electrical charge carriers during charge-discharge.

-

Citations

Citations to this article as recorded by- Recent Development in Performance Enhancement of PVDF-Nanopowder Composite-based Energy Harvesting Devices

Geon-Ju Choi, Il-Kyu Park

Journal of Korean Powder Metallurgy Institute.2020; 27(3): 247. CrossRef

- Recent Development in Performance Enhancement of PVDF-Nanopowder Composite-based Energy Harvesting Devices

- [Korean]

- Dispersion Control and Characterization of the SiO2/PMMA Particles Using Surface Charge

- Yubin Kang, Soojung Son, Kun-Jae Lee

- J Korean Powder Metall Inst. 2015;22(6):403-407. Published online December 1, 2015

- DOI: https://doi.org/10.4150/KPMI.2015.22.6.403

- 872 View

- 7 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF Poly-methylmetacrylate (PMMA) is mainly applied in the plastic manufacturing industry, but PMMA is weak and gradually got discolor. The strength of PMMA can be improved through organic-inorganic hybrid nano composites with inorganic nano particles such as, SiO2 or ZrO. However, inorganic nano particles are mostly agglomerated spontaneously. In this study, the zeta potential is controlled using different types of organic solvent with different concentrations, dispersibillity of SiO2 nano particles on the PMMA particle are analyzed. When 3 M acetic acid is used, absolute value of the zeta potential is higher, SiO2 nano particle is well attached, and dispersed on the PMMA particle surface. Results indicate that the absolute value of the zeta potential affects the stability of SiO2 dispersion.

-

Citations

Citations to this article as recorded by- A Study of Organic Impurity Removal Efficiency for Waste LCD Touch Panel Glass by Solvents Types

Yubin Kang, Jin-Ju Choi, Jae Layng Park, Chan Gi Lee

Journal of the Korean Institute of Resources Recycling.2020; 29(6): 57. CrossRef - Hard Surface-adhesive Properties of TiO2 Nanoparticles-encapsulated Microparticles Prepared by Spray Drying and Surface Coating Method

Su-Kyung Kim, Jong-Duk Kim, Seung-Jun Lee

Fibers and Polymers.2018; 19(6): 1303. CrossRef

- A Study of Organic Impurity Removal Efficiency for Waste LCD Touch Panel Glass by Solvents Types

- [Korean]

- Microstructure Evolution of 15Cr ODS Steel by a Simple Torsion Test

- Hyun Ju Jin, Suk Hoon Kang, Tae Kyu Kim

- J Korean Powder Metall Inst. 2014;21(4):271-276. Published online August 1, 2014

- DOI: https://doi.org/10.4150/KPMI.2014.21.4.271

- 640 View

- 1 Download

- 4 Citations

-

Abstract

Abstract

PDF

PDF 15Cr-1Mo base oxide dispersion strengthened (ODS) steel which is considered to be as a promising candidate for high- temperature components in nuclear fusion and fission systems because of its excellent high temperature strength, corrosion and radiation resistance was fabricated by using mechanical alloying, hot isostatic pressing and hot rolling. Torsion tests were performed at room temperature, leading to two different shear strain routes in the forward and reverse directions. In this study, microstructure evolution of the ODS steel during simple shearing was investigated. Fine grained microstructure and a cell structure of dislocation with low angle boundaries were characterized with shear strain in the shear deformed region by electron backscattered diffraction (EBSD). Grain refinement with shear strain resulted in an increase in hardness. After the forward-reverse torsion, the hardness value was measured to be higher than that of the forward torsion only with an identical shear strain amount, suggesting that new dislocation cell structures inside the grain were generated, thus resulting in a larger strengthening of the steel.

-

Citations

Citations to this article as recorded by- Effect of high-energy ball milling on the microstructure and mechanical properties of Ni-based ODS alloys fabricated using gas-atomized powder

Chun Woong Park, Won June Choi, Jongmin Byun, Young Do Kim

Journal of Materials Science.2022; 57(38): 18195. CrossRef - Analysis on Milling Behavior of Oxide Dispersion Strengthened Ni-based Atomizing Powder with Ni5Y Intermetallic Phase

Chun Woong Park, Jong Min Byun, Won June Choi, Young Do Kim

Journal of Korean Powder Metallurgy Institute.2019; 26(2): 101. CrossRef - Current Status and Future Prospective of Advanced Radiation Resistant Oxide Dispersion Strengthened Steel (ARROS) Development for Nuclear Reactor System Applications

Tae Kyu Kim, Sanghoon Noh, Suk Hoon Kang, Jin Ju Park, Hyun Ju Jin, Min Ku Lee, Jinsugn Jang, Chang Kyu Rhee

Nuclear Engineering and Technology.2016; 48(2): 572. CrossRef - A Precipitation Behavior of Nano-Oxide Particles in Mechanically Alloyed Fe-5Y2O3Powders

Ga Eon Kim, Sanghoon Noh, Ji Eun Choi, Young Do Kim, Tae Kyu Kim

Journal of Korean Powder Metallurgy Institute.2015; 22(1): 46. CrossRef

- Effect of high-energy ball milling on the microstructure and mechanical properties of Ni-based ODS alloys fabricated using gas-atomized powder

- [Korean]

- Fabrication of Porous Cu by Freeze-drying Process of Camphene Slurry with CuO-coated Cu Powders

- Su-Ryong Bang, Sung-Tag Oh

- J Korean Powder Metall Inst. 2014;21(3):191-195. Published online June 1, 2014

- DOI: https://doi.org/10.4150/KPMI.2014.21.3.191

- 714 View

- 0 Download

- 3 Citations

-

Abstract

Abstract

PDF

PDF This study reports a simple way of fabricating the porous Cu with unidirectional pore channels by freeze drying camphene slurry with Cu oxide coated Cu powders. The coated powders were prepared by calcination of ballmilled powder mixture of Cu and Cu-nitrate. Improved dispersion stability of camphene slurry could be achieved using the Cu oxide coated Cu powders instead of pure Cu powders. Pores in the frozen specimen at -25°C were generated by sublimation of the camphene during drying in air, and the green bodies were sintered at 750°C for 1 h in H2 atmosphere. XRD analysis revealed that the coated layer of Cu oxide was completely converted to Cu phase without any reaction phases by hydrogen heat treatment. The porous Cu specimen prepared from pure Cu powders showed partly large pores with unidirectional pore channels, but most of pores were randomly distributed. In contrast, large and aligned parallel pores to the camphene growth direction were clearly observed in the sample using Cu oxide coated Cu powders. Pore formation behavior depending on the initial powders was discussed based on the degree of powder rearrangement and dispersion stability in slurry.

-

Citations

Citations to this article as recorded by- Effect of Freezing and Sintering Condition of CuO-SnO2/Camphene Slurries on the Pore Structure of Porous Cu-Sn

Joo-Hyung Kim, Sung-Tag Oh, Chang-Yong Hyun

Journal of Korean Powder Metallurgy Institute.2016; 23(1): 49. CrossRef - Fabrication of Cu-30 vol% SiC Composites by Pressureless Sintering of Polycarbosilane Coated SiC and Cu Powder Mixtures

Yeon Su Kim, Na-Yeon Kwon, Young-Keun Jeong, Sung-Tag Oh

Korean Journal of Materials Research.2016; 26(6): 337. CrossRef - Synthesis of Aligned Porous Sn by Freeze-Drying of Tin Chloride/camphene Slurry

수룡 방, 승탁 오

Korean Journal of Materials Research.2015; 25(1): 27~31. CrossRef

- Effect of Freezing and Sintering Condition of CuO-SnO2/Camphene Slurries on the Pore Structure of Porous Cu-Sn

- [Korean]

- Synthesis of Highly Dispersible Metal Nanoparticles in P3HT:PCBM Layers and Their Effects on the Performance of Polymer Solar Cells

- Min-Ji Kim, Gyu-Chae Choi, Young-Kuk Kim, Yang-Do Kim, Youn-Kyoung Baek

- J Korean Powder Metall Inst. 2014;21(3):179-184. Published online June 1, 2014

- DOI: https://doi.org/10.4150/KPMI.2014.21.3.179

- 407 View

- 0 Download

-

Abstract

Abstract

PDF

PDF In this study, we prepare polymer solar cells incorporating organic ligand-modified Ag nanoparticles (OAgNPs) highly dispersed in the P3HT:PCBM layer. Ag nanoparticles decorated with water-dispersible ligands (WAgNPs) were also utilized as a control sample. The existence of the ligands on the Ag surface was confirmed by FTIR spectra. Metal nanoparticles with different surface chemistries exhibited different dispersion tendencies. O-AgNPs were highly dispersed even at high concentrations, whereas W-AgNPs exhibited significant aggregation in the polymer layer. Both dispersion and blending concentration of the Ag nanoparticles in P3HT:PCBM matrix had critical effects on the device performance as well as light absorption. The significant changes in short-circuit current density (JSC) of the solar cells seemed to be related to the change in the polymer morphology according to the concentration of AgNPs introduced. These findings suggested the importance of uniform dispersion of plasmonic metal nanoparticles and their blending concentration conditions in order to boost the solar cell performance.

- [Korean]

- Synthesis and Antifungal Property of Porous Al2O3 with Dispersions of Cu Nanoparticles

- Ho-Suk Yoo, Min-Sung Kim, Sung-Tag Oh, Chang-Yong Hyun

- J Korean Powder Metall Inst. 2014;21(1):16-20. Published online February 1, 2014

- DOI: https://doi.org/10.4150/KPMI.2014.21.1.16

- 889 View

- 1 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF In order to fabricate the porous Al2O3 with dispersion of nano-sized Cu particles, freeze-drying of camphene/ Al2O3 slurry and solution chemistry process using Cu-nitrate are introduced. Camphene slurries with 10 vol% Al2O3 was frozen at -25°C. Pores were generated by sublimation of the camphene during drying in air. The sintered samples at 1400 and 1500°C showed the same size of large pores which were aligned parallel to the sublimable vehicles growth direction. However, the size of fine pores in the internal walls of large pores decreased with increase in sintering temperature. It was shown that Cu particles with the size of 100 nm were homogeneously dispersed on the surfaces of the large pores. Antibacterial test using fungus revealed that the porous Al2O3/1 vol% Cu composite showed antifungal property due to the dispersion of Cu particles. The results are suggested that the porous composites with required pore characteristics and functional property can be fabricated by freeze-drying process and addition of functional nano particles by chemical method.

-

Citations

Citations to this article as recorded by- Collection of Industrial Oil Using Nanoparticles and Porous Powders of Silica

Y.-S. Cho, J.-W. Moon

Archives of Metallurgy and Materials.2017; 62(2): 1371. CrossRef - Fabrication and Mechanical Properties of STS316L Porous Metal for Vacuum Injection Mold

Se Hoon Kim, Sang Min Kim, Sang Ho Noh, Jin Pyeong Kim, Jae Hyuck Shin, Si-Young Sung, Jin Kwang Jin, Taean Kim

Journal of Korean Powder Metallurgy Institute.2015; 22(3): 197. CrossRef

- Collection of Industrial Oil Using Nanoparticles and Porous Powders of Silica

TOP

KPMI

KPMI

First

First Prev

Prev