Search

- Page Path

- HOME > Search

- [English]

- Morphological Control and Surface Modification Characteristics of Nickel Oxalate Synthesized via Oxalic Acid Precipitation

- Eunbi Park, Jongwon Bae, Sera Kang, Minsu Kang, Suseong Lee, Kun-Jae Lee

- J Powder Mater. 2025;32(5):375-382. Published online October 31, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00248

- 982 View

- 21 Download

-

Abstract

Abstract

PDF

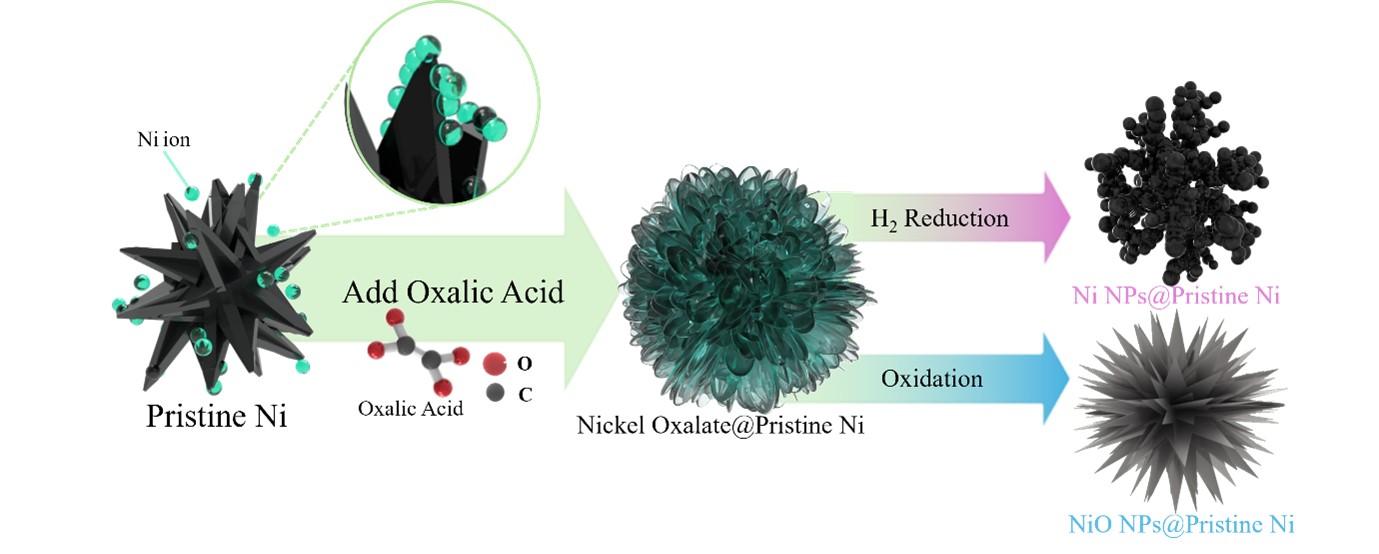

PDF - Nickel is widely used in industrial fields such as electrocatalysis and energy storage devices. Although micron-sized nickel particles exhibit excellent mechanical durability, their low specific surface area limits their reactivity. We modified the surface of micron-sized nickel particles with nanostructured nickel oxalate and investigated the effects of the solvent dielectric constant, surfactant, and thermal treatment atmosphere on the resulting particle morphology and phase transformation. Rietveld refinement analysis confirmed that changes in the solvent dielectric constant led to increased or diminished crystallinity of specific planes in nickel oxalate, resulting in diffraction patterns distinct from standard JCPDS data. These structural changes were also found to influence the morphology of the synthesized nickel oxalate. The results demonstrate that nickel oxalate serves as an effective precursor for producing Ni and NiO phases, and shape control of the final product can increase the surface reactivity of micron-sized nickel materials.

- [English]

- Recovery of Barium, Nickel, and Titanium Powders from Waste MLCC

- Haein Shin, Kun-Jae Lee

- J Powder Mater. 2024;31(5):374-381. Published online October 31, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00192

- 2,049 View

- 51 Download

-

Abstract

Abstract

PDF

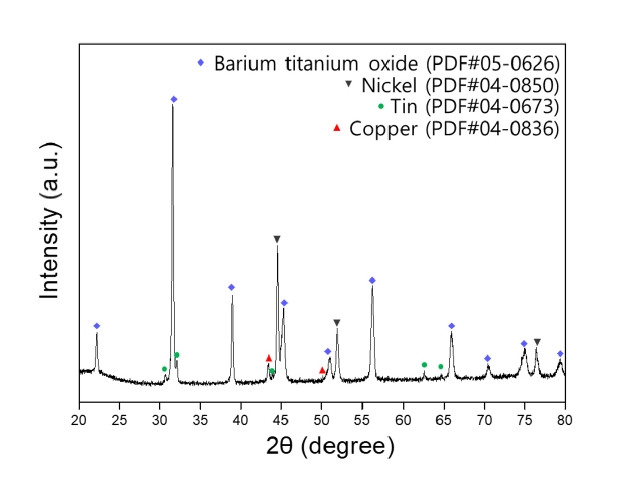

PDF - The development of the electronics industry has led to an increased demand for the manufacture of MLCC (Multilayer Ceramic Capacitors), which in turn is expected to result in a rise in MLCC waste. The MLCC contains various metals, notably barium, titanium, and nickel, whose disposal is anticipated to increase correspondingly. Recently, recycling technologies for electronic waste have garnered attention as they address waste management and raw material supply challenges. This paper investigates the recovery of barium, nickel, and titanium from the MLCC by a hydrometallurgical process. Using citric acid, which is an organic acid, the metal inside the MLCC was leached. Additionally, metal materials were recovered through precipitation and complexing processes. As a result, barium and titanium were recovered from the leachate of the waste MLCC, and 93% of the nickel-based powder was recovered. Furthermore, the optimal recovery process conditions for recycling these metal elements were investigated.

- [Korean]

- Characterization of Compacted and Pressureless Sintered Parts for Molybdenum Oxide Powder according to Hydrogen Reduction Temperature

- Jong Hoon Lee, Kun-Jae Lee

- J Powder Mater. 2024;31(4):336-341. Published online August 30, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00241

- 1,163 View

- 16 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF - Molybdenum, valued for its high melting point and exceptional physical and chemical properties, is studied in diverse fields such as electronics, petrochemicals, and aviation. Among molybdenum oxides, molybdenum dioxide stands out for its higher electrical conductivity than other transition metal oxides due to its structural characteristics, exhibiting metallic properties. It is applied as pellets to gas sensors, semiconductors, and secondary batteries for its properties. Thus, research on molybdenum dioxide compaction and pressureless sintering is necessary, yet research on pressureless sintering is currently insufficient. This study synthesized MoO₃ powder via solution combustion synthesis and reduced it using the 3% hydrogen/argon gas mixture to investigate the effect of reduction temperature on the powder. Additionally, the reduced powder was compacted and subjected to pressureless sintering with temperature as a variable. The density and the microstructure of brown parts were analyzed and discussed.

-

Citations

Citations to this article as recorded by- High-sensitivity optical fiber hydrogen sensing with MoO3/PANI/Pd nanocomposite

Mohammed M. Alkhabet, Saad H. Girei, Ammar H. Farhan, Fatimah F. Hashim, Jaafar A. Jaafar, Husam K. Salih, Manar F. Abbood, Mohd H. Yaacob

Materials Science in Semiconductor Processing.2025; 200: 110021. CrossRef

- High-sensitivity optical fiber hydrogen sensing with MoO3/PANI/Pd nanocomposite

- [Korean]

- Fabrication of Nanowire by Electrospinning Process Using Nickel Oxide Particle Recovered from MLCC

- Haein Shin, Jongwon Bae, Minsu Kang, Kun-Jae Lee

- J Powder Mater. 2023;30(6):502-508. Published online December 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.6.502

- 700 View

- 13 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF With the increasing demand for electronic products, the amount of multilayer ceramic capacitor (MLCC) waste has also increased. Recycling technology has recently gained attention because it can simultaneously address raw material supply and waste disposal issues. However, research on recovering valuable metals from MLCCs and converting the recovered metals into high-value-added materials remains insufficient. Herein, we describe an electrospinning (E-spinning) process to recover nickel from MLCCs and modulate the morphology of the recovered nickel oxide particles. The nickel oxalate powder was recovered using organic acid leaching and precipitation. Nickel oxide nanoparticles were prepared via heat treatment and ultrasonic milling. A mixture of nickel oxide particles and polyvinylpyrrolidone (PVP) was used as the E-spinning solution. A PVP/NiO nanowire composite was fabricated via Espinning, and a nickel oxide nanowire with a network structure was manufactured through calcination. The nanowire diameters and morphologies are discussed based on the nickel oxide content in the E-spinning solution.

-

Citations

Citations to this article as recorded by- Morphological Control and Surface Modification Characteristics of Nickel Oxalate Synthesized via Oxalic Acid Precipitation

Eunbi Park, Jongwon Bae, Sera Kang, Minsu Kang, Suseong Lee, Kun-Jae Lee

Journal of Powder Materials.2025; 32(5): 375. CrossRef

- Morphological Control and Surface Modification Characteristics of Nickel Oxalate Synthesized via Oxalic Acid Precipitation

- [Korean]

- The Synthesis of Lithium Lanthanum Titanium Oxide for Solid Electrolyte via Ultrasonic Spray Pyrolysis

- Jaeseok Roh, MinHo Yang, Kun-Jae Lee

- J Powder Mater. 2022;29(6):485-491. Published online December 1, 2022

- DOI: https://doi.org/10.4150/KPMI.2022.29.6.485

- 1,427 View

- 23 Download

-

Abstract

Abstract

PDF

PDF Lithium lanthanum titanium oxide (LLTO) is a promising ceramic electrolyte because of its high ionic conductivity at room temperature, low electrical conductivity, and outstanding physical properties. Several routes for the synthesis of bulk LLTO are known, in particular, solid-state synthesis and sol-gel method. However, the extremely low ionic conductivity of LLTO at grain boundaries is one of the major problems for practical applications. To diminish the grain boundary effect, the structure of LLTO is tuned to nanoscale morphology with structures of different dimensionalities (0D spheres, and 1D tubes and wires); this strategy has great potential to enhance the ion conduction by intensifying Li diffusion and minimizing the grain boundary resistance. Therefore, in this work, 0D spherical LLTO is synthesized using ultrasonic spray pyrolysis (USP). The USP method primarily yields spherical particles from the droplets generated by ultrasonic waves passed through several heating zones. LLTO is synthesized using USP, and the effects of each precursor and their mechanisms as well as synthesis parameters are analyzed and discussed to optimize the synthesis. The phase structure of the obtained materials is analyzed using X-ray diffraction, and their morphology and particle size are analyzed using field-emission scanning electron microscopy.

- [Korean]

- Analysis of Wafer Cleaning Solution Characteristics and Metal Dissolution Behavior according to the Addition of Chelating Agent

- Myungsuk Kim, Keunhyuk Ryu, Kun-Jae Lee

- J Korean Powder Metall Inst. 2021;28(1):25-30. Published online February 1, 2021

- DOI: https://doi.org/10.4150/KPMI.2021.28.1.25

- 914 View

- 12 Download

-

Abstract

Abstract

PDF

PDF The surface of silicon dummy wafers is contaminated with metallic impurities owing to the reaction with and adhesion of chemicals during the oxidation process. These metallic impurities negatively affect the device performance, reliability, and yield. To solve this problem, a wafer-cleaning process that removes metallic impurities is essential. RCA (Radio Corporation of America) cleaning is commonly used, but there are problems such as increased surface roughness and formation of metal hydroxides. Herein, we attempt to use a chelating agent (EDTA) to reduce the surface roughness, improve the stability of cleaning solutions, and prevent the re-adsorption of impurities. The bonding between the cleaning solution and metal powder is analyzed by referring to the Pourbaix diagram. The changes in the ionic conductivity, H2O2 decomposition behavior, and degree of dissolution are checked with a conductivity meter, and the changes in the absorbance and particle size before and after the reaction are confirmed by ultraviolet-visible spectroscopy (UV-vis) and dynamic light scattering (DLS) analyses. Thus, the addition of a chelating agent prevents the decomposition of H2O2 and improves the life of the silicon wafer cleaning solution, allowing it to react smoothly with metallic impurities.

- [Korean]

- Synthesis and Nucleation Behavior of MoO3 Nano Particles with Concentration of Precursors

- Seyoung Lee, Namhun Kwon, Jaeseok Roh, Kun-Jae Lee

- J Korean Powder Metall Inst. 2020;27(5):394-400. Published online October 1, 2020

- DOI: https://doi.org/10.4150/KPMI.2020.27.5.394

- 1,484 View

- 8 Download

- 1 Citations

-

Abstract

Abstract

PDF

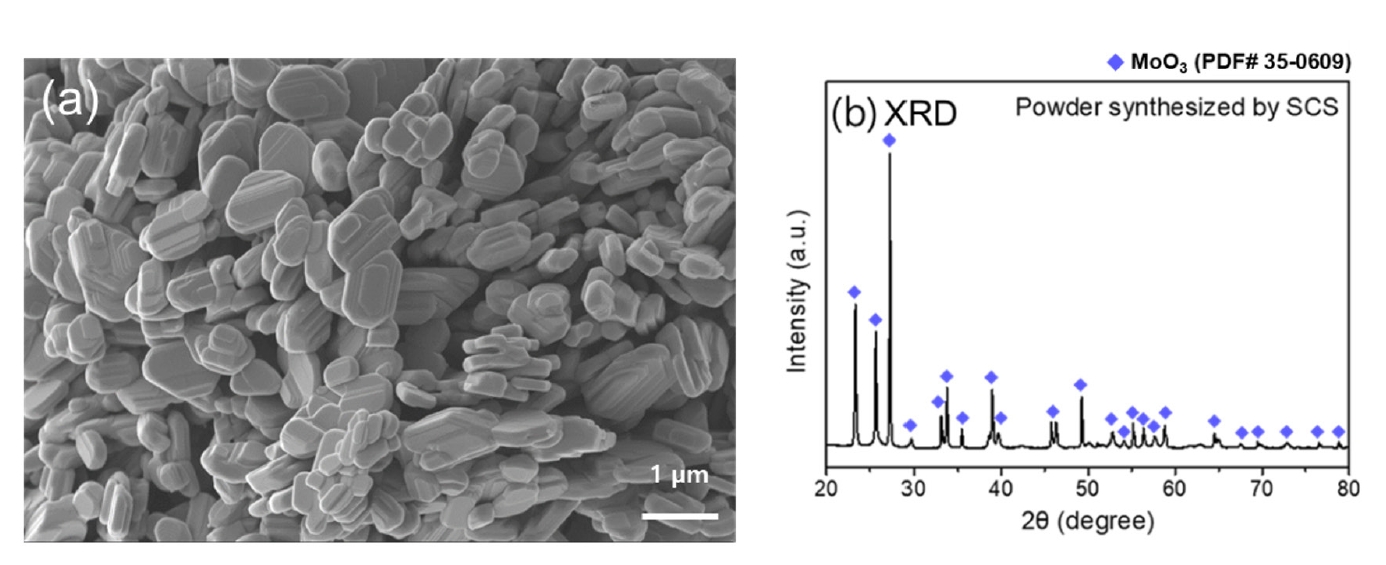

PDF Molybdenum trioxide (MoO3) is used in various applications including sensors, photocatalysts, and batteries owing to its excellent ionic conductivity and thermal properties. It can also be used as a precursor in the hydrogen reduction process to obtain molybdenum metals. Control of the parameters governing the MoO3 synthesis process is extremely important because the size and shape of MoO3 in the reduction process affect the shape, size, and crystallization of Mo metal. In this study, we fabricated MoO3 nanoparticles using a solution combustion synthesis (SCS) method that utilizes an organic additive, thereby controlling their morphology. The nucleation behavior and particle morphology were confirmed using ultraviolet-visible spectroscopy (UV-vis) and field emission scanning electron microscopy (FE-SEM). The concentration of the precursor (ammonium heptamolybdate tetrahydrate) was adjusted to be 0.1, 0.2, and 0.4 M. Depending on this concentration, different nucleation rates were obtained, thereby resulting in different particle morphologies.

-

Citations

Citations to this article as recorded by- Characterization of Compacted and Pressureless Sintered Parts for Molybdenum Oxide Powder according to Hydrogen Reduction Temperature

Jong Hoon Lee, Kun-Jae Lee

Journal of Powder Materials.2024; 31(4): 336. CrossRef

- Characterization of Compacted and Pressureless Sintered Parts for Molybdenum Oxide Powder according to Hydrogen Reduction Temperature

- [Korean]

- A Study on the Preparation and Growth Mechanism of Titanium Dioxide using Organic-Inorganic Hybrid Titanium Complex

- Yubin Kang, Jin-Ju Choi, Nam Hun Kwon, Dae-Guen Kim, Kun-Jae Lee

- J Korean Powder Metall Inst. 2019;26(6):487-492. Published online December 1, 2019

- DOI: https://doi.org/10.4150/KPMI.2019.26.6.487

- 1,108 View

- 15 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF Titanium dioxide (TiO2) is a typical inorganic material that has an excellent photocatalytic property and a high refractive index. It is used in water/air purifiers, solar cells, white pigments, refractory materials, semiconductors, etc.; its demand is continuously increasing. In this study, anatase and rutile phase titanium dioxide is prepared using hydroxyl and carboxyl; the titanium complex and its mechanism are investigated. As a result of analyzing the phase transition characteristics by a heat treatment temperature using a titanium complex having a hydroxyl group and a carboxyl group, it is confirmed that the material properties were different from each other and that the anatase and rutile phase contents can be controlled. The titanium complexes prepared in this study show different characteristics from the titania-formation temperatures of the known anatase and rutile phases. It is inferred that this is due to the change of electrostatic adsorption behavior due to the complexing function of the oxygen sharing point, which crystals of the TiO6 structure share.

-

Citations

Citations to this article as recorded by- Thermal Stability and Weight Reduction of Al0.75V2.82CrZr Refractory High Entropy Alloy Prepared Via Mechanical Alloying

Minsu Kim, Hansung Lee, Byungmin Ahn

journal of Korean Powder Metallurgy Institute.2023; 30(6): 478. CrossRef

- Thermal Stability and Weight Reduction of Al0.75V2.82CrZr Refractory High Entropy Alloy Prepared Via Mechanical Alloying

- [Korean]

- Investigation on Size Distribution of Tungsten-based Alloy Particles with Solvent Viscosity During Ultrasonic Ball Milling Process

- KeunHyuk Ryu, HyeongSub So, JiSeok Yun, InHo Kim, Kun-Jae Lee

- J Korean Powder Metall Inst. 2019;26(3):201-207. Published online June 1, 2019

- DOI: https://doi.org/10.4150/KPMI.2019.26.3.201

- 1,089 View

- 3 Download

- 3 Citations

-

Abstract

Abstract

PDF

PDF Tungsten heavy alloys (W–Ni–Fe) play an important role in various industries because of their excellent mechanical properties, such as the excellent hardness of tungsten, low thermal expansion, corrosion resistance of nickel, and ductility of iron. In tungsten heavy alloys, tungsten nanoparticles allow the relatively low-temperature molding of high-melting-point tungsten and can improve densification. In this study, to improve the densification of tungsten heavy alloy, nanoparticles are manufactured by ultrasonic milling of metal oxide. The physical properties of the metal oxide and the solvent viscosity are selected as the main parameters. When the density is low and the Mohs hardness is high, the particle size distribution is relatively high. When the density is high and the Mohs hardness is low, the particle size distribution is relatively low. Additionally, the average particle size tends to decrease with increasing viscosity. Metal oxides prepared by ultrasonic milling in high-viscosity solvent show an average particle size of less than 300 nm based on the dynamic light scattering and scanning electron microscopy analysis. The effects of the physical properties of the metal oxide and the solvent viscosity on the pulverization are analyzed experimentally.

-

Citations

Citations to this article as recorded by- Morphological Control and Surface Modification Characteristics of Nickel Oxalate Synthesized via Oxalic Acid Precipitation

Eunbi Park, Jongwon Bae, Sera Kang, Minsu Kang, Suseong Lee, Kun-Jae Lee

Journal of Powder Materials.2025; 32(5): 375. CrossRef - Manufacture of high sensitive Ag-Fe3O4-PDMS nanocomposite pressure sensor through morphology control of conductive filler

Keunhyuk Ryu, Namhun Kwon, Kun-Jae Lee

Advanced Powder Technology.2021; 32(7): 2441. CrossRef - Grinding behavior of WO3, NiO, Fe2O3 by ultrasonic milling parameters control and preparation of nanocomposite powder

Keunhyuk Ryu, Kun-Jae Lee

Advanced Powder Technology.2020; 31(9): 3867. CrossRef

- Morphological Control and Surface Modification Characteristics of Nickel Oxalate Synthesized via Oxalic Acid Precipitation

- [Korean]

- Recovery and Synthesis of Silver Nanoparticles from Leaching Solution of LTCC Electrode By-Products

- Juyeon Yoo, Yubin Kang, Jinju Park, Hojin Ryu, Jin-Ho Yoon, Kun-Jae Lee

- J Korean Powder Metall Inst. 2017;24(4):315-320. Published online August 1, 2017

- DOI: https://doi.org/10.4150/KPMI.2017.24.4.315

- 490 View

- 2 Download

-

Abstract

Abstract

PDF

PDF There has been much interest in recycling electronic wastes in order to mitigate environmental problems and to recover the large amount of constituent metals. Silver recovery from electronic waste is extensively studied because of environmental and economic benefits and the use of silver in fabricating nanodevices. Hydrometallurgical processing is often used for silver recovery because it has the advantages of low cost and ease of control. Research on synthesis recovered silver into nanoparticles is needed for application to transistors and solar cells. In this study, silver is selectively recovered from the by-product of electrodes. Silver precursors are prepared using the dissolution characteristics of the leaching solution. In the liquid reduction process, silver nanoparticles are synthesized under various surfactant conditions and then analyzed. The purity of the recovered silver is 99.24%, and the average particle size of the silver nanoparticles is 68 nm.

- [Korean]

- The Preparation and Growth Mechanism of the Recovered Bi2Te3 Particles with Respect to Surfactants

- Hyeongsub So, Eunpil Song, Yong-Ho Choa, Kun-Jae Lee

- J Korean Powder Metall Inst. 2017;24(2):141-146. Published online April 1, 2017

- DOI: https://doi.org/10.4150/KPMI.2017.24.2.141

- 1,150 View

- 9 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF Bi2Te3 powders are recovered by wet chemical reduction for waste n-type thermoelectric chips, and the recovered particles with different morphologies are prepared using various surfactants such as cetyltrimethylammonium bromide (CTAB), sodium dodecylbenzenesulfonate (SDBS), and ethylenediaminetetraacetic acid (EDTA). When citric acid is added as the surfactant, the shape of the aggregated particles shows no distinctive features. On the other hand, rod-shaped particles are formed in the sample with CTAB, and sheet-like particles are synthesized with the addition of SDBS. Further, particles with a tripod shape are observed when EDTA is added as the surfactant. The growth mechanism of the particle shapes depending on the surfactant is investigated, with a focus on the nucleation and growth phenomena. These results help to elucidate the intrinsic formation mechanism of the rod, plate, and tripod structures of the Bi2Te3 recovered by the wet reduction process.

-

Citations

Citations to this article as recorded by- Recovery of Barium, Nickel, and Titanium Powders from Waste MLCC

Haein Shin, Kun-Jae Lee

Journal of Powder Materials.2024; 31(5): 374. CrossRef

- Recovery of Barium, Nickel, and Titanium Powders from Waste MLCC

- [Korean]

- Fabrication and Characterization of Ag Particles by Polyol Process and Wet Chemical Process

- Juyeon Yoo, Hyosung Jang, Kun-Jae Lee

- J Korean Powder Metall Inst. 2016;23(4):297-302. Published online August 1, 2016

- DOI: https://doi.org/10.4150/KPMI.2016.23.4.297

- 767 View

- 3 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF Ag nanoparticles are extensively studied and utilized due to their excellent catalysis, antibiosis and optical properties. They can be easily synthesized by chemical reduction methods and it is possible to prepare particles of uniform size and high purity. These methods are divided into vapor methods and liquid phase reduction methods. In the present study, Ag particles are prepared and analyzed through two chemical reduction methods using solvents containing a silver nitrate precursor. When Ag ions are reduced using a reductant in the aqueous solution, it is possible to control the Ag particle size by controlling the formic acid ratio. In addition, in the Polyol process, Ag nanoparticles prepared at various temperatures and reaction time conditions have multiple twinned and anisotropic structures, and the particle size variation can be confirmed using field emissions scanning electron microscopy and by analyzing the UV-vis spectrum.

-

Citations

Citations to this article as recorded by- Recovery and Synthesis of Silver Nanoparticles from Leaching Solution of LTCC Electrode By-Products

Juyeon Yoo, Yubin Kang, Jinju Park, Hojin Ryu, Jin-Ho Yoon, Kun-Jae Lee

Journal of Korean Powder Metallurgy Institute.2017; 24(4): 315. CrossRef

- Recovery and Synthesis of Silver Nanoparticles from Leaching Solution of LTCC Electrode By-Products

- [Korean]

- Dispersion Control and Characterization of the SiO2/PMMA Particles Using Surface Charge

- Yubin Kang, Soojung Son, Kun-Jae Lee

- J Korean Powder Metall Inst. 2015;22(6):403-407. Published online December 1, 2015

- DOI: https://doi.org/10.4150/KPMI.2015.22.6.403

- 952 View

- 7 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF Poly-methylmetacrylate (PMMA) is mainly applied in the plastic manufacturing industry, but PMMA is weak and gradually got discolor. The strength of PMMA can be improved through organic-inorganic hybrid nano composites with inorganic nano particles such as, SiO2 or ZrO. However, inorganic nano particles are mostly agglomerated spontaneously. In this study, the zeta potential is controlled using different types of organic solvent with different concentrations, dispersibillity of SiO2 nano particles on the PMMA particle are analyzed. When 3 M acetic acid is used, absolute value of the zeta potential is higher, SiO2 nano particle is well attached, and dispersed on the PMMA particle surface. Results indicate that the absolute value of the zeta potential affects the stability of SiO2 dispersion.

-

Citations

Citations to this article as recorded by- A Study of Organic Impurity Removal Efficiency for Waste LCD Touch Panel Glass by Solvents Types

Yubin Kang, Jin-Ju Choi, Jae Layng Park, Chan Gi Lee

Journal of the Korean Institute of Resources Recycling.2020; 29(6): 57. CrossRef - Hard Surface-adhesive Properties of TiO2 Nanoparticles-encapsulated Microparticles Prepared by Spray Drying and Surface Coating Method

Su-Kyung Kim, Jong-Duk Kim, Seung-Jun Lee

Fibers and Polymers.2018; 19(6): 1303. CrossRef

- A Study of Organic Impurity Removal Efficiency for Waste LCD Touch Panel Glass by Solvents Types

- [Korean]

- Characteristics of the Ceramic Filter with the Control of Particle Size and Graphite Additive for the Hazardous Particle and Gas Removal

- Eul-Hun Cho, Kun-Jae Lee

- J Korean Powder Metall Inst. 2014;21(6):454-459. Published online December 1, 2014

- DOI: https://doi.org/10.4150/KPMI.2014.21.6.454

- 525 View

- 2 Download

-

Abstract

Abstract

PDF

PDF In this study, the porous ceramic filter was developed to be able to remove both dust and hazardous gas contained in fuel gas at high temperature. The porous ceramic filters were fabricated and used as a catalyst support. And the effects have been investigated such as the mean particle size, organic content and addition of foaming agent on the porosity, compressive strength and pressure drop of ceramic filters. With the increase of mean powder size and the organic content for the cordierite filter, the porosity was increased, but the compressive strength and pressure drop were decreased. From the results of the research, the optimum condition for the fabrication of ceramic filters could be acquired and they had the porosity of 58%, the compressive strength of 13.4 MPa and the pressure drop of 250 Pa. It was expected that this ceramic filter was able to be applied to the glass melting furnace, combustor, and dust/toxic gas removal filter.

- [Korean]

- Synthesis and Electrochemical Performance of Li2MnSiO4 for Lithium Ion Battery Prepared by Amorphous Silica Precusor

- Yun-Ho Jin, Kun-Jae Lee, Lee-Seung Kang, Hang-Chul Jung, Hyun-Seon Hong

- J Korean Powder Metall Inst. 2012;19(3):210-214.

- DOI: https://doi.org/10.4150/KPMI.2012.19.3.210

- 621 View

- 0 Download

-

Abstract

Abstract

PDF

PDF - Mass production-capable Li_2MnSiO_4 powder was synthesized for use as cathode material in state-of-the-art lithium-ion batteries. These batteries are main powder sources for high tech-end digital electronic equipments and electric vehicles in the near future and they must possess high specific capacity and durable charge-discharge characteristics. Amorphous silicone was quite superior to crystalline one as starting material to fabricate silicone oxide with high reactivity between precursors of sol-gel type reaction intermediates. The amorphous silicone starting material also has beneficial effect of efficiently controlling secondary phases, most notably Li_xSiO_x. Lastly, carbon was coated on Li_2MnSiO_4 powders by using sucrose to afford some improved electrical conductivity. The carbon-coated Li_2MnSiO_4 cathode material was further characterized using SEM, XRD, and galvanostatic charge/discharge test method for morphological and electrochemical examinations. Coin cell was subject to 1.5-4.8 V at C/20, where 74 mAh/g was observed during primary discharge cycle.

- [Korean]

- Microstructure and Mechanical Properties of Al2O3/Fe-Ni Nanocomposite Prepared by Rapid Sintering

- Young-In Lee, Kun-Jae Lee, Dae-Hwan Jang, Jae-Kyo Yang, Yong-Ho Cho

- J Korean Powder Metall Inst. 2010;17(3):203-208.

- DOI: https://doi.org/10.4150/KPMI.2010.17.3.203

- 560 View

- 1 Download

-

Abstract

Abstract

PDF

PDF - A new High Frequency Induction Heating (HFIH) process has been developed to fabricate dense Al_2O_3 reinforced with Fe-Ni magnetic metal dispersion particles. The process is based on the reduction of metal oxide particles immediately prior to sintering. The synthesized Al_2O_3/Fe-Ni nanocomposite powders were formed directly from the selective reduction of metal oxide powders, such as NiO and Fe_2O_3. Dense Al_2O_3/Fe-Ni nanocomposite was fabricated using the HFIH method with an extremely high heating rate of 2000°C/min. Phase identification and microstructure of nanocomposite powders and sintered specimens were determined by X-ray diffraction and SEM and TEM, respectively. Vickers hardness experiment were performed to investigate the mechanical properties of the Al_2O_3/Fe-Ni nanocomposite.

- [Korean]

- Synthesis of Eu3+ Doped (Y,Gd)BO3 Powder by Mechanochemical Process

- Hee-Sub Won, Wan-Jae Lee, Je-Seok Kim, Gun-Young Hong, Kun-Jae Lee, Yong-Ho Choa

- J Korean Powder Metall Inst. 2008;15(2):136-141.

- DOI: https://doi.org/10.4150/KPMI.2008.15.2.136

- 876 View

- 1 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF - The mechanochemical process were employed to prepare the red phosphors (Y,Gd)BO_3:Eu3+. The main factors affecting particle size, particle distribution, and luminescent properties of the product were investigated in details. Particles sized around 200-600 nm are formed after intensive milling. The phosphors were characterized by X-ray diffraction (XRD), scanning electron microscope (SEM) and photoluminescence spectrum. Results revealed that phosphors with different morphology, small particle size and high luminescence intensity could be obtained by mechanochemical process.

-

Citations

Citations to this article as recorded by- Photoluminescence Properties of Green Phosphor Y1-xBO3:Tbx3+Synthesized by Solid-state Reaction Method

Shin-Ho Cho

Journal of the Korean Institute of Electrical and Electronic Material Engineers.2011; 24(8): 659. CrossRef

- Photoluminescence Properties of Green Phosphor Y1-xBO3:Tbx3+Synthesized by Solid-state Reaction Method

- [Korean]

- Fabrication and Characterization of Ag Nanoparticle Dispersed Polymer Nanofiber and Ag Nanofiber Using Electrospinning Method

- Hee-Taik Kim, Chi-Yong Hwang, Han-Bok Song, Kun-Jae Lee, Yeon-Jun Joo, Seong-Jei Hong, Nam-Kee Kang, Seong-Dae Park, Ki-Do Kim, Yong-Ho Cho

- J Korean Powder Metall Inst. 2008;15(2):114-118.

- DOI: https://doi.org/10.4150/KPMI.2008.15.2.114

- 1,020 View

- 3 Download

- 3 Citations

-

Abstract

Abstract

PDF

PDF - Functional nanomaterial is expected to have improved capacities on various fields. Especially, metal nanoparticles dispersed in polymer matrix and metal nanofiber, one of the functional nanomaterials, are able to achieve improvement of property in the electric and other related fields. In this study, the fabrication of metal (Ag) nanoparticle dispersed nanofibers were attempted. The Ag nanoparticle dispersed polymer nanofiber and Ag nanofiber were fabricated by electrospinning method using electric force. First, PVP/AgNO_3 nanofibers were synthesized by electrospinning in 18sim22kV voltage with the starting materials (Ag-nitrate) added polymer (PVP; poly (vinylpyrrolidone)). Then Ag nanoparticle dispersed polymer nanofibers were fabricated to reduce hydrogen reduction at 150°C for 3hr. And Ag nanofibers were synthesized by the decomposited of PVP at 300sim500°C for 3hr. The nanofibers were analyzed by XRD, TGA, FE-SEM and TEM. The experimental results showed that the Ag nanofibers could be applied in many fields as an advanced material.

-

Citations

Citations to this article as recorded by- Fabrication of Nanowire by Electrospinning Process Using Nickel Oxide Particle Recovered from MLCC

Haein Shin, Jongwon Bae, Minsu Kang, Kun-Jae Lee

journal of Korean Powder Metallurgy Institute.2023; 30(6): 502. CrossRef - Fabrication of Flake-like LiCoO2Nanopowders using Electrospinning

Bon-Ryul Koo, Geon-Hyoung An, Hyo-Jin Ahn

Journal of Korean Powder Metallurgy Institute.2014; 21(2): 108. CrossRef - Synthesis of Fe-Doped TiO2/α-Fe2O3 Core-Shell Nanowires Using Co-Electrospinning and Their Magnetic Property

본율 구, 효진 안

Korean Journal of Materials Research.2014; 24(8): 423~428. CrossRef

- Fabrication of Nanowire by Electrospinning Process Using Nickel Oxide Particle Recovered from MLCC

- [Korean]

- Development and Application of Metal Nanoparticles for Printed Electronics: Application to Metal Ink in Ink-Jet Technology

- Kun-Jae Lee, Yong-Ho Choa

- J Korean Powder Metall Inst. 2008;15(2):81-86.

- DOI: https://doi.org/10.4150/KPMI.2008.15.2.081

- 709 View

- 2 Download

- [Korean]

- Fabrication of Sn and SnO2 Nanopowders by Low-Temperature Phase Transformation Method

- Kun-Jae Lee, Yeon-Jun Joo, Yong-Dae So, Nam-Hoon Kim, Jai-Sung Lee, Yong-Ho Choa

- J Korean Powder Metall Inst. 2006;13(1):46-51.

- DOI: https://doi.org/10.4150/KPMI.2006.13.1.046

- 462 View

- 1 Download

-

Abstract

Abstract

PDF

PDF - Through the volume change of Sn in a low-temperature phase transformation, the Sn nanopowder with high, purity, was fabricated by an economic and eco-friendly process. The fine cracks were spontaneously generated. in, Sn ingot, which was reduced to powders in the repetition of phase transformation. The Sn nanopowder with 50 run in size was obtained by the 24th repetitions of phase transformation by low-temperature and ultrasonic treatments. Also, the SnO_2 powder was fabricated by the oxidation of the produced Sn powder to the ingot and milled by the ultrasonic milling method. The SnO_2 nanopowder of 20 nm in size was fabricated after the milling for 180 h.

TOP

KPMI

KPMI

First

First Prev

Prev