Search

- Page Path

- HOME > Search

- [English]

- The Effect of Aluminum Powder Size on the Structure and Mechanical Properties of Foam

- Seunghyeok Choi, Sungjin Kim, Tae-Young Ahn, Yu-Song Choi, Jae-Gil Jung, Seung Bae Son, Seok-Jae Lee

- J Powder Mater. 2025;32(3):232-243. Published online June 30, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00157

- 1,278 View

- 50 Download

- 1 Citations

-

Abstract

Abstract

PDF

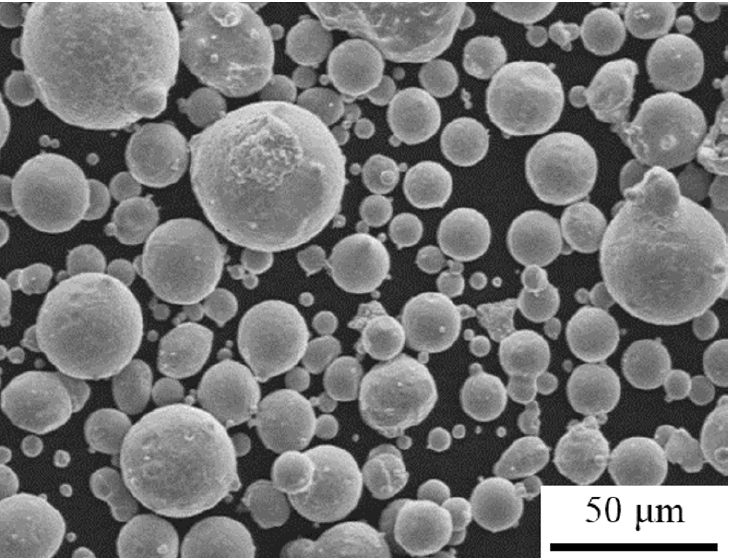

PDF - In this study, we analyzed the structural and mechanical properties of aluminum foams fabricated using aluminum powders of varying sizes and mixtures. The effects of sintering and pore structure at each size on the integrity and mechanical properties of the foams were investigated. Structural characteristics were examined using scanning electron microscopy and micro–computed tomography, while mechanical properties were evaluated through compression testing. The experimental results demonstrated that smaller powder sizes improved foam integrity, reduced porosity and pore size, and resulted in thinner cell walls. In combination, these effects increased compressive strength as the powder size decreased. The findings of this study contribute to the understanding and improvement of the mechanical properties of aluminum foams and highlight their potential for use in a wide range of applications.

-

Citations

Citations to this article as recorded by- Sustainable Manufacturing of Graphene–Aluminum Composites: A Comparative Life Cycle Assessment

Xinwei Yang, Qian Peng, Changke Chen, Qingcui Liu, Yudai Huang

Journal of Sustainable Metallurgy.2026; 12(1): 727. CrossRef

- Sustainable Manufacturing of Graphene–Aluminum Composites: A Comparative Life Cycle Assessment

- [Korean]

- Effect of Sintering Conditions on the Microstructure of an FeCrMnNiCo High-Entropy Alloy

- Seonghyun Park, Sang-Hwa Lee, Junho Lee, Seok-Jae Lee, Jae-Gil Jung

- J Powder Mater. 2024;31(5):406-413. Published online October 31, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00185

- 1,216 View

- 39 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF - We investigated the microstructure of an FeCrMnNiCo alloy fabricated by spark plasma sintering under different sintering temperatures (1000–1100°C) and times (1–600 s). All sintered alloys consisted of a single face-centered cubic phase. As the sintering time or temperature increased, the grains of the sintered alloys became partially coarse. The formation of Cr7C3 carbide occurred on the surface of the sintered alloys due to carbon diffusion from the graphite crucible. The depth of the layer containing Cr7C3 carbides increased to ~110 μm under severe sintering conditions (1100°C, 60 s). A molten zone was observed on the surface of the alloys sintered at higher temperatures (>1060°C) due to severe carbon diffusion that reduced the melting point of the alloy. The porosity of the sintered alloys decreased with increasing time at 1000°C, but increased at higher temperatures above 1060°C due to melting-induced porosity formation.

-

Citations

Citations to this article as recorded by- Fabrication and Alloying Behavior of Ultra-Lightweight AlTiCrVMg High-Entropy Alloy via Al-Mg Mutual Solubility and Sintering Control

Eunhyo Song, Hansung Lee, Byungmin Ahn

Journal of Powder Materials.2025; 32(3): 254. CrossRef - Microstructure and mechanical properties of oxide-dispersion-strengthened CrMnFeCoNiC0.2O0.2 high-entropy alloy fabricated by mechanical alloying and spark plasma sintering

Sang-Hwa Lee, Seonghyun Park, Ka Ram Lim, Seok-Jae Lee, Jae-Gil Jung

Materials Science and Engineering: A.2025; 947: 149284. CrossRef

- Fabrication and Alloying Behavior of Ultra-Lightweight AlTiCrVMg High-Entropy Alloy via Al-Mg Mutual Solubility and Sintering Control

- [Korean]

- Effect of Heat Treatment on Microstructure and Mechanical Properties of Al–Zn–Mg–Cu–Si Sintered Alloys with and Without High-energy Ball Milling

- Junho Lee, Seonghyun Park, Sang-Hwa Lee, Seung Bae Son, Seok-Jae Lee, Jae-Gil Jung

- J Powder Mater. 2023;30(6):470-477. Published online December 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.6.470

- 2,730 View

- 32 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF The effects of annealing on the microstructure and mechanical properties of Al–Zn–Mg–Cu–Si alloys fabricated by high-energy ball milling (HEBM) and spark plasma sintering (SPS) were investigated. The HEBM-free sintered alloy primarily contained Mg2Si, Q-AlCuMgSi, and Si phases. Meanwhile, the HEBM-sintered alloy contains Mg-free Si and θ-Al2Cu phases due to the formation of MgO, which causes Mg depletion in the Al matrix. Annealing without and with HEBM at 500°C causes partial dissolution and coarsening of the Q-AlCuMgSi and Mg2Si phases in the alloy and dissolution of the θ-Al2Cu phase in the alloy, respectively. In both alloys, a thermally stable α-AlFeSi phase was formed after long-term heat treatment. The grain size of the sintered alloys with and without HEBM increased from 0.5 to 1.0 μm and from 2.9 to 6.3 μm, respectively. The hardness of the sintered alloy increases after annealing for 1 h but decreases significantly after 24 h of annealing. Extending the annealing time to 168 h improved the hardness of the alloy without HEBM but had little effect on the alloy with HEBM. The relationship between the microstructural factors and the hardness of the sintered and annealed alloys is discussed.

-

Citations

Citations to this article as recorded by- Microstructural evolution and thermal stability of Al–Zn–Mg–Cu–Si–Zr alloy fabricated via spark plasma sintering

Junho Lee, Seonghyun Park, Sang-Hwa Lee, Seung Bae Son, Hanjung Kwon, Seok-Jae Lee, Jae-Gil Jung

Journal of Materials Research and Technology.2024; 31: 205. CrossRef

- Microstructural evolution and thermal stability of Al–Zn–Mg–Cu–Si–Zr alloy fabricated via spark plasma sintering

- [Korean]

- Application of Explainable Artificial Intelligence for Predicting Hardness of AlSi10Mg Alloy Manufactured by Laser Powder Bed Fusion

- Junhyub Jeon, Namhyuk Seo, Min-Su Kim, Seung Bae Son, Jae-Gil Jung, Seok-Jae Lee

- J Powder Mater. 2023;30(3):210-216. Published online June 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.3.210

- 1,240 View

- 25 Download

-

Abstract

Abstract

PDF

PDF In this study, machine learning models are proposed to predict the Vickers hardness of AlSi10Mg alloys fabricated by laser powder bed fusion (LPBF). A total of 113 utilizable datasets were collected from the literature. The hyperparameters of the machine-learning models were adjusted to select an accurate predictive model. The random forest regression (RFR) model showed the best performance compared to support vector regression, artificial neural networks, and k-nearest neighbors. The variable importance and prediction mechanisms of the RFR were discussed by Shapley additive explanation (SHAP). Aging time had the greatest influence on the Vickers hardness, followed by solution time, solution temperature, layer thickness, scan speed, power, aging temperature, average particle size, and hatching distance. Detailed prediction mechanisms for RFR are analyzed using SHAP dependence plots.

- [Korean]

- Effect of Mo Addition on the Austenite Stability of Nanocrystalline Fe-7wt.%Mn Alloy Fabricated by Spark Plasma Sintering

- Woochul Shin, Seung Bae Son, Jae-Gil Jung, Seok-Jae Lee

- J Powder Mater. 2022;29(6):517-522. Published online December 1, 2022

- DOI: https://doi.org/10.4150/KPMI.2022.29.6.517

- 856 View

- 12 Download

-

Abstract

Abstract

PDF

PDF We investigate the austenite stability in nanocrystalline Fe-7%Mn-X%Mo (X = 0, 1, and 2) alloys fabricated by spark plasma sintering. Mo is known as a ferrite stabilizing element, whereas Mn is an austenite stabilizing element, and many studies have focused on the effect of Mn addition on austenite stability. Herein, the volume fraction of austenite in nanocrystalline Fe-7%Mn alloys with different Mo contents is measured using X-ray diffraction. Using a disk compressive test, austenite in Fe–Mn–Mo alloys is confirmed to transform into strain-induced martensite during plastic deformation by a disk d. The variation in austenite stability in response to the addition of Mo is quantitatively evaluated by comparing the k-parameters of the kinetic equation for the strain-induced martensite transformation.

- [English]

- Optimization of VIGA Process Parameters for Power Characteristics of Fe-Si-Al-P Soft Magnetic Alloy using Machine Learning

- Sung-Min Kim, Eun-Ji Cha, Do-Hun Kwon, Sung-Uk Hong, Yeon-Joo Lee, Seok-Jae Lee, Kee-Ahn Lee, Hwi-Jun Kim

- J Powder Mater. 2022;29(6):459-467. Published online December 1, 2022

- DOI: https://doi.org/10.4150/KPMI.2022.29.6.459

- 834 View

- 13 Download

-

Abstract

Abstract

PDF

PDF Soft magnetic powder materials are used throughout industries such as motors and power converters. When manufacturing Fe-based soft magnetic composites, the size and shape of the soft magnetic powder and the microstructure in the powder are closely related to the magnetic properties. In this study, Fe-Si-Al-P alloy powders were manufactured using various manufacturing process parameter sets, and the process parameters of the vacuum induction melt gas atomization process were set as melt temperature, atomization gas pressure, and gas flow rate. Process variable data that records are converted into 6 types of data for each powder recovery section. Process variable data that recorded minute changes were converted into 6 types of data and used as input variables. As output variables, a total of 6 types were designated by measuring the particle size, flowability, apparent density, and sphericity of the manufactured powders according to the process variable conditions. The sensitivity of the input and output variables was analyzed through the Pearson correlation coefficient, and a total of 6 powder characteristics were analyzed by artificial neural network model. The prediction results were compared with the results through linear regression analysis and response surface methodology, respectively.

- [Korean]

- Evaluation of Mechanical Properties and Microstructure Depending on Sintering Heating Rate of IN 939W Alloy

- Junhyub Jeon, Junho Lee, Namhyuk Seo, Seung Bae Son, Jae-Gil Jung, Seok-Jae Lee

- J Powder Mater. 2022;29(5):399-410. Published online October 1, 2022

- DOI: https://doi.org/10.4150/KPMI.2022.29.5.399

- 1,637 View

- 31 Download

-

Abstract

Abstract

PDF

PDF Changes in the mechanical properties and microstructure of an IN 939 W alloy according to the sintering heating rate were evaluated. IN 939 W alloy samples were fabricated by spark plasma sintering. The phase fraction, number density, and mean radius of the IN 939W alloy were calculated using a thermodynamic calculation. A universal testing machine and micro-Vickers hardness tester were employed to confirm the mechanical properties of the IN 939W alloy. X-ray diffraction, optical microscopy, field-emission scanning electron microscopy, Cs-corrected-field emission transmission electron microscopy, and energy dispersive X-ray spectrometry were used to evaluate the microstructure of the alloy. The rapid sintering heating rate resulted in a slightly dispersed γ' phase and chromium oxide. It also suppressed the precipitation of the η phase. These helped to reinforce the mechanical properties.

- [Korean]

- Gradient Microstructure and Mechanical Properties of Fe-6%Mn Alloy by Different Sized Powder Stacking

- Namhyuk Seo, Junho Lee, Woocheol Shin, Junhyub Jeon, Jungbin Park, Seung Bae Son, Jae-Gil Jung, Seok-Jae Lee

- J Powder Mater. 2022;29(5):382-389. Published online October 1, 2022

- DOI: https://doi.org/10.4150/KPMI.2022.29.5.382

- 726 View

- 10 Download

-

Abstract

Abstract

PDF

PDF A typical trade-off relationship exists between strength and elongation in face-centered cubic metals. Studies have recently been conducted to enhance strength without ductility reduction through surface-treatment-based ultrasonic nanocrystalline surface modification (UNSM), which creates a gradient microstructure in which grains become smaller from the inside to the surface. The transformation-induced plasticity effect in Fe-Mn alloys results in excellent strength and ductility due to their high work-hardening rate. This rate is achieved through strain-induced martensitic transformation when an alloy is plastically deformed. In this study, Fe-6%Mn powders with different sizes were prepared by high-energy ball milling and sintered through spark plasma sintering to produce Fe-6%Mn samples. A gradient microstructure was obtained by stacking the different-sized powders to achieve similar effects as those derived from UNSM. A compressive test was performed to investigate the mechanical properties, including the yielding behavior. The deformed microstructure was observed through electron backscatter diffraction to determine the effects of gradient plastic deformation.

- [Korean]

- Improvement of the Mechanical Property and Corrosion Resistivity of the Ni-/Fe-based Hybrid Coating Layer using High-velocity Oxygen Fuel Spraying by Heat Treatment

- Jungjoon Kim, Yeonjoo Lee, Song-Yi Kim, Jong-Jae Lee, Jae-hun Kim, Seok-Jae Lee, Hyunkyu Lim, Min-Ha Lee, Hwi-Jun Kim, Hyunjoo Choi

- J Powder Mater. 2022;29(3):240-246. Published online June 1, 2022

- DOI: https://doi.org/10.4150/KPMI.2022.29.3.240

- 875 View

- 5 Download

-

Abstract

Abstract

PDF

PDF Novel Ni- and Fe-based alloys are developed to impart improved mechanical properties and corrosion resistance. The designed alloys are manufactured as a powder and deposited on a steel substrate using a high-velocity oxygen-fuel process. The coating layer demonstrates good corrosion resistance, and the thus-formed passive film is beneficial because of the Cr contained in the alloy system. Furthermore, during low-temperature heat treatment, factors that deteriorate the properties and which may arise during high-temperature heat treatment, are avoided. For the heattreated coating layers, the hardness increases by up to 32% and the corrosion resistance improves. The influence of the heat treatment is investigated through various methods and is considered to enhance the mechanical properties and corrosion resistance of the coating layer.

- [Korean]

- Spark Plasma Sintering Method to Replace Carburizing Process

- Junhyub Jeon, Junho Lee, Namhyuk Seo, Seung Bae Son, Jae-Gil Jung, Seok-Jae Lee

- J Powder Mater. 2022;29(3):219-225. Published online June 1, 2022

- DOI: https://doi.org/10.4150/KPMI.2022.29.3.219

- 501 View

- 4 Download

-

Abstract

Abstract

PDF

PDF An alternative fabrication method for carburizing steel using spark plasma sintering (SPS) is investigated. The sintered carburized sample, which exhibits surface modification effects such as carburizing, sintered Fe, and sintered Fe–0.8 wt.%C alloys, is fabricated using SPS. X-ray diffraction and micro Vickers tests are employed to confirm the phase and properties. Finite element analysis is performed to evaluate the change in hardness and analyze the carbon content and residual stress of the carburized sample. The change in the hardness of the carburized sample has the same tendency to predict hardness. The difference in hardness between the carburized sample and the predicted value is also discussed. The carburized sample exhibits a compressive residual stress at the surface. These results indicate that the carburized sample experiences a surface modification effect without carburization. Field emission scanning electron microscopy is employed to verify the change in phase. A novel fabrication method for altering the carburization is successfully proposed. We expect this fabrication method to solve the problems associated with carburization.

- [Korean]

- Development of Amorphous Iron Based Coating Layer using High-velocity Oxygen Fuel (HVOF) Spraying

- Jungjoon Kim, Song-Yi Kim, Jong-Jae Lee, Seok-Jae Lee, Hyunkyu Lim, Min-Ha Lee, Hwi-Jun Kim, Hyunjoo Choi

- J Korean Powder Metall Inst. 2021;28(6):483-490. Published online December 1, 2021

- DOI: https://doi.org/10.4150/KPMI.2021.28.6.483

- 681 View

- 6 Download

-

Abstract

Abstract

PDF

PDF A new Fe-Cr-Mo-B-C amorphous alloy is designed, which offers high mechanical strength, corrosion resistance as well as high glass-forming ability and its gas-atomized amorphous powder is deposited on an ASTM A213-T91 steel substrate using the high-velocity oxygen fuel (HVOF) process. The hybrid coating layer, consisting of nanocrystalline and amorphous phases, exhibits strong bonding features with the substrate, without revealing significant pore formation. By the coating process, it is possible to obtain a dense structure in which pores are hardly observed not only inside the coating layer but also at the interface between the coating layer and the substrate. The coating layer exhibits good adhesive strength as well as good wear resistance, making it suitable for coating layers for biomass applications.

- [Korean]

- Porosity Prediction of the Coating Layer Based on Process Conditions of HVOF Thermal Spray Coating

- Junhyub Jeon, Namhyuk Seo, Jong Jae Lee, Seung Bae Son, Seok-Jae Lee

- J Korean Powder Metall Inst. 2021;28(6):478-482. Published online December 1, 2021

- DOI: https://doi.org/10.4150/KPMI.2021.28.6.478

- 422 View

- 2 Download

-

Abstract

Abstract

PDF

PDF The effect of the process conditions of high-velocity oxygen fuel (HVOF) thermal spray coating on the porosity of the coating layer is investigated. HVOF coating layers are formed by depositing amorphous FeMoCrBC powder. Oxygen pressure varies from 126 to 146 psi and kerosene pressure from 110 to 130 psi. The Microstructural analysis confirms its porosity. Data analysis is performed using experimental data. The oxygen pressure-kerosene pressure ratio is found to be a key contributor to the porosity. An empirical model is proposed using linear regression analysis. The proposed model is then validated using additional test data. We confirm that the oxygen pressure-kerosene pressure ratio exponentially increases porosity. We present a porosity prediction model relationship for the oxygen pressure-kerosene pressure ratio.

- [Korean]

- Austenite Stability and Mechanical Properties of Nanocrystalline FeNiCrMoMnSiC Alloy Fabricated by Spark Plasma Sintering

- Jungbin Park, Junhyub Jeon, Namhyuk Seo, Gwanghun Kim, Seung Bae Son, Seok-Jae Lee

- J Korean Powder Metall Inst. 2021;28(4):336-341. Published online August 1, 2021

- DOI: https://doi.org/10.4150/KPMI.2021.28.4.336

- 895 View

- 4 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF In this study, a nanocrystalline FeNiCrMoMnSiC alloy was fabricated, and its austenite stability, microstructure, and mechanical properties were investigated. A sintered FeNiCrMoMnSiC alloy sample with nanosized crystal was obtained by high-energy ball milling and spark plasma sintering. The sintering behavior was investigated by measuring the displacement according to the temperature of the sintered body. Through microstructural analysis, it was confirmed that a compact sintered body with few pores was produced, and cementite was formed. The stability of the austenite phase in the sintered samples was evaluated by X-ray diffraction analysis and electron backscatter diffraction. Results revealed a measured value of 51.6% and that the alloy had seven times more austenite stability than AISI 4340 wrought steel. The hardness of the sintered alloy was 60.4 HRC, which was up to 2.4 times higher than that of wrought steel.

-

Citations

Citations to this article as recorded by- Microstructure and mechanical behavior of AISI 4340 steel fabricated via spark plasma sintering and post-heat treatment

Jungbin Park, Junhyub Jeon, Namhyuk Seo, Singon Kang, Seung Bae Son, Seok-Jae Lee, Jae-Gil Jung

Materials Science and Engineering: A.2023; 862: 144433. CrossRef

- Microstructure and mechanical behavior of AISI 4340 steel fabricated via spark plasma sintering and post-heat treatment

- [Korean]

- Improvement of Mechanical Properties of Nanocrystalline FeCrC Alloy via Strain-Induced Martensitic Transformation

- Gwanghun Kim, Junhyub Jeon, Namhyuk Seo, Jungbin Park, Seung Bae Son, Seok-Jae Lee

- J Korean Powder Metall Inst. 2021;28(3):246-252. Published online June 1, 2021

- DOI: https://doi.org/10.4150/KPMI.2021.28.3.246

- 506 View

- 3 Download

-

Abstract

Abstract

PDF

PDF The effect of sintering conditions on the austenite stability and strain-induced martensitic transformation of nanocrystalline FeCrC alloy is investigated. Nanocrystalline FeCrC alloys are successfully fabricated by spark plasma sintering with an extremely short densification time to obtain the theoretical density value and prevent grain growth. The nanocrystallite size in the sintered alloys contributes to increased austenite stability. The phase fraction of the FeCrC sintered alloy before and after deformation according to the sintering holding time is measured using X-ray diffraction and electron backscatter diffraction analysis. During compressive deformation, the volume fraction of strain-induced martensite resulting from austenite decomposition is increased. The transformation kinetics of the strain-induced martensite is evaluated using an empirical equation considering the austenite stability factor. The hardness of the S0W and S10W samples increase to 62.4-67.5 and 58.9-63.4 HRC before and after deformation. The hardness results confirmed that the mechanical properties are improved owing to the effects of grain refinement and strain-induced martensitic transformation in the nanocrystalline FeCrC alloy.

- [Korean]

- Effect of Sintering Condition on Tensile Strength of Fe-based Non-equiatomic High Entropy Alloy

- Namhyuk Seo, Junhyub Jeon, Gwanghun Kim, Jungbin Park, Seung Bae Son, Seok-Jae Lee

- J Korean Powder Metall Inst. 2021;28(3):221-226. Published online June 1, 2021

- DOI: https://doi.org/10.4150/KPMI.2021.28.3.221

- 939 View

- 8 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF We fabricate the non-equiatomic high-entropy alloy (NE-HEA) Fe49.5Mn30Co10Cr10C0.5 (at.%) using spark plasma sintering under various sintering conditions. Each elemental pure powder is milled by high-energy ball milling to prepare NE-HEA powder. The microstructure and mechanical properties of the sintered samples are investigated using various methods. We use the X-ray diffraction (XRD) method to investigate the microstructural characteristics. Quantitative phase analysis is performed by direct comparison of the XRD results. A tensile test is used to compare the mechanical properties of small samples. Next, electron backscatter diffraction analysis is performed to analyze the phase fraction, and the results are compared to those of XRD analysis. By combining different sintering durations and temperature conditions, we attempt to identify suitable spark plasma sintering conditions that yield mechanical properties comparable with previously reported values. The samples sintered at 900 and 1000°C with no holding time have a tensile strength of over 1000 MPa.

-

Citations

Citations to this article as recorded by- Fabrication and Alloying Behavior of Ultra-Lightweight AlTiCrVMg High-Entropy Alloy via Al-Mg Mutual Solubility and Sintering Control

Eunhyo Song, Hansung Lee, Byungmin Ahn

Journal of Powder Materials.2025; 32(3): 254. CrossRef

- Fabrication and Alloying Behavior of Ultra-Lightweight AlTiCrVMg High-Entropy Alloy via Al-Mg Mutual Solubility and Sintering Control

- [Korean]

- Influence of Milling Conditions on the Microstructural Characteristics and Mechanical Properties of Non-equiatomic High Entropy Alloy

- Namhyuk Seo, Junhyub Jeon, Gwanghoon Kim, Jungbin Park, Seung Bae Son, Seok-Jae Lee

- J Korean Powder Metall Inst. 2021;28(2):103-109. Published online April 1, 2021

- DOI: https://doi.org/10.4150/KPMI.2021.28.2.103

- 847 View

- 5 Download

-

Abstract

Abstract

PDF

PDF High-entropy alloys have excellent mechanical properties under extreme environments, rendering them promising candidates for next-generation structural materials. It is desirable to develop non-equiatomic high-entropy alloys that do not require many expensive or heavy elements, contrary to the requirements of typical high-entropy alloys. In this study, a non-equiatomic high-entropy alloy powder Fe49.5Mn30Co10Cr10C0.5 (at.%) is prepared by high energy ball milling and fabricated by spark plasma sintering. By combining different ball milling times and ball-topowder ratios, we attempt to find a proper mechanical alloying condition to achieve improved mechanical properties. The milled powder and sintered specimens are examined using X-ray diffraction to investigate the progress of mechanical alloying and microstructural changes. A miniature tensile specimen after sintering is used to investigate the mechanical properties. Furthermore, quantitative analysis of the microstructure is performed using electron backscatter diffraction.

- [Korean]

- Austenite Stability of Sintered Fe-based Alloy

- Seunggyu Choi, Namhyuk Seo, Junhyub Jun, Seung Bae Son, Seok-Jae Lee

- J Korean Powder Metall Inst. 2020;27(5):414-419. Published online October 1, 2020

- DOI: https://doi.org/10.4150/KPMI.2020.27.5.414

- 1,221 View

- 10 Download

-

Abstract

Abstract

PDF

PDF In the present study, we investigated the austenite stability of a sintered Fe-based nanocrystalline alloy. The volume fraction of austenite was measured based on the X-ray diffraction data of sintered Fe-based nanocrystalline alloys, which were prepared by high-energy ball milling and spark plasma sintering. The sintered alloy samples showed a higher volume fraction of austenite at room temperature as compared to the equilibrium volume fraction of austenite obtained using thermodynamic calculations, which resulted from the nanosized crystalline structure of the sintered alloy. It was proved that the austenite stability of the sintered Fe-based alloy increased with a rise in the amount of austenite stabilizing elements such as Mn, Ni, and C; however, it increased more effectively with a decrease in the actual grain size. Furthermore, we proposed a new equation to predict the martensite starting temperature for sintered Fe-based alloys.

- [Korean]

- Austenite Stability of Nanocrystalline FeMnNiC Alloy

- Seung-Jin Oh, Junhyub Jeon, In-Jin Shon, Seok-Jae Lee

- J Korean Powder Metall Inst. 2019;26(5):389-394. Published online October 1, 2019

- DOI: https://doi.org/10.4150/KPMI.2019.26.5.389

- 867 View

- 4 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF In the present study, we have investigated the effect of sintering process conditions on the stability of the austenite phase in the nanocrystalline Fe-5wt.%Mn-0.2wt.%C alloy. The stability and volume fraction of the austenite phase are the key factors that determine the mechanical properties of FeMnC alloys, because strain-induced austenitemartensite transformation occurs under the application of an external stress at room temperature. Nanocrystalline Fe-5wt.%Mn-0.2wt.%C samples are fabricated using the spark plasma sintering method. The stability of the austenite phase in the sintered samples is evaluated by X-ray diffraction analysis and hardness test. The volume fraction of austenite at room temperature increases as the sample is held for 10 min at the sintering temperature, because of carbon diffusion in austenite. Moreover, water quenching effectively prevents the formation of cementite during cooling, resulting in a higher volume fraction of austenite. Furthermore, it is found that the hardness is influenced by both the austenite carbon content and volume fraction.

-

Citations

Citations to this article as recorded by- Influence of Cobalt Content on Austenite Stability and Strain-Induced Martensite Transformation of Nanocrystalline Fe-7Mn Alloy Fabricated by Spark Plasma Sintering

Sungjin Kim, Seung Bae Son, Seok-Jae Lee

MATERIALS TRANSACTIONS.2025; 66(7): 811. CrossRef - Austenite Stability of Sintered Fe-based Alloy

Seunggyu Choi, Namhyuk Seo, Junhyub Jun, Seung Bae Son, Seok-Jae Lee

Journal of Korean Powder Metallurgy Institute.2020; 27(5): 414. CrossRef

- Influence of Cobalt Content on Austenite Stability and Strain-Induced Martensite Transformation of Nanocrystalline Fe-7Mn Alloy Fabricated by Spark Plasma Sintering

- [Korean]

- Effect of Milling Time and Addition of PCA on Austenite Stability of Fe-7%Mn Alloy

- Seung-Jin Oh, In-Jin Shon, Seok-Jae Lee

- J Korean Powder Metall Inst. 2018;25(2):126-131. Published online April 1, 2018

- DOI: https://doi.org/10.4150/KPMI.2018.25.2.126

- 742 View

- 9 Download

- 5 Citations

-

Abstract

Abstract

PDF

PDF In the present study, we investigate the effects of milling time and the addition of a process control agent (PCA) on the austenite stability of a nanocrystalline Fe-7%Mn alloy by XRD analysis and micrograph observation. Nanocrystalline Fe-7%Mn alloys samples are successfully fabricated by spark plasma sintering. The crystallite size of ball-milled powder and the volume fraction of austenite in the sintered sample are calculated using XRD analysis. Changes in the shape and structure of alloyed powder according to milling conditions are observed through FE-SEM. It is found that the crystallite size is reduced with increasing milling time and amount of PCA addition due to the variation in the balance between the cold-welding and fracturing processes. As a result, the austenite stability increased, resulting in an exceptionally high volume fraction of austenite retained at room temperature.

-

Citations

Citations to this article as recorded by- Effects of mechanical milling on microstructure and mechanical properties of CrMnFeCoNi high-entropy alloy fabricated via spark plasma sintering

Seonghyun Park, Sang-Hwa Lee, Eunjoo Shin, Seok-Jae Lee, Jae-Gil Jung

Journal of Materials Research and Technology.2025; 39: 4854. CrossRef - Effect of Cooling Rate on Microstructure and Hardness during Solution Treatment and Aging Process of Ti-6Al-4V Alloy for Aerospace Components

Seongji Seo, Hojoon Choi, Geeyoung Lee, Kee-Ahn Lee, Jeongho Han, Minsu Jung

Journal of Materials Engineering and Performance.2021; 30(5): 3406. CrossRef - Development of Fe-Mn-based Hybrid Materials Containing Nano-scale Oxides by a Powder Metallurgical Route

Jonggyu Jeon, Jungjoon Kim, Hyunjoo Choi

Journal of Korean Powder Metallurgy Institute.2020; 27(3): 203. CrossRef - Austenite Stability of Sintered Fe-based Alloy

Seunggyu Choi, Namhyuk Seo, Junhyub Jun, Seung Bae Son, Seok-Jae Lee

Journal of Korean Powder Metallurgy Institute.2020; 27(5): 414. CrossRef - Austenite Stability of Nanocrystalline FeMnNiC Alloy

Seung-Jin Oh, Junhyub Jeon, In-Jin Shon, Seok-Jae Lee

Journal of Korean Powder Metallurgy Institute.2019; 26(5): 389. CrossRef

- Effects of mechanical milling on microstructure and mechanical properties of CrMnFeCoNi high-entropy alloy fabricated via spark plasma sintering

TOP

KPMI

KPMI

First

First Prev

Prev