Search

- Page Path

- HOME > Search

- [Korean]

- Microstructure and Mechanical Properties of AA3003 Tube for Heat Exchanger Processed by Floating Plug Drawing

- Hyeon-Jun Heo, Sung Jun Oh, Seong-Hee Lee

- J Powder Mater. 2025;32(6):459-465. Published online December 31, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00346

- 720 View

- 8 Download

-

Abstract

Abstract

PDF

PDF - An AA3003 tube was severely deformed by cold floating plug drawing, and then annealed at temperatures from 210 to 460℃. The as drawn Al tube exhibited a typical deformation structure in which the grains were greatly elongated along the drawing direction. The hardness increased with increasing the reduction of cross-sectional area (RA), became 68Hv after RA= 99%. Up to 310℃, the Al tube still mainly exhibited a deformed structure. While complete recrystallization occurred at temperatures above 360℃. The hardness decreased with increasing the annealing temperature, and it became 33Hv after annealing at 410℃. Both the tensile and yield strengths also decreased with increasing the annealing temperature, but the decrease was larger in yield strength than in tensile strength. The elongation increased with increasing the annealing temperature. The changes in the strength and the elongation with the annealing temperature were the largest at 360℃, in which the complete recrystallization occurred.

- [English]

- Cost-effective Fabrication of Near β-Ti Alloy via L-PBF: Process Optimization of In-situ Alloying Ti-3Fe

- Sehun Kim, Ukju Gim, Taehu Kang, Jongik Lee, Sanghee Jeong, Jimin Han, Bin Lee

- J Powder Mater. 2025;32(4):288-298. Published online August 29, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00213

- 1,183 View

- 25 Download

-

Abstract

Abstract

PDF

PDF - This study presents a cost-effective approach to fabricating near β-Ti alloys via in-situ alloying during laser powder bed fusion (L-PBF). A blend of non-spherical pure Ti, 3 wt.% Fe, and 0.1 wt.% SiO2 nanoparticles was used to induce β-phase stabilization and improve flowability. Twenty-five process conditions were evaluated across a volumetric energy density range of 31.75-214.30 J/mm3, achieving a maximum relative density of 99.21% at 89.29 J/mm3. X-ray diffraction analysis revealed that the β-Ti phase was partially retained at room temperature, accompanied by lattice contraction in the α’-Ti structure, indicating successful Fe incorporation. Elemental mapping confirmed that the Fe distribution was homogeneous, without significant segregation. Compared to pure Ti, the Ti-3Fe sample exhibited a 49.2% increase in Vickers hardness and notable improvements in yield and ultimate tensile strengths. These results demonstrate the feasibility of in-situ alloying with low-cost elemental powders to produce high-performance near β-Ti alloys using L-PBF.

- [English]

- The Effect of Aluminum Powder Size on the Structure and Mechanical Properties of Foam

- Seunghyeok Choi, Sungjin Kim, Tae-Young Ahn, Yu-Song Choi, Jae-Gil Jung, Seung Bae Son, Seok-Jae Lee

- J Powder Mater. 2025;32(3):232-243. Published online June 30, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00157

- 1,391 View

- 55 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF - In this study, we analyzed the structural and mechanical properties of aluminum foams fabricated using aluminum powders of varying sizes and mixtures. The effects of sintering and pore structure at each size on the integrity and mechanical properties of the foams were investigated. Structural characteristics were examined using scanning electron microscopy and micro–computed tomography, while mechanical properties were evaluated through compression testing. The experimental results demonstrated that smaller powder sizes improved foam integrity, reduced porosity and pore size, and resulted in thinner cell walls. In combination, these effects increased compressive strength as the powder size decreased. The findings of this study contribute to the understanding and improvement of the mechanical properties of aluminum foams and highlight their potential for use in a wide range of applications.

-

Citations

Citations to this article as recorded by- Sustainable Manufacturing of Graphene–Aluminum Composites: A Comparative Life Cycle Assessment

Xinwei Yang, Qian Peng, Changke Chen, Qingcui Liu, Yudai Huang

Journal of Sustainable Metallurgy.2026; 12(1): 727. CrossRef

- Sustainable Manufacturing of Graphene–Aluminum Composites: A Comparative Life Cycle Assessment

- [Korean]

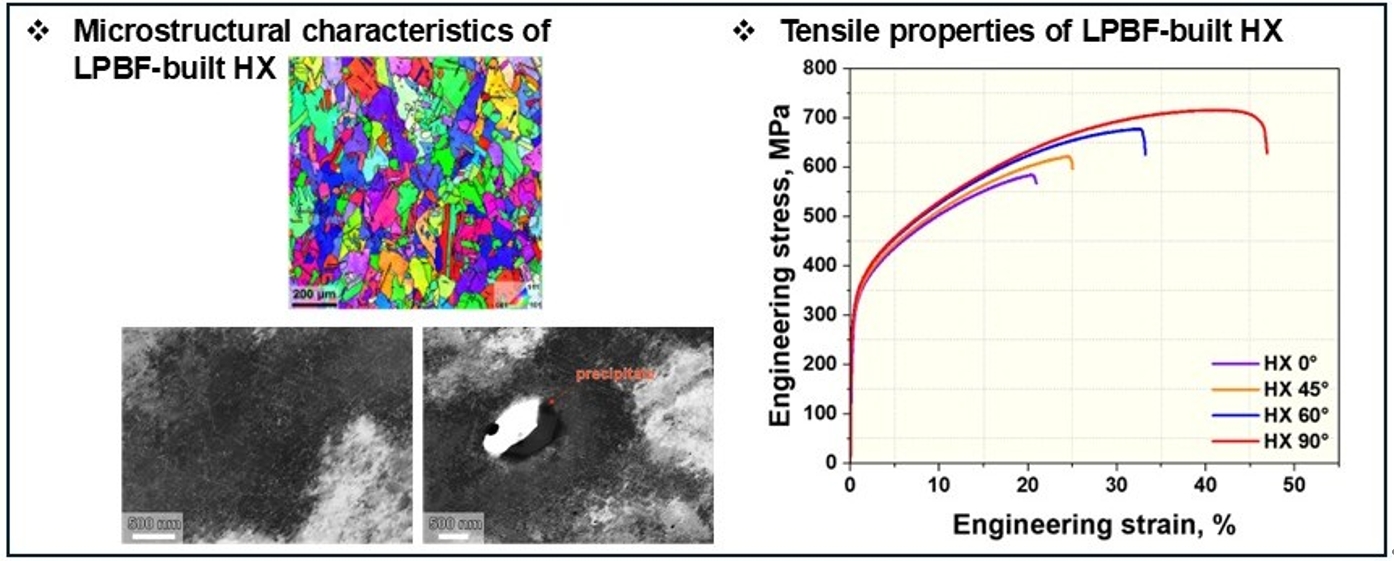

- Effect of Building Orientation on Tensile Properties of Hastelloy X alloy Manufactured by Laser Powder Bed Fusion

- Seong-June Youn, GooWon Noh, Seok Su Sohn, Young-Sang Na, Young-Kyun Kim

- J Powder Mater. 2025;32(2):131-137. Published online April 30, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00080

- 1,147 View

- 32 Download

-

Abstract

Abstract

PDF

PDF - In this study, the effect of build orientation on the mechanical properties of Hastelloy X fabricated by laser powder bed fusion (LPBF) process was investigated. Initial microstructural analysis revealed an equiaxed grain structure with random crystallographic orientation and annealing twins. Intragranular precipitates identified as Cr-rich M23C6 and Mo-rich M6C carbides were observed, along with a dense dislocation network and localized dislocation accumulation around the carbides. Mechanical testing showed negligible variation in yield strength with respect to build orientation; however, both ultimate tensile strength and elongation exhibited a clear increasing trend with higher build angles. Notably, the specimen built at 90° exhibited approximately 22% higher tensile strength and more than twice the elongation compared to the 0° specimen.

- [English]

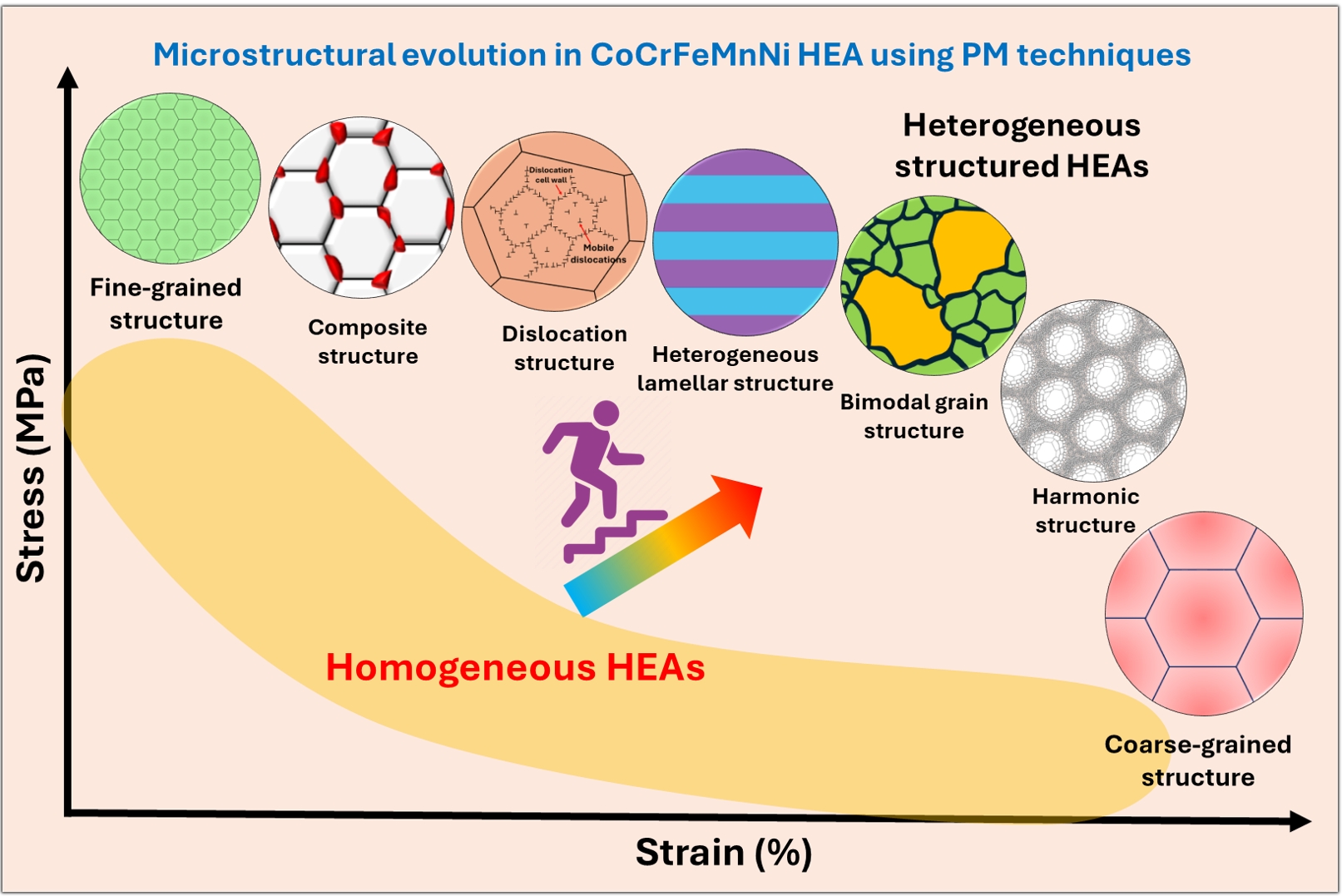

- A Review of Recent Developments in CoCrFeMnNi High-Entropy Alloys Processed by Powder Metallurgy

- Cheenepalli Nagarjuna, Sheetal Kumar Dewangan, Hansung Lee, Eunhyo Song, K. Raja Rao, Byungmin Ahn

- J Powder Mater. 2025;32(2):145-164. Published online April 30, 2025

- DOI: https://doi.org/10.4150/jpm.2024.00430

- 4,550 View

- 119 Download

- 4 Citations

-

Abstract

Abstract

PDF

PDF - In recent years, high-entropy alloys (HEAs) have attracted considerable attention in materials engineering due to their unique phase stability and mechanical properties compared to conventional alloys. Since the inception of HEAs, CoCrFeMnNi alloys have been widely investigated due to their outstanding strength and fracture toughness at cryogenic temperatures. However, their lower yield strength at room temperature limits their structural applications. The mechanical properties of HEAs are greatly influenced by their processing methods and microstructural features. Unlike traditional melting techniques, powder metallurgy (PM) provides a unique opportunity to produce HEAs with nanocrystalline structures and uniform compositions. The current review explores recent advances in optimizing the microstructural characteristics in CoCrFeMnNi HEAs by using PM techniques to improve mechanical performance. The most promising strategies include grain refinement, dispersion strengthening, and the development of heterogeneous microstructures (e.g., harmonic, bimodal, and multi-metal lamellar structures). Thermomechanical treatments along with additive manufacturing techniques are also summarized. Additionally, the review addresses current challenges and suggests future research directions for designing advanced HEAs through PM techniques.

-

Citations

Citations to this article as recorded by- Effect of annealing temperature on thermal expansion and cryogenic mechanical properties of low-thermal-expansion Co22.2Cr6.2Fe48.8Ni17.8Cu5.0 medium-entropy alloy

Wooyoung Lee, Munsu Choi, Sungwook Kim, Dae-Kyeom Kim, Myungsuk Song, Taek-Soo Kim, Jungwan Lee, Hyoung Seop Kim, Hyunjoo Choi, Soo-Hyun Joo

Materials Science and Engineering: A.2026; 954: 149811. CrossRef - Structural and mechanical characteristics of high-entropy CoCrFeMnNi alloys manufactured by vacuum induction melting

V. K. Drobyshev, I. A. Panchenko, S. V. Konovalov, E. M. Zapolskaya

Russian Physics Journal.2026;[Epub] CrossRef - Sustainable powder metallurgy route to Densify oxide-derived CoCrFeNi high-entropy alloy

Taehyeob Im, Minjong Kim, Gertrude Mugwe Mongella, Nelson Bayi, Caroline Sunyong Lee

Materials Today Sustainability.2026; 34: 101330. CrossRef - Thermodynamic and Electronic Descriptor-Driven Machine Learning for Phase Prediction in High-Entropy Alloys: Experimental Validation

Nguyen Lam Khoa, Nguyen Duy Khanh, Hoang Thi Ngoc Quyen, Nguyen Thi Hoang, Oanh, Le Hong Thang, Nguyen Hoa Khiem, Nguyen Hoang Viet

Journal of Powder Materials.2025; 32(3): 191. CrossRef

- Effect of annealing temperature on thermal expansion and cryogenic mechanical properties of low-thermal-expansion Co22.2Cr6.2Fe48.8Ni17.8Cu5.0 medium-entropy alloy

- [English]

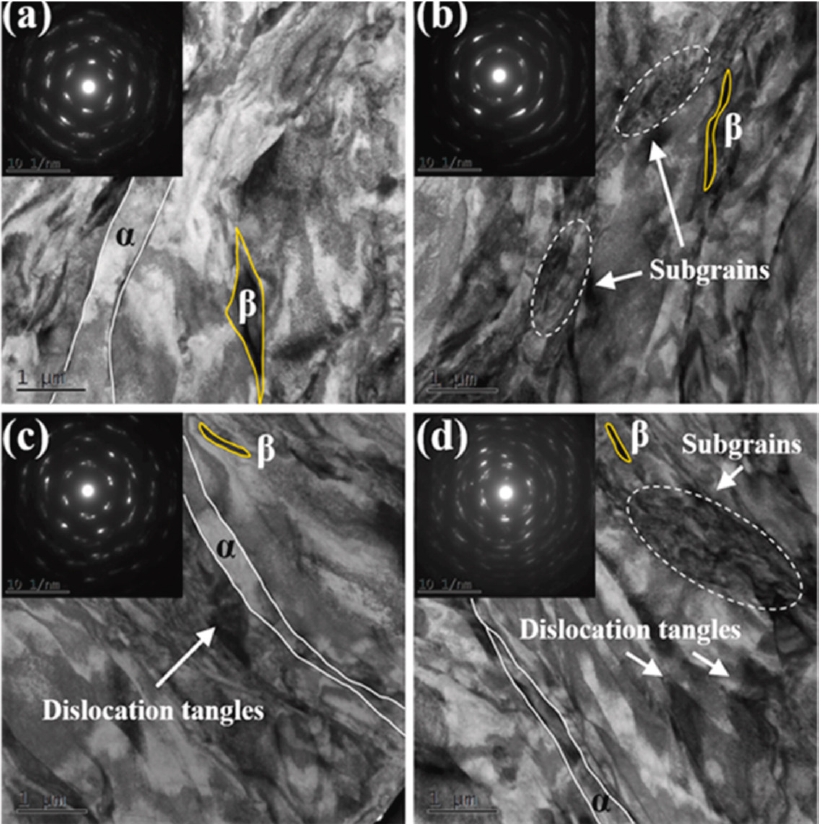

- Comparative Review of the Microstructural and Mechanical Properties of Ti-6Al-4V Fabricated via Wrought and Powder Metallurgy Processes

- Raj Narayan Hajra, Gargi Roy, An Seong Min, Hyunseok Lee, Jeoung Han Kim

- J Powder Mater. 2024;31(5):365-373. Published online October 31, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00213

- 2,851 View

- 67 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF - This review examines the microstructural and mechanical properties of a Ti-6Al-4V alloy produced by wrought processing and powder metallurgy (PM), specifically laser powder bed fusion (LPBF) and hot isostatic pressing. Wrought methods, such as forging and rolling, create equiaxed alpha (α) and beta (β) grain structures with balanced properties, which are ideal for fatigue resistance. In contrast, PM methods, particularly LPBF, often yield a martensitic α′ structure with high microhardness, enabling complex geometries but requiring post-processing to improve its properties and reduce stress. The study evaluated the effects of processing parameters on grain size, phase distribution, and material characteristics, guiding the choice of fabrication techniques for optimizing Ti-6Al-4V performance in aerospace, biomedical, and automotive applications. The analysis emphasizes tailored processing to meet advanced engineering demands.

-

Citations

Citations to this article as recorded by- Removal of Organic and Inorganic Contaminants from Titanium Turning Scrap via Alkali and Acid Two-Step Cleaning

Seong Min An, Raj Narayan Hajra, Chan Hee Park, Jin-Ho Yoon, Jinsung Rho, Chang-Min Yoon, Jeoung Han Kim

MATERIALS TRANSACTIONS.2025; 66(7): 855. CrossRef - Effect of oxygen content in feedstock powders on microstructure and mechanical properties of ELI Ti-6Al-4V fabricated via laser powder bed fusion

Woo Hyeok Kim, Sang Woo Kim, Raj Narayan Hajra, Gargi Roy, Jeoung Han Kim

Powder Metallurgy.2025; 68(4): 307. CrossRef

- Removal of Organic and Inorganic Contaminants from Titanium Turning Scrap via Alkali and Acid Two-Step Cleaning

- [Korean]

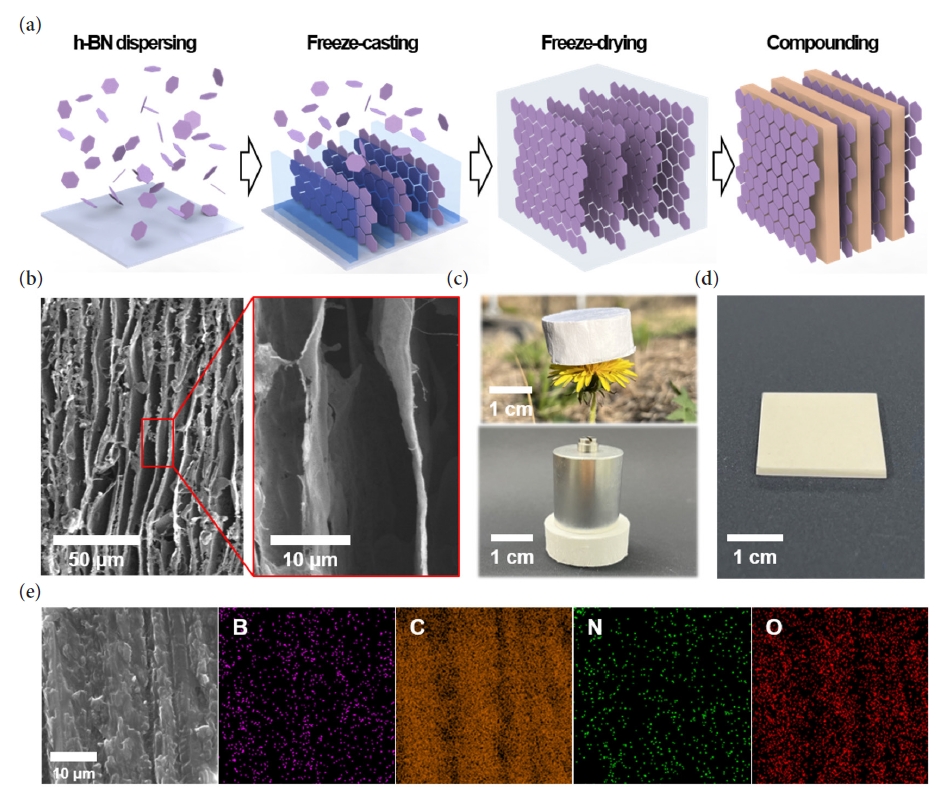

- Fabrication of 3D Aligned h-BN based Polymer Composites with Enhanced Mechanical Properties for Battery Housing

- Kiho Song, Hyunseung Song, Sang In Lee, Changui Ahn

- J Powder Mater. 2024;31(4):329-335. Published online August 30, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00220

- 1,401 View

- 32 Download

-

Abstract

Abstract

PDF

PDF Supplementary Material

Supplementary Material - As the demand for electric vehicles increases, the stability of batteries has become one of the most significant issues. The battery housing, which protects the battery from external stimuli such as vibration, shock, and heat, is the crucial element in resolving safety problems. Conventional metal battery housings are being converted into polymer composites due to their lightweight and improved corrosion resistance to moisture. The transition to polymer composites requires high mechanical strength, electrical insulation, and thermal stability. In this paper, we proposes a high-strength nanocomposite made by infiltrating epoxy into a 3D aligned h-BN structure. The developed 3D aligned h-BN/epoxy composite not only exhibits a high compressive strength (108 MPa) but also demonstrates excellent electrical insulation and thermal stability, with a stable electrical resistivity at 200 °C and a low thermal expansion coefficient (11.46ⅹppm/℃), respectively.

- [Korean]

- Phase Formation and Mechanical Property of YSZ‒30 vol.% WC Composite Ceramics Fabricated by Hot Pressing

- Jin-Kwon Kim, Jae-Hyeong Choi, Nahm Sahn, Sung-Soo Ryu, Seongwon Kim

- J Powder Mater. 2023;30(5):409-414. Published online October 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.5.409

- 592 View

- 5 Download

-

Abstract

Abstract

PDF

PDF YSZ (Y2O3-stabilized zirconia)-based ceramics have excellent mechanical properties, such as high strength and wear resistance. In the application, YSZ is utilized in the bead mill, a fine-grinding process. YSZ-based parts, such as the rotor and pin, can be easily damaged by continuous application with high rpm in the bead mill process. In that case, adding WC particles improves the tribological and mechanical properties. YSZ-30 vol.% WC composite ceramics are manufactured via hot pressing under different pressures (10/30/60 MPa). The hot-pressed composite ceramics measure the physical properties, such as porosity and bulk density values. In addition, the phase formation of these composite ceramics is analyzed and discussed with those of physical properties. For the increased applied pressure of hot pressing, the tetragonality of YSZ and the crystallinity of WC are enhanced. The mechanical properties indicate an improved tendency with the increase in the applied pressure of hot pressing.

- [Korean]

- Fabrication of Polymer Composite with Enhanced Insulation and Mechanical Properties using Aluminum Borate Nanowhiskers

- Junhyeok Choi, Sangin Lee, Kiho Song, Taekyung Kim, Changui Ahn

- J Powder Mater. 2023;30(4):356-362. Published online August 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.4.356

- 961 View

- 2 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF Inorganic-organic composites find extensive application in various fields, including electronic devices and light-emitting diodes. Notably, encapsulation technologies are employed to shield electronic devices (such as printed circuit boards and batteries) from stress and moisture exposure while maintaining electrical insulation. Polymer composites can be used as encapsulation materials because of their controllable mechanical and electrical properties. In this study, we propose a polymer composite that provides good electrical insulation and enhanced mechanical properties. This is achieved by using aluminum borate nanowhiskers (ABOw), which are fabricated using a facile synthesis method. The ABOw fillers are created via a hydrothermal method using aluminum chloride and boric acid. We confirm that the synthesis occurs in various morphologies based on the molar ratio. Specifically, nanowhiskers are synthesized at a molar ratio of 1:3 and used as fillers in the composite. The fabricated ABOw/epoxy composites exhibit a 48.5% enhancement in mechanical properties, similar to those of pure epoxy, while maintaining good electrical insulation.

-

Citations

Citations to this article as recorded by- Fabrication of Al18B4O33 Spherical Powder with Increased Fluidity via Control of B2O3 Particle Size and Distribution

Kiho Song, Sang in Lee, Hyunseung Song, Changui Ahn

Journal of Powder Materials.2024; 31(6): 513. CrossRef

- Fabrication of Al18B4O33 Spherical Powder with Increased Fluidity via Control of B2O3 Particle Size and Distribution

- [Korean]

- Comparison of Properties with Different Sintering Process of 3Y-TZP/WC Composites

- Min-Soo Nam, Jae-Hyung Choi, Sahn Nahm, Seongwon Kim

- J Powder Mater. 2022;29(5):424-431. Published online October 1, 2022

- DOI: https://doi.org/10.4150/KPMI.2022.29.5.424

- 891 View

- 3 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF 3Y-TZP ceramics obtained by doping 3 mol.% of Y2O3 to ZrO2 to stabilize the phase transition are widely used in the engineering ceramic industry due to their excellent mechanical properties such as high strength, fracture toughness, and wear resistance. An additional increase in mechanical properties is possible by manufacturing a composite in which a high-hardness material such as oxide or carbide is added to the 3Y-TZP matrix. In this study, composite powder was prepared by dispersing a designated percentage of WC in the 3Y-TZP matrix, and the results were compared after manufacturing the composite using the different processes of spark plasma sintering and HP. The difference between the densification behavior and porosity with the process mechanism was investigated. The correlation between the process conditions and phase formation was examined based on the crystalline phase formation behavior. Changes to the microstructure according to the process conditions were compared using field-emission scanning electron microscopy. The toughness-strengthening mechanism of the composite with densification and phase formation was also investigated.

-

Citations

Citations to this article as recorded by- Phase Formation and Mechanical Property of YSZ‒30 vol.% WC Composite Ceramics Fabricated by Hot Pressing

Jin-Kwon Kim, Jae-Hyeong Choi, Nahm Sahn, Sung-Soo Ryu, Seongwon Kim

journal of Korean Powder Metallurgy Institute.2023; 30(5): 409. CrossRef

- Phase Formation and Mechanical Property of YSZ‒30 vol.% WC Composite Ceramics Fabricated by Hot Pressing

- [Korean]

- Evaluation of Mechanical Properties and Microstructure Depending on Sintering Heating Rate of IN 939W Alloy

- Junhyub Jeon, Junho Lee, Namhyuk Seo, Seung Bae Son, Jae-Gil Jung, Seok-Jae Lee

- J Powder Mater. 2022;29(5):399-410. Published online October 1, 2022

- DOI: https://doi.org/10.4150/KPMI.2022.29.5.399

- 1,684 View

- 31 Download

-

Abstract

Abstract

PDF

PDF Changes in the mechanical properties and microstructure of an IN 939 W alloy according to the sintering heating rate were evaluated. IN 939 W alloy samples were fabricated by spark plasma sintering. The phase fraction, number density, and mean radius of the IN 939W alloy were calculated using a thermodynamic calculation. A universal testing machine and micro-Vickers hardness tester were employed to confirm the mechanical properties of the IN 939W alloy. X-ray diffraction, optical microscopy, field-emission scanning electron microscopy, Cs-corrected-field emission transmission electron microscopy, and energy dispersive X-ray spectrometry were used to evaluate the microstructure of the alloy. The rapid sintering heating rate resulted in a slightly dispersed γ' phase and chromium oxide. It also suppressed the precipitation of the η phase. These helped to reinforce the mechanical properties.

- [Korean]

- Microstructures and Mechanical Properties of Ti-20Mo-0.5EB Composites

- Suhyun Bae, Wonki Jeong, Se-Eun Shin

- J Korean Powder Metall Inst. 2021;28(5):403-409. Published online October 1, 2021

- DOI: https://doi.org/10.4150/KPMI.2021.28.5.403

- 653 View

- 8 Download

-

Abstract

Abstract

PDF

PDF In this study, Ti-Mo-EB composites are prepared by ball milling and spark plasma sintering (SPS) to obtain a low elastic modulus and high strength and to evaluate the microstructure and mechanical properties as a function of the process conditions. As the milling time and sintering temperature increased, Mo, as a β-Ti stabilizing element, diffused, and the microstructure of β-Ti increased. In addition, the size of the observed phase was small, so the modulus and hardness of α-Ti and β-Ti were measured using nanoindentation equipment. In both phases, as the milling time and sintering temperature increased, the modulus of elasticity decreased, and the hardness increased. After 12 h of milling, the specimen sintered at 1000°C showed the lowest values of modulus of elasticity of 117.52 and 101.46 GPa for α-Ti and β-Ti, respectively, confirming that the values are lower compared to the that in previously reported studies.

- [Korean]

- Improvement of Mechanical Properties of Nanocrystalline FeCrC Alloy via Strain-Induced Martensitic Transformation

- Gwanghun Kim, Junhyub Jeon, Namhyuk Seo, Jungbin Park, Seung Bae Son, Seok-Jae Lee

- J Korean Powder Metall Inst. 2021;28(3):246-252. Published online June 1, 2021

- DOI: https://doi.org/10.4150/KPMI.2021.28.3.246

- 537 View

- 3 Download

-

Abstract

Abstract

PDF

PDF The effect of sintering conditions on the austenite stability and strain-induced martensitic transformation of nanocrystalline FeCrC alloy is investigated. Nanocrystalline FeCrC alloys are successfully fabricated by spark plasma sintering with an extremely short densification time to obtain the theoretical density value and prevent grain growth. The nanocrystallite size in the sintered alloys contributes to increased austenite stability. The phase fraction of the FeCrC sintered alloy before and after deformation according to the sintering holding time is measured using X-ray diffraction and electron backscatter diffraction analysis. During compressive deformation, the volume fraction of strain-induced martensite resulting from austenite decomposition is increased. The transformation kinetics of the strain-induced martensite is evaluated using an empirical equation considering the austenite stability factor. The hardness of the S0W and S10W samples increase to 62.4-67.5 and 58.9-63.4 HRC before and after deformation. The hardness results confirmed that the mechanical properties are improved owing to the effects of grain refinement and strain-induced martensitic transformation in the nanocrystalline FeCrC alloy.

- [Korean]

- Effect of Sintering Condition on Tensile Strength of Fe-based Non-equiatomic High Entropy Alloy

- Namhyuk Seo, Junhyub Jeon, Gwanghun Kim, Jungbin Park, Seung Bae Son, Seok-Jae Lee

- J Korean Powder Metall Inst. 2021;28(3):221-226. Published online June 1, 2021

- DOI: https://doi.org/10.4150/KPMI.2021.28.3.221

- 988 View

- 8 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF We fabricate the non-equiatomic high-entropy alloy (NE-HEA) Fe49.5Mn30Co10Cr10C0.5 (at.%) using spark plasma sintering under various sintering conditions. Each elemental pure powder is milled by high-energy ball milling to prepare NE-HEA powder. The microstructure and mechanical properties of the sintered samples are investigated using various methods. We use the X-ray diffraction (XRD) method to investigate the microstructural characteristics. Quantitative phase analysis is performed by direct comparison of the XRD results. A tensile test is used to compare the mechanical properties of small samples. Next, electron backscatter diffraction analysis is performed to analyze the phase fraction, and the results are compared to those of XRD analysis. By combining different sintering durations and temperature conditions, we attempt to identify suitable spark plasma sintering conditions that yield mechanical properties comparable with previously reported values. The samples sintered at 900 and 1000°C with no holding time have a tensile strength of over 1000 MPa.

-

Citations

Citations to this article as recorded by- Fabrication and Alloying Behavior of Ultra-Lightweight AlTiCrVMg High-Entropy Alloy via Al-Mg Mutual Solubility and Sintering Control

Eunhyo Song, Hansung Lee, Byungmin Ahn

Journal of Powder Materials.2025; 32(3): 254. CrossRef

- Fabrication and Alloying Behavior of Ultra-Lightweight AlTiCrVMg High-Entropy Alloy via Al-Mg Mutual Solubility and Sintering Control

- [Korean]

- Influence of Milling Conditions on the Microstructural Characteristics and Mechanical Properties of Non-equiatomic High Entropy Alloy

- Namhyuk Seo, Junhyub Jeon, Gwanghoon Kim, Jungbin Park, Seung Bae Son, Seok-Jae Lee

- J Korean Powder Metall Inst. 2021;28(2):103-109. Published online April 1, 2021

- DOI: https://doi.org/10.4150/KPMI.2021.28.2.103

- 866 View

- 5 Download

-

Abstract

Abstract

PDF

PDF High-entropy alloys have excellent mechanical properties under extreme environments, rendering them promising candidates for next-generation structural materials. It is desirable to develop non-equiatomic high-entropy alloys that do not require many expensive or heavy elements, contrary to the requirements of typical high-entropy alloys. In this study, a non-equiatomic high-entropy alloy powder Fe49.5Mn30Co10Cr10C0.5 (at.%) is prepared by high energy ball milling and fabricated by spark plasma sintering. By combining different ball milling times and ball-topowder ratios, we attempt to find a proper mechanical alloying condition to achieve improved mechanical properties. The milled powder and sintered specimens are examined using X-ray diffraction to investigate the progress of mechanical alloying and microstructural changes. A miniature tensile specimen after sintering is used to investigate the mechanical properties. Furthermore, quantitative analysis of the microstructure is performed using electron backscatter diffraction.

- [Korean]

- Experimental Study on Improving Compressive Strength of Hexagonal Boron Nitride Reinforced Cement Composite

- Yomin Choi, Hyun‐Gyoo Shin

- J Korean Powder Metall Inst. 2020;27(6):503-508. Published online December 1, 2020

- DOI: https://doi.org/10.4150/KPMI.2020.27.6.503

- 648 View

- 1 Download

-

Abstract

Abstract

PDF

PDF The mechanical properties and microstructures of hexagonal boron nitride (h-BN)-reinforced cement composites are experimentally studied for three and seven curing days. Various sizes (5, 10, and 18 μm) and concentrations (0.1%, 0.25%, 0.5%, and 1.0%) of h-BN are dispersed by the tip ultrasonication method in water and incorporated into the cement composite. The compressive strength of the h-BN reinforced cements increases by 40.9%, when 0.5 wt% of 18 μm-sized h-BN is added. However, the compressive strength decreases when the 1.0 wt% cement composite is added, owing to the aggregation of the h-BNs in the cement composite. The microstructural characterization of the h-BN-reinforced cement composite indicates that the h-BNs act as bridges connecting the cracks, resulting in improved mechanical properties for the reinforced cement composite.

- [Korean]

- Development of Fe-Mn-based Hybrid Materials Containing Nano-scale Oxides by a Powder Metallurgical Route

- Jonggyu Jeon, Jungjoon Kim, Hyunjoo Choi

- J Korean Powder Metall Inst. 2020;27(3):203-209. Published online June 1, 2020

- DOI: https://doi.org/10.4150/KPMI.2020.27.3.203

- 898 View

- 7 Download

-

Abstract

Abstract

PDF

PDF The automotive industry has focused on the development of metallic materials with high specific strength, which can meet both fuel economy and safety goals. Here, a new class of ultrafine-grained high-Mn steels containing nano-scale oxides is developed using powder metallurgy. First, high-energy mechanical milling is performed to dissolve alloying elements in Fe and reduce the grain size to the nanometer regime. Second, the ball-milled powder is consolidated using spark plasma sintering. During spark plasma sintering, nanoscale manganese oxides are generated in Fe-15Mn steels, while other nanoscale oxides (e.g., aluminum, silicon, titanium) are produced in Fe-15Mn-3Al-3Si and Fe-15Mn-3Ti steels. Finally, the phases and resulting hardness of a variety of high-Mn steels are compared. As a result, the sintered pallets exhibit superior hardness when elements with higher oxygen affinity are added; these elements attract oxygen from Mn and form nanoscale oxides that can greatly improve the strength of high-Mn steels.

- [Korean]

- Structural Characteristics, Microstructure and Mechanical Properties of Fe-Cr-Al Metallic Foam Fabricated by Powder Alloying Process

- Kyu-Sik Kim, Byeong-Hoon Kang, Man-Ho Park, Jung-Yeul Yun, Kee-Ahn Lee

- J Korean Powder Metall Inst. 2020;27(1):37-43. Published online February 1, 2020

- DOI: https://doi.org/10.4150/KPMI.2020.27.1.37

- 656 View

- 5 Download

-

Abstract

Abstract

PDF

PDF The Fe-22wt.%Cr-6wt.%Al foams were fabricated via the powder alloying process in this study. The structural characteristics, microstructure, and mechanical properties of Fe-Cr-Al foams with different average pore sizes were investigated. Result of the structural analysis shows that the average pore sizes were measured as 474 μm (450 foam) and 1220 μm (1200 foam). Regardless of the pore size, Fe-Cr-Al foams had a Weaire-Phelan bubble structure, and α-ferrite was the major constituent phase. Tensile and compressive tests were conducted with an initial strain rate of 10−3 /s. Tensile yield strengths were 3.4 MPa (450 foam) and 1.4 MPa (1200 foam). Note that the total elongation of 1200 foam was higher than that of 450 foam. Furthermore, their compressive yield strengths were 2.5 MPa (450 foam) and 1.1 MPa (1200 foam), respectively. Different compressive deformation behaviors according to the pore sizes of the Fe-Cr-Al foams were characterized: strain hardening for the 450 foam and constant flow stress after a slight stress drop for the 1200 foam. The effect of structural characteristics on the mechanical properties was also discussed.

- [English]

- Spark Plasma Sintering of the Ni-graphite Composite Powder Prepared by Electrical Explosion of Wire in Liquid and Its Properties

- Minh Thuyet-Nguyena, Jin-Chun Kim

- J Korean Powder Metall Inst. 2020;27(1):14-24. Published online February 1, 2020

- DOI: https://doi.org/10.4150/KPMI.2020.27.1.14

- 989 View

- 3 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF In this work, the electrical explosion of wire in liquid and subsequent spark plasma sintering (SPS) was introduced for the fabrication of Ni-graphite nanocomposites. The fabricated composite exhibited good enhancements in mechanical properties, such as yield strength and hardness, but reduced the ductility in comparison with that of nickel. The as-synthesized Ni-graphite (5 vol.% graphite) nanocomposite exhibited a compressive yield strength of 275 MPa (about 1.6 times of SPS-processed monolithic nickel ~170 MPa) and elongation to failure ~22%. The hardness of Nigraphite composite had a value of 135.46 HV, which is about 1.3 times higher than that of pure SPS-processed Ni (105.675 HV). In terms of processing, this work demonstrated that this processing route is a novel, simple, and low-cost method for the synthesis of nickel-graphite composites.

-

Citations

Citations to this article as recorded by- Top-down strategies for achieving high-quality graphene: Recent advancements

Arpana Agrawal

Journal of Industrial and Engineering Chemistry.2025; 142: 103. CrossRef - Electrodeposition of nickel-titanium dioxide coatings and powders from aqueous sulfate solutions

Tazhibayeva Aigerim Shotaevna, Bayeshova Azhar Kospanovna, Bayeshov Abduali, Osińska Małgorzata

Polyhedron.2025; 277: 117571. CrossRef

- Top-down strategies for achieving high-quality graphene: Recent advancements

- [Korean]

- Effects of Sintering Additives on the Thermal and Mechanical Properties of AlN by Pressureless Sintering

- Jin Uk Hwang, So Youn Mun, Sang Yong Nam, Hwan Soo Dow

- J Korean Powder Metall Inst. 2019;26(5):395-404. Published online October 1, 2019

- DOI: https://doi.org/10.4150/KPMI.2019.26.5.395

- 2,290 View

- 53 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF Aluminum nitride (AlN) has excellent electrical insulation property, high thermal conductivity, and a low thermal expansion coefficient; therefore, it is widely used as a heat sink, heat-conductive filler, and heat dissipation substrate. However, it is well known that the AlN-based materials have disadvantages such as low sinterability and poor mechanical properties. In this study, the effects of addition of various amounts (1-6 wt.%) of sintering additives Y2O3 and Sm2O3 on the thermal and mechanical properties of AlN samples pressureless sintered at 1850°C in an N2 atmosphere for a holding time of 2 h are examined. All AlN samples exhibit relative densities of more than 97%. It showed that the higher thermal conductivity as the Y2O3 content increased than the Sm2O3 additive, whereas all AlN samples exhibited higher mechanical properties as Sm2O3 content increased. The formation of secondary phases by reaction of Y2O3, Sm2O3 with oxygen from AlN lattice influenced the thermal and mechanical properties of AlN samples due to the reaction of the oxygen contents in AlN lattice.

-

Citations

Citations to this article as recorded by- Effects of YH2 addition on pressureless sintered AlN ceramics

Liang Wang, Wei-Ming Guo, Peng-Fei Sheng, Li-Fu Lin, Xiao Zong, Shang-Hua Wu

Journal of the European Ceramic Society.2023; 43(3): 862. CrossRef

- Effects of YH2 addition on pressureless sintered AlN ceramics

- [Korean]

- The Microstructure and the Mechanical Properties of Sintered TiO2-Co Composite Prepared Via Thermal Hydrogenation Method

- Myeongsun Ko, Ilsong Park, Jeshin Park

- J Korean Powder Metall Inst. 2019;26(4):290-298. Published online August 1, 2019

- DOI: https://doi.org/10.4150/KPMI.2019.26.4.290

- 397 View

- 1 Download

-

Abstract

Abstract

PDF

PDF TiO2-particles containing Co grains are fabricated via thermal hydrogenation and selective oxidation of Ti-Co alloy. For comparison, TiO2-Co composite powders are prepared by two kinds of methods which were the mechanical carbonization and oxidation process, and the conventional mixing process. The microstructural characteristics of the prepared composites are analyzed by X-ray diffraction, field-emission scattering electron microscopy, and transmission electron microscopy. In addition, the composite powders are sintered at 800°C by spark plasma sintering. The flexural strength and fracture toughness of the sintered samples prepared by thermal hydrogenation and mechanical carbonization are found to be higher than those of the samples prepared by the conventional mixing process. Moreover, the microstructures of sintered samples prepared by thermal hydrogenation and mechanical carbonization processes are found to be similar. The difference in the mechanical properties of sintered samples prepared by thermal hydrogenation and mechanical carbonization processes is attributed to the different sizes of metallic Co particles in the samples.

- [Korean]

- Property Evaluation of Tungsten-Carbide Hard Materials as a Function of Binder

- Ju-Hun Kim, Ik-Hyun Oh, Jeong-Han Lee, Sung-Kil Hong, Hyun-Kuk Park

- J Korean Powder Metall Inst. 2019;26(2):132-137. Published online April 1, 2019

- DOI: https://doi.org/10.4150/KPMI.2019.26.2.132

- 1,079 View

- 8 Download

- 3 Citations

-

Abstract

Abstract

PDF

PDF Tungsten carbide (WC) hard materials are used in various industries and possess a superior hardness compared to other hard materials. They have particularly high melting points, high strength, and abrasion resistance. Accordingly, tungsten carbide hard materials are used for wear-resistant tools, cutting tools, machining tools, and other tooling materials. In this study, the WC-5wt.%Co, Fe, Ni hard materials are densified using the horizontal ball milled WC-Co, WC-Fe, and WC-Ni powders by a spark plasma sintering process. The WC-5Co, WC-5Fe, and WC-5Ni hard materials are almost completely densified with a relative density of up to 99.6% after simultaneous application of a pressure of 60 MPa and an electric current for about 15 min without any significant change in the grain size. The average grain size of WC-5Co, WC-5Fe, and WC-5Ni that was produced through SPS was about 0.421, 0.779, and 0.429 μm, respectively. The hardness and fracture toughness of the dense WC-5Co, WC-5Fe, WC-5Ni hard materials were also investigated.

-

Citations

Citations to this article as recorded by- Enhancing Mechanical Properties via Grain Growth Suppression and High Densification in WC Compacts

Jong Min Gwak, Min Soo Park, Gook Hyun Ha, Nam Hyun Kang

Metals and Materials International.2025; 31(12): 3733. CrossRef - Synthesis of W2C by Spark Plasma Sintering of W-WC Powder Mixture and Its Etching Property

Gyu-Sang Oh, Sung-Min Lee, Sung-Soo Ryu

Journal of Korean Powder Metallurgy Institute.2020; 27(4): 293. CrossRef - Fabrication and Properties of Densified Tungsten by Magnetic Pulse Compaction and Spark Plasma Sintering

Eui Seon Lee, Jongmin Byun, Young-Keun Jeong, Sung-Tag Oh

Korean Journal of Materials Research.2020; 30(6): 321. CrossRef

- Enhancing Mechanical Properties via Grain Growth Suppression and High Densification in WC Compacts

- [Korean]

- Effect of Porosity on Mechanical Anisotropy of 316L Austenitic Stainless Steel Additively Manufactured by Selective Laser Melting

- Jeong Min Park, Jin Myoung Jeon, Jung Gi Kim, Yujin Seong, Sun Hong Park, Hyoung Seop Kim

- J Korean Powder Metall Inst. 2018;25(6):475-481. Published online December 1, 2018

- DOI: https://doi.org/10.4150/KPMI.2018.25.6.475

- 1,351 View

- 12 Download

- 12 Citations

-

Abstract

Abstract

PDF

PDF Selective laser melting (SLM), a type of additive manufacturing (AM) technology, leads a global manufacturing trend by enabling the design of geometrically complex products with topology optimization for optimized performance. Using this method, three-dimensional (3D) computer-aided design (CAD) data components can be built up directly in a layer-by-layer fashion using a high-energy laser beam for the selective melting and rapid solidification of thin layers of metallic powders. Although there are considerable expectations that this novel process will overcome many traditional manufacturing process limits, some issues still exist in applying the SLM process to diverse metallic materials, particularly regarding the formation of porosity. This is a major processing-induced phenomenon, and frequently observed in almost all SLM-processed metallic components. In this study, we investigate the mechanical anisotropy of SLM-produced 316L stainless steel based on microstructural factors and highly-oriented porosity. Tensile tests are performed to investigate the microstructure and porosity effects on mechanical anisotropy in terms of both strength and ductility.

-

Citations

Citations to this article as recorded by- Effect of temperature and impact loading condition on deformation behavior in 316L austenitic stainless steel manufactured by laser powder bed fusion

Tae Hyeong Kim, Haeum Park, Jun Seok Lee, Jeong Min Park, Jae Wung Bae

Materials Science and Engineering: A.2025; 933: 148286. CrossRef - Selective laser melting additive manufactured H13 tool steel for aluminum extrusion die component construction

Evangelos Giarmas, Vasileios Tsakalos, Emmanuel Tzimtzimis, Nikolaos Kladovasilakis, Ioannis Kostavelis, Dimitrios Tzovaras, Dimitrios Tzetzis

The International Journal of Advanced Manufacturing Technology.2024; 133(9-10): 4385. CrossRef - Nanoindentation Creep Behavior of Additively Manufactured H13 Steel by Utilizing Selective Laser Melting Technology

Evangelos Giarmas, Emmanouil K. Tzimtzimis, Nikolaos Kladovasilakis, Dimitrios Tzovaras, Dimitrios Tzetzis

Materials.2024; 17(15): 3756. CrossRef - A Parametric Study on the L-PBF Process of an AlSi10Mg Alloy for High-Speed Productivity of Automotive Prototype Parts

Yeonha Chang, Hyomoon Joo, Wanghyun Yong, Yeongcheol Jo, Seongjin Kim, Hanjae Kim, Yeon Woo Kim, Kyung Tae Kim, Jeong Min Park

Journal of Powder Materials.2024; 31(5): 390. CrossRef - Development of multi-defect diagnosis algorithm for the directed energy deposition (DED) process with in situ melt-pool monitoring

Hyewon Shin, Jimin Lee, Seung-Kyum Choi, Sang Won Lee

The International Journal of Advanced Manufacturing Technology.2023; 125(1-2): 357. CrossRef - Corrosion Resistance of Laser Powder Bed Fused AISI 316L Stainless Steel and Effect of Direct Annealing

Kichang Bae, Dongmin Shin, Jonghun Lee, Seohan Kim, Wookjin Lee, Ilguk Jo, Junghoon Lee

Materials.2022; 15(18): 6336. CrossRef - Experimental investigation on the effect of process parameters in additive/subtractive hybrid manufacturing 316L stainless steel

Chengming Tang, Jibin Zhao, Zhiguo Wang, Yuhui Zhao, Tianran Wang

The International Journal of Advanced Manufacturing Technology.2022; 121(3-4): 2461. CrossRef - Interface characteristics and mechanical behavior of additively manufactured multi-material of stainless steel and Inconel

Man Jae Sagong, Eun Seong Kim, Jeong Min Park, Gangaraju Manogna Karthik, Byeong-Joo Lee, Jung-Wook Cho, Chong Soo Lee, Takayoshi Nakano, Hyoung Seop Kim

Materials Science and Engineering: A.2022; 847: 143318. CrossRef - Effect of heat treatment on microstructural heterogeneity and mechanical properties of 1%C-CoCrFeMnNi alloy fabricated by selective laser melting

Jeong Min Park, Eun Seong Kim, Hyeonseok Kwon, Praveen Sathiyamoorthi, Kyung Tae Kim, Ji-Hun Yu, Hyoung Seop Kim

Additive Manufacturing.2021; 47: 102283. CrossRef - Manufacturing Aluminum/Multiwalled Carbon Nanotube Composites via Laser Powder Bed Fusion

Eo Ryeong Lee, Se Eun Shin, Naoki Takata, Makoto Kobashi, Masaki Kato

Materials.2020; 13(18): 3927. CrossRef - Effects of microstructure and internal defects on mechanical anisotropy and asymmetry of selective laser-melted 316L austenitic stainless steel

Jin Myoung Jeon, Jeong Min Park, Ji-Hun Yu, Jung Gi Kim, Yujin Seong, Sun Hong Park, Hyoung Seop Kim

Materials Science and Engineering: A.2019; 763: 138152. CrossRef - Microstructural effects on the tensile and fracture behavior of selective laser melted H13 tool steel under varying conditions

Jungsub Lee, Jungho Choe, Junhyeok Park, Ji-Hun Yu, Sangshik Kim, Im Doo Jung, Hyokyung Sung

Materials Characterization.2019; 155: 109817. CrossRef

- Effect of temperature and impact loading condition on deformation behavior in 316L austenitic stainless steel manufactured by laser powder bed fusion

- [Korean]

- Stretch-Flangeability of Harmonic Structure Material Manufactured by Powder Metallurgy Method

- Jae Ik Yoon, Hak Hyeon Lee, Hyung Keun Park, Kei Ameyama, Hyoung Seop Kim

- J Korean Powder Metall Inst. 2017;24(2):128-132. Published online April 1, 2017

- DOI: https://doi.org/10.4150/KPMI.2017.24.2.128

- 864 View

- 1 Download

-

Abstract

Abstract

PDF

PDF Harmonic structure materials are materials with a core–shell structure having a shell with a small grain size and a core with a relatively large grain size. They are in the spotlight because their mechanical properties reportedly feature strength similar to that of a sintered powder with a fine grain size and elongation similar to that of a sintered powder with a coarse grain size at the same time. In this study, the tensile properties, microstructure, and stretchflangeability of harmonic structure SUS304L made using powder metallurgy are investigated to check its suitability for automotive applications. The harmonic powders are made by mechanical milling and sintered using a spark plasma sintering method at 1173 K and a pressure of 50 MPa in a cylindrical die. The sintered powders of SUS304L having harmonic structure (harmonic SUS304L) exhibit excellent tensile properties compared with sintered powders of SUS304L having homogeneous microstructure. In addition, the harmonic SUS304L has excellent stretch-flangeability compared with commercial advanced high-strength steels (AHSSs) at a similar strength grade. Thus, the harmonic SUS304L is more suitable for automotive applications than conventional AHSSs because it exhibits both excellent tensile properties and stretch-flangeability.

- [Korean]

- Study on Microstructures and Hardness of STS316L Fabricated by Selective Laser Melting

- Gi Hun Shin, Joon Phil Choi, Kyung Tae Kim, Byoung Kee Kim, Ji Hun Yu

- J Korean Powder Metall Inst. 2016;24(3):210-215. Published online June 1, 2016

- DOI: https://doi.org/10.4150/KPMI.2017.24.3.210

- 980 View

- 2 Download

- 7 Citations

-

Abstract

Abstract

PDF

PDF In this study, STS316L powders prepared by gas atomization are used to manufacture bulk structures with dimensions of 10 × 10 × 10 mm3 using selective laser melting (SLM). The microstructures and hardness of the fabricated 316L stainless steel has been investigated with the laser beam overlap varied from 10% to 70%. The microstructures of the fabricated STS316L samples show a decrease in the balling and satellite of powders introducing defect in the bulk samples and the porosity caused by the gap between the molten metal pools disappearing as the overlap ratio increases, whereas a low overlap ratio results in significant balling and a large amount of isolated powders due to the increased gap between the melt pools. Furthermore, the highest value in Vickers hardness is obtained for the sample fabricated by 30% overlapped laser beams. These results show that the overlap ratio of laser beams in the SLM process should be considered as an important process parameter.

-

Citations

Citations to this article as recorded by- Fabrication and mechanical properties of Al–Si-based alloys by selective laser melting process

Yeong Seong Eom, Kyung Tae Kim, Dong Won Kim, Soo ho Jung, Jung Woo Nam, Dong Yeol Yang, Jungho Choe, Ji Hun Yu, Injoon Son

Powder Metallurgy.2021; 64(3): 198. CrossRef - Effect of laser remelting on the surface characteristics of 316L stainless steel fabricated via directed energy deposition

Seung Yeong Cho, Gwang Yong Shin, Do Sik Shim

Journal of Materials Research and Technology.2021; 15: 5814. CrossRef - Investigation on Interfacial Microstructures of Stainless Steel/Inconel Bonded by Directed Energy Deposition of alloy Powders

Yeong Seong Eom, Kyung Tae Kim, Soo-Ho Jung, Jihun Yu, Dong Yeol Yang, Jungho Choe, Chul Yong Sim, Seung Jun An

Journal of Korean Powder Metallurgy Institute.2020; 27(3): 219. CrossRef - Influence of Powder Size on Properties of Selectively Laser-Melted- AlSi10Mg Alloys

Yeong Seong Eom, Dong Won Kim, Kyung Tae Kim, Sang Sun Yang, Jungho Choe, Injoon Son, Ji Hun Yu

Journal of Korean Powder Metallurgy Institute.2020; 27(2): 103. CrossRef - Microstructural effects on the tensile and fracture behavior of selective laser melted H13 tool steel under varying conditions

Jungsub Lee, Jungho Choe, Junhyeok Park, Ji-Hun Yu, Sangshik Kim, Im Doo Jung, Hyokyung Sung

Materials Characterization.2019; 155: 109817. CrossRef - Microstructures and Characterization of Al-Si-Mg Alloy Processed by Selective Laser Melting with Post-Heat-treatment

Gi Seung Lee, Yeong Seong Eom, Kyung Tae Kim, Byoung Kee Kim, Ji Hun Yu

Journal of Korean Powder Metallurgy Institute.2019; 26(2): 138. CrossRef - Correlation between Microstructure and Mechanical Properties of the Additive Manufactured H13 Tool Steel

Woojin An, Junhyeok Park, Jungsub Lee, Jungho Choe, Im Doo Jung, Ji-Hun Yu, Sangshik Kim, Hyokyung Sung

Korean Journal of Materials Research.2018; 28(11): 663. CrossRef

- Fabrication and mechanical properties of Al–Si-based alloys by selective laser melting process

- [Korean]

- Fabrication and Mechanical Properties of STS316L Porous Metal for Vacuum Injection Mold

- Se Hoon Kim, Sang Min Kim, Sang Ho Noh, Jin Pyeong Kim, Jae Hyuck Shin, Si-Young Sung, Jin Kwang Jin, Taean Kim

- J Korean Powder Metall Inst. 2015;22(3):197-202. Published online June 1, 2015

- DOI: https://doi.org/10.4150/KPMI.2015.22.3.197

- 846 View

- 2 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF In this study, porous stainless steel (STS316L) sintered body was fabricated by powder metallurgy method and its properties such as porosity, compressive yield strength, hardness, and permeability were evaluated. 67.5Fe-17Cr- 13Ni-2.5Mo (wt%) powder was produced by a water atomization. The atomized powder was classified into size with under 45 μm and over 180 μm, and then they were compacted with various pressures and sintered at 1210°C for 1 h in a vacuum atmosphere. The porosities of sintered bodies could be obtained in range of 20~53% by controlling the compaction pressure. Compressive yield strength and hardness were achieved up to 268 MPa and 94 Shore D, respectively. Air permeability was obtained up to 79 l/min·cm2. As a result, mechanical properties and air permeability of the optimized porous body having a porosity of 25~40% were very superior to that of Al alloy.

-

Citations

Citations to this article as recorded by- Printability and physical properties of iron slag powder composites using material extrusion-based 3D printing

Hyungjin Kim, Sangkyu Lee

Journal of Iron and Steel Research International.2021; 28(1): 111. CrossRef - Study on Effects of Mold Temperature on the Injection Molded Article

J.-H. Han, Y.-C. Kim

Archives of Metallurgy and Materials.2017; 62(2): 1271. CrossRef

- Printability and physical properties of iron slag powder composites using material extrusion-based 3D printing

- [Korean]

- Effect of the SiC Size on the Thermal and Mechanical Properties of Reaction-bonded Silicon Carbide Ceramics

- Chang-Sup Kwon, Yoon-Suk Oh, Sung-Min Lee, Yoonsoo Han, Hyun-Ick Shin, Youngseok Kim, Seongwon Kim

- J Korean Powder Metall Inst. 2014;21(6):467-472. Published online December 1, 2014

- DOI: https://doi.org/10.4150/KPMI.2014.21.6.467

- 1,480 View

- 13 Download

- 3 Citations

-

Abstract

Abstract

PDF

PDF RBSC (reaction-bonded silicon carbide) represents a family of composite ceramics processed by infiltrating with molten silicon into a skeleton of SiC particles and carbon in order to fabricate a fully dense body of silicon carbide. RBSC has been commercially used and widely studied for many years, because of its advantages, such as relatively low temperature for fabrication and easier to form components with near-net-shape and high relative density, compared with other sintering methods. In this study, RBSC was fabricated with different size of SiC in the raw material. Microstructure, thermal and mechanical properties were characterized with the reaction-sintered samples in order to examine the effect of SiC size on the thermal and mechanical properties of RBSC ceramics. Especially, phase volume fraction of each component phase, such as Si, SiC, and C, was evaluated by using an image analyzer. The relationship between microstructures and physical properties was also discussed.

-

Citations

Citations to this article as recorded by- Structural and Mechanical Properties of SiC-Rich By-Products of the Metal Grade Si Process

Thomas Hafner, Jonas Hafner, Frank Kimm, Vira Bovda, Oleksandr Bovda, Oleksandr Kuprin, Anatoliy Pikalov, Kostiantyn Lentsov, Pavlo Schikhaylo, Yriy Onyschuk, Andriy Tarasuk, Viktoriya Podhurska, Bogdan Vasyliv, Oleksandr Shcheretsky, Ihor Vorona, Roman Y

Materials Science Forum.2024; 1113: 87. CrossRef - Effect of Y2O3 Additive Amount on Densification of Reaction Bonded Silicon Carbides Prepared by Si Melt Infiltration into All Carbon Preform

Kyeong-Sik Cho, Min-Ho Jang

Korean Journal of Materials Research.2021; 31(5): 301. CrossRef - Mechanical Strength Values of Reaction-Bonded-Silicon-Carbide Tubes with Different Sample Size

Seongwon Kim, Soyul Lee, Yoon-Suk Oh, Sung-Min Lee, Yoonsoo Han, Hyun-Ick Shin, Youngseok Kim

Journal of Korean Powder Metallurgy Institute.2017; 24(6): 450. CrossRef

- Structural and Mechanical Properties of SiC-Rich By-Products of the Metal Grade Si Process

- [Korean]

- Microstructure and Elevated Temperature Strength of W-ZrC Composites with Micrometric and Nanosized ZrC Particles

- Yoon Soo Han, Sung-Soo Ryu

- J Korean Powder Metall Inst. 2014;21(6):415-421. Published online December 1, 2014

- DOI: https://doi.org/10.4150/KPMI.2014.21.6.415

- 663 View

- 1 Download

-

Abstract

Abstract

PDF

PDF W-10vol.%ZrC composites reinforced by micrometric and nanosized ZrC particles were prepared by hot-pressing of 25 MPa for 2 h at 1900°C. The effect of ZrC particle size on microstructure and mechanical properties at room temperature and elevated temperatures was investigated by X-ray diffraction analysis, scanning electron microscope and transmission electron microscope observations and the flexural strength test of the W-ZrC composite. Microstructural analysis of the W-ZrC composite revealed that nanosized ZrC particles were homogeneously dispersed in the W matrix inhibiting W grain growth compared to W specimen with micrometric ZrC particle. As a result, its flexural strength was significantly improved. The flexural strength at room temperature for W-ZrC composite using nanosized ZrC particle being 740 MPa increased by around 2 times than that of specimen using micrometric ZrC particle which was 377 MPa. The maximum strength of 935 MPa was tested at 1200°C on the W composite specimen containing nanosized ZrC particle.

TOP

KPMI

KPMI

First

First Prev

Prev