Search

- Page Path

- HOME > Search

- [Korean]

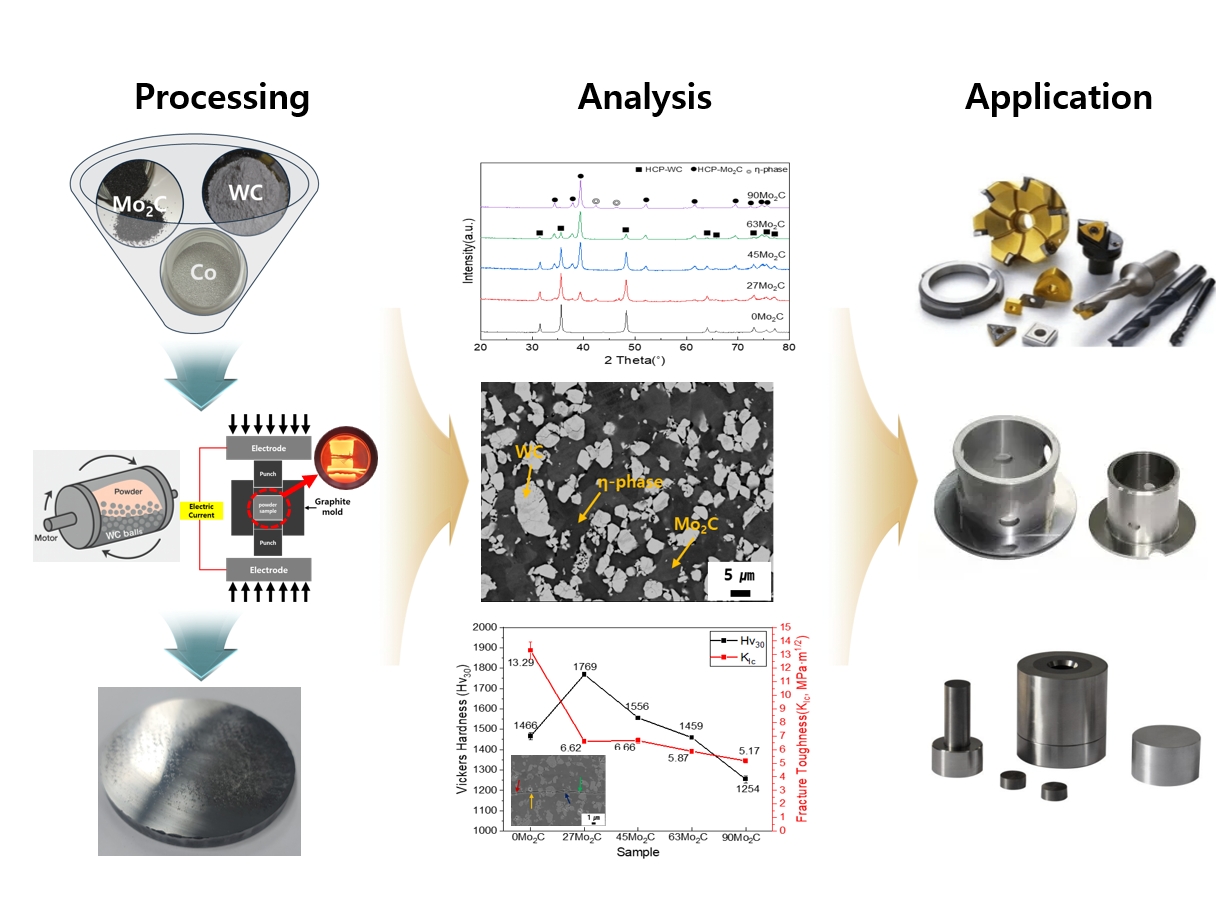

- Optimization of Mechanical Properties in WC–Mo₂C–Co Cemented Carbides via Dual Hard-Phase Based Heterogeneous Microstructure Design

- Jinwoo Seok, Jong Tae Kim, Juree Jung, SongYi Kim, Bin Lee, Junhee Han, Leeseung Kang

- J Powder Mater. 2025;32(5):428-436. Published online October 31, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00297

- 514 View

- 15 Download

-

Abstract

Abstract

PDF

PDF - WC–Mo₂C–Co cemented carbides were fabricated to investigate the effects of Mo₂C addition on microstructure and mechanical properties. Dual hard-phase design using WC and Mo₂C was employed to optimize the balance between hardness and toughness. Spark plasma sintering (SPS) was conducted at various temperatures after ball milling, and 1300 °C for 5 min was identified as the optimized sintering condition, achieving complete densification and phase stability. The addition of Mo₂C refined the microstructure by suppressing abnormal WC grain growth through preferential dissolution of Mo₂C into the Co binder. Hardness increased up to 1769 Hv30 due to grain refinement and solid-solution strengthening, while promoted η-phase formation and reduced fracture toughness.The 27Mo₂C composition exhibited the most balanced combination of hardness and toughness. These results demonstrate that controlled Mo₂C addition enables dual hard-phase strengthening and microstructure optimization in WC–Mo₂C–Co carbides for advanced cutting and forming applications.

- [English]

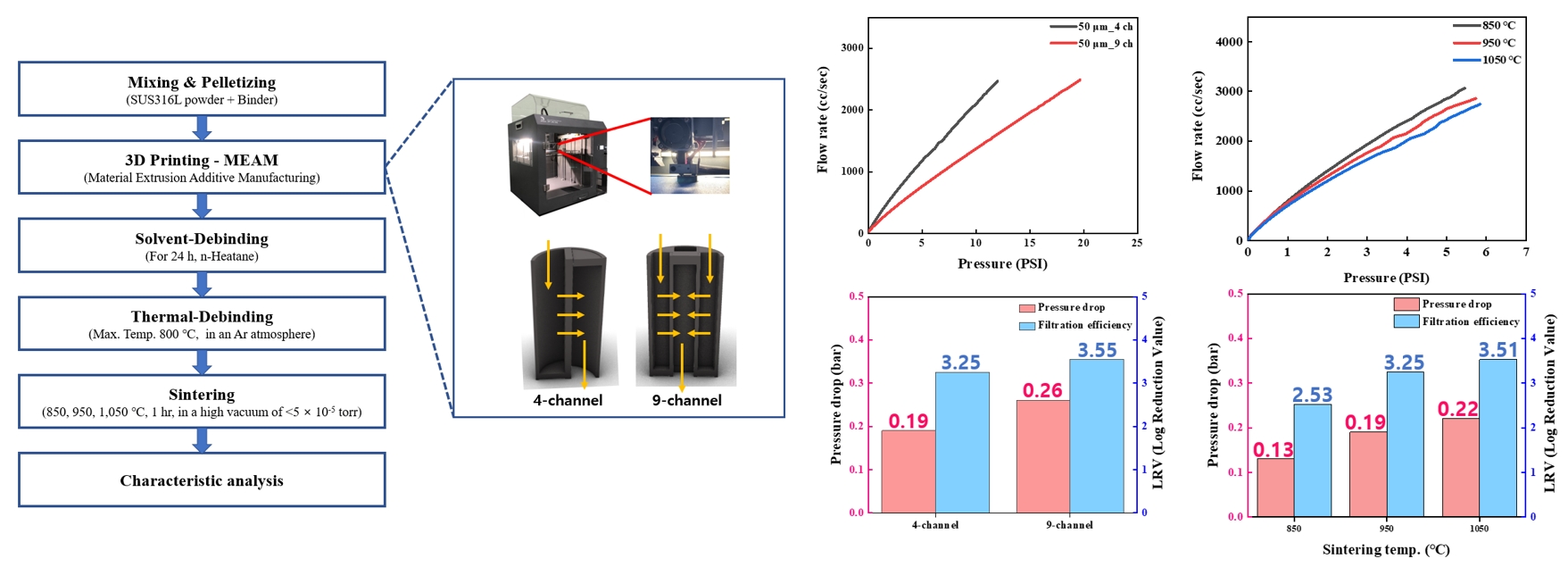

- Fabrication and Pore Characteristics of Metal Powder Filters with a Cross-Sealed Honeycomb Shape Using Material Extrusion Additive Manufacturing

- Minji Kim, Min-Jeong Lee, Su-Jin Yun, Poong-Yeon Kim, Hyeon Ju Kim, Juyong Kim, Jung Woo Lee, Jung-Yeul Yun

- J Powder Mater. 2025;32(4):299-308. Published online August 29, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00234

- 957 View

- 26 Download

-

Abstract

Abstract

PDF

PDF - The development of high-performance metal filters is essential for maintaining ultra-clean environments in semiconductor manufacturing. In this study, cross-sealed honeycomb filters were fabricated using STS316L powder via material extrusion additive manufacturing (MEAM) for semiconductor gas filtration. The effects of filter geometry (4 or 9 channels) and sintering temperature (850°C, 950°C, or 1,050°C) on performance were examined. First, 4-channel and 9-channel filters sintered at the same temperature (950°C) exhibited similar porosities of 50.08% and 50.57%, but the 9-channel filter showed a higher pressure-drop (0.26 bar) and better filtration-efficiency (3.55 LRV) than the 4-channel filter (0.19 bar and 3.25 LRV, respectively). Second, for filters with the same geometry (4-channel) increasing the sintering temperature reduced porosity from 64.52% to 40.33%, while the pressure-drop increased from 0.13 bar to 0.22 bar and filtration-efficiency improved from 2.53 LRV to 3.51 LRV. These findings demonstrate that filter geometry and sintering temperature are key factors governing the trade-off between air permeability, pressure-drop, and filtration efficiency. This work provides insights and data for optimizing MEAM-based high-performance metal powder filter design.

- [English]

- The Effect of Aluminum Powder Size on the Structure and Mechanical Properties of Foam

- Seunghyeok Choi, Sungjin Kim, Tae-Young Ahn, Yu-Song Choi, Jae-Gil Jung, Seung Bae Son, Seok-Jae Lee

- J Powder Mater. 2025;32(3):232-243. Published online June 30, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00157

- 1,345 View

- 51 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF - In this study, we analyzed the structural and mechanical properties of aluminum foams fabricated using aluminum powders of varying sizes and mixtures. The effects of sintering and pore structure at each size on the integrity and mechanical properties of the foams were investigated. Structural characteristics were examined using scanning electron microscopy and micro–computed tomography, while mechanical properties were evaluated through compression testing. The experimental results demonstrated that smaller powder sizes improved foam integrity, reduced porosity and pore size, and resulted in thinner cell walls. In combination, these effects increased compressive strength as the powder size decreased. The findings of this study contribute to the understanding and improvement of the mechanical properties of aluminum foams and highlight their potential for use in a wide range of applications.

-

Citations

Citations to this article as recorded by- Sustainable Manufacturing of Graphene–Aluminum Composites: A Comparative Life Cycle Assessment

Xinwei Yang, Qian Peng, Changke Chen, Qingcui Liu, Yudai Huang

Journal of Sustainable Metallurgy.2026; 12(1): 727. CrossRef

- Sustainable Manufacturing of Graphene–Aluminum Composites: A Comparative Life Cycle Assessment

- [Korean]

- Fabrication and Alloying Behavior of Ultra-Lightweight AlTiCrVMg High-Entropy Alloy via Al-Mg Mutual Solubility and Sintering Control

- Eunhyo Song, Hansung Lee, Byungmin Ahn

- J Powder Mater. 2025;32(3):254-261. Published online June 12, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00059

- 652 View

- 23 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF - High-entropy alloys (HEAs) incorporating low-melting-point elements (Mg and Al) and high-melting-point elements (Ti, Cr, and V) were fabricated via mechanical alloying and spark plasma sintering. Sintering temperatures were varied to investigate phase behavior and microstructural evolution. X-ray diffraction was used to identify phase structures, scanning electron microscopy to analyze microstructures, X-ray fluorescence to determine elemental composition, and a gas pycnometer to measure density. Micro-Vickers hardness testing was conducted to evaluate mechanical properties. Mechanical-alloyed HEAs exhibited a body-centered cubic (BCC) phase and lamellar structures with element-enriched regions. Sintering introduced additional BCC and Laves phases, while higher temperatures promoted Mg liquid-phase sintering, increasing density and hardness. This study highlights the effects of sintering on HEAs containing elements with differing melting points to optimize their properties.

-

Citations

Citations to this article as recorded by- Effect of annealing temperature on thermal expansion and cryogenic mechanical properties of low-thermal-expansion Co22.2Cr6.2Fe48.8Ni17.8Cu5.0 medium-entropy alloy

Wooyoung Lee, Munsu Choi, Sungwook Kim, Dae-Kyeom Kim, Myungsuk Song, Taek-Soo Kim, Jungwan Lee, Hyoung Seop Kim, Hyunjoo Choi, Soo-Hyun Joo

Materials Science and Engineering: A.2026; 954: 149811. CrossRef

- Effect of annealing temperature on thermal expansion and cryogenic mechanical properties of low-thermal-expansion Co22.2Cr6.2Fe48.8Ni17.8Cu5.0 medium-entropy alloy

- [English]

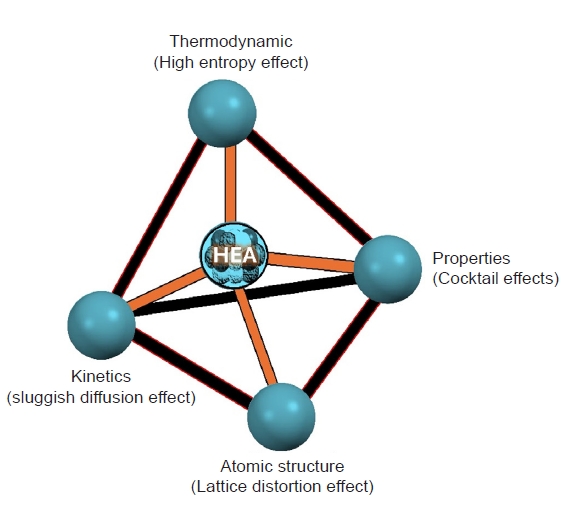

- Advances in Powder Metallurgy for High-Entropy Alloys

- Sheetal Kumar Dewangan, Cheenepalli Nagarjuna, Hansung Lee, K. Raja Rao, Man Mohan, Reliance Jain, Byungmin Ahn

- J Powder Mater. 2024;31(6):480-492. Published online December 31, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00297

- 4,970 View

- 168 Download

- 3 Citations

-

Abstract

Abstract

PDF

PDF - High-entropy alloys (HEAs) represent a revolutionary class of materials characterized by their multi-principal element compositions and exceptional mechanical properties. Powder metallurgy, a versatile and cost-effective manufacturing process, offers significant advantages for the development of HEAs, including precise control over their composition, microstructure, and mechanical properties. This review explores innovative approaches integrating powder metallurgy techniques in the synthesis and optimization of HEAs. Key advances in powder production, sintering methods, and additive manufacturing are examined, highlighting their roles in improving the performance, advancement, and applicability of HEAs. The review also discusses the mechanical properties, potential industrial applications, and future trends in the field, providing a comprehensive overview of the current state and future prospects of HEA development using powder metallurgy.

-

Citations

Citations to this article as recorded by- Fabrication and Alloying Behavior of Ultra-Lightweight AlTiCrVMg High-Entropy Alloy via Al-Mg Mutual Solubility and Sintering Control

Eunhyo Song, Hansung Lee, Byungmin Ahn

Journal of Powder Materials.2025; 32(3): 254. CrossRef - Thermodynamic and Electronic Descriptor-Driven Machine Learning for Phase Prediction in High-Entropy Alloys: Experimental Validation

Nguyen Lam Khoa, Nguyen Duy Khanh, Hoang Thi Ngoc Quyen, Nguyen Thi Hoang, Oanh, Le Hong Thang, Nguyen Hoa Khiem, Nguyen Hoang Viet

Journal of Powder Materials.2025; 32(3): 191. CrossRef - Latest Advancements and Mechanistic Insights into High-Entropy Alloys: Design, Properties and Applications

Anthoula Poulia, Alexander E. Karantzalis

Materials.2025; 18(24): 5616. CrossRef

- Fabrication and Alloying Behavior of Ultra-Lightweight AlTiCrVMg High-Entropy Alloy via Al-Mg Mutual Solubility and Sintering Control

- [Korean]

- Effect of Sintering Conditions on the Microstructure of an FeCrMnNiCo High-Entropy Alloy

- Seonghyun Park, Sang-Hwa Lee, Junho Lee, Seok-Jae Lee, Jae-Gil Jung

- J Powder Mater. 2024;31(5):406-413. Published online October 31, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00185

- 1,274 View

- 40 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF - We investigated the microstructure of an FeCrMnNiCo alloy fabricated by spark plasma sintering under different sintering temperatures (1000–1100°C) and times (1–600 s). All sintered alloys consisted of a single face-centered cubic phase. As the sintering time or temperature increased, the grains of the sintered alloys became partially coarse. The formation of Cr7C3 carbide occurred on the surface of the sintered alloys due to carbon diffusion from the graphite crucible. The depth of the layer containing Cr7C3 carbides increased to ~110 μm under severe sintering conditions (1100°C, 60 s). A molten zone was observed on the surface of the alloys sintered at higher temperatures (>1060°C) due to severe carbon diffusion that reduced the melting point of the alloy. The porosity of the sintered alloys decreased with increasing time at 1000°C, but increased at higher temperatures above 1060°C due to melting-induced porosity formation.

-

Citations

Citations to this article as recorded by- Fabrication and Alloying Behavior of Ultra-Lightweight AlTiCrVMg High-Entropy Alloy via Al-Mg Mutual Solubility and Sintering Control

Eunhyo Song, Hansung Lee, Byungmin Ahn

Journal of Powder Materials.2025; 32(3): 254. CrossRef - Microstructure and mechanical properties of oxide-dispersion-strengthened CrMnFeCoNiC0.2O0.2 high-entropy alloy fabricated by mechanical alloying and spark plasma sintering

Sang-Hwa Lee, Seonghyun Park, Ka Ram Lim, Seok-Jae Lee, Jae-Gil Jung

Materials Science and Engineering: A.2025; 947: 149284. CrossRef

- Fabrication and Alloying Behavior of Ultra-Lightweight AlTiCrVMg High-Entropy Alloy via Al-Mg Mutual Solubility and Sintering Control

- [Korean]

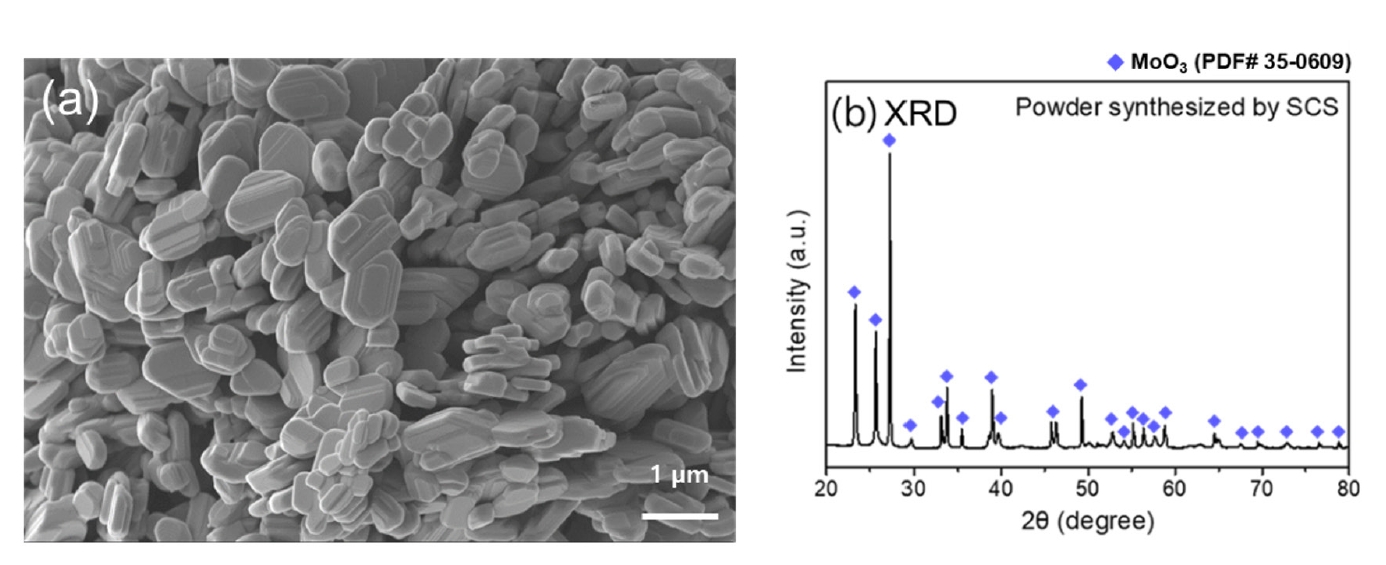

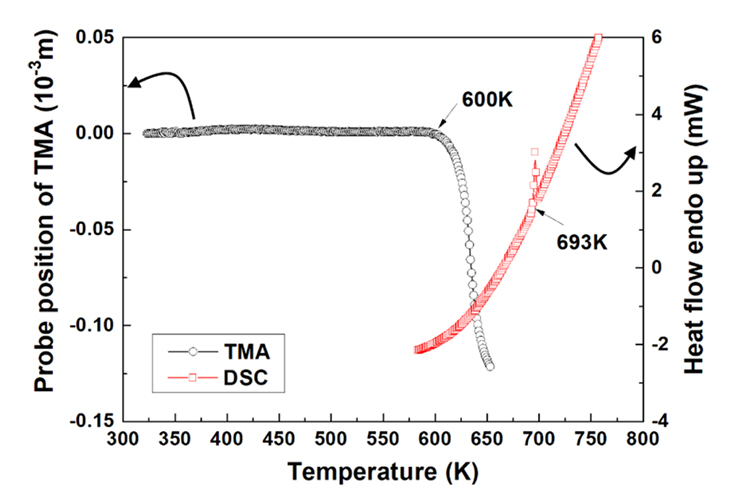

- Characterization of Compacted and Pressureless Sintered Parts for Molybdenum Oxide Powder according to Hydrogen Reduction Temperature

- Jong Hoon Lee, Kun-Jae Lee

- J Powder Mater. 2024;31(4):336-341. Published online August 30, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00241

- 1,217 View

- 16 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF - Molybdenum, valued for its high melting point and exceptional physical and chemical properties, is studied in diverse fields such as electronics, petrochemicals, and aviation. Among molybdenum oxides, molybdenum dioxide stands out for its higher electrical conductivity than other transition metal oxides due to its structural characteristics, exhibiting metallic properties. It is applied as pellets to gas sensors, semiconductors, and secondary batteries for its properties. Thus, research on molybdenum dioxide compaction and pressureless sintering is necessary, yet research on pressureless sintering is currently insufficient. This study synthesized MoO₃ powder via solution combustion synthesis and reduced it using the 3% hydrogen/argon gas mixture to investigate the effect of reduction temperature on the powder. Additionally, the reduced powder was compacted and subjected to pressureless sintering with temperature as a variable. The density and the microstructure of brown parts were analyzed and discussed.

-

Citations

Citations to this article as recorded by- High-sensitivity optical fiber hydrogen sensing with MoO3/PANI/Pd nanocomposite

Mohammed M. Alkhabet, Saad H. Girei, Ammar H. Farhan, Fatimah F. Hashim, Jaafar A. Jaafar, Husam K. Salih, Manar F. Abbood, Mohd H. Yaacob

Materials Science in Semiconductor Processing.2025; 200: 110021. CrossRef

- High-sensitivity optical fiber hydrogen sensing with MoO3/PANI/Pd nanocomposite

- [English]

- The Effect of TiO2 Addition on Low-temperature Sintering Behaviors in a SnO2-CoO-CuO System

- Jae-Sang Lee, Kyung-Sik Oh, Yeong-Kyeun Paek

- J Powder Mater. 2024;31(2):146-151. Published online April 30, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00024

- 1,180 View

- 18 Download

-

Abstract

Abstract

PDF

PDF - Pure SnO2 has proven very difficult to densify. This poor densification can be useful for the fabrication of SnO2 with a porous microstructure, which is used in electronic devices such as gas sensors. Most electronic devices based on SnO2 have a porous microstructure, with a porosity of > 40%. In pure SnO2, a high sintering temperature of approximately 1300C is required to obtain > 40% porosity. In an attempt to reduce the required sintering temperature, the present study investigated the low-temperature sinterability of a current system. With the addition of TiO2, the compositions of the samples were Sn1-xTixO2-CoO(0.3wt%)-CuO(2wt%) in the range of x ≤ 0.04. Compared to the samples without added TiO2, densification was shown to be improved when the samples were sintered at 950C. The dominant mass transport mechanism appears to be grain-boundary diffusion during heat treatment at 950C.

- [Korean]

- Fabrication of Bi2Te2.5Se0.5 by Combining Oxide-reduction and Compressive-forming Process and Its Thermoelectric Properties

- Young Soo Lim, Gil-Geun Lee

- J Powder Mater. 2024;31(1):50-56. Published online February 28, 2024

- DOI: https://doi.org/10.4150/KPMI.2024.31.1.50

- 1,076 View

- 20 Download

- [Korean]

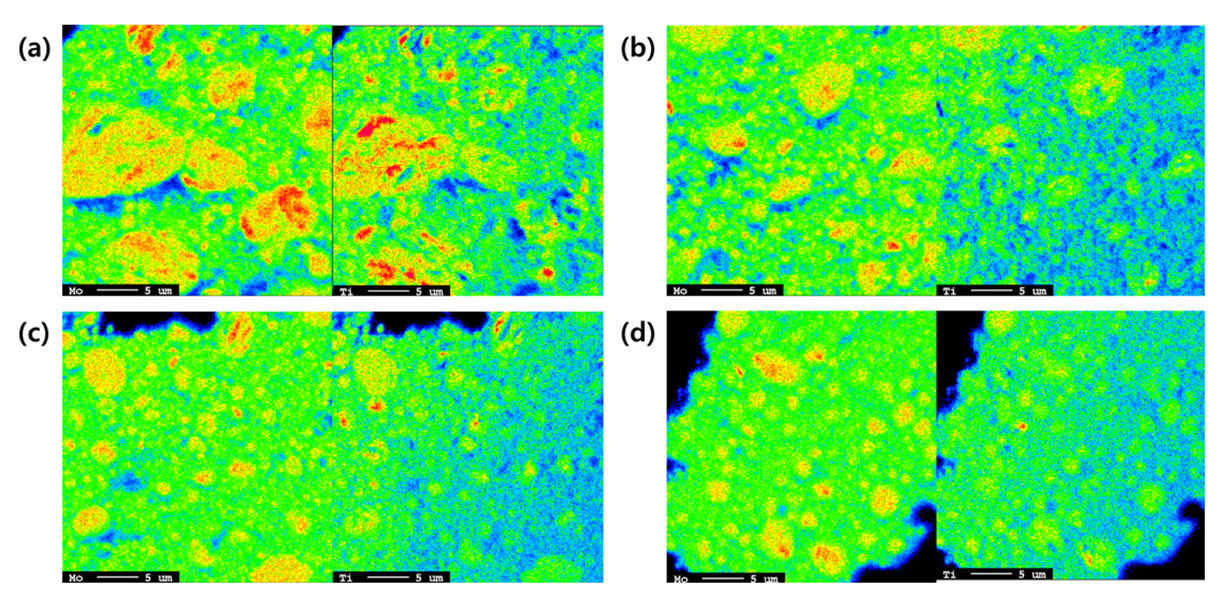

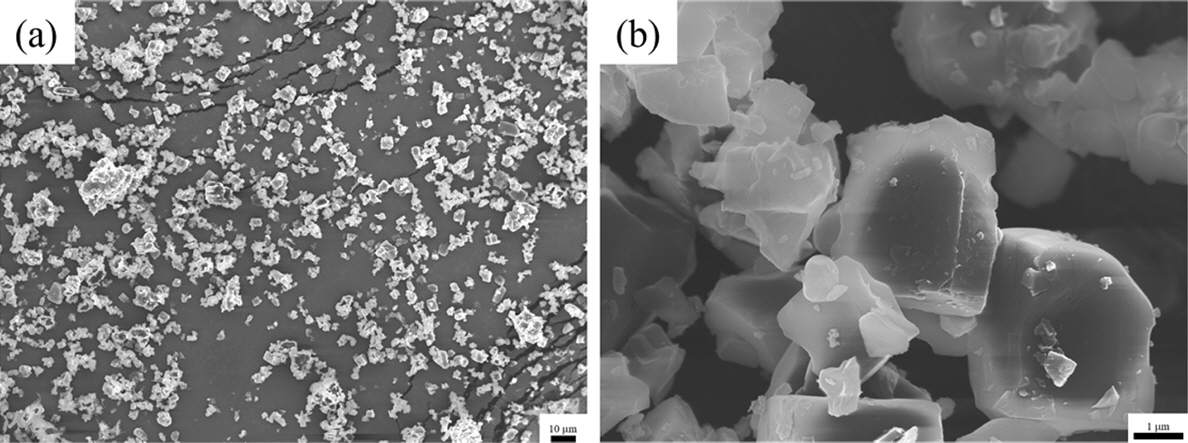

- Fabrication of Ti-Mo Core-shell Powder and Sintering Properties for Application as a Sputtering Target

- Won Hee Lee, Chun Woong Park, Heeyeon Kim, Yuncheol Ha, Jongmin Byun, Young Do Kim

- J Powder Mater. 2024;31(1):43-49. Published online February 28, 2024

- DOI: https://doi.org/10.4150/KPMI.2024.31.1.43

- 1,526 View

- 36 Download

- [Korean]

- Effect of Abnormal Grain Growth on Ionic Conductivity in LATP

- Hyungik Choi, Yoonsoo Han

- J Powder Mater. 2024;31(1):23-29. Published online February 28, 2024

- DOI: https://doi.org/10.4150/KPMI.2024.31.1.23

- 2,925 View

- 66 Download

- 2 Citations

-

PDF

PDF -

Citations

Citations to this article as recorded by- Temperature-dependent microstructural evolution in a compositionally complex solid electrolyte: The role of a grain boundary transition

Shu-Ting Ko, Chaojie Du, Huiming Guo, Hasti Vahidi, Jenna L. Wardini, Tom Lee, Yi Liu, Jingjing Yang, Francisco Guzman, Timothy J. Rupert, William J. Bowman, Shen J. Dillon, Xiaoqing Pan, Jian Luo

Journal of Advanced Ceramics.2025; 14(3): 9221047. CrossRef - Effect of bimodal particle size distribution on Li1.5Al0.5Ti1.5(PO4)3 solid electrolytes: Microstructures and electrochemical properties

Gi Jeong Kim, Yeon Hee Kim, Seul Ki Choi, Jong Won Bae, Kun-Jae Lee, Minho Yang

Powder Technology.2025; 466: 121407. CrossRef

- Temperature-dependent microstructural evolution in a compositionally complex solid electrolyte: The role of a grain boundary transition

- [Korean]

- Evaluation of Microstructures and Mechanical Properties of Ni-Y2O3 Sintered Alloys Based on the Powder Preparation Methods

- Gun-Woo Jung, Ji-Ho Cha, Min-Seo Jang, Minsuk Oh, Jeshin Park

- J Powder Mater. 2023;30(6):484-492. Published online December 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.6.484

- 1,091 View

- 15 Download

-

Abstract

Abstract

PDF

PDF In this study, Ni-Y2O3 powder was prepared by alloying recomposition oxidation sintering (AROS), solution combustion synthesis (SCS), and conventional mechanical alloying (MA). The microstructure and mechanical properties of the alloys were investigated by spark plasma sintering (SPS). Among the Ni-Y2O3 powders synthesized by the three methods, the AROS powder had approximately 5 nm of Y2O3 crystals uniformly distributed within the Ni particles, whereas the SCS powder contained a mixture of Ni and Y2O3 nanoparticles, and the MA powder formed small Y2O3 crystals on the surface of large Ni particles by milling the mixture of Ni and Y2O3. The average grain size of Y2O3 in the sintered alloys was approximately 15 nm, with the AROS sinter having the smallest, followed by the SCS sinter at 18 nm, and the MA sinter at 22 nm. The yield strength (YS) of the SCS- and MA-sintered alloys were 1511 and 1688 MPa, respectively, which are lower than the YS value of 1697 MPa for the AROS-sintered alloys. The AROS alloy exhibited improved strength compared to the alloys fabricated by SCS and conventional MA methods, primarily because of the increased strengthening from the finer Y2O3 particles and Ni grains.

- [Korean]

- Effect of Heat Treatment on Microstructure and Mechanical Properties of Al–Zn–Mg–Cu–Si Sintered Alloys with and Without High-energy Ball Milling

- Junho Lee, Seonghyun Park, Sang-Hwa Lee, Seung Bae Son, Seok-Jae Lee, Jae-Gil Jung

- J Powder Mater. 2023;30(6):470-477. Published online December 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.6.470

- 2,765 View

- 32 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF The effects of annealing on the microstructure and mechanical properties of Al–Zn–Mg–Cu–Si alloys fabricated by high-energy ball milling (HEBM) and spark plasma sintering (SPS) were investigated. The HEBM-free sintered alloy primarily contained Mg2Si, Q-AlCuMgSi, and Si phases. Meanwhile, the HEBM-sintered alloy contains Mg-free Si and θ-Al2Cu phases due to the formation of MgO, which causes Mg depletion in the Al matrix. Annealing without and with HEBM at 500°C causes partial dissolution and coarsening of the Q-AlCuMgSi and Mg2Si phases in the alloy and dissolution of the θ-Al2Cu phase in the alloy, respectively. In both alloys, a thermally stable α-AlFeSi phase was formed after long-term heat treatment. The grain size of the sintered alloys with and without HEBM increased from 0.5 to 1.0 μm and from 2.9 to 6.3 μm, respectively. The hardness of the sintered alloy increases after annealing for 1 h but decreases significantly after 24 h of annealing. Extending the annealing time to 168 h improved the hardness of the alloy without HEBM but had little effect on the alloy with HEBM. The relationship between the microstructural factors and the hardness of the sintered and annealed alloys is discussed.

-

Citations

Citations to this article as recorded by- Microstructural evolution and thermal stability of Al–Zn–Mg–Cu–Si–Zr alloy fabricated via spark plasma sintering

Junho Lee, Seonghyun Park, Sang-Hwa Lee, Seung Bae Son, Hanjung Kwon, Seok-Jae Lee, Jae-Gil Jung

Journal of Materials Research and Technology.2024; 31: 205. CrossRef

- Microstructural evolution and thermal stability of Al–Zn–Mg–Cu–Si–Zr alloy fabricated via spark plasma sintering

- [Korean]

- Fabrication and Sintering Behavior Analysis of Molybdenum-tungsten Nanopowders by Pechini Process

- Suyeon Kim, Taehyun Kwon, Seulgi Kim, Dongju Lee

- J Powder Mater. 2023;30(5):436-441. Published online October 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.5.436

- 897 View

- 8 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF Molybdenum-tungsten (Mo-W) alloy sputtering targets are widely utilized in fields like electronics, nanotechnology, sensors, and as gate electrodes for TFT-LCDs, owing to their superior properties such as hightemperature stability, low thermal expansion coefficient, electrical conductivity, and corrosion resistance. To achieve optimal performance in application, these targets’ purity, relative density, and grain size of these targets must be carefully controlled. We utilized nanopowders, prepared via the Pechini method, to obtain uniform and fine powders, then carried out spark plasma sintering (SPS) to densify these powders. Our studies revealed that the sintered compacts made from these nanopowders exhibited outstanding features, such as a high relative density of more than 99%, consistent grain size of 3.43 μm, and shape, absence of preferred orientation.

-

Citations

Citations to this article as recorded by- Ultrafast Synthesis of Molybdenum Disulfide via Flashlamp Annealing

Chan Hyeon Yang, Jaehak Lee, Jung Hwan Park

Journal of Powder Materials.2025; 32(6): 509. CrossRef

- Ultrafast Synthesis of Molybdenum Disulfide via Flashlamp Annealing

- [English]

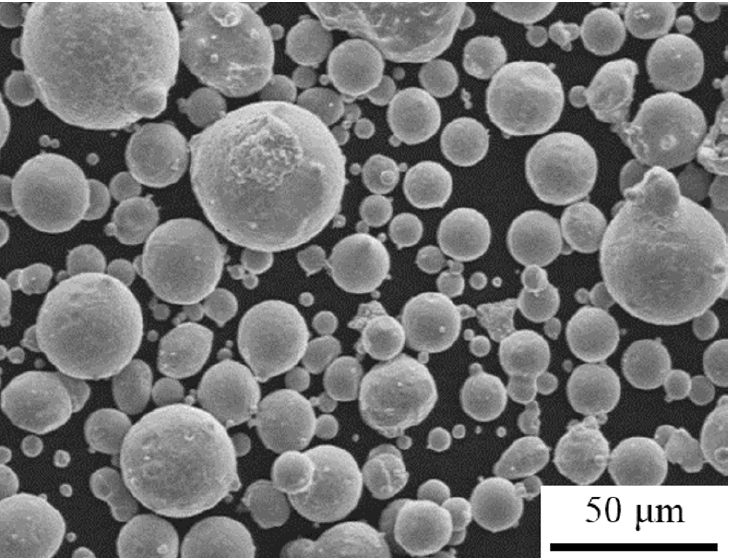

- Selective Laser Sintering of Co-Cr Alloy Powders and Sintered Products Properties

- Dong-Wan Lee, Minh-Thuyet Nguyen, Jin-Chun Kim

- J Powder Mater. 2023;30(1):7-12. Published online February 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.1.7

- 1,456 View

- 24 Download

-

Abstract

Abstract

PDF

PDF Metal-additive manufacturing techniques, such as selective laser sintering (SLS), are increasingly utilized for new biomaterials, such as cobalt-chrome (Co-Cr). In this study, Co-Cr gas-atomized powders are used as charge materials for the SLS process. The aim is to understand the consolidation of Co-Cr alloy powder and characterization of samples sintered using SLS under various conditions. The results clearly suggest that besides the matrix phase, the second phase, which is attributed to pores and oxidation particles, is observed in the sintered specimens. The as-built samples exhibit completely different microstructural features compared with the casting or wrought products reported in the literature. The microstructure reveals melt pools, which represent the characteristics of the scanning direction, in particular, or of the SLS conditions, in general. It also exposes extremely fine grain sizes inside the melt pools, resulting in an enhancement in the hardness of the as-built products. Thus, the hardness values of the samples prepared by SLS under all parameter conditions used in this study are evidently higher than those of the casting products.

- [Korean]

- Synthesis of Al-Ni-Co-Y Bulk Metallic Glass fabricated by Spark Plasma Sintering

- Jeong Pyo Lee, Jin Kyu Lee

- J Powder Mater. 2023;30(1):41-46. Published online February 1, 2023

- DOI: https://doi.org/10.4150/KPMI.2023.30.1.41

- 915 View

- 2 Download

-

Abstract

Abstract

PDF

PDF In this study, an Al82Ni7Co3Y8 (at%) bulk metallic glass is fabricated using gas-atomized Al82Ni7Co3Y8 metallic glass powder and subsequent spark plasma sintering (SPS). The effect of powder size on the consolidation of bulk metallic glass is considered by dividing it into 5 μm or less and 20–45 μm. The sintered Al82Ni7Co3Y8 bulk metallic glasses exhibit crystallization behavior and crystallization enthalpy similar to those of the Al82Ni7Co3Y8 powder with 5 μm or less and it is confirmed that no crystallization occurred during the sintering process. From these results, we conclude that the Z-position-controlled spark plasma sintering process, using superplastic deformation by viscous flow in the supercooled liquid-phase region of amorphous powder, is an effective process for manufacturing bulk metallic glass.

- [Korean]

- Effect of Mo Addition on the Austenite Stability of Nanocrystalline Fe-7wt.%Mn Alloy Fabricated by Spark Plasma Sintering

- Woochul Shin, Seung Bae Son, Jae-Gil Jung, Seok-Jae Lee

- J Powder Mater. 2022;29(6):517-522. Published online December 1, 2022

- DOI: https://doi.org/10.4150/KPMI.2022.29.6.517

- 887 View

- 12 Download

-

Abstract

Abstract

PDF

PDF We investigate the austenite stability in nanocrystalline Fe-7%Mn-X%Mo (X = 0, 1, and 2) alloys fabricated by spark plasma sintering. Mo is known as a ferrite stabilizing element, whereas Mn is an austenite stabilizing element, and many studies have focused on the effect of Mn addition on austenite stability. Herein, the volume fraction of austenite in nanocrystalline Fe-7%Mn alloys with different Mo contents is measured using X-ray diffraction. Using a disk compressive test, austenite in Fe–Mn–Mo alloys is confirmed to transform into strain-induced martensite during plastic deformation by a disk d. The variation in austenite stability in response to the addition of Mo is quantitatively evaluated by comparing the k-parameters of the kinetic equation for the strain-induced martensite transformation.

- [Korean]

- Analysis of Monoclinic Phase Change and Microstructure According to High-temperature Heat Treatment of Oxide-doped YSZ

- Gye-Won Lee, Yong-Seok Choi, Chang-Woo Jeon, In-Hwan Lee, Yoon-Suk Oh

- J Powder Mater. 2022;29(6):468-476. Published online December 1, 2022

- DOI: https://doi.org/10.4150/KPMI.2022.29.6.468

- 1,319 View

- 9 Download

-

Abstract

Abstract

PDF

PDF Yttria-stabilized zirconia (YSZ) has a low thermal conductivity, high thermal expansion coefficient, and excellent mechanical properties; thus, it is used as a thermal barrier coating material for gas turbines. However, during long-time exposure of YSZ to temperatures of 1200°C or higher, a phase transformation accompanied by a volume change occurs, causing the YSZ coating layer to peel off. To solve this problem, YSZ has been doped with trivalent and tetravalent oxides to obtain coating materials with low thermal conductivity and suppressed phase transformation of zirconia. In this study, YSZ is doped with trivalent oxides, Nd2O3, Yb2O3, Al2O3, and tetravalent oxide, TiO2, and the thermal conductivity of the obtained materials is analyzed according to the composition; furthermore, the relative density change, microstructure change, and m-phase formation behavior are analyzed during long-time heat treatment at high temperatures.

- [Korean]

- Comparison of Properties with Different Sintering Process of 3Y-TZP/WC Composites

- Min-Soo Nam, Jae-Hyung Choi, Sahn Nahm, Seongwon Kim

- J Powder Mater. 2022;29(5):424-431. Published online October 1, 2022

- DOI: https://doi.org/10.4150/KPMI.2022.29.5.424

- 883 View

- 3 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF 3Y-TZP ceramics obtained by doping 3 mol.% of Y2O3 to ZrO2 to stabilize the phase transition are widely used in the engineering ceramic industry due to their excellent mechanical properties such as high strength, fracture toughness, and wear resistance. An additional increase in mechanical properties is possible by manufacturing a composite in which a high-hardness material such as oxide or carbide is added to the 3Y-TZP matrix. In this study, composite powder was prepared by dispersing a designated percentage of WC in the 3Y-TZP matrix, and the results were compared after manufacturing the composite using the different processes of spark plasma sintering and HP. The difference between the densification behavior and porosity with the process mechanism was investigated. The correlation between the process conditions and phase formation was examined based on the crystalline phase formation behavior. Changes to the microstructure according to the process conditions were compared using field-emission scanning electron microscopy. The toughness-strengthening mechanism of the composite with densification and phase formation was also investigated.

-

Citations

Citations to this article as recorded by- Phase Formation and Mechanical Property of YSZ‒30 vol.% WC Composite Ceramics Fabricated by Hot Pressing

Jin-Kwon Kim, Jae-Hyeong Choi, Nahm Sahn, Sung-Soo Ryu, Seongwon Kim

journal of Korean Powder Metallurgy Institute.2023; 30(5): 409. CrossRef

- Phase Formation and Mechanical Property of YSZ‒30 vol.% WC Composite Ceramics Fabricated by Hot Pressing

- [Korean]

- Evaluation of Mechanical Properties and Microstructure Depending on Sintering Heating Rate of IN 939W Alloy

- Junhyub Jeon, Junho Lee, Namhyuk Seo, Seung Bae Son, Jae-Gil Jung, Seok-Jae Lee

- J Powder Mater. 2022;29(5):399-410. Published online October 1, 2022

- DOI: https://doi.org/10.4150/KPMI.2022.29.5.399

- 1,672 View

- 31 Download

-

Abstract

Abstract

PDF

PDF Changes in the mechanical properties and microstructure of an IN 939 W alloy according to the sintering heating rate were evaluated. IN 939 W alloy samples were fabricated by spark plasma sintering. The phase fraction, number density, and mean radius of the IN 939W alloy were calculated using a thermodynamic calculation. A universal testing machine and micro-Vickers hardness tester were employed to confirm the mechanical properties of the IN 939W alloy. X-ray diffraction, optical microscopy, field-emission scanning electron microscopy, Cs-corrected-field emission transmission electron microscopy, and energy dispersive X-ray spectrometry were used to evaluate the microstructure of the alloy. The rapid sintering heating rate resulted in a slightly dispersed γ' phase and chromium oxide. It also suppressed the precipitation of the η phase. These helped to reinforce the mechanical properties.

- [Korean]

- Gradient Microstructure and Mechanical Properties of Fe-6%Mn Alloy by Different Sized Powder Stacking

- Namhyuk Seo, Junho Lee, Woocheol Shin, Junhyub Jeon, Jungbin Park, Seung Bae Son, Jae-Gil Jung, Seok-Jae Lee

- J Powder Mater. 2022;29(5):382-389. Published online October 1, 2022

- DOI: https://doi.org/10.4150/KPMI.2022.29.5.382

- 743 View

- 10 Download

-

Abstract

Abstract

PDF

PDF A typical trade-off relationship exists between strength and elongation in face-centered cubic metals. Studies have recently been conducted to enhance strength without ductility reduction through surface-treatment-based ultrasonic nanocrystalline surface modification (UNSM), which creates a gradient microstructure in which grains become smaller from the inside to the surface. The transformation-induced plasticity effect in Fe-Mn alloys results in excellent strength and ductility due to their high work-hardening rate. This rate is achieved through strain-induced martensitic transformation when an alloy is plastically deformed. In this study, Fe-6%Mn powders with different sizes were prepared by high-energy ball milling and sintered through spark plasma sintering to produce Fe-6%Mn samples. A gradient microstructure was obtained by stacking the different-sized powders to achieve similar effects as those derived from UNSM. A compressive test was performed to investigate the mechanical properties, including the yielding behavior. The deformed microstructure was observed through electron backscatter diffraction to determine the effects of gradient plastic deformation.

- [English]

- The Effect of SnO2 Addition on Sintering Behaviors in a Titanium Oxide-Copper Oxide System

- Ju-Won Lee, Kyung-Sik Oh, Tai-Joo Chung, Yeong-Kyeun Paek

- J Powder Mater. 2022;29(5):357-362. Published online October 1, 2022

- DOI: https://doi.org/10.4150/KPMI.2022.29.5.357

- 817 View

- 4 Download

-

Abstract

Abstract

PDF

PDF The low-temperature sinterability of TiO2-CuO systems was investigated using a solid solution of SnO2. Sample powders were prepared through conventional ball milling of mixed raw powders. With the SnO2 content, the compositions of the samples were Ti1-xSnxO2-CuO(2 wt.%) in the range of x ≤ 0.08. Compared with the samples without SnO2 addition, the densification was enhanced when the samples were sintered at 900°C. The dominant mass transport mechanism seemed to be grain-boundary diffusion during heat treatment at 900°C, where active grain-boundary diffusion was responsible for the improved densification. The rapid grain growth featured by activated sintering was also obstructed with the addition of SnO2. This suggested that both CuO as an activator and SnO2 dopant synergistically reduced the sintering temperature of TiO2.

- [Korean]

- Spark Plasma Sintering Method to Replace Carburizing Process

- Junhyub Jeon, Junho Lee, Namhyuk Seo, Seung Bae Son, Jae-Gil Jung, Seok-Jae Lee

- J Powder Mater. 2022;29(3):219-225. Published online June 1, 2022

- DOI: https://doi.org/10.4150/KPMI.2022.29.3.219

- 522 View

- 4 Download

-

Abstract

Abstract

PDF

PDF An alternative fabrication method for carburizing steel using spark plasma sintering (SPS) is investigated. The sintered carburized sample, which exhibits surface modification effects such as carburizing, sintered Fe, and sintered Fe–0.8 wt.%C alloys, is fabricated using SPS. X-ray diffraction and micro Vickers tests are employed to confirm the phase and properties. Finite element analysis is performed to evaluate the change in hardness and analyze the carbon content and residual stress of the carburized sample. The change in the hardness of the carburized sample has the same tendency to predict hardness. The difference in hardness between the carburized sample and the predicted value is also discussed. The carburized sample exhibits a compressive residual stress at the surface. These results indicate that the carburized sample experiences a surface modification effect without carburization. Field emission scanning electron microscopy is employed to verify the change in phase. A novel fabrication method for altering the carburization is successfully proposed. We expect this fabrication method to solve the problems associated with carburization.

- [Korean]

- Microstructure and Characteristics of Ag-SnO2-Bi2O3 Contact Materials by Powder Compaction

- Jin Kyu Lee

- J Powder Mater. 2022;29(1):41-46. Published online February 1, 2022

- DOI: https://doi.org/10.4150/KPMI.2022.29.1.41

- 533 View

- 5 Download

-

Abstract

Abstract

PDF

PDF In this study, we report the microstructure and characteristics of Ag-SnO2-Bi2O3 contact materials using a controlled milling process with a subsequent compaction process. Using magnetic pulsed compaction (MPC), the milled Ag-SnO2-Bi2O3 powders have been consolidated into bulk samples. The effects of the compaction conditions on the microstructure and characteristics have been investigated in detail. The nanoscale SnO2 phase and microscale Bi2O3 phase are well-distributed homogeneously in the Ag matrix after the consolidation process. The successful consolidation of Ag-SnO2-Bi2O3 contact materials was achieved by an MPC process with subsequent atmospheric sintering, after which the hardness and electrical conductivity of the Ag-SnO2-Bi2O3 contact materials were found to be 62–75 HV and 52–63% IACS, respectively, which is related to the interfacial stability between the Ag matrix, the SnO2 phase, and the Bi2O3 phase.

- [Korean]

- Austenite Stability and Mechanical Properties of Nanocrystalline FeNiCrMoMnSiC Alloy Fabricated by Spark Plasma Sintering

- Jungbin Park, Junhyub Jeon, Namhyuk Seo, Gwanghun Kim, Seung Bae Son, Seok-Jae Lee

- J Korean Powder Metall Inst. 2021;28(4):336-341. Published online August 1, 2021

- DOI: https://doi.org/10.4150/KPMI.2021.28.4.336

- 925 View

- 4 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF In this study, a nanocrystalline FeNiCrMoMnSiC alloy was fabricated, and its austenite stability, microstructure, and mechanical properties were investigated. A sintered FeNiCrMoMnSiC alloy sample with nanosized crystal was obtained by high-energy ball milling and spark plasma sintering. The sintering behavior was investigated by measuring the displacement according to the temperature of the sintered body. Through microstructural analysis, it was confirmed that a compact sintered body with few pores was produced, and cementite was formed. The stability of the austenite phase in the sintered samples was evaluated by X-ray diffraction analysis and electron backscatter diffraction. Results revealed a measured value of 51.6% and that the alloy had seven times more austenite stability than AISI 4340 wrought steel. The hardness of the sintered alloy was 60.4 HRC, which was up to 2.4 times higher than that of wrought steel.

-

Citations

Citations to this article as recorded by- Microstructure and mechanical behavior of AISI 4340 steel fabricated via spark plasma sintering and post-heat treatment

Jungbin Park, Junhyub Jeon, Namhyuk Seo, Singon Kang, Seung Bae Son, Seok-Jae Lee, Jae-Gil Jung

Materials Science and Engineering: A.2023; 862: 144433. CrossRef

- Microstructure and mechanical behavior of AISI 4340 steel fabricated via spark plasma sintering and post-heat treatment

- [Korean]

- Improvement of Mechanical Properties of Nanocrystalline FeCrC Alloy via Strain-Induced Martensitic Transformation

- Gwanghun Kim, Junhyub Jeon, Namhyuk Seo, Jungbin Park, Seung Bae Son, Seok-Jae Lee

- J Korean Powder Metall Inst. 2021;28(3):246-252. Published online June 1, 2021

- DOI: https://doi.org/10.4150/KPMI.2021.28.3.246

- 527 View

- 3 Download

-

Abstract

Abstract

PDF

PDF The effect of sintering conditions on the austenite stability and strain-induced martensitic transformation of nanocrystalline FeCrC alloy is investigated. Nanocrystalline FeCrC alloys are successfully fabricated by spark plasma sintering with an extremely short densification time to obtain the theoretical density value and prevent grain growth. The nanocrystallite size in the sintered alloys contributes to increased austenite stability. The phase fraction of the FeCrC sintered alloy before and after deformation according to the sintering holding time is measured using X-ray diffraction and electron backscatter diffraction analysis. During compressive deformation, the volume fraction of strain-induced martensite resulting from austenite decomposition is increased. The transformation kinetics of the strain-induced martensite is evaluated using an empirical equation considering the austenite stability factor. The hardness of the S0W and S10W samples increase to 62.4-67.5 and 58.9-63.4 HRC before and after deformation. The hardness results confirmed that the mechanical properties are improved owing to the effects of grain refinement and strain-induced martensitic transformation in the nanocrystalline FeCrC alloy.

- [Korean]

- Effect of Sintering Condition on Tensile Strength of Fe-based Non-equiatomic High Entropy Alloy

- Namhyuk Seo, Junhyub Jeon, Gwanghun Kim, Jungbin Park, Seung Bae Son, Seok-Jae Lee

- J Korean Powder Metall Inst. 2021;28(3):221-226. Published online June 1, 2021

- DOI: https://doi.org/10.4150/KPMI.2021.28.3.221

- 979 View

- 8 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF We fabricate the non-equiatomic high-entropy alloy (NE-HEA) Fe49.5Mn30Co10Cr10C0.5 (at.%) using spark plasma sintering under various sintering conditions. Each elemental pure powder is milled by high-energy ball milling to prepare NE-HEA powder. The microstructure and mechanical properties of the sintered samples are investigated using various methods. We use the X-ray diffraction (XRD) method to investigate the microstructural characteristics. Quantitative phase analysis is performed by direct comparison of the XRD results. A tensile test is used to compare the mechanical properties of small samples. Next, electron backscatter diffraction analysis is performed to analyze the phase fraction, and the results are compared to those of XRD analysis. By combining different sintering durations and temperature conditions, we attempt to identify suitable spark plasma sintering conditions that yield mechanical properties comparable with previously reported values. The samples sintered at 900 and 1000°C with no holding time have a tensile strength of over 1000 MPa.

-

Citations

Citations to this article as recorded by- Fabrication and Alloying Behavior of Ultra-Lightweight AlTiCrVMg High-Entropy Alloy via Al-Mg Mutual Solubility and Sintering Control

Eunhyo Song, Hansung Lee, Byungmin Ahn

Journal of Powder Materials.2025; 32(3): 254. CrossRef

- Fabrication and Alloying Behavior of Ultra-Lightweight AlTiCrVMg High-Entropy Alloy via Al-Mg Mutual Solubility and Sintering Control

- [Korean]

- Influence of Milling Conditions on the Microstructural Characteristics and Mechanical Properties of Non-equiatomic High Entropy Alloy

- Namhyuk Seo, Junhyub Jeon, Gwanghoon Kim, Jungbin Park, Seung Bae Son, Seok-Jae Lee

- J Korean Powder Metall Inst. 2021;28(2):103-109. Published online April 1, 2021

- DOI: https://doi.org/10.4150/KPMI.2021.28.2.103

- 859 View

- 5 Download

-

Abstract

Abstract

PDF

PDF High-entropy alloys have excellent mechanical properties under extreme environments, rendering them promising candidates for next-generation structural materials. It is desirable to develop non-equiatomic high-entropy alloys that do not require many expensive or heavy elements, contrary to the requirements of typical high-entropy alloys. In this study, a non-equiatomic high-entropy alloy powder Fe49.5Mn30Co10Cr10C0.5 (at.%) is prepared by high energy ball milling and fabricated by spark plasma sintering. By combining different ball milling times and ball-topowder ratios, we attempt to find a proper mechanical alloying condition to achieve improved mechanical properties. The milled powder and sintered specimens are examined using X-ray diffraction to investigate the progress of mechanical alloying and microstructural changes. A miniature tensile specimen after sintering is used to investigate the mechanical properties. Furthermore, quantitative analysis of the microstructure is performed using electron backscatter diffraction.

- [Korean]

- Sintering Behavior and Microstructures of Tantalum and Tantalum-Tungsten Alloys Powders

- Youngmoo Kim, Sung Ho Yang, Seong Lee, Sung Ho Lee, Joon-Woong Noh

- J Korean Powder Metall Inst. 2020;27(5):373-380. Published online October 1, 2020

- DOI: https://doi.org/10.4150/KPMI.2020.27.5.373

- 1,058 View

- 9 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF The purpose of this study is to investigate the densification behavior and the corresponding microstructural evolution of tantalum and tantalum-tungsten alloy powders for explosively formed liners. The inherent inhomogeneous microstructures of tantalum manufactured by an ingot metallurgy might degrade the capability of the warhead. Therefore, to overcome such drawbacks, powder metallurgy was incorporated into the near-net shape process in this study. Spark plasma-sintered tantalum and its alloys with finer particle sizes exhibited higher densities and lower grain sizes. However, they were contaminated from the graphite mold during sintering. Higher compaction pressures in die and isostatic compaction techniques also enhanced the sinterability of the tantalum powders; however, a full densification could not be achieved. On the other hand, the powders exhibited full densification after being subjected to hot isostatic pressing over two times. Consequently, it was found that the hot isostatic-pressed tantalum might exhibit a lower grain size and a higher density as compared to those obtained in previous studies.

-

Citations

Citations to this article as recorded by- Understanding the phase evolution and elemental distribution in MoWTaNbVTix manufactured via powder metallurgical approach

Surya T. Bijjala, Ryan Wilkerson, Chad Beamer, Pankaj Kumar

The International Journal of Advanced Manufacturing Technology.2024; 135(11-12): 5925. CrossRef - Thermal Stability and Weight Reduction of Al0.75V2.82CrZr Refractory High Entropy Alloy Prepared Via Mechanical Alloying

Minsu Kim, Hansung Lee, Byungmin Ahn

journal of Korean Powder Metallurgy Institute.2023; 30(6): 478. CrossRef

- Understanding the phase evolution and elemental distribution in MoWTaNbVTix manufactured via powder metallurgical approach

- [English]

- Correlation of Sintering Parameters with Density and Hardness of Nano-sized Titanium Nitride reinforced Titanium Alloys using Neural Networks

- A. K. Maurya, P. L Narayana, Hong In Kim, N. S. Reddy

- J Korean Powder Metall Inst. 2020;27(5):365-372. Published online October 1, 2020

- DOI: https://doi.org/10.4150/KPMI.2020.27.5.365

- 1,451 View

- 6 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF Predicting the quality of materials after they are subjected to plasma sintering is a challenging task because of the non-linear relationships between the process variables and mechanical properties. Furthermore, the variables governing the sintering process affect the microstructure and the mechanical properties of the final product. Therefore, an artificial neural network modeling was carried out to correlate the parameters of the spark plasma sintering process with the densification and hardness values of Ti-6Al-4V alloys dispersed with nano-sized TiN particles. The relative density (%), effective density (g/cm3), and hardness (HV) were estimated as functions of sintering temperature (°C), time (min), and composition (change in % TiN). A total of 20 datasets were collected from the open literature to develop the model. The high-level accuracy in model predictions (>80%) discloses the complex relationships among the sintering process variables, product quality, and mechanical performance. Further, the effect of sintering temperature, time, and TiN percentage on the density and hardness values were quantitatively estimated with the help of the developed model.

-

Citations

Citations to this article as recorded by- Application of Machine Learning Algorithms and SHAP for Prediction and Feature Analysis of Tempered Martensite Hardness in Low-Alloy Steels

Junhyub Jeon, Namhyuk Seo, Seung Bae Son, Seok-Jae Lee, Minsu Jung

Metals.2021; 11(8): 1159. CrossRef

- Application of Machine Learning Algorithms and SHAP for Prediction and Feature Analysis of Tempered Martensite Hardness in Low-Alloy Steels

- [Korean]

- Synthesis of W2C by Spark Plasma Sintering of W-WC Powder Mixture and Its Etching Property

- Gyu-Sang Oh, Sung-Min Lee, Sung-Soo Ryu

- J Korean Powder Metall Inst. 2020;27(4):293-299. Published online August 1, 2020

- DOI: https://doi.org/10.4150/KPMI.2020.27.4.293

- 898 View

- 9 Download

-

Abstract

Abstract

PDF

PDF W2C is synthesized through a reaction-sintering process from an ultrafine-W and WC powder mixture using spark plasma sintering (SPS). The effect of various parameters, such as W:WC molar ratio, sintering temperature, and sintering time, on the synthesis behavior of W2C is investigated through X-ray diffraction (XRD) analysis, scanning electron microscopy (SEM) analysis of the microstructure, and final sintered density. Further, the etching properties of a W2C specimen are analyzed. A W2C sintered specimen with a particle size of 2.0 μm and a relative density over 98% could be obtained from a W-WC powder mixture with 55 mol%, after SPS at 1700°C for 20 min under a pressure of 50 MPa. The sample etching rate is similar to that of SiC. Based on X-ray photoelectron spectroscopy (XPS) analysis, it is confirmed that fluorocarbon-based layers such as C-F and C-F2 with lower etch rates are also formed.

- [Korean]

- Sintering Behavior of M-type Sr-Hexaferrite by MnCO3 Addition

- MinSeok Jeong, Changjae You, Jung Young Cho, Kyoung-Seok Moon

- J Korean Powder Metall Inst. 2020;27(2):126-131. Published online April 1, 2020

- DOI: https://doi.org/10.4150/KPMI.2020.27.2.126

- 586 View

- 1 Download

-

Abstract

Abstract

PDF

PDF The grain growth behavior of M-type Sr hexaferrite (SrM) grains is investigated with the addition of MnCO3. First, the SrM powder is synthesized by a conventional solid-state reaction. The powder compacts of SrM are sintered at 1250°C for 2 h with various amounts of MnCO3 (0, 0.5, 1.0, and 4.0 mol%). There is no secondary solid phase in any of the sintered samples. Relative density increases when MnCO3 is added to the SrM. Obvious abnormal grain growth does not appear in any of the SrM samples with MnCO3. The average grain size increases when 0.5 mol% MnCO3 is added to the SrM. However, as the amount of MnCO3 increase to over 0.5 mol%, the average grain size decreases. These observations allow us to conclude that the growth of SrM grains is governed by the two-dimensional nucleation grain growth mechanism, and the critical driving force for the growth of a grain decreases as the amount of MnCO3 increases.

- [Korean]

- Effect of Milling Time on the Microstructure and Mechanical Properties of Ta20Nb20V20W20Ti20 High Entropy Alloy

- Da Hye Song, Yeong Gyeom Kim, Jin Kyu Lee

- J Korean Powder Metall Inst. 2020;27(1):52-57. Published online February 1, 2020

- DOI: https://doi.org/10.4150/KPMI.2020.27.1.52

- 883 View

- 5 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF In this study, we report the microstructure and characterization of Ta20Nb20V20W20Ti20 high-entropy alloy powders and sintered samples. The effects of milling time on the microstructure and mechanical properties were investigated in detail. Microstructure and structural characterization were performed by scanning electron microscopy and X-ray diffraction. The mechanical properties of the sintered samples were analyzed through a compressive test at room temperature with a strain rate of 1 × 10−4 s−1. The microstructure of sintered Ta20Nb20V20W20Ti20 high-entropy alloy is composed of a BCC phase and a TiO phase. A better combination of compressive strength and strain was achieved by using prealloyed Ta20Nb20V20W20Ti20 powder with low oxygen content. The results suggest that the oxide formed during the sintering process affects the mechanical properties of Ta20Nb20V20W20Ti20 high-entropy alloys, which are related to the interfacial stability between the BCC matrix and TiO phase.

-

Citations

Citations to this article as recorded by- Mechanisms of high-entropy carbide formation (TiVTaNbW)C via high-energy milling: structural, chemical, and spectroscopic analysis

Anderson C. Marques, Thalita Q. Silva, Pâmala S. Vieira, Celmo Hudson Reis Paula, Maria J.S. Lima, Rubens M. Nascimento, Marcello Filgueira, Uílame U. Gomes, Meysam Mashhadikarimi

Materials Science and Engineering: B.2026; 323: 118787. CrossRef

- Mechanisms of high-entropy carbide formation (TiVTaNbW)C via high-energy milling: structural, chemical, and spectroscopic analysis

- [Korean]

- Effect of Phosphorus Addition on Microstructure and Mechanical Properties of Sintered Low Alloy Steel

- Yoo-Young Kim, Kwon-Koo Cho

- J Korean Powder Metall Inst. 2020;27(1):31-36. Published online February 1, 2020

- DOI: https://doi.org/10.4150/KPMI.2020.27.1.31

- 797 View

- 5 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF Phosphorus is an element that plays many important roles in powder metallurgy as an alloy element. The purpose of this study is to investigate the influence of phosphorus addition on the microstructures and mechanical properties of sintered low-alloy steel. The sintered low-alloy steels Fe-0.6%C-3.89%Ni-1.95%Cu-1.40%Mo-xP (x=0, 0.05, 0.10, 0.15, 0.20%) were manufactured by compacting at 700 MPa, sintering in H2-N2 at 1260 °C, rapid cooling, and low-temperature tempering in Ar at 160 °C. The microstructure, pore, density, hardness, and transverse rupture strength (TRS) of the sintered low-alloy steels were evaluated. The hardness increased as the phosphorus content increased, whereas the density and TRS showed maximum values when the content of P was 0.05%. Based on microstructure observation, the phase of the microstructure changed from bainite to martensite as the content of phosphorus is increased. Hence, the most appropriate addition of phosphorus in this study was 0.05%.

-

Citations

Citations to this article as recorded by- A new strategy for metal additive manufacturing using an economical water-atomized iron powder for laser powder bed fusion

Taehyeob Im, Kopila Gurung, Sebastian Meyers, Antonio Cutolo, Huengseok Oh, Jai-Sung Lee, Brecht Van Hooreweder, Caroline Sunyong Lee

Journal of Materials Processing Technology.2022; 308: 117705. CrossRef

- A new strategy for metal additive manufacturing using an economical water-atomized iron powder for laser powder bed fusion

- [Korean]

- Thermophysical Properties of Copper/graphite Flake Composites by Electroless Plating and Spark Plasma Sintering

- Jaesung Lee, Ji Yeon Kang, Seulgi Kim, Chanhoe Jung, Dongju Lee

- J Korean Powder Metall Inst. 2020;27(1):25-30. Published online February 1, 2020

- DOI: https://doi.org/10.4150/KPMI.2020.27.1.25

- 1,322 View

- 15 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF Recently, the amount of heat generated in devices has been increasing due to the miniaturization and high performance of electronic devices. Cu-graphite composites are emerging as a heat sink material, but its capability is limited due to the weak interface bonding between the two materials. To overcome these problems, Cu nanoparticles were deposited on a graphite flake surface by electroless plating to increase the interfacial bonds between Cu and graphite, and then composite materials were consolidated by spark plasma sintering. The Cu content was varied from 20 wt.% to 60 wt.% to investigate the effect of the graphite fraction and microstructure on thermal conductivity of the Cu-graphite composites. The highest thermal conductivity of 692 W m−1K−1 was achieved for the composite with 40 wt.% Cu. The measured coefficients of thermal expansion of the composites ranged from 5.36 × 10−6 to 3.06 × 10−6 K−1. We anticipate that the Cu-graphite composites have remarkable potential for heat dissipation applications in energy storage and electronics owing to their high thermal conductivity and low thermal expansion coefficient.

-

Citations

Citations to this article as recorded by- Experimental and numerical investigation of thermally stable Cu/Mo/Cu spacer with low-CTE and high-k for double side cooling power semiconductor modules

YehRi Kim, Byeongchan Kim, Kue Jin Han, Taeseong Han, Dongjin Kim

Applied Thermal Engineering.2026; 288: 129661. CrossRef

- Experimental and numerical investigation of thermally stable Cu/Mo/Cu spacer with low-CTE and high-k for double side cooling power semiconductor modules

- [Korean]

- Effect of Li2O-Bi2O3 Addition on the Piezoelectric Properties of Pb(Mg1/3Nb2/3)0.65Ti0.35O3 Ceramics

- Jae Hyuk Kim, Shi Yeon Kim, Jeoung Sik Choi, Dong-Hun Yeo, Hyo-Soon Shin, Sahn Nahm

- J Korean Powder Metall Inst. 2019;26(5):405-409. Published online October 1, 2019

- DOI: https://doi.org/10.4150/KPMI.2019.26.5.405

- 727 View

- 1 Download

-

Abstract

Abstract

PDF

PDF Piezoelectric ceramic specimens with the Pb(Mg1/3Nb2/3)0.65Ti0.35O3 (PMN-PT) composition are prepared by the solid state reaction method known as the “columbite precursor” method. Moreover, the effects of the Li2O-Bi2O3 additive on the microstructure, crystal structure, and piezoelectric properties of sintered PMN-PT ceramic samples are investigated. The addition of Li2O-Bi2O3 lowers the sintering temperature from 1,200°C to 950°C. Moreover, with the addition of >5 wt.% additive, the crystal structure changes from tetragonal to rhombohedral. Notably, the sample with 3 wt.% additive exhibits excellent piezoelectric properties (d33 = 596 pC/N and Kp = 57%) and a sintered density of 7.92 g/cm3 after sintering at 950°C. In addition, the sample exhibits a curie temperature of 138.6°C at 1 kHz. Finally, the compatibility of the sample with a Cu electrode is examined, because the energy-dispersive X-ray spectroscopy data indicate the absence of interdiffusion between Cu and the ceramic material.

- [Korean]

- Effects of Sintering Additives on the Thermal and Mechanical Properties of AlN by Pressureless Sintering

- Jin Uk Hwang, So Youn Mun, Sang Yong Nam, Hwan Soo Dow

- J Korean Powder Metall Inst. 2019;26(5):395-404. Published online October 1, 2019

- DOI: https://doi.org/10.4150/KPMI.2019.26.5.395

- 2,249 View

- 53 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF Aluminum nitride (AlN) has excellent electrical insulation property, high thermal conductivity, and a low thermal expansion coefficient; therefore, it is widely used as a heat sink, heat-conductive filler, and heat dissipation substrate. However, it is well known that the AlN-based materials have disadvantages such as low sinterability and poor mechanical properties. In this study, the effects of addition of various amounts (1-6 wt.%) of sintering additives Y2O3 and Sm2O3 on the thermal and mechanical properties of AlN samples pressureless sintered at 1850°C in an N2 atmosphere for a holding time of 2 h are examined. All AlN samples exhibit relative densities of more than 97%. It showed that the higher thermal conductivity as the Y2O3 content increased than the Sm2O3 additive, whereas all AlN samples exhibited higher mechanical properties as Sm2O3 content increased. The formation of secondary phases by reaction of Y2O3, Sm2O3 with oxygen from AlN lattice influenced the thermal and mechanical properties of AlN samples due to the reaction of the oxygen contents in AlN lattice.

-

Citations

Citations to this article as recorded by- Effects of YH2 addition on pressureless sintered AlN ceramics

Liang Wang, Wei-Ming Guo, Peng-Fei Sheng, Li-Fu Lin, Xiao Zong, Shang-Hua Wu

Journal of the European Ceramic Society.2023; 43(3): 862. CrossRef

- Effects of YH2 addition on pressureless sintered AlN ceramics

- [Korean]

- Austenite Stability of Nanocrystalline FeMnNiC Alloy

- Seung-Jin Oh, Junhyub Jeon, In-Jin Shon, Seok-Jae Lee

- J Korean Powder Metall Inst. 2019;26(5):389-394. Published online October 1, 2019

- DOI: https://doi.org/10.4150/KPMI.2019.26.5.389

- 903 View

- 4 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF In the present study, we have investigated the effect of sintering process conditions on the stability of the austenite phase in the nanocrystalline Fe-5wt.%Mn-0.2wt.%C alloy. The stability and volume fraction of the austenite phase are the key factors that determine the mechanical properties of FeMnC alloys, because strain-induced austenitemartensite transformation occurs under the application of an external stress at room temperature. Nanocrystalline Fe-5wt.%Mn-0.2wt.%C samples are fabricated using the spark plasma sintering method. The stability of the austenite phase in the sintered samples is evaluated by X-ray diffraction analysis and hardness test. The volume fraction of austenite at room temperature increases as the sample is held for 10 min at the sintering temperature, because of carbon diffusion in austenite. Moreover, water quenching effectively prevents the formation of cementite during cooling, resulting in a higher volume fraction of austenite. Furthermore, it is found that the hardness is influenced by both the austenite carbon content and volume fraction.

-

Citations

Citations to this article as recorded by- Influence of Cobalt Content on Austenite Stability and Strain-Induced Martensite Transformation of Nanocrystalline Fe-7Mn Alloy Fabricated by Spark Plasma Sintering

Sungjin Kim, Seung Bae Son, Seok-Jae Lee

MATERIALS TRANSACTIONS.2025; 66(7): 811. CrossRef - Austenite Stability of Sintered Fe-based Alloy

Seunggyu Choi, Namhyuk Seo, Junhyub Jun, Seung Bae Son, Seok-Jae Lee

Journal of Korean Powder Metallurgy Institute.2020; 27(5): 414. CrossRef

- Influence of Cobalt Content on Austenite Stability and Strain-Induced Martensite Transformation of Nanocrystalline Fe-7Mn Alloy Fabricated by Spark Plasma Sintering

- [Korean]

- Effects of Powder Shape and Densification Mechanism on the Microstructures and Mechanical Properties of Ti-6Al-4V Components

- Youngmoo Kim, Young-Sam Kwon, Young-Beom Song, Sung Ho Lee

- J Korean Powder Metall Inst. 2019;26(4):311-318. Published online August 1, 2019

- DOI: https://doi.org/10.4150/KPMI.2019.26.4.311

- 654 View

- 2 Download

-

Abstract

Abstract

PDF

PDF The objective of this study is to investigate the influence of powder shape and densification mechanism on the microstructure and mechanical properties of Ti-6Al-4V components. BE powders are uniaxially and isostatically pressed, and PA ones are injection molded because of their high strengths. The isostatically compacted samples exhibit a density of 80%, which is higher than those of other samples, because hydrostatic compression can lead to higher strain hardening. Owing to the higher green density, the density of BE-CS (97%) is found to be as high as that of other samples (BE-DS (95%) and P-S (94%)). Furthermore, we have found that BE powders can be consolidated by sintering densification and chemical homogenization, whereas PA ones can be consolidated only by simple densification. After sintering, BE-CS and P-S are hot isostatically pressed and BE-DS is hot forged to remove residual pores in the sintered samples. Apparent microstructural evolution is not observed in BE-CSH and P-SH. Moreover, BE-DSF exhibits significantly fine grains and high density of low-angle grain boundaries. Thus, these microstructures provide Ti-6Al-4V components with enhanced mechanical properties (tensile strength of 1179 MPa).

- [Korean]

- Fabrication of Nb-Si-B Alloys Using the Pulverized Nb-T2 Alloy Powder

- Min-Ho Cho, Sung-Jun Kim, Hyun-Ji Kang, Sung-Tag Oh, Young Do Kim, Seong Lee, Myung Jin Suk

- J Korean Powder Metall Inst. 2019;26(4):299-304. Published online August 1, 2019

- DOI: https://doi.org/10.4150/KPMI.2019.26.4.299

- 848 View

- 5 Download

-

Abstract

Abstract

PDF

PDF Nb-Si-B alloys with Nb-rich compositions are fabricated by spark plasma sintering for high-temperature structural applications. Three compositions are selected: 75 at% Nb (Nb0.7), 82 at% Nb (Nb1.5), and 88 at% Nb (Nb3), the atomic ratio of Si to B being 2. The microstructures of the prepared alloys are composed of Nb and T2 phases. The T2 phase is an intermetallic compound with a stoichiometry of Nb5Si3-xBx (0 ≤ x ≤ 2). In some previous studies, Nb-Si-B alloys have been prepared by spark plasma sintering (SPS) using Nb and T2 powders (SPS 1). In the present work, the same alloys are prepared by the SPS process (SPS 2) using Nb powders and hypereutectic alloy powders with composition 67at%Nb-22at%Si-11at%B (Nb67). The Nb67 alloy powders comprise T2 and eutectic (T2 + Nb) phases. The microstructures and hardness of the samples prepared in the present work have been compared with those previously reported; the samples prepared in this study exhibit finer and more uniform microstructures and higher hardness.

- [Korean]

- The Microstructure and the Mechanical Properties of Sintered TiO2-Co Composite Prepared Via Thermal Hydrogenation Method

- Myeongsun Ko, Ilsong Park, Jeshin Park

- J Korean Powder Metall Inst. 2019;26(4):290-298. Published online August 1, 2019

- DOI: https://doi.org/10.4150/KPMI.2019.26.4.290

- 389 View

- 1 Download

-

Abstract

Abstract

PDF

PDF TiO2-particles containing Co grains are fabricated via thermal hydrogenation and selective oxidation of Ti-Co alloy. For comparison, TiO2-Co composite powders are prepared by two kinds of methods which were the mechanical carbonization and oxidation process, and the conventional mixing process. The microstructural characteristics of the prepared composites are analyzed by X-ray diffraction, field-emission scattering electron microscopy, and transmission electron microscopy. In addition, the composite powders are sintered at 800°C by spark plasma sintering. The flexural strength and fracture toughness of the sintered samples prepared by thermal hydrogenation and mechanical carbonization are found to be higher than those of the samples prepared by the conventional mixing process. Moreover, the microstructures of sintered samples prepared by thermal hydrogenation and mechanical carbonization processes are found to be similar. The difference in the mechanical properties of sintered samples prepared by thermal hydrogenation and mechanical carbonization processes is attributed to the different sizes of metallic Co particles in the samples.

- [Korean]

- Fabrication of Molybdenum Alloys with Improved Fracture Toughness through the Dispersion of Lanthanum Oxide

- Won June Choi, Chun Woong Park, Jung Hyo Park, Young Do Kim, Jongmin Byun

- J Korean Powder Metall Inst. 2019;26(3):208-213. Published online June 1, 2019

- DOI: https://doi.org/10.4150/KPMI.2019.26.3.208

- 863 View

- 1 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF In this study, lanthanum oxide (La2O3) dispersed molybdenum (Mo–La2O3) alloys are fabricated using lanthanum nitrate solution and nanosized Mo particles produced by hydrogen reduction of molybdenum oxide. The effect of La2O3 dispersion in a Mo matrix on the fracture toughness at room temperature is demonstrated through the formation behavior of La2O3 from the precursor and three-point bending test using a single-edge notched bend specimen. The relative density of the Mo–0.3La2O3 specimen sintered by pressureless sintering is approximately 99%, and La2O3 with a size of hundreds of nanometers is uniformly distributed in the Mo matrix. It is also confirmed that the fracture toughness is 19.46 MPa·m1/2, an improvement of approximately 40% over the fracture toughness of 13.50 MPa·m1/2 on a pure-Mo specimen without La2O3, and this difference in the fracture toughness occurs because of the changes in fracture mode of the Mo matrix caused by the dispersion of La2O3.

-

Citations

Citations to this article as recorded by- Sintering property of micro/nano core-shell molybdenum powder synthesized by mechanochemical process

Chun Woong Park, Heeyeon Kim, Won Hee Lee, Wonjune Choi, Jongmin Byun, Young Do Kim

International Journal of Refractory Metals and Hard Materials.2024; 119: 106532. CrossRef - Novel design of Mo-Si-B + La2O3 powder with multi-shell structure for ideal microstructure and enhanced mechanical property

Wonjune Choi, Chun Woong Park, Young Do Kim, Jongmin Byun

International Journal of Refractory Metals and Hard Materials.2024; 120: 106611. CrossRef

- Sintering property of micro/nano core-shell molybdenum powder synthesized by mechanochemical process

- [Korean]

- Property Evaluation of Tungsten-Carbide Hard Materials as a Function of Binder

- Ju-Hun Kim, Ik-Hyun Oh, Jeong-Han Lee, Sung-Kil Hong, Hyun-Kuk Park

- J Korean Powder Metall Inst. 2019;26(2):132-137. Published online April 1, 2019

- DOI: https://doi.org/10.4150/KPMI.2019.26.2.132

- 1,059 View

- 8 Download

- 3 Citations

-

Abstract

Abstract

PDF

PDF Tungsten carbide (WC) hard materials are used in various industries and possess a superior hardness compared to other hard materials. They have particularly high melting points, high strength, and abrasion resistance. Accordingly, tungsten carbide hard materials are used for wear-resistant tools, cutting tools, machining tools, and other tooling materials. In this study, the WC-5wt.%Co, Fe, Ni hard materials are densified using the horizontal ball milled WC-Co, WC-Fe, and WC-Ni powders by a spark plasma sintering process. The WC-5Co, WC-5Fe, and WC-5Ni hard materials are almost completely densified with a relative density of up to 99.6% after simultaneous application of a pressure of 60 MPa and an electric current for about 15 min without any significant change in the grain size. The average grain size of WC-5Co, WC-5Fe, and WC-5Ni that was produced through SPS was about 0.421, 0.779, and 0.429 μm, respectively. The hardness and fracture toughness of the dense WC-5Co, WC-5Fe, WC-5Ni hard materials were also investigated.

-

Citations

Citations to this article as recorded by- Enhancing Mechanical Properties via Grain Growth Suppression and High Densification in WC Compacts

Jong Min Gwak, Min Soo Park, Gook Hyun Ha, Nam Hyun Kang

Metals and Materials International.2025; 31(12): 3733. CrossRef - Synthesis of W2C by Spark Plasma Sintering of W-WC Powder Mixture and Its Etching Property

Gyu-Sang Oh, Sung-Min Lee, Sung-Soo Ryu

Journal of Korean Powder Metallurgy Institute.2020; 27(4): 293. CrossRef - Fabrication and Properties of Densified Tungsten by Magnetic Pulse Compaction and Spark Plasma Sintering

Eui Seon Lee, Jongmin Byun, Young-Keun Jeong, Sung-Tag Oh

Korean Journal of Materials Research.2020; 30(6): 321. CrossRef

- Enhancing Mechanical Properties via Grain Growth Suppression and High Densification in WC Compacts

- [Korean]

- Effect of MgO-CaO-Al2O3-SiO2 Glass Additive Content on Properties of Aluminum Nitride Ceramics

- Kyung Min Kim, Su-Hyun Baik, Sung-Soo Ryu

- J Korean Powder Metall Inst. 2018;25(6):494-500. Published online December 1, 2018

- DOI: https://doi.org/10.4150/KPMI.2018.25.6.494

- 1,449 View

- 25 Download

-

Abstract

Abstract

PDF

PDF In this study, the effect of the content of MgO-CaO-Al2O3-SiO2 (MCAS) glass additives on the properties of AlN ceramics is investigated. Dilatometric analysis and isothermal sintering for AlN compacts with MCAS contents varying between 5 and 20 wt% are carried out at temperatures ranging up to 1600°C. The results showed that the shrinkage of the AlN specimens increases with increasing MCAS content, and that full densification can be obtained irrespective of the MCAS content. Moreover, properties of the AlN-MCAS specimens such as microhardness, thermal conductivity, dielectric constant, and dielectric loss are analyzed. Microhardness and thermal conductivity decrease with increasing MCAS content. An acceptable candidate for AlN application is obtained: an AlN-MCAS composite with a thermal conductivity over 70 W/m·K and a dielectric loss tangent (tan δ) below 0.6 × 10−3, with up to 10 wt% MCAS content.

- [Korean]

- Effects of the Mixing Method and Sintering Temperature on the Characteristics of PZNN-PZT Piezoelectric Ceramic Materials

- So Won Kim, Yong Jeong Jeong, Hee Chul Lee

- J Korean Powder Metall Inst. 2018;25(6):487-493. Published online December 1, 2018

- DOI: https://doi.org/10.4150/KPMI.2018.25.6.487

- 950 View

- 5 Download

- 5 Citations

-

Abstract

Abstract

PDF

PDF The impact of different mixing methods and sintering temperatures on the microstructure and piezoelectric properties of PZNN-PZT ceramics is investigated. To improve the sinterability and piezoelectric properties of these ceramics, the composition of 0.13Pb((Zn0.8Ni0.2)1/3Nb2/3)O3-0.87Pb(Zr0.5Ti0.5)O3 (PZNN-PZT) containing a Pb-based relaxor component is selected. Two methods are used to create the powder for the PZNN-PZT ceramics. The first involves blending all source powders at once, followed by calcination. The second involves the preferential creation of columbite as a precursor, by reacting NiO with Nb2O5 powder. Subsequently, PZNN-PZT powder can be prepared by mixing the columbite powder, PbO, and other components, followed by an additional calcination step. All the PZNNPZT powder samples in this study show a nearly-pure perovskite phase. High-density PZNN-PZT ceramics can be fabricated using powders prepared by a two-step calcination process, with the addition of 0.3 wt% MnO2 at even relatively low sintering temperatures from 800°C to 1000°C. The grain size of the ceramics at sintering temperatures above 900°C is increased to approximately 3 μm. The optimized PZNN-PZT piezoelectric ceramics show a piezoelectric constant (d33) of 360 pC/N, an electromechanical coupling factor (kp) of 0.61, and a quality factor (Qm) of 275.

-

Citations

Citations to this article as recorded by- An Analysis of Edge Chipping in LiTaO3 Wafer Grinding Using a Scratch Test and FEA Simulation

Haeseong Hwang, Seungho Han, Hyunseop Lee

Lubricants.2023; 11(7): 297. CrossRef - A generalized rule for phase transition generated by additives in piezoelectric ceramics

Jae-Min Cha, Young-Kook Moon, Jung-hwan Kim, Hyun-Ae Cha, Jong-Jin Choi, Byung-Dong Hahn, Seog-Young Yoon, Cheol-Woo Ahn

Materials Today Communications.2023; 37: 107290. CrossRef - Low-Temperature Sintering Properties of Bi2O3 Doped PZT-5H Piezoelectric Ceramics

Wanzi Mao, Qing Xu, Duanping Huang, Huajun Sun, Feng Zhang, Xiaobin Xie

Journal of Electronic Materials.2023; 52(5): 3334. CrossRef - Effect of LiBiO2 on low-temperature sintering of PZT-PZNN ceramics

Sung Cheul Hong, Shi Yeon Kim, Dong-Hun Yeo, Hyo-Soon Shin, Zee Hoon Park, Sahn Nahm

Journal of the Korean Ceramic Society.2022; 59(5): 638. CrossRef - Two-Stage De-binding for Cu Electrode Application to PZT-PZNN Multilayer Actuator

Sung Cheul Hong, Zeehoon Park, Dong-Hun Yeo, Hyo-Soon Shin, Sahn Nahm

Transactions on Electrical and Electronic Materials.2022; 23(4): 348. CrossRef

- An Analysis of Edge Chipping in LiTaO3 Wafer Grinding Using a Scratch Test and FEA Simulation

- [Korean]

- Sintering Behavior and Thermal Conductivity of Aluminum Nitride Ceramics with MgO–CaO–Al2O3–SiO2 Nano-glass Additive

- Su-Hyun Baik, Kyung Min Kim, Sung-Soo Ryu

- J Korean Powder Metall Inst. 2018;25(5):426-434. Published online October 1, 2018

- DOI: https://doi.org/10.4150/KPMI.2018.25.5.426

- 1,172 View

- 10 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF In this study, MgO–CaO–Al2O3–SiO2 (MCAS) nanocomposite glass powder having a mean particle size of 50 nm and a specific surface area of 40 m2/g is used as a sintering additive for AlN ceramics. Densification behaviors and thermal properties of AlN with 5 wt% MCAS nano-glass additive are investigated. Dilatometric analysis and isothermal sintering of AlN-5wt% MCAS compact demonstrates that the shrinkage of the AlN specimen increases significantly above 1,300°C via liquid phase sintering of MCAS additive, and complete densification could be achieved after sintering at 1,600°C, which is a reduction in sintering temperature by 200°C compared to conventional AlN-Y2O3 systems. The MCAS glass phase is satisfactorily distributed between AlN particles after sintering at 1,600°C, existing as an amorphous secondary phase. The AlN specimen attained a thermal conductivity of 82.6 W/m·K at 1,600°C.

-

Citations

Citations to this article as recorded by- Effect of MgO-CaO-Al2O3-SiO2 Glass Additive Content on Properties of Aluminum Nitride Ceramics

Kyung Min Kim, Su-Hyun Baik, Sung-Soo Ryu

Journal of Korean Powder Metallurgy Institute.2018; 25(6): 494. CrossRef

- Effect of MgO-CaO-Al2O3-SiO2 Glass Additive Content on Properties of Aluminum Nitride Ceramics

- [Korean]

- Fabrication of Molybdenum Silicide-based Composites with Uniformly Dispersed Silicon Carbide

- Won June Choi, Chun Woong Park, Young Do Kim, Jong Min Byun

- J Korean Powder Metall Inst. 2018;25(5):402-407. Published online October 1, 2018

- DOI: https://doi.org/10.4150/KPMI.2018.25.5.402

- 477 View

- 3 Download

-

Abstract

Abstract

PDF

PDF Molybdenum silicide has gained interest for high temperature structural applications. However, poor fracture toughness at room temperatures and low creep resistance at elevated temperatures have hindered its practical applications. This study uses a novel powder metallurgical approach applied to uniformly mixed molybdenum silicidebased composites with silicon carbide. The degree of powder mixing with different ball milling time is also demonstrated by Voronoi diagrams. Core-shell composite powder with Mo nanoparticles as the shell and β-SiC as the core is prepared via chemical vapor transport. Using this prepared core-shell composite powder, the molybdenum silicide-based composites with uniformly dispersed β-SiC are fabricated using pressureless sintering. The relative density of the specimens sintered at 1500°C for 10 h is 97.1%, which is similar to pressure sintering owing to improved sinterability using Mo nanoparticles.

- [Korean]

- Thermoelectric Properties of PbTe Prepared by Spark Plasma Sintering of Nano Powders

- Eun-Young Jun, Ho-Young Kim, Cham Kim, Kyung-Sik Oh, Tai-Joo Chung

- J Korean Powder Metall Inst. 2018;25(5):384-389. Published online October 1, 2018

- DOI: https://doi.org/10.4150/KPMI.2018.25.5.384