Search

- Page Path

- HOME > Search

- [English]

- Ultra-Low-Temperature (4.2 K) Tensile Properties and Deformation Mechanism of Stainless Steel 304L Manufactured by Laser Powder Bed Fusion

- Seung-Min Jeon, Young-Sang Na, Young-Kyun Kim

- J Powder Mater. 2025;32(2):95-103. Published online April 30, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00066

- 1,927 View

- 57 Download

- 3 Citations

-

Abstract

Abstract

PDF

PDF - This study investigated the ultra-low-temperature (4.2 K) tensile properties and deformation mechanisms of stainless steel 304L manufactured via laser powder bed fusion (LPBF). The tensile properties of LPBF 304L were compared to those of conventional 304L to assess its suitability for cryogenic applications. The results revealed that LPBF 304L exhibited a significantly higher yield strength but lower ultimate tensile strength and elongation than conventional 304L at 4.2 K. The temperature dependence of the yield strength also favored LPBF 304L. Microstructural analysis demonstrated that LPBF 304L features a high density of dislocation cells and nano-inclusions, contributing to its greater strength. Furthermore, strain-induced martensitic transformation was observed as a key deformation mechanism at cryogenic temperatures, where austenite transformed into both hexagonal-closed packed (HCP) and body-centered cubic (BCC) martensite. Notably, BCC martensite nucleation occurred within a single HCP band. These findings provide critical insights into the mechanical behavior of LPBF 304L at cryogenic temperatures and its potential for applications in extreme environments.

-

Citations

Citations to this article as recorded by- Extremely low-temperature tensile behavior of 316L stainless steel additively manufactured by laser powder bed fusion

Haeum Park, Heechan Jung, Min Young Sung, Young-Kyun Kim, Jaimyun Jung, Yoona Lee, Namhyun Kang, Kyung Tae Kim, Young-Sang Na, Seok Su Sohn, Jeong Min Park

Materials Science and Engineering: A.2026; 950: 149460. CrossRef - Twinning- and transformation-induced high cryogenic strength and ductility of the CoCrFeNi high-entropy alloy: Experiment and MD simulation

Yuze Wu, Zhide Li, Charlie Kong, M.W. Fu, Hailiang Yu

International Journal of Plasticity.2026; 196: 104553. CrossRef - Understanding the unique appearance behavior of shear bands during tensile deformation of α-brass at 4.2 K

Seon-Keun Oh, Sang-Hun Shim, Young-Kyun Kim, Young-Sang Na

Materials Science and Engineering: A.2025; 945: 148989. CrossRef

- Extremely low-temperature tensile behavior of 316L stainless steel additively manufactured by laser powder bed fusion

- [English]

- Stretch-Flangeability of Laser Powder Bed Fusion-Processed 316L Stainless Steel

- Rae Eon Kim, Yeon Taek Choi, Sang Guk Jeong, Do Won Lee, Hyoung Seop Kim

- J Powder Mater. 2025;32(2):87-94. Published online April 30, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00017

- 2,271 View

- 23 Download

-

Abstract

Abstract

PDF

PDF Supplementary Material

Supplementary Material - Metal additive manufacturing (AM) facilitates the production of complex geometries with enhanced functionality. Among various AM techniques, laser powder bed fusion (LPBF) is distinguished by its precision and exceptional mechanical properties achieved via laser fusion deposition. Recent advancements in AM have focused on combining LPBF with post-processing methods such as cold rolling, high-pressure torsion, and forming processes. Therefore, understanding the forming behavior of LPBF-processed materials is essential for industrial adoption. This study investigates the stretch-flangeability of LPBF-fabricated 316L stainless steel, emphasizing its anisotropic microstructure and mechanical properties. Hole expansion tests were employed to assess stretch-flangeability in comparison to wrought 316L stainless steel. The results demonstrate that LPBF-processed samples exhibit significant anisotropic behavior, demonstrating the influence of microstructural evolution on formability. These findings contribute valuable insights into optimizing LPBF materials for industrial forming applications.

- [Korean]

- Friction Stir Spot Welding Characteristics of Dissimilar Materials of Aluminum-Based Damping Composites and Steel Plates

- Si-Seon Park, Young-Keun Jeong

- J Powder Mater. 2025;32(1):43-49. Published online February 28, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00010

- 671 View

- 10 Download

-

Abstract

Abstract

PDF

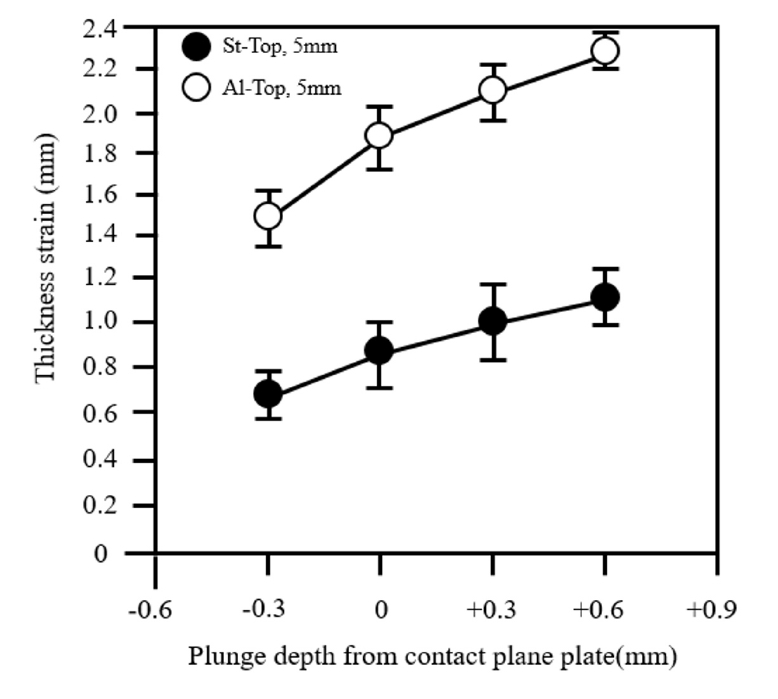

PDF - Friction Stir Spot Welding (FSSW) is a solid-state welding technology that is rapidly growing in the automotive industry. Achieving superior welding characteristics requires the proper selection of tool geometry and process conditions. In this study, FSSW was performed on dissimilar materials comprising AA5052-HO/hot-melt aluminum alloy sheets and Steel Plate Cold Rolled for Deep Drawing Use(SPCUD) steel sheets. The effects of tool geometry, plate arrangement, and tool plunge depth on the welding process were investigated. At the joint interface between the aluminum alloy and the steel sheet, new intermetallic compounds (IMCs) were observed. As the plunge depth increased, thicker and more continuous IMC layers were formed. However, excessive plunge depth led to discontinuous layers and cracking defects. An analysis of the IMCs revealed a correlation between the IMC thickness and the shear tensile load. Furthermore, compared to the conventional Al-Top arrangement, the St-Top arrangement exhibited reduced deformation and superior shear tensile load values. These findings indicate that plate arrangement significantly influences the mechanical properties of the joint.

- [Korean]

- Effect of Hatch Spacing on the Microstructure and Mechanical Properties of SA508 Gr.3 Steel Fabricated by Laser Powder Bed Fusion

- Yuanjiu Huang, Ho Jin Ryu, Kee-Ahn Lee

- J Powder Mater. 2025;32(1):50-58. Published online February 28, 2025

- DOI: https://doi.org/10.4150/jpm.2024.00479

- 1,167 View

- 27 Download

- 1 Citations

-

Abstract

Abstract

PDF

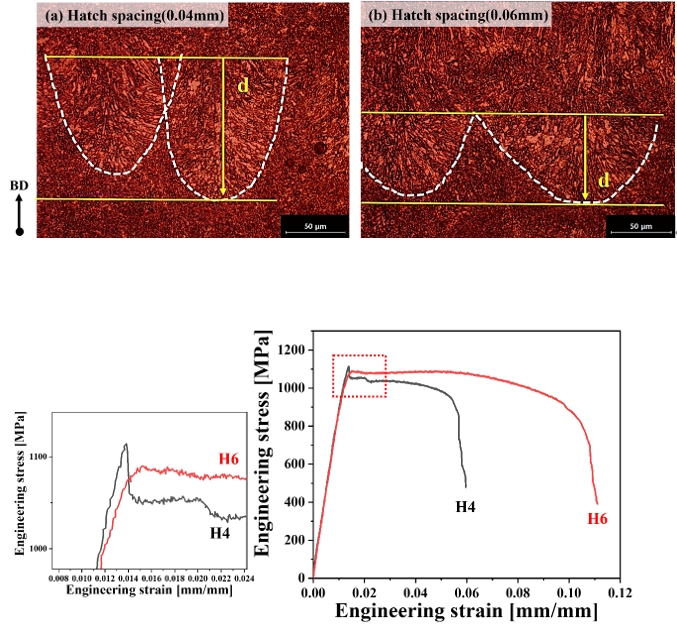

PDF - This study investigated the effect of the hatch spacing parameter on the microstructure and mechanical properties of SA508 Gr.3 steel manufactured by laser powder bed fusion (L-PBF) for a nuclear pressure vessel. Materials were prepared with varying hatch spacing (0.04 mm [H4] and 0.06 mm [H6]). The H4 exhibited finer and more uniformly distributed grains, while the H6 showed less porosity and a lower defect fraction. The yield strength of the H4 material was higher than that of the H6 material, but there was a smaller difference between the materials in tensile strength. The measured elongation was 5.65% for the H4 material and 10.41% for the H6 material, showing a significantly higher value for H6. An explanation for this is that although the H4 material had a microstructure of small and uniform grains, it contained larger and more numerous pore defects than the H6 material, facilitating stress concentration and the initiation of microcracks.

-

Citations

Citations to this article as recorded by- Extremely low temperature mechanical behavior of in-situ oxide containing 304L stainless steel fabricated by laser powder bed fusion

Kwangtae Son, Seung-Min Jeon, Brian K. Paul, Young-Sang Na, Kijoon Lee, Young-Kyun Kim

Journal of Materials Science & Technology.2025; 234: 319. CrossRef

- Extremely low temperature mechanical behavior of in-situ oxide containing 304L stainless steel fabricated by laser powder bed fusion

- [English]

- Effect of the Cross-rolling Process on the Microstructures and Mechanical Properties of 9Cr-1W ODS Steel

- Bu-An Kim, Sanghoon Noh

- J Powder Mater. 2025;32(1):37-42. Published online February 28, 2025

- DOI: https://doi.org/10.4150/jpm.2024.00332

- 1,025 View

- 32 Download

-

Abstract

Abstract

PDF

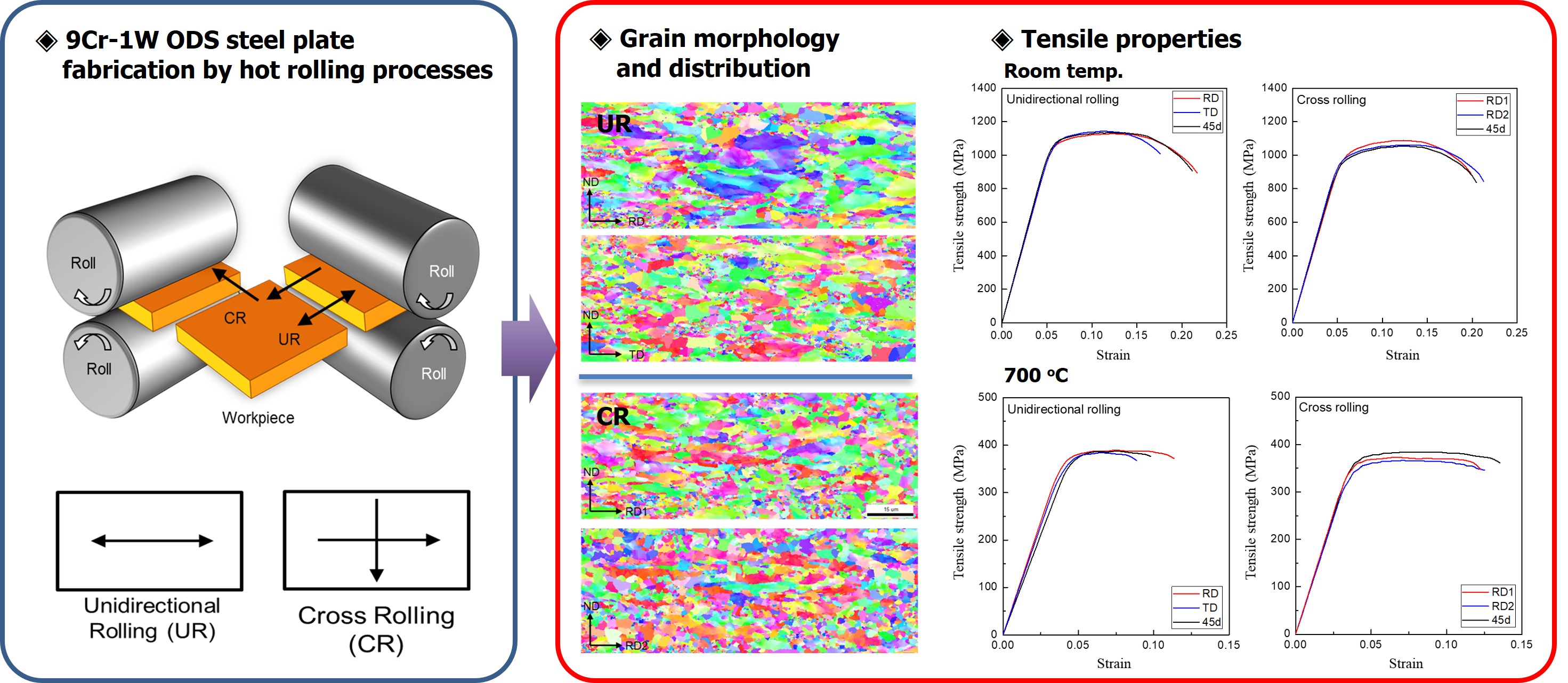

PDF - This study employed a cross-rolling process to fabricate oxide dispersion strengthened (ODS) steel plates and investigated their microstructures and mechanical properties. The 9Cr-1W ODS ferritic steel was fabricated using mechanical alloying and hot isostatic pressing. The hot cross-rolling process produced thick ODS ferritic steel plates with a well-extended rectangular shape. The working direction greatly affected the grain structure and crystal texture of the ODS ferritic steel. Cross-rolled plates showed fine micro-grains with random crystal orientation, while unidirectionally rolled plates exhibited a strong orientation with larger, elongated grains. Transmission electron microscopy revealed a uniform distribution of nano-oxide particles in both rolling methods, with no major differences. Tensile tests of the ODS ferritic steel plates showed that the unidirectional rolled plates had anisotropic elongation, while cross-rolled plates exhibited isotropic behavior with uniform elongation. Cross-rolling produced finer, more uniform grains, reducing anisotropy and improving mechanical properties, making it ideal for manufacturing wide ODS steel components.

- [Korean]

- Effect of Anisotropy on the Wear Behavior of Age-Treated Maraging Steel Manufactured by LPBF

- Seung On Lim, Se-Eun Shin

- J Powder Mater. 2024;31(4):308-317. Published online August 5, 2024

- DOI: https://doi.org/10.4150/jpm.2024.00171

- 2,125 View

- 38 Download

- 2 Citations

-

Abstract

Abstract

PDF

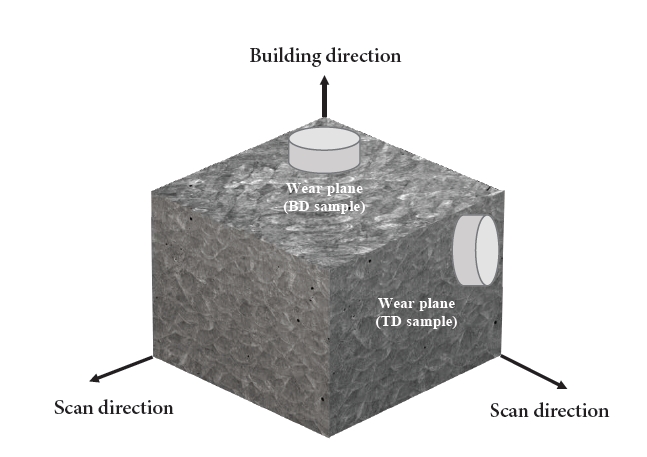

PDF - Maraging steel has excellent mechanical properties resulting from the formation of precipitates within the matrix through aging treatment. Maraging steel fabricated by the laser powder bed fusion (LPBF) process is suitable for applications including precise components and optimized design. The anisotropic characteristic, which depends on the stacking direction, affects the mechanical properties. This study aimed to analyze the influence of anisotropy on the wear behavior of maraging steel after aging treatment. The features of additive manufacturing tended to disappear after heat treatment. However, some residual cellular and dendrite structures were observed. In the wear tests, a high wear rate was observed on the building direction plane for all counter materials. This is believed to be because the oxides formed on the wear track positively affected the wear characteristics; meanwhile, the bead shape in the stacking direction surface was vulnerable to wear, leading to significant wear.

-

Citations

Citations to this article as recorded by- Unveiling age-hardening mechanisms: first-principles carbide insights and enhanced thermomechanical fatigue in niobium-bearing austenitic stainless steels

Godwin Kwame Ahiale, Jin Woong Park, Raj Narayan Hajra, Yong-Jun Oh, Won Doo Choi, Tae-Wook Na, Gi Yong Kim, Hyun-Ju Choi, Jeoung Han Kim

Materials Science and Engineering: A.2026; 949: 149397. CrossRef - A Parametric Study on the L-PBF Process of an AlSi10Mg Alloy for High-Speed Productivity of Automotive Prototype Parts

Yeonha Chang, Hyomoon Joo, Wanghyun Yong, Yeongcheol Jo, Seongjin Kim, Hanjae Kim, Yeon Woo Kim, Kyung Tae Kim, Jeong Min Park

Journal of Powder Materials.2024; 31(5): 390. CrossRef

- Unveiling age-hardening mechanisms: first-principles carbide insights and enhanced thermomechanical fatigue in niobium-bearing austenitic stainless steels

- [Korean]

- Gradient Microstructure and Mechanical Properties of Fe-6%Mn Alloy by Different Sized Powder Stacking

- Namhyuk Seo, Junho Lee, Woocheol Shin, Junhyub Jeon, Jungbin Park, Seung Bae Son, Jae-Gil Jung, Seok-Jae Lee

- J Powder Mater. 2022;29(5):382-389. Published online October 1, 2022

- DOI: https://doi.org/10.4150/KPMI.2022.29.5.382

- 750 View

- 10 Download

-

Abstract

Abstract

PDF

PDF A typical trade-off relationship exists between strength and elongation in face-centered cubic metals. Studies have recently been conducted to enhance strength without ductility reduction through surface-treatment-based ultrasonic nanocrystalline surface modification (UNSM), which creates a gradient microstructure in which grains become smaller from the inside to the surface. The transformation-induced plasticity effect in Fe-Mn alloys results in excellent strength and ductility due to their high work-hardening rate. This rate is achieved through strain-induced martensitic transformation when an alloy is plastically deformed. In this study, Fe-6%Mn powders with different sizes were prepared by high-energy ball milling and sintered through spark plasma sintering to produce Fe-6%Mn samples. A gradient microstructure was obtained by stacking the different-sized powders to achieve similar effects as those derived from UNSM. A compressive test was performed to investigate the mechanical properties, including the yielding behavior. The deformed microstructure was observed through electron backscatter diffraction to determine the effects of gradient plastic deformation.

- [Korean]

- Manufacturing of Fe-Mn-Al-C Based Low Mn Lightweight Steel Via Direct Energy Deposition

- Kwang Kyu Ko, Han Sol Son, Cha Hee Jung, Hyo Ju Bae, Eun Hye Park, Jung Gi Kim, Hyunjoo Choi, Jae Bok Seol

- J Powder Mater. 2022;29(4):320-324. Published online August 1, 2022

- DOI: https://doi.org/10.4150/KPMI.2022.29.4.320

- 1,291 View

- 30 Download

-

Abstract

Abstract

PDF

PDF Lightweight steel is a crucial material that is being actively studied because of increased carbon emissions, tightening regulations regarding fuel efficiency, and the emergence of UAM, all of which have been recently labeled as global issues. Hence, new strategies concerning the thickness and size reduction of steel are required. In this study, we manufacture lightweight steel of the Fe-Mn-Al-C system, which has been recently studied using the DED process. By using 2.8 wt.% low-Mn lightweight steel, we attempt to solve the challenge of joining steel parts with a large amount of Mn. Among the various process variables, the laser scan power is set at 600 and 800W, and the laser scan speed is fixed at 16.67 mm/s before the experiments. Several pores and cracks are observed under both conditions, and negligibly small pores of approximately 0.5 μm are observed.

- [Korean]

- Evaluation of Microstructures and Mechanical Properties in Functionally Graded Materials (STS 316L and Low Alloy Steel) Produced by DED Processes

- G. Shin, W. Choo, J. H. Yoon, S. Y. Yang, J. H. Kim

- J Powder Mater. 2022;29(4):309-313. Published online August 1, 2022

- DOI: https://doi.org/10.4150/KPMI.2022.29.4.309

- 796 View

- 6 Download

-

Abstract

Abstract

PDF

PDF In this study, additive manufacturing of a functionally graded material (FGM) as an alternative to joining dissimilar metals is investigated using directed energy deposition (DED). FGM consists of five different layers, which are mixtures of austenitic stainless steel (type 316 L) and low-alloy steel (LAS, ferritic steel) at ratios of 100:0 (A layer), 75:25 (B layer), 50:50 (C layer), 25:75 (D layer), and 0:100 (E layer), respectively, in each deposition layer. The FGM samples are successfully fabricated without cracks or delamination using the DED method, and specimens are characterized using optical and scanning electron microscopy to monitor their microstructures. In layers C and D of the sample, the tensile strength is determined to be very high owing to the formation of ferrite and martensite structures. However, the elongation is high in layers A and B, which contain a large fraction of austenite.

- [Korean]

- Microstructural Analysis of STS316L Samples Manufactured by Powder Bed Fusion and Post-heat Treatments

- S. Y. Song, D. W. Lee, D. V. Cong, J. W. Kim, S. M. Lee, S. H. Joo, J. C. Kim

- J Powder Mater. 2022;29(1):14-21. Published online February 1, 2022

- DOI: https://doi.org/10.4150/KPMI.2022.29.1.14

- 1,094 View

- 10 Download

- 3 Citations

-

Abstract

Abstract

PDF

PDF In the powder bed fusion (PBF) process, a 3D shape is formed by the continuous stacking of very fine powder layers using computer-aided design (CAD) modeling data, following which laser irradiation can be used to fuse the layers forming the desired product. In this method, the main process parameters for manufacturing the desired 3D products are laser power, laser speed, powder form, powder size, laminated thickness, and laser diameter. Stainless steel (STS) 316L exhibits excellent strength at high temperatures, and is also corrosion resistant. Due to this, it is widely used in various additive manufacturing processes, and in the production of corrosion-resistant components with complicated shapes. In this study, rectangular specimens have been manufactured using STS 316L powder via the PBF process. Further, the effect of heat treatment at 800 °C on the microstructure and hardness has been investigated.

-

Citations

Citations to this article as recorded by- Effect of Phase Composition on Microstructure and Mechanical Properties of Biomedical Ti-15Nb-5Sn Alloy Prepared by Material Extrusion Additive Manufacturing

Jin-hwan Lim, Gyeong-ho Kang, Shuanglei Li, Tae-hyun Nam

Journal of Materials Engineering and Performance.2025;[Epub] CrossRef - Effect of thermal debinding conditions on microstructure and mechanical properties of a biomedical Ti-15Nb-5Sn alloy prepared by material extrusion additive manufacturing (MEAM) process

Jin-hwan Lim, Soo-yeong Kim, Tae-gyun Gu, Shuanglei Li, Tae-hyun Nam

Journal of Alloys and Compounds.2025; 1044: 184366. CrossRef - In vitro Evaluation of Cytotoxicity and Cell Viability of Ultra-high Molecular Weight Polyethylene for 3D-printed Artificial Joint Manufacturing

Seung-Lim Yoo, Da-Been Lee, Min-Gyu Park, Junyeong Lim, Chanwoo Sim, Taeho Yoon, Youngmin Seo, Dae-Wui Yoon

Biomedical Science Letters.2024; 30(4): 291. CrossRef

- Effect of Phase Composition on Microstructure and Mechanical Properties of Biomedical Ti-15Nb-5Sn Alloy Prepared by Material Extrusion Additive Manufacturing

- [Korean]

- Effect of Process Stopping and Restarting on the Microstructure and Local Property of 316L Stainless Steel Manufactured by Selective Laser Melting Process

- Hyunjin Joo, Jeongmin Woo, Yongho Sohn, Kee-Ahn Lee

- J Powder Mater. 2022;29(1):1-7. Published online February 1, 2022

- DOI: https://doi.org/10.4150/KPMI.2022.29.1.1

- 780 View

- 7 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF This study investigates the effect of process stopping and restarting on the microstructure and local nanoindentation properties of 316L stainless steel manufactured via selective laser melting (SLM). We find that stopping the SLM process midway, exposing the substrate to air having an oxygen concentration of 22% or more for 12 h, and subsequently restarting the process, makes little difference to the density of the restarted area (~ 99.8%) as compared to the previously melted area of the substrate below. While the microstructure and pore distribution near the stop/restart area changes, this modified process does not induce the development of unusual features, such as an inhomogeneous microstructure or irregular pore distribution in the substrate. An analysis of the stiffness and hardness values of the nano-indented steel also reveals very little change at the joint of the stop/restart area. Further, we discuss the possible and effective follow-up actions of stopping and subsequently restarting the SLM process.

-

Citations

Citations to this article as recorded by- On the Fabrication of Functionally Graded Prototypes with Laser Powder Bed Fusion from Reused Ni-625 and 17-4 PH Stainless Steel Powder

Bharat Kalia, Rupinder Singh, B. S. Pabla

Journal of Materials Engineering and Performance.2025; 34(22): 27160. CrossRef - Additive Manufacturing of SS316L/IN718 Bimetallic Structure via Laser Powder Bed Fusion

Asif Mahmud, Nicolas Ayers, Thinh Huynh, Yongho Sohn

Materials.2023; 16(19): 6527. CrossRef

- On the Fabrication of Functionally Graded Prototypes with Laser Powder Bed Fusion from Reused Ni-625 and 17-4 PH Stainless Steel Powder

- [Korean]

- Oxidation Behaviors and Degradation Properties of Aluminide Coated Stainless Steel at High Temperature

- Cheol Hong Hwang, Hyo Min Lee, Jeong Seok Oh, Dong Hyeon Hwang, Yu Seok Hwang, Jong Won Lee, Jeong Mook Choi, Joon Sik Park

- J Korean Powder Metall Inst. 2021;28(5):396-402. Published online October 1, 2021

- DOI: https://doi.org/10.4150/KPMI.2021.28.5.396

- 758 View

- 2 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF Stainless steel, a type of steel used for high-temperature parts, may cause damage when exposed to high temperatures, requiring additional coatings. In particular, the Cr2O3 product layer is unstable at 1000°C and higher temperatures; therefore, it is necessary to improve the oxidation resistance. In this study, an aluminide (Fe2Al5 and FeAl3) coating layer was formed on the surface of STS 630 specimens through Al diffusion coatings from 500°C to 700°C for up to 25 h. Because the coating layers of Fe2Al5 and FeAl3 could not withstand temperatures above 1200°C, an Al2O3 coating layer is deposited on the surface through static oxidation treatment at 500°C for 10 h. To confirm the ablation resistance of the resulting coating layer, dynamic flame exposure tests were conducted at 1350°C for 5–15 min. Excellent oxidation resistance is observed in the coated base material beneath the aluminide layer. The conditions of the flame tests and coating are discussed in terms of microstructural variations.

-

Citations

Citations to this article as recorded by- Thermal Stability and Degradation Properties of Aluminide Coated and Uncoated Ti-6Al-4V Alloys Exposed to High Temperature Flame

C. Hwang, J. Park, J. Oh, D. Han, S. Lee, K. Shin, J. Choi, K. P. Shinde, J. S. Park

Metals and Materials International.2023; 29(7): 1855. CrossRef

- Thermal Stability and Degradation Properties of Aluminide Coated and Uncoated Ti-6Al-4V Alloys Exposed to High Temperature Flame

- [Korean]

- Microstructure and High Temperature Mechanical Properties of Oxide Dispersion Strengthened Steels Manufactured by Combination Milling Process

- Jung-Uk Lee, Young-Kyun Kim, Jeoung Han Kim, Hwi-Jin Kim, Kee-Ahn Lee

- J Korean Powder Metall Inst. 2021;28(5):389-395. Published online October 1, 2021

- DOI: https://doi.org/10.4150/KPMI.2021.28.5.389

- 809 View

- 9 Download

-

Abstract

Abstract

PDF

PDF Oxide dispersion-strengthened (ODS) steel has excellent high-temperature properties, corrosion resistance, and oxidation resistance, and is expected to be applicable in various fields. Recently, various studies on mechanical alloying (MA) have been conducted for the dispersion of oxide particles in ODS steel with a high number density. In this study, ODS steel is manufactured by introducing a complex milling process in which planetary ball milling, cryogenic ball milling, and drum ball milling are sequentially performed, and the microstructure and high-temperature mechanical properties of the ODS steel are investigated. The microstructure observation revealed that the structure is stretched in the extrusion direction, even after the heat treatment. In addition, transmission electron microscopy (TEM) analysis confirmed the presence of oxide particles in the range of 5 to 10 nm. As a result of the room-temperature and high-temperature compression tests, the yield strengths were measured as 1430, 1388, 418, and 163 MPa at 25, 500, 700, and 900°C, respectively. Based on these results, the correlation between the microstructure and mechanical properties of ODS steel manufactured using the composite milling process is also discussed.

- [Korean]

- Evolution on Microstructures and Tensile Properties of 10Cr-1Mo ODS Steel with Different Lengths of Mechanical Alloying Process Times

- Sanghoon Noh, Tae Kyu Kim

- J Korean Powder Metall Inst. 2021;28(5):375-380. Published online October 1, 2021

- DOI: https://doi.org/10.4150/KPMI.2021.28.5.375

- 922 View

- 6 Download

-

Abstract

Abstract

PDF

PDF In this study, we investigate the effect of the duration of mechanical alloying on the microstructures and mechanical properties of ODS ferritic/martensitic steel. The Fe(bal.)-10Cr-1Mo pre-alloyed powder and Y2O3 powder are mechanically alloyed for the different mechanical alloying duration (0 to 40 h) and then constantly fabricated using a uniaxial hot pressing process. Upon increasing the mechanical alloying time, the average powder diameter and crystallite size increased dramatically. In the initial stages within 5 h of mechanical alloying, inhomogeneous grain morphology is observed along with coarsened carbide and oxide distributions; thus, precipitate phases are temporarily observed between the two powders because of insufficient collision energy to get fragmented. After 40 h of the MA process, however, fine martensitic grains and uniformly distributed oxide particles are observed. This led to a favorable tensile strength and elongation at room temperature and 650°C.

- [Korean]

- High Temperature Oxidation Behavior of 316L Austenitic Stainless Steel Manufactured by Laser Powder Bed Fusion Process

- Yu-Jin Hwang, Dong-Yeol Wi, Kyu-Sik Kim, Kee-Ahn Lee

- J Korean Powder Metall Inst. 2021;28(2):110-119. Published online April 1, 2021

- DOI: https://doi.org/10.4150/KPMI.2021.28.2.110

- 1,200 View

- 26 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF In this study, the high-temperature oxidation properties of austenitic 316L stainless steel manufactured by laser powder bed fusion (LPBF) is investigated and compared with conventional 316L manufactured by hot rolling (HR). The initial microstructure of LPBF-SS316L exhibits a molten pool ~100 μm in size and grains grown along the building direction. Isotropic grains (~35 μm) are detected in the HR-SS316L. In high-temperature oxidation tests performed at 700°C and 900°C, LPBF-SS316L demonstrates slightly superior high-temperature oxidation resistance compared to HR-SS316L. After the initial oxidation at 700°C, shown as an increase in weight, almost no further oxidation is observed for both materials. At 900°C, the oxidation weight displays a parabolic trend and both materials exhibit similar behavior. However, at 1100°C, LPBF-SS316L oxidizes in a parabolic manner, but HR-SS316L shows a breakaway oxidation behavior. The oxide layers of LPBF-SS316L and HR-SS316L are mainly composed of Cr2O3, Febased oxides, and spinel phases. In LPBF-SS316L, a uniform Cr depletion region is observed, whereas a Cr depletion region appears at the grain boundary in HR-SS316L. It is evident from the results that the microstructure and the hightemperature oxidation characteristics and behavior are related.

-

Citations

Citations to this article as recorded by- Retention factor-based constitutive model of high-strength austenitic A4–80 bolts after fire exposure

Hui Wang, Bo Yang, Tao Sun, Weilai Yao, Wei Jiang

Journal of Constructional Steel Research.2025; 235: 109930. CrossRef - Study of structural stability at high temperature of pseudo-single tube with double layer as an alternative method for accident-tolerant fuel cladding

Jong Woo Kim, Hyeong Woo Min, Jaehwan Ko, Yonghee Kim, Young Soo Yoon

Journal of Nuclear Materials.2022; 566: 153800. CrossRef

- Retention factor-based constitutive model of high-strength austenitic A4–80 bolts after fire exposure

- [Korean]

- Effect of Cobalt Contents on the Microstructure and Charpy Impact Properties of Ferritic/martensitic Oxide Dispersion Strengthened Steel

- Daehyun Kwon, Sanghoon Noh, Jung Gu Lee

- J Korean Powder Metall Inst. 2020;27(4):311-317. Published online August 1, 2020

- DOI: https://doi.org/10.4150/KPMI.2020.27.4.311

- 914 View

- 5 Download

-

Abstract

Abstract

PDF

PDF In this study, the effects of Co content on the microstructure and Charpy impact properties of Fe-Cr-W ferritic/martensitic oxide dispersion strengthened (F/M ODS) steels are investigated. F/M ODS steels with 0–5 wt% Co are fabricated by mechanical alloying, followed by hot isostatic pressing, hot-rolling, and normalizing/tempering heat treatment. All the steels commonly exhibit two-phase microstructures consisting of ferrite and tempered martensite. The volume fraction of ferrite increases with the increase in the Co content, since the Co element considerably lowers the hardenability of the F/M ODS steel. Despite the lowest volume fraction of tempered martensite, the F/M ODS steel with 5 wt% Co shows the highest micro-Vickers hardness, owing to the solid solution-hardening effect of the alloyed Co. The high hardness of the steel improves the resistance to fracture initiation, thereby resulting in the enhanced fracture initiation energy in a Charpy impact test at – 40°C. Furthermore, the addition of Co suppresses the formation of coarse oxide inclusions in the F/M ODS steel, while simultaneously providing a high resistance to fracture propagation. Owing to these combined effects of Co, the Charpy impact energy of the F/M ODS steel increases gradually with the increase in the Co content.

- [Korean]

- Development of Fe-Mn-based Hybrid Materials Containing Nano-scale Oxides by a Powder Metallurgical Route

- Jonggyu Jeon, Jungjoon Kim, Hyunjoo Choi

- J Korean Powder Metall Inst. 2020;27(3):203-209. Published online June 1, 2020

- DOI: https://doi.org/10.4150/KPMI.2020.27.3.203

- 893 View

- 7 Download

-

Abstract

Abstract

PDF

PDF The automotive industry has focused on the development of metallic materials with high specific strength, which can meet both fuel economy and safety goals. Here, a new class of ultrafine-grained high-Mn steels containing nano-scale oxides is developed using powder metallurgy. First, high-energy mechanical milling is performed to dissolve alloying elements in Fe and reduce the grain size to the nanometer regime. Second, the ball-milled powder is consolidated using spark plasma sintering. During spark plasma sintering, nanoscale manganese oxides are generated in Fe-15Mn steels, while other nanoscale oxides (e.g., aluminum, silicon, titanium) are produced in Fe-15Mn-3Al-3Si and Fe-15Mn-3Ti steels. Finally, the phases and resulting hardness of a variety of high-Mn steels are compared. As a result, the sintered pallets exhibit superior hardness when elements with higher oxygen affinity are added; these elements attract oxygen from Mn and form nanoscale oxides that can greatly improve the strength of high-Mn steels.

- [Korean]

- Effect of Phosphorus Addition on Microstructure and Mechanical Properties of Sintered Low Alloy Steel

- Yoo-Young Kim, Kwon-Koo Cho

- J Korean Powder Metall Inst. 2020;27(1):31-36. Published online February 1, 2020

- DOI: https://doi.org/10.4150/KPMI.2020.27.1.31

- 808 View

- 5 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF Phosphorus is an element that plays many important roles in powder metallurgy as an alloy element. The purpose of this study is to investigate the influence of phosphorus addition on the microstructures and mechanical properties of sintered low-alloy steel. The sintered low-alloy steels Fe-0.6%C-3.89%Ni-1.95%Cu-1.40%Mo-xP (x=0, 0.05, 0.10, 0.15, 0.20%) were manufactured by compacting at 700 MPa, sintering in H2-N2 at 1260 °C, rapid cooling, and low-temperature tempering in Ar at 160 °C. The microstructure, pore, density, hardness, and transverse rupture strength (TRS) of the sintered low-alloy steels were evaluated. The hardness increased as the phosphorus content increased, whereas the density and TRS showed maximum values when the content of P was 0.05%. Based on microstructure observation, the phase of the microstructure changed from bainite to martensite as the content of phosphorus is increased. Hence, the most appropriate addition of phosphorus in this study was 0.05%.

-

Citations

Citations to this article as recorded by- A new strategy for metal additive manufacturing using an economical water-atomized iron powder for laser powder bed fusion

Taehyeob Im, Kopila Gurung, Sebastian Meyers, Antonio Cutolo, Huengseok Oh, Jai-Sung Lee, Brecht Van Hooreweder, Caroline Sunyong Lee

Journal of Materials Processing Technology.2022; 308: 117705. CrossRef

- A new strategy for metal additive manufacturing using an economical water-atomized iron powder for laser powder bed fusion

- [Korean]

- Effect of Porosity on Mechanical Anisotropy of 316L Austenitic Stainless Steel Additively Manufactured by Selective Laser Melting

- Jeong Min Park, Jin Myoung Jeon, Jung Gi Kim, Yujin Seong, Sun Hong Park, Hyoung Seop Kim

- J Korean Powder Metall Inst. 2018;25(6):475-481. Published online December 1, 2018

- DOI: https://doi.org/10.4150/KPMI.2018.25.6.475

- 1,342 View

- 12 Download

- 12 Citations

-

Abstract

Abstract

PDF

PDF Selective laser melting (SLM), a type of additive manufacturing (AM) technology, leads a global manufacturing trend by enabling the design of geometrically complex products with topology optimization for optimized performance. Using this method, three-dimensional (3D) computer-aided design (CAD) data components can be built up directly in a layer-by-layer fashion using a high-energy laser beam for the selective melting and rapid solidification of thin layers of metallic powders. Although there are considerable expectations that this novel process will overcome many traditional manufacturing process limits, some issues still exist in applying the SLM process to diverse metallic materials, particularly regarding the formation of porosity. This is a major processing-induced phenomenon, and frequently observed in almost all SLM-processed metallic components. In this study, we investigate the mechanical anisotropy of SLM-produced 316L stainless steel based on microstructural factors and highly-oriented porosity. Tensile tests are performed to investigate the microstructure and porosity effects on mechanical anisotropy in terms of both strength and ductility.

-

Citations

Citations to this article as recorded by- Effect of temperature and impact loading condition on deformation behavior in 316L austenitic stainless steel manufactured by laser powder bed fusion

Tae Hyeong Kim, Haeum Park, Jun Seok Lee, Jeong Min Park, Jae Wung Bae

Materials Science and Engineering: A.2025; 933: 148286. CrossRef - Selective laser melting additive manufactured H13 tool steel for aluminum extrusion die component construction

Evangelos Giarmas, Vasileios Tsakalos, Emmanuel Tzimtzimis, Nikolaos Kladovasilakis, Ioannis Kostavelis, Dimitrios Tzovaras, Dimitrios Tzetzis

The International Journal of Advanced Manufacturing Technology.2024; 133(9-10): 4385. CrossRef - Nanoindentation Creep Behavior of Additively Manufactured H13 Steel by Utilizing Selective Laser Melting Technology

Evangelos Giarmas, Emmanouil K. Tzimtzimis, Nikolaos Kladovasilakis, Dimitrios Tzovaras, Dimitrios Tzetzis

Materials.2024; 17(15): 3756. CrossRef - A Parametric Study on the L-PBF Process of an AlSi10Mg Alloy for High-Speed Productivity of Automotive Prototype Parts

Yeonha Chang, Hyomoon Joo, Wanghyun Yong, Yeongcheol Jo, Seongjin Kim, Hanjae Kim, Yeon Woo Kim, Kyung Tae Kim, Jeong Min Park

Journal of Powder Materials.2024; 31(5): 390. CrossRef - Development of multi-defect diagnosis algorithm for the directed energy deposition (DED) process with in situ melt-pool monitoring

Hyewon Shin, Jimin Lee, Seung-Kyum Choi, Sang Won Lee

The International Journal of Advanced Manufacturing Technology.2023; 125(1-2): 357. CrossRef - Corrosion Resistance of Laser Powder Bed Fused AISI 316L Stainless Steel and Effect of Direct Annealing

Kichang Bae, Dongmin Shin, Jonghun Lee, Seohan Kim, Wookjin Lee, Ilguk Jo, Junghoon Lee

Materials.2022; 15(18): 6336. CrossRef - Experimental investigation on the effect of process parameters in additive/subtractive hybrid manufacturing 316L stainless steel

Chengming Tang, Jibin Zhao, Zhiguo Wang, Yuhui Zhao, Tianran Wang

The International Journal of Advanced Manufacturing Technology.2022; 121(3-4): 2461. CrossRef - Interface characteristics and mechanical behavior of additively manufactured multi-material of stainless steel and Inconel

Man Jae Sagong, Eun Seong Kim, Jeong Min Park, Gangaraju Manogna Karthik, Byeong-Joo Lee, Jung-Wook Cho, Chong Soo Lee, Takayoshi Nakano, Hyoung Seop Kim

Materials Science and Engineering: A.2022; 847: 143318. CrossRef - Effect of heat treatment on microstructural heterogeneity and mechanical properties of 1%C-CoCrFeMnNi alloy fabricated by selective laser melting

Jeong Min Park, Eun Seong Kim, Hyeonseok Kwon, Praveen Sathiyamoorthi, Kyung Tae Kim, Ji-Hun Yu, Hyoung Seop Kim

Additive Manufacturing.2021; 47: 102283. CrossRef - Manufacturing Aluminum/Multiwalled Carbon Nanotube Composites via Laser Powder Bed Fusion

Eo Ryeong Lee, Se Eun Shin, Naoki Takata, Makoto Kobashi, Masaki Kato

Materials.2020; 13(18): 3927. CrossRef - Effects of microstructure and internal defects on mechanical anisotropy and asymmetry of selective laser-melted 316L austenitic stainless steel

Jin Myoung Jeon, Jeong Min Park, Ji-Hun Yu, Jung Gi Kim, Yujin Seong, Sun Hong Park, Hyoung Seop Kim

Materials Science and Engineering: A.2019; 763: 138152. CrossRef - Microstructural effects on the tensile and fracture behavior of selective laser melted H13 tool steel under varying conditions

Jungsub Lee, Jungho Choe, Junhyeok Park, Ji-Hun Yu, Sangshik Kim, Im Doo Jung, Hyokyung Sung

Materials Characterization.2019; 155: 109817. CrossRef

- Effect of temperature and impact loading condition on deformation behavior in 316L austenitic stainless steel manufactured by laser powder bed fusion

- [Korean]

- A study about sculpture characteristic of SKD61 tool steel fabricated by selective laser melting(SLM) process

- Jaecheol Yun, Jungho Choe, Ki-Bong Kim, Sangsun Yang, Dong-Yeol Yang, Yong-Jin Kim, Chang-Woo Lee, Chang-Woo Lee

- J Korean Powder Metall Inst. 2018;25(2):137-143. Published online April 1, 2018

- DOI: https://doi.org/10.4150/KPMI.2018.25.2.137

- 1,108 View

- 4 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF In this study, two types of SKD61 tool-steel samples are built by a selective laser melting (SLM) process using the different laser scan speeds. The characteristics of two kinds of SKD61 tool-steel powders used in the SLM process are evaluated. Commercial SKD61 tool-steel power has a flowability of 16.68 sec/50 g and its Hausner ratio is calculated to be 1.25 by apparent and tapped density. Also, the fabricated SKD61 tool steel powder fabricated by a gas atomization process has a flowability of 21.3 sec/50 g and its Hausner ratio is calculated to be 1.18. Therefore, we confirmed that the two powders used in this study have excellent flowability. Samples are fabricated to measure mechanical properties. The highest densities of the SKD61 tool-steel samples, fabricated under the same conditions, are 7.734 g/cm3 (using commercial SKD61 powder) and 7.652 g/cm3 (using fabricated SKD61 powder), measured with Archimedes method. Hardness is measured by Rockwell hardness testing equipment 5 times and the highest hardnesses of the samples are 54.56 HRC (commercial powder) and 52.62 HRC (fabricated powder). Also, the measured tensile strengths are approximately 1,721 MPa (commercial SKD61 powder) and 1,552 MPa (fabricated SKD61 powder), respectively.

-

Citations

Citations to this article as recorded by- Microstructural effects on the tensile and fracture behavior of selective laser melted H13 tool steel under varying conditions

Jungsub Lee, Jungho Choe, Junhyeok Park, Ji-Hun Yu, Sangshik Kim, Im Doo Jung, Hyokyung Sung

Materials Characterization.2019; 155: 109817. CrossRef

- Microstructural effects on the tensile and fracture behavior of selective laser melted H13 tool steel under varying conditions

- [Korean]

- Microstructure and Wear Properties of Oxide Dispersion Strengthened Steel Powder Added Steel-Based Composite Material for Automotive Part

- Young-Kyun Kim, Jong-Kwan Park, Kee-Ahn Lee

- J Korean Powder Metall Inst. 2018;25(1):36-42. Published online February 1, 2018

- DOI: https://doi.org/10.4150/KPMI.2018.25.1.36

- 834 View

- 4 Download

- 2 Citations

-

Abstract

Abstract

PDF

PDF In order to expand the application of oxide dispersion-strengthened (ODS) steel, a composite material is manufactured by adding mechanically alloyed ODS steel powder to conventional steel and investigated in terms of microstructure and wear properties. For comparison, a commercial automobile part material is also tested. Initial microstructural observations confirm that the composite material with added ODS steel contains i) a pearlitic Fe matrix area and ii) an area with Cr-based carbides and ODS steel particles in the form of a Fe-Fe3C structure. In the commercial material, various hard Co-, Fe-Mo-, and Cr-based particles are present in a pearlitic Fe matrix. Wear testing using the VSR engine simulation wear test confirms that the seatface widths of the composite material with added ODS steel and the commercial material are increased by 24% and 47%, respectively, with wear depths of 0.05 mm and 0.1 mm, respectively. The ODS steel-added composite material shows better wear resistance. Post-wear-testing surface and cross-sectional observations show that particles in the commercial material easily fall off, while the ODS steel-added material has an even, smooth wear surface.

-

Citations

Citations to this article as recorded by- First principles determination of formation of a Cr shell on the interface between Y–Ti–O nanoparticles and a ferritic steel matrix

Ki-Ha Hong, Jae Bok Seol, Jeoung Han Kim

Applied Surface Science.2019; 481: 69. CrossRef - Thermal Properties and Microstructural Changes of Fe-Co System Valve Seat Alloy by High Densification Process

In-Shup Ahn, Dong-Kyu Park, Kwang-Bok Ahn, Seoung-Mok Shin

Journal of Korean Powder Metallurgy Institute.2019; 26(2): 112. CrossRef

- First principles determination of formation of a Cr shell on the interface between Y–Ti–O nanoparticles and a ferritic steel matrix

- [Korean]

- The Microstructure and Mechanical Properties of Y2O3-Dispersed Fe-C and Fe-CNT Sintered Steels

- Jin Young Lim, Jung-Ho Ahn

- J Korean Powder Metall Inst. 2017;24(4):298-301. Published online August 1, 2017

- DOI: https://doi.org/10.4150/KPMI.2017.24.4.298

- 626 View

- 1 Download

-

Abstract

Abstract

PDF

PDF In the present work, we use multiwall carbon nanotubes (MWCNT) as the starting material for the fabrication of sintered carbon steel. A comparison is made with conventionally sintered carbon steel, where graphite is used as the starting material. Milling is performed using a horizontal mill sintered in a vacuum furnace. We analyze the grain size, number of pores, X-ray diffraction patterns, and microstructure. Changes in the physical properties are determined by using the Archimedes method and Vickers hardness measurements. The result shows that the use of MWCNTs instead of graphite significantly reduces the size and volume of the pores as well as the grain size after sintering. The addition of Y2O3.to the Fe-MWCNT samples further inhibits the growth of grains.

- [Korean]

- High Temperature Oxidation Behavior of Fe-14Cr Ferritic Oxide Dispersion Strengthened Steels Manufactured by Mechanical Alloying Process

- Young-Kyun Kim, Jong-Kwan Park, Hwi-Jun Kim, Man-Sik Kong, Kee-Ahn Lee

- J Korean Powder Metall Inst. 2017;24(2):133-140. Published online April 1, 2017

- DOI: https://doi.org/10.4150/KPMI.2017.24.2.133

- 686 View

- 5 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF This study investigates the oxidation properties of Fe-14Cr ferritic oxide-dispersion-strengthened (ODS) steel at various high temperatures (900, 1000, and 1100°C for 24 h). The initial microstructure shows that no clear structural change occurs even under high-temperature heat treatment, and the average measured grain size is 0.4 and 1.1 μm for the as-fabricated and heat-treated specimens, respectively. Y–Ti–O nanoclusters 10–50 nm in size are observed. High-temperature oxidation results show that the weight increases by 0.27 and 0.29 mg/cm2 for the asfabricated and heat-treated (900°C) specimens, and by 0.47 and 0.50 mg/cm2 for the as-fabricated and heat-treated (1000°C) specimens, respectively. Further, after 24 h oxidation tests, the weight increases by 56.50 and 100.60 mg/cm2 for the as-fabricated and heat-treated (1100°C) specimens, respectively; the latter increase is approximately 100 times higher than that at 1000°C. Observation of the surface after the oxidation test shows that Cr2O3 is the main oxide on a specimen tested at 1000°C, whereas Fe2O3 and Fe3O4 phases also form on a specimen tested at 1100°C, where the weight increases rapidly. The high-temperature oxidation behavior of Fe-14Cr ODS steel is confirmed to be dominated by changes in the Cr2O3 layer and generation of Fe-based oxides through evaporation.

-

Citations

Citations to this article as recorded by- Microstructure and Wear Properties of Oxide Dispersion Strengthened Steel Powder Added Steel-Based Composite Material for Automotive Part

Young-Kyun Kim, Jong-Kwan Park, Kee-Ahn Lee

journal of Korean Powder Metallurgy Institute.2018; 25(1): 36. CrossRef

- Microstructure and Wear Properties of Oxide Dispersion Strengthened Steel Powder Added Steel-Based Composite Material for Automotive Part

- [Korean]

- Stretch-Flangeability of Harmonic Structure Material Manufactured by Powder Metallurgy Method

- Jae Ik Yoon, Hak Hyeon Lee, Hyung Keun Park, Kei Ameyama, Hyoung Seop Kim

- J Korean Powder Metall Inst. 2017;24(2):128-132. Published online April 1, 2017

- DOI: https://doi.org/10.4150/KPMI.2017.24.2.128

- 858 View

- 1 Download

-

Abstract

Abstract

PDF

PDF Harmonic structure materials are materials with a core–shell structure having a shell with a small grain size and a core with a relatively large grain size. They are in the spotlight because their mechanical properties reportedly feature strength similar to that of a sintered powder with a fine grain size and elongation similar to that of a sintered powder with a coarse grain size at the same time. In this study, the tensile properties, microstructure, and stretchflangeability of harmonic structure SUS304L made using powder metallurgy are investigated to check its suitability for automotive applications. The harmonic powders are made by mechanical milling and sintered using a spark plasma sintering method at 1173 K and a pressure of 50 MPa in a cylindrical die. The sintered powders of SUS304L having harmonic structure (harmonic SUS304L) exhibit excellent tensile properties compared with sintered powders of SUS304L having homogeneous microstructure. In addition, the harmonic SUS304L has excellent stretch-flangeability compared with commercial advanced high-strength steels (AHSSs) at a similar strength grade. Thus, the harmonic SUS304L is more suitable for automotive applications than conventional AHSSs because it exhibits both excellent tensile properties and stretch-flangeability.

- [Korean]

- Microstructures of Powders and Additively Manufactured Objects of an Alloy Tool Steel for Cold-Work Dies

- Jun-Yun Kang, Jaecheol Yun, Hoyoung Kim, Byunghwan Kim, Jungho Choe, Sangsun Yang, Ji-Hun Yu, Yong-Jin Kim

- J Korean Powder Metall Inst. 2016;24(3):202-209. Published online June 1, 2016

- DOI: https://doi.org/10.4150/KPMI.2017.24.3.202

- 925 View

- 1 Download

- 3 Citations

-

Abstract

Abstract

PDF

PDF A cold-work tool steel powder is used to fabricate 3-dimensional objects by selective laser melting using a high-pressure gas atomization process. The spherical powder particles form continuous carbide networks among the austenite matrix and its decomposition products. The carbides comprise Nb-rich MC and Mo-rich M2C. In the SLM process, the process parameters such as the laser power (90 W), layer thickness (25 μm), and hatch spacing (80 μm) are kept fixed, while the scan speed is changed from 50 mm/s to 4000 mm/s. At a low scan speed of 50 mm/s, spherical cavities develop due to over melting, while they are substantially reduced on increasing the speed to 2000 mm/s. The carbide network spacing decreases with increasing speed. At an excessively high speed of 4000 mm/s, long and irregularly shaped cavities are developed due to incomplete melting. The influence of the scan pattern is examined, for which 1 × 1 mm2 blocks constituting a processing layer are irradiated in a random sequence. This island-type pattern exhibits the same effect as that of a low scan speed. Post processing of an object using hot isostatic pressing leads to a great reduction in the porosity but causes coarsening of the microstructure.

-

Citations

Citations to this article as recorded by- Nanoindentation Creep Behavior of Additively Manufactured H13 Steel by Utilizing Selective Laser Melting Technology

Evangelos Giarmas, Emmanouil K. Tzimtzimis, Nikolaos Kladovasilakis, Dimitrios Tzovaras, Dimitrios Tzetzis

Materials.2024; 17(15): 3756. CrossRef - Micro-Texture Analyses of a Cold-Work Tool Steel for Additive Manufacturing

Jun-Yun Kang, Jaecheol Yun, Byunghwan Kim, Jungho Choe, Sangsun Yang, Seong-Jun Park, Ji-Hun Yu, Yong-Jin Kim

Materials.2020; 13(3): 788. CrossRef - Microstructural effects on the tensile and fracture behavior of selective laser melted H13 tool steel under varying conditions

Jungsub Lee, Jungho Choe, Junhyeok Park, Ji-Hun Yu, Sangshik Kim, Im Doo Jung, Hyokyung Sung

Materials Characterization.2019; 155: 109817. CrossRef

- Nanoindentation Creep Behavior of Additively Manufactured H13 Steel by Utilizing Selective Laser Melting Technology

- [Korean]

- Mechanical Property Improvement of the H13 Tool Steel Sculptures Built by Metal 3D Printing Process via Optimum Conditions

- Jaecheol Yun, Jungho Choe, Haengna Lee, Ki-Bong Kim, Sangsun Yang, Dong-Yeol Yang, Yong-Jin Kim, Chang-Woo Lee, Ji-Hun Yu

- J Korean Powder Metall Inst. 2016;24(3):195-201. Published online June 1, 2016

- DOI: https://doi.org/10.4150/KPMI.2017.24.3.195

- 1,272 View

- 12 Download

- 9 Citations

-

Abstract

Abstract

PDF

PDF In this study, H13 tool steel sculptures are built by a metal 3D printing process at various laser scan speeds. The properties of commercial H13 tool steel powders are confirmed for the metal 3D printing process used: powder bed fusion (PBF), which is a selective laser melting (SLM) process. Commercial H13 powder has an excellent flowability of 16.68 s/50 g with a Hausner ratio of 1.25 and a density of 7.68 g/cm3. The sculptures are built with dimensions of 10 × 10 × 10 mm3 in size using commercial H13 tool steel powder. The density measured by the Archimedes method is 7.64 g/cm3, similar to the powder density of 7.68 g/cm3. The hardness is measured by Rockwell hardness equipment 5 times to obtain a mean value of 54.28 HRC. The optimum process conditions in order to build the sculptures are a laser power of 90 W, a layer thickness of 25 μm, an overlap of 30%, and a laser scan speed of 200 mm/s.

-

Citations

Citations to this article as recorded by- Enhancement of resistance to cracking under thermal cycling of EDM-treated H13 steel by shot peening with optimized intensity

Pengpeng Zuo, Zhiyang Dou, Huikai Yang, Haoyan Hou, Yafeng Zheng

Engineering Failure Analysis.2026; 187: 110622. CrossRef - A Study on Fabrication of PCD Boring Tool Body based on Metal 3D Printing Technology

Ho Min Son, Dong Gyu Kim, Min-Woo Sa

Journal of the Korean Society for Precision Engineering.2026; 43(2): 189. CrossRef - Spheroidization of Enamel Powders by Radio Frequency Plasma Treatment and Application to Additive Manufacturing

Ki-Bong Kim, Dong-Yeol Yang, Yong-Jin Kim, Jungho Choe, Ji-Na Kwak, Woo-Hyung Jung

Journal of Korean Powder Metallurgy Institute.2020; 27(5): 388. CrossRef - Microstructural effects on the tensile and fracture behavior of selective laser melted H13 tool steel under varying conditions

Jungsub Lee, Jungho Choe, Junhyeok Park, Ji-Hun Yu, Sangshik Kim, Im Doo Jung, Hyokyung Sung

Materials Characterization.2019; 155: 109817. CrossRef - Nano-mechanical Behavior of H13 Tool Steel Fabricated by a Selective Laser Melting Method

Van Luong Nguyen, Eun-ah Kim, Jaecheol Yun, Jungho Choe, Dong-yeol Yang, Hak-sung Lee, Chang-woo Lee, Ji-Hun Yu

Metallurgical and Materials Transactions A.2019; 50(2): 523. CrossRef - Correlation between Microstructure and Mechanical Properties of the Additive Manufactured H13 Tool Steel

Woojin An, Junhyeok Park, Jungsub Lee, Jungho Choe, Im Doo Jung, Ji-Hun Yu, Sangshik Kim, Hyokyung Sung

Korean Journal of Materials Research.2018; 28(11): 663. CrossRef - Evaluation of Strain-Rate Sensitivity of Selective Laser Melted H13 Tool Steel Using Nanoindentation Tests

Van Luong Nguyen, Eun-ah Kim, Seok-Rok Lee, Jaecheol Yun, Jungho Choe, Dong-yeol Yang, Hak-sung Lee, Chang-woo Lee, Ji-Hun Yu

Metals.2018; 8(8): 589. CrossRef - Comparison of Nano-Mechanical Behavior between Selective Laser Melted SKD61 and H13 Tool Steels

Jaecheol Yun, Van Luong Nguyen, Jungho Choe, Dong-Yeol Yang, Hak-Sung Lee, Sangsun Yang, Ji-Hun Yu

Metals.2018; 8(12): 1032. CrossRef - A study about sculpture characteristic of SKD61 tool steel fabricated by selective laser melting(SLM) process

Jaecheol Yun, Jungho Choe, Ki-Bong Kim, Sangsun Yang, Dong-Yeol Yang, Yong-Jin Kim, Chang-Woo Lee, Chang-Woo Lee

Journal of Korean Powder Metallurgy Institute.2018; 25(2): 137. CrossRef

- Enhancement of resistance to cracking under thermal cycling of EDM-treated H13 steel by shot peening with optimized intensity

- [Korean]

- The Effect of Oxide Compound on Electrical Resistivity and Oxidation Stability in High-temperature for Ferritic P/M Stainless Steel

- Jin-Woo Park, Byung-Hyun Ko, Woo-young Jung, Dong-Kyu Park, In-Shup Ahn

- J Korean Powder Metall Inst. 2016;23(3):240-246. Published online June 1, 2016

- DOI: https://doi.org/10.4150/KPMI.2016.23.3.240

- 606 View

- 1 Download

-

Abstract

Abstract

PDF

PDF In order to improve the high-temperature oxidation stability, sintered 434L stainless steel is studied, focusing on the effect of the addition of metallic oxides to form stable oxide films on the inner particle surface. The green compacts of Fecralloy powder or amorphous silica are added on STS434L and oxidized at 950°C up to 210 h. The weight change ratio of 434L with amorphous silica is higher than that of 434L mixed with Fecralloy, and the weight increase follows a parabolic law, which implies that the oxide film grows according to oxide diffusion through the densely formed oxide film. In the case of 434L mixed with Fecralloy, the elements in the matrix diffuse through the grain boundaries and form Al2O3 and Fe-Cr oxides. Stable high temperature corrosion resistance and electrical resistivity are obtained for STS434L mixed with Fecralloy.

- [English]

- Spark Plasma Sintering of Fe-Ni-Cu-Mo-C Low Alloy Steel Powder

- Hong-Hai Nguyen, Minh-Thuyet Nguyen, Won Joo Kim, Ho Yoon Kim, Sung Gye Park, Jin-Chun Kim

- J Korean Powder Metall Inst. 2016;23(3):207-212. Published online June 1, 2016

- DOI: https://doi.org/10.4150/KPMI.2016.23.3.207

- 1,365 View

- 10 Download

- 4 Citations

-

Abstract

Abstract

PDF

PDF In this study, Fe-Cu-Ni-Mo-C low alloy steel powder is consolidated by spark plasma sintering (SPS) process. The internal structure and the surface fracture behavior are studied using field-emission scanning electron microscopy and optical microscopy techniques. The bulk samples are polished and etched in order to observe the internal structure. The sample sintered at 900°C with holding time of 10 minutes achieves nearly full density of 98.9% while the density of the as-received conventionally sintered product is 90.3%. The fracture microstructures indicate that the sample prepared at 900°C by the SPS process is hard to break out because of the presence of both grain boundaries and internal particle fractures. Moreover, the lamellar pearlite structure is also observed in this sample. The samples sintered at 1000 and 1100°C exhibit a large number of tiny particles and pores due to the melting of Cu and aggregation of the alloy elements during the SPS process. The highest hardness value of 296.52 HV is observed for the sample sintered at 900°C with holding time of 10 minutes.

-

Citations

Citations to this article as recorded by- Fabrication of Fe-Si-B Based Amorphous Powder Cores by Spark Plasma Sintered and Their Magnetic Properties

Liang Yan, Biao Yan, Yin Jian

Materials.2022; 15(4): 1603. CrossRef - Effect of Milling Time and Addition of PCA on Austenite Stability of Fe-7%Mn Alloy

Seung-Jin Oh, In-Jin Shon, Seok-Jae Lee

Journal of Korean Powder Metallurgy Institute.2018; 25(2): 126. CrossRef - Sintering and Microstructures of SUS 316L Powder Produced by 3D Printing Process

W.J. Kim, H.-H. Nguyen, H.Y. Kim, M.-T. Nguyen, H.S. Park, J.-C. Kim

Archives of Metallurgy and Materials.2017; 62(2): 1215. CrossRef - Fabrication and Mechanical Property of Fe-20Cu-1C Compacts by SPS process with Different Heating Rate

Jung-Han Ryu, Soo-Sik Shin, Byung-Rok Ryu, Kyung-Sik Kim, Jun-Ho Jang, Ik-Hyun Oh, Kap-Tae Kim, Hyun-Kuk Park

Journal of Korean Powder Metallurgy Institute.2017; 24(4): 302. CrossRef

- Fabrication of Fe-Si-B Based Amorphous Powder Cores by Spark Plasma Sintered and Their Magnetic Properties

- [Korean]

- The Effect of Oxides Additives on Anti-corrosion Properties of Sintered 316L Stainless Steel

- Jong-Pil Lee, Ji-Hyun Hong, Dong-Kyu Park, In-Shup Ahn

- J Korean Powder Metall Inst. 2015;22(4):271-277. Published online August 1, 2015

- DOI: https://doi.org/10.4150/KPMI.2015.22.4.271

- 598 View

- 2 Download

-

Abstract

Abstract

PDF

PDF As wrought stainless steel, sintered stainless steel (STS) has excellent high-temperature anti-corrosion even at high temperature of 800ºC and exhibit corrosion resistance in air. The oxidation behavior and oxidation mechanism of the sintered 316L stainless was reported at the high temperature in our previous study. In this study, the effects of additives on high-temperature corrosion resistances were investigated above 800ºC at the various oxides (SiO2, Al2O3, MgO and Y2O3) added STS respectively as an oxidation inhibitor. The morphology of the oxide layers were observed by SEM and the oxides phase and composition were confirmed by XRD and EDX. As a result, the weight of STS 316L sintered body increased sharply at 1000oC and the relative density of specimen decreased as metallic oxide addition increased. Compared with STS 316L sintered parts, weight change ratio corresponding to different oxidation time at 900oC and 1000oC, decreased gradually with the addition of metallic oxide. The best corrosion resistance properties of STS could be improved in case of using Y2O3. The oxidation rate was diminished dramatically by suppression the peeling on oxide layers at Y2O3 added sintered stainless steel.

- [Korean]

- The Effects of Composition and Microstructure Variation on the Oxidation Characteristics of Stainless Steels Manufactured by Powder Metallurgy Method

- Jong-Pil Lee, Ji-Hyun Hong, Dong-Kyu Park, In-Shup Ahn

- J Korean Powder Metall Inst. 2015;22(1):52-59. Published online February 1, 2015

- DOI: https://doi.org/10.4150/KPMI.2015.22.1.52

- 1,305 View

- 11 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF As well-known wrought stainless steel, sintered stainless steel (STS) has excellent high-temperature anticorrosion even at high temperature of 800°C, and exhibits good corrosion resistance in air. However, when temperature increases above 900°C, the corrosion resistance of STS begins to deteriorate and dramatically decreases. In this study, the effects of phase and composition of STS on high-temperature corrosion resistances are investigated for STS 316L, STS 304 and STS 434L above 800°C. The morphology of the oxide layers are observed. The oxides phase and composition are identified using X-ray diffractometer and energy dispersive spectroscopy. The results demonstrate that the best corrosion resistance of STS could be improved to that of 434L. The poor corrosion resistance of the austenitic stainless steels is due to the fact that NiFe2O4 oxides forming poor adhesion between the matrix and oxide film increase the oxidation susceptibility of the material at high temperature.

-

Citations

Citations to this article as recorded by- The effect of different turbulent flow on failure behavior in secondary loop of the pressurized water reactor

Y. Hu, L. Zhao, Y.H. Lu, T. Shoji

Nuclear Engineering and Design.2020; 368: 110812. CrossRef

- The effect of different turbulent flow on failure behavior in secondary loop of the pressurized water reactor

- [Korean]

- Microstructure Evolution of 15Cr ODS Steel by a Simple Torsion Test

- Hyun Ju Jin, Suk Hoon Kang, Tae Kyu Kim

- J Korean Powder Metall Inst. 2014;21(4):271-276. Published online August 1, 2014

- DOI: https://doi.org/10.4150/KPMI.2014.21.4.271

- 782 View

- 1 Download

- 4 Citations

-

Abstract

Abstract

PDF

PDF 15Cr-1Mo base oxide dispersion strengthened (ODS) steel which is considered to be as a promising candidate for high- temperature components in nuclear fusion and fission systems because of its excellent high temperature strength, corrosion and radiation resistance was fabricated by using mechanical alloying, hot isostatic pressing and hot rolling. Torsion tests were performed at room temperature, leading to two different shear strain routes in the forward and reverse directions. In this study, microstructure evolution of the ODS steel during simple shearing was investigated. Fine grained microstructure and a cell structure of dislocation with low angle boundaries were characterized with shear strain in the shear deformed region by electron backscattered diffraction (EBSD). Grain refinement with shear strain resulted in an increase in hardness. After the forward-reverse torsion, the hardness value was measured to be higher than that of the forward torsion only with an identical shear strain amount, suggesting that new dislocation cell structures inside the grain were generated, thus resulting in a larger strengthening of the steel.

-

Citations

Citations to this article as recorded by- Effect of high-energy ball milling on the microstructure and mechanical properties of Ni-based ODS alloys fabricated using gas-atomized powder

Chun Woong Park, Won June Choi, Jongmin Byun, Young Do Kim

Journal of Materials Science.2022; 57(38): 18195. CrossRef - Analysis on Milling Behavior of Oxide Dispersion Strengthened Ni-based Atomizing Powder with Ni5Y Intermetallic Phase

Chun Woong Park, Jong Min Byun, Won June Choi, Young Do Kim

Journal of Korean Powder Metallurgy Institute.2019; 26(2): 101. CrossRef - Current Status and Future Prospective of Advanced Radiation Resistant Oxide Dispersion Strengthened Steel (ARROS) Development for Nuclear Reactor System Applications

Tae Kyu Kim, Sanghoon Noh, Suk Hoon Kang, Jin Ju Park, Hyun Ju Jin, Min Ku Lee, Jinsugn Jang, Chang Kyu Rhee

Nuclear Engineering and Technology.2016; 48(2): 572. CrossRef - A Precipitation Behavior of Nano-Oxide Particles in Mechanically Alloyed Fe-5Y2O3Powders

Ga Eon Kim, Sanghoon Noh, Ji Eun Choi, Young Do Kim, Tae Kyu Kim

Journal of Korean Powder Metallurgy Institute.2015; 22(1): 46. CrossRef

- Effect of high-energy ball milling on the microstructure and mechanical properties of Ni-based ODS alloys fabricated using gas-atomized powder

- [English]

- Spark Plasma Sintering of Stainless Steel Powders Fabricated by High Energy Ball Milling

- Si Young Chang, Sung-Tag Oh, Myung-Jin Suk, Chan Seok Hong

- J Korean Powder Metall Inst. 2014;21(2):97-101. Published online April 1, 2014

- DOI: https://doi.org/10.4150/KPMI.2014.21.2.97

- 1,062 View

- 9 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF The 304 stainless steel powders were prepared by high energy ball milling and subsequently sintered by spark plasma sintering, and the microstructural characteristics and micro-hardness were investigated. The initial size of the irregular shaped 304 stainless steel powders was approximately 42 μm. After high energy ball milling at 800 rpm for 5h, the powders became spherical with a size of approximately 2 μm, and without formation of reaction compounds. From TEM analysis, it was confirmed that the as-milled powders consisted of the aggregates of the nano-sized particles. As the sintering temperature increased from 1073K to 1573K, the relative density and micro-hardness of sintered sample increased. The sample sintered at 1573K showed the highest relative density of approximately 95% and a micro-hardness of 550 Hv.

-

Citations

Citations to this article as recorded by- Investigating molybdenum’s sulphur scavenging ability for MoS2 formation in preventing pitting corrosion of stainless steels

Kai Xiang Kuah, Daniel J. Blackwood

npj Materials Degradation.2023;[Epub] CrossRef

- Investigating molybdenum’s sulphur scavenging ability for MoS2 formation in preventing pitting corrosion of stainless steels

TOP

KPMI

KPMI

First

First Prev

Prev