Search

- Page Path

- HOME > Search

Critical Review

- [Korean]

- Research Trends in Magneto-Mechano-Electric (MME) Energy Harvesting Devices

- So Ie Jeong, Geon-Tae Hwang

- J Powder Mater. 2025;32(6):529-541. Published online December 31, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00493

- 756 View

- 8 Download

-

Abstract

Abstract

PDF

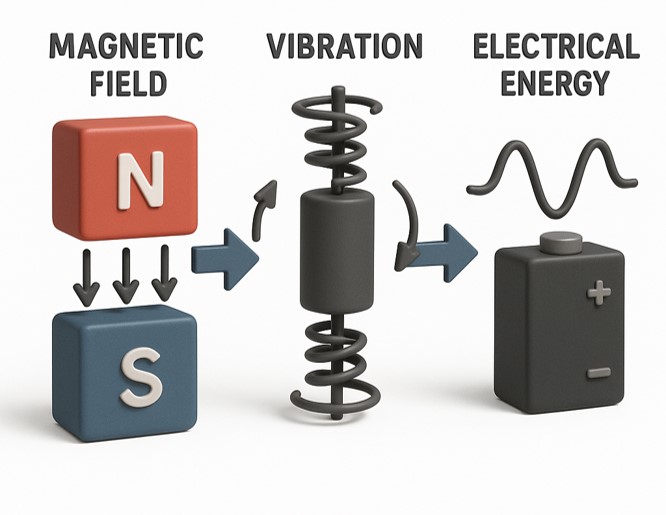

PDF - Magneto-mechano-electric (MME) energy harvesters have emerged as a promising solution for maintenance-free power generation in rapidly expanding Internet of Things (IoT) environments, where replacing or wiring batteries is impractical. MME devices convert weak alternating magnetic fields, ubiquitous around power infrastructures, into useful electrical energy through sequential magnetic, mechanical, and electrical transduction processes. This review summarizes recent advances across triboelectric-, piezoelectric-, and hybrid MME architectures. Triboelectric MME generators employing nano-engineered polymer surfaces, flash-induced surface modification, and nanoscale pattern replication demonstrate low-cost fabrication routes while achieving significantly enhanced voltage and current outputs. Piezoelectric MME systems based on Mn-doped PMN-PZT single crystals highlight strategies for improving mechanical quality factors and resonance-driven power generation. Further, hybrid MME designs that integrate piezoelectric and electromagnetic induction mechanisms enable high-power outputs exceeding tens of milliwatts, sufficient to operate multifunctional IoT platforms and charge practical energy-storage devices. Collectively, these studies illustrate a transition of MME harvesting technologies from laboratory concepts to application-ready self-powered systems. Future opportunities lie in broadband resonance design, modular harvester integration, advanced power management, and multi-source hybridization for robust long-term operation in real environments.

Research Articles

- [English]

- A Self-Powered Cationic Microfiber-Based Triboelectric Air Filter for High-Speed Particulate Matter Removal and Smart Monitoring

- Tae-hyung Kim, Jin-Kyeom Kim

- J Powder Mater. 2025;32(6):481-491. Published online December 31, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00465

- 818 View

- 4 Download

-

Abstract

Abstract

PDF

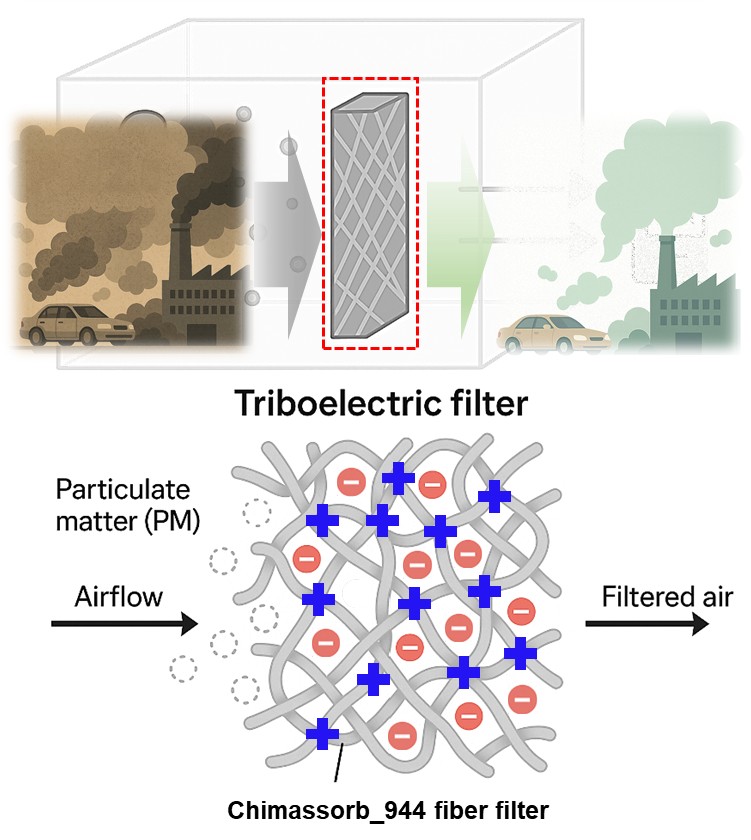

PDF - Particulate matter (PM) pollution demands air filters that combine high efficiency with low pressure drop. Here, we report a self-powered electrostatic filter based on an electrospun cationic microfiber web of Chimassorb 944 (C-fiber). The C-fiber functions as a triboelectric nanogenerator (TENG), generating a surface charge density of 85.8 85.8 μC/m2 when paired with polytetrafluoroethylene (PTFE), which creates a strong electrostatic field for capturing sub-micron particles, including the most penetrating particle size (MPPS). As a result, the triboelectrically charged C-fiber filter maintains >80% filtration efficiency at a high wind speed of 60 cm/s, far exceeding uncharged mechanical filters (<20%) while retaining low air resistance. Kelvin probe force microscopy (KPFM) visualizes the surface-potential change after particle capture, and the gradual decay of TENG output provides a built-in indicator of dust loading. This strategy offers a promising platform for next-generation smart air purification systems.

- [Korean]

- Preparation of Porous W-Cu by Freeze Casting of Tert-butyl Alcohol Slurry Mixed with WO3-CuO Powder

- Youngmin Kim, Ji Young Kim, Minju Son, Wonyong Kwon, Eui Seon Lee, Sung-Tag Oh

- J Powder Mater. 2025;32(6):466-471. Published online December 31, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00437

- 683 View

- 7 Download

-

Abstract

Abstract

PDF

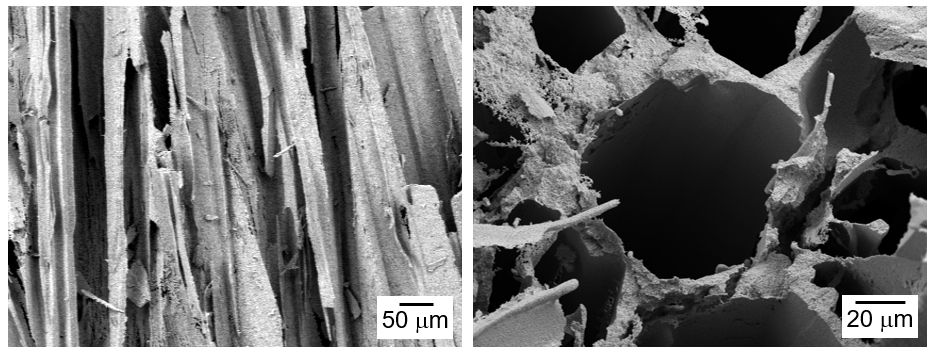

PDF - The influence of process conditions on the microstructure of porous W-Cu, fabricated by freeze casting using tert-butyl alcohol as the freezing agent, was investigated. The slurries containing 10 vol% of WO3-CuO powder were prepared by milling with a small amount of citric acid and polyethylene glycol as dispersants. The slurries with dispersion stability were frozen in a mold with the lower part cooled to -25°C, followed by sublimation in a vacuum to remove the freezing agent. The sintered W-1 vol% Cu in a hydrogen atmosphere exhibited aligned pores with the size of 50 μm, which were generated by sublimation of directionally solidified tert-butyl alcohol crystals. In the cross-section of the specimen, hexagonal pores corresponding to the crystal structure of tert-butyl alcohol was observed. Microstructure analysis of the struts revealed that Cu was distributed non-uniformly due to the mutual insolubility and low wettability of the W-Cu system.

- [Korean]

- Comparison of the Properties of Rare-Earth Zirconate Thermal Barrier Coatings for Hydrogen-Fueled Gas Turbines

- Gun-Woong Lee, Min-Soo Nam, Min-Ji Kim, HyunSuk Jung, Seongwon Kim

- J Powder Mater. 2025;32(6):472-480. Published online December 31, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00423

- 734 View

- 11 Download

-

Abstract

Abstract

PDF

PDF - Thermal barrier coatings (TBCs) for hydrogen-fueled gas turbines withstand higher combustion temperatures and increased steam concentrations compared to conventional natural-gas systems. These harsh operating conditions significantly accelerate the thermal degradation of widely used YSZ coatings, emphasizing the need for alternative top-coat materials with improved phase stability and reduced thermal conductivity. In this study, rare-earth zirconate ceramics, Gd2Zr2O7 (GdZO), Tm2Zr2O7 (TmZO), and a mixed composition (Gd0.5Tm0.5)2Zr2O7 (Gd/TmZO), are synthesized and investigated as potential next-generation TBC candidates. Each material was comparatively examined with a focus on crystal structure, thermophysical properties, and thermal conductivity. Furthermore, high-temperature steam exposure experiments were performed to simulate hydrogen combustion environments. Microstructural analyses, high-temperature degradation behavior, and phase stability evaluations were carried out to obtain fundamental experimental data. This study provides essential baseline information for the design and development of high-performance TBC materials suitable for the hydrogen-fueled gas turbine systems.

- [Korean]

- Enhancement of the Electrochemical Performance of SiOx Anodes by Al2O3 Coating via Powder Atomic Layer Deposition

- Donggeon Shin, Yoonsoo Han

- J Powder Mater. 2025;32(6):501-508. Published online December 31, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00416

- 663 View

- 6 Download

-

Abstract

Abstract

PDF

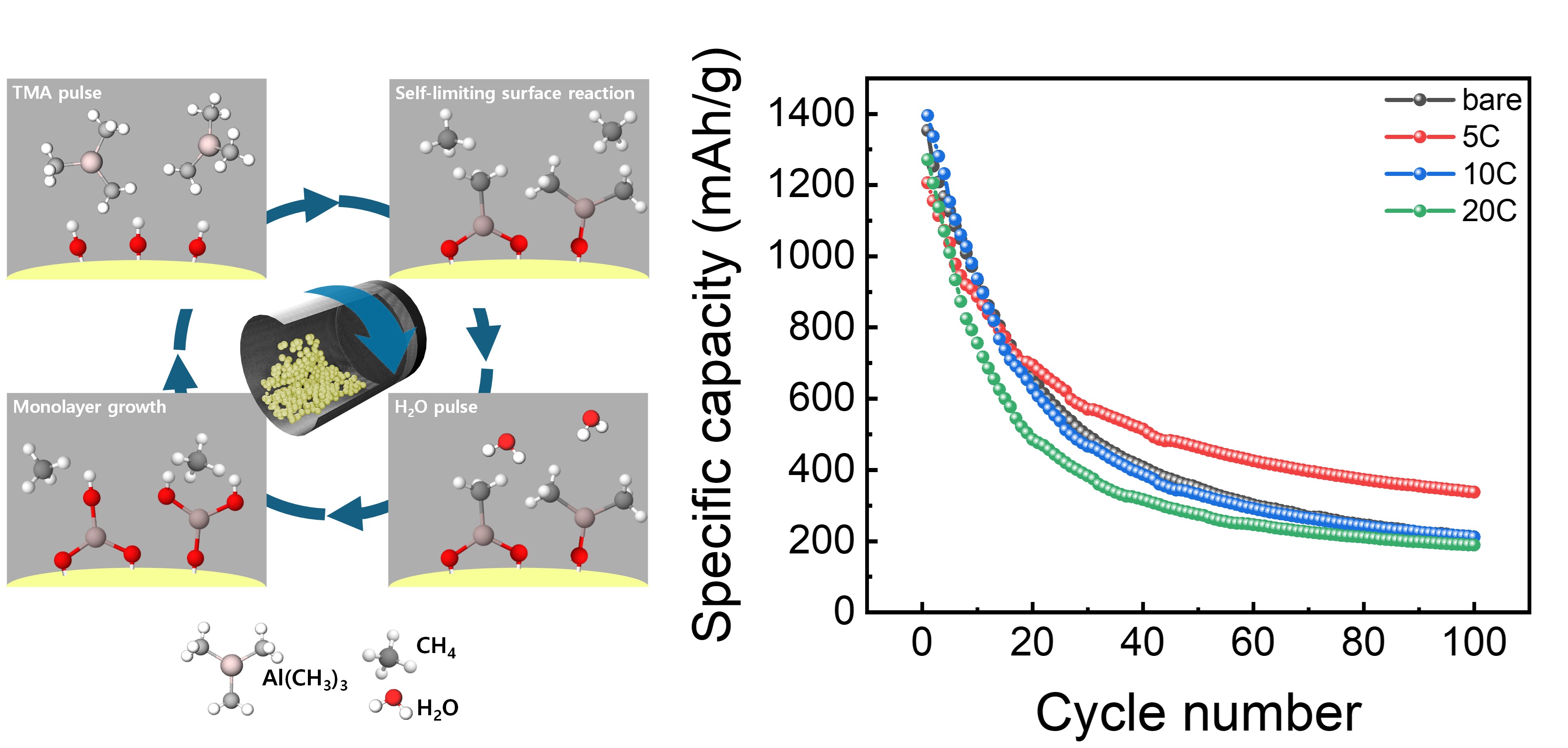

PDF - Silicon based anode materials offer high theoretical capacity but suffer from severe volume expansion and unstable interfacial properties during repeated lithiation and delithiation, resulting in rapid performance degradation. In this study, a thin aluminum oxide coating layer was deposited on Si/SiOx Carbon anode materials using a powder atomic layer deposition (PALD) process to address these limitations. EDS mapping and XRD analyses confirmed the uniform formation of an amorphous aluminum oxide coating with increasing thickness as the deposition cycles increased. Electrochemical evaluation showed that the electrode coated with 5 PALD cycles exhibited approximately 78% higher capacity retention after 100 cycles at 1 A g-1 and a higher initial Coulombic efficiency compared to the bare electrode. The coated electrode also delivered approximately 22% higher capacity at a high current density of 5 A g-1, indicating enhanced rate capability. Cyclic voltammetry analysis revealed increased surface controlled reaction contributions and improved reaction kinetics. These results demonstrate that PALD derived aluminum oxide coatings effectively stabilize the electrode electrolyte interface and enhance the electrochemical performance of silicon based anodes, highlighting their potential for next generation high capacity lithium ion batteries. generation high capacity lithium ion battery anode materials.

- [English]

- Finite Element and Discrete Element Analyses of Anisotropic Powder Compaction for Axial Flux Motor Cores

- Jeong Ah Lee, Do Won Lee, , Hyojeong Ha, Ki Hyuk Kwon, Eon Byeong Park, Taeyoung Kim, Hyoung Seop Kim

- J Powder Mater. 2025;32(6):451-458. Published online December 31, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00409

- 824 View

- 14 Download

-

Abstract

Abstract

PDF

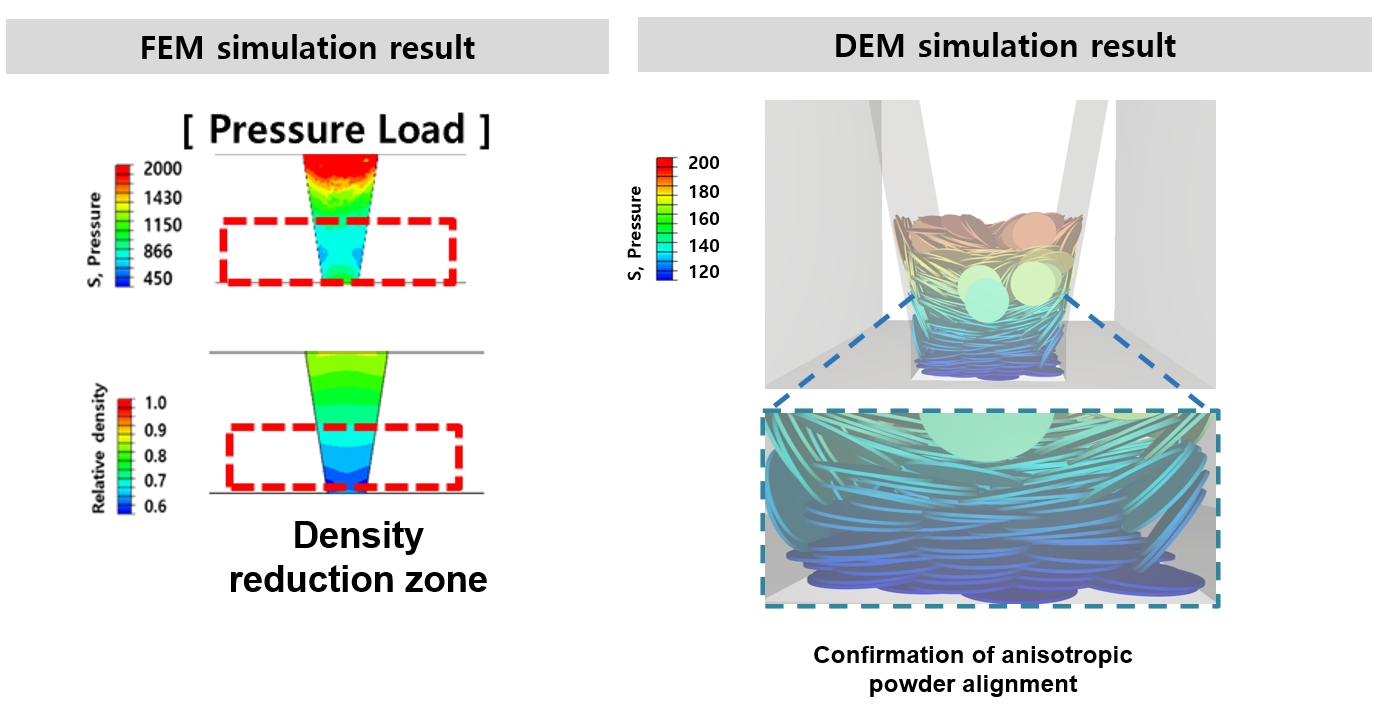

PDF - This study investigates the compaction behavior of anisotropic, plate-like powders used in axial flux motor cores through a combined FEM–DEM approach. A porous continuum FEM model captures stress and density evolution during die pressing, revealing strong gradients along the compaction direction, with higher stress and densification near the upper punch and reduced compaction in the lower region. Guided by these results, DEM simulations examine particle packing, orientation, and contact pressure in representative zones. The DEM analysis shows that higher local pressure promotes denser packing and in-plane particle alignment near the upper punch, while the lower region exhibits more random orientations and lower contact forces. As a result, the multi-scale FEM–DEM framework clarifies how anisotropic particle behavior governs local densification and offers practical guidance for die design and process optimization to achieve more uniform density and controlled magnetic-property-relevant particle alignment in axial flux motor cores.

Critical Review

- [Korean]

- Smelting and Recycling of Niobium

- Ho-Sang Sohn

- J Powder Mater. 2025;32(6):517-528. Published online December 31, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00367

- 683 View

- 7 Download

-

Abstract

Abstract

PDF

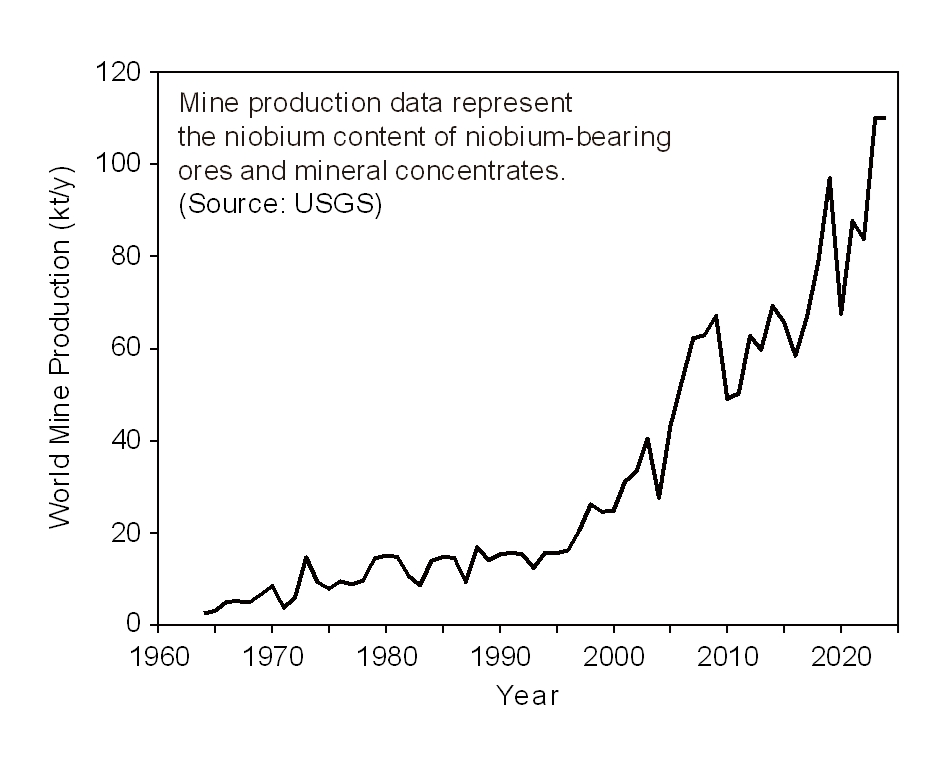

PDF - Global annual production of niobium is only around 100,000 tonnes; however, it is a critical metal for modern industry and is mined in only a limited number of regions. This study reviews the current status of niobium smelting and recycling technologies. Approximately 90% of niobium is produced as ferroniobium (FeNb) for use in steel alloys, although niobium is also utilized in superalloys, superconductors, capacitors, semiconductors, and other applications. Niobium coexists with tantalum in columbite and tantalite ores. These ores are decomposed by hydrofluoric acid digestion or alkali fusion, followed by solvent extraction to separate Nb2O5 and Ta2O5. Niobium metal and FeNb are produced from Nb2O5 primarily via aluminothermic reduction, although metallic niobium can also be manufactured by thermal reduction using Mg, Ca, or C, as well as by molten salt electrolysis. Crude niobium is subsequently refined into high-purity niobium through molten salt electrolytic refining, high-temperature vacuum treatment, and electron beam melting. Because most niobium is used as an alloying element in stainless steel and high-strength low-alloy steel, recycling practices for niobium remain poorly documented.

Research Articles

- [Korean]

- Microstructure and Mechanical Properties of AA3003 Tube for Heat Exchanger Processed by Floating Plug Drawing

- Hyeon-Jun Heo, Sung Jun Oh, Seong-Hee Lee

- J Powder Mater. 2025;32(6):459-465. Published online December 31, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00346

- 678 View

- 8 Download

-

Abstract

Abstract

PDF

PDF - An AA3003 tube was severely deformed by cold floating plug drawing, and then annealed at temperatures from 210 to 460℃. The as drawn Al tube exhibited a typical deformation structure in which the grains were greatly elongated along the drawing direction. The hardness increased with increasing the reduction of cross-sectional area (RA), became 68Hv after RA= 99%. Up to 310℃, the Al tube still mainly exhibited a deformed structure. While complete recrystallization occurred at temperatures above 360℃. The hardness decreased with increasing the annealing temperature, and it became 33Hv after annealing at 410℃. Both the tensile and yield strengths also decreased with increasing the annealing temperature, but the decrease was larger in yield strength than in tensile strength. The elongation increased with increasing the annealing temperature. The changes in the strength and the elongation with the annealing temperature were the largest at 360℃, in which the complete recrystallization occurred.

- [Korean]

- Ultrafast Synthesis of Molybdenum Disulfide via Flashlamp Annealing

- Chan Hyeon Yang, Jaehak Lee, Jung Hwan Park

- J Powder Mater. 2025;32(6):509-516. Published online December 31, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00339

- 645 View

- 4 Download

-

Abstract

Abstract

PDF

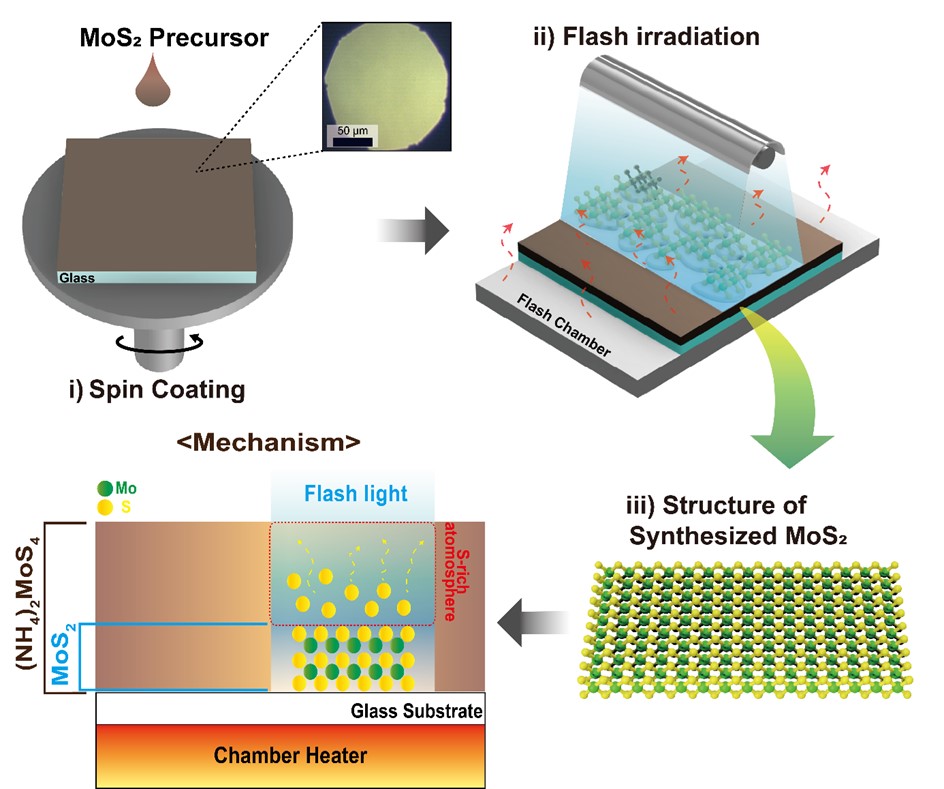

PDF - This study presents the synthesis of molybdenum disulfide (MoS₂) using flashlamp annealing and provides a comprehensive investigation of its structural and physical properties. The proposed flash-induced approach enables rapid production of high-quality MoS₂, offering superior process efficiency compared to conventional synthesis techniques. The structural, electronic, and thermal characteristics of the synthesized MoS₂ were systematically examined using multiple analytical methods, with particular attention to how synthesis conditions influence layer structure, crystallinity, and defect density. The results indicate that MoS₂ produced through this method exhibits material properties suitable for high-performance electronic devices and energy storage applications. Moreover, this work demonstrates the potential of flash-induced synthesis for scalable and practical fabrication of MoS₂-based nanomaterials, thereby contributing to the broader advancement of transition metal dichalcogenide technologies across diverse nanotechnology applications.

- [Korean]

- Laser-Induced Porous Graphene Electrodes for Flexible Heater

- Min Gi An, Jaehak Lee, Jung Hwan Park

- J Powder Mater. 2025;32(6):492-500. Published online December 31, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00332

- 703 View

- 5 Download

-

Abstract

Abstract

PDF

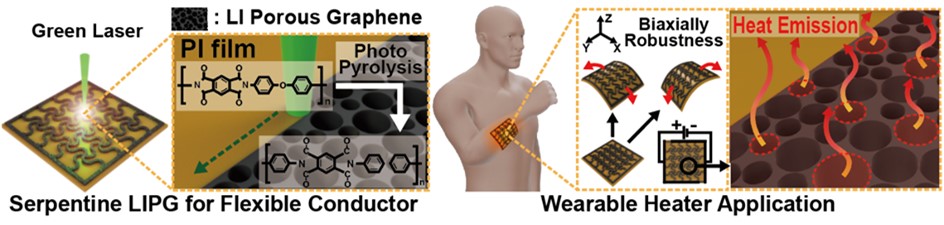

PDF - A flexible heater with high thermal efficiency and mechanical durability was developed by fabricating laser-induced porous graphene (LIPG) electrodes on polyimide films using a 532 nm green laser. Laser power, scan speed, and line distance were precisely optimized based on photothermal simulations to generate uniform porous graphene structures with large surface area and excellent heat dissipation characteristics. Raman, X-ray diffraction, and X-ray photoelectron spectroscopy analyses confirmed that the optimized LIPG exhibited highly graphitized features with low oxygen defects. Scanning electron microscope analysis revealed that porous morphologies formed only within a specific laser scan speed range, whereas excessive or insufficient irradiation resulted in collapsed or absent porosity. The serpentine-patterned LIPG heater maintained stable electrical resistance under repeated multidirectional bending, demonstrating excellent flexibility and mechanical stability. The heater also achieved rapid and uniform heating up to 80 °C within seconds, maintaining consistent temperature distribution even on curved surfaces.

- [Korean]

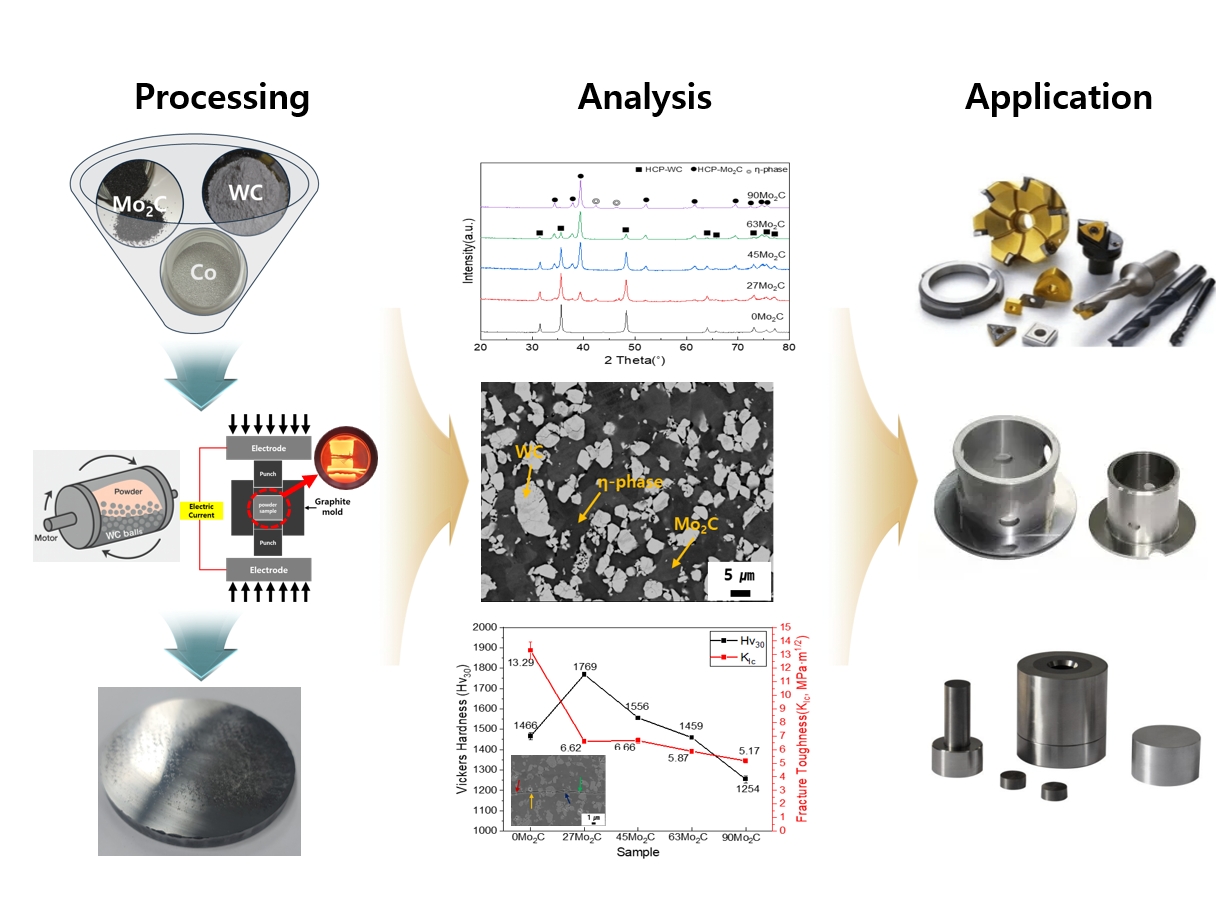

- Optimization of Mechanical Properties in WC–Mo₂C–Co Cemented Carbides via Dual Hard-Phase Based Heterogeneous Microstructure Design

- Jinwoo Seok, Jong Tae Kim, Juree Jung, SongYi Kim, Bin Lee, Junhee Han, Leeseung Kang

- J Powder Mater. 2025;32(5):428-436. Published online October 31, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00297

- 514 View

- 15 Download

-

Abstract

Abstract

PDF

PDF - WC–Mo₂C–Co cemented carbides were fabricated to investigate the effects of Mo₂C addition on microstructure and mechanical properties. Dual hard-phase design using WC and Mo₂C was employed to optimize the balance between hardness and toughness. Spark plasma sintering (SPS) was conducted at various temperatures after ball milling, and 1300 °C for 5 min was identified as the optimized sintering condition, achieving complete densification and phase stability. The addition of Mo₂C refined the microstructure by suppressing abnormal WC grain growth through preferential dissolution of Mo₂C into the Co binder. Hardness increased up to 1769 Hv30 due to grain refinement and solid-solution strengthening, while promoted η-phase formation and reduced fracture toughness.The 27Mo₂C composition exhibited the most balanced combination of hardness and toughness. These results demonstrate that controlled Mo₂C addition enables dual hard-phase strengthening and microstructure optimization in WC–Mo₂C–Co carbides for advanced cutting and forming applications.

- [Korean]

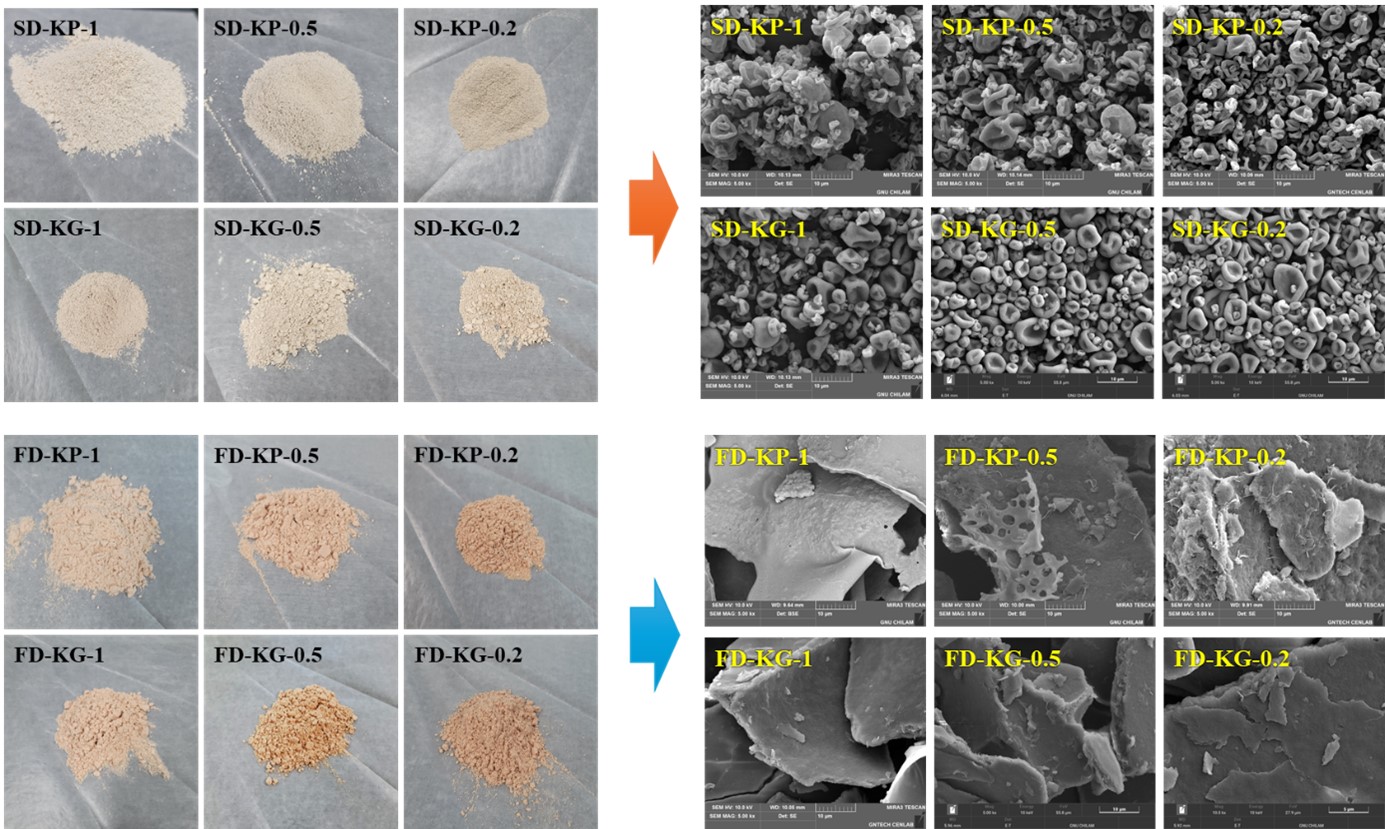

- Powderization Strategy for Porcine Organ By-Products: A Comparative Study on the Effects of Drying Method and Polymer Additives

- Seo Wan Yun, Eun Ju Jeong, Eui-Cheol Shin, Hyun-Wook Kim, Kyeong Soo Kim

- J Powder Mater. 2025;32(5):416-427. Published online October 31, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00269

- 536 View

- 11 Download

-

Abstract

Abstract

PDF

PDF - This study aimed to develop a powderization strategy using porcine by-products (kidney, liver, and heart) by evaluating the effects of raw material type, pretreatment, and additives (hydroxypropyl methyl cellulose P645 and gelatin) on powder characteristics. Powders from kidney tissue were analyzed for yield, particle structure, compressibility, and size distribution, based on the drying method and additive composition. The spray-dried sample with gelatin at 1:0.5 (w/w) showed 20.4% compressibility and the smallest, most uniform particles, indicating excellent flowability. Due to its superior structural stability, gelatin was selected over HPMC P645. Liver and heart samples that underwent enzymatic hydrolysis and the Maillard reaction were spray-dried with gelatin and assessed for yield and microstructure. The Alcalase-treated liver sample showed the highest yield. Surface analysis confirmed that gelatin formed a protective film enhancing particle stability. These findings suggest gelatin-based spray drying is effective for producing high-quality powders from protein-rich by-products.

- [Korean]

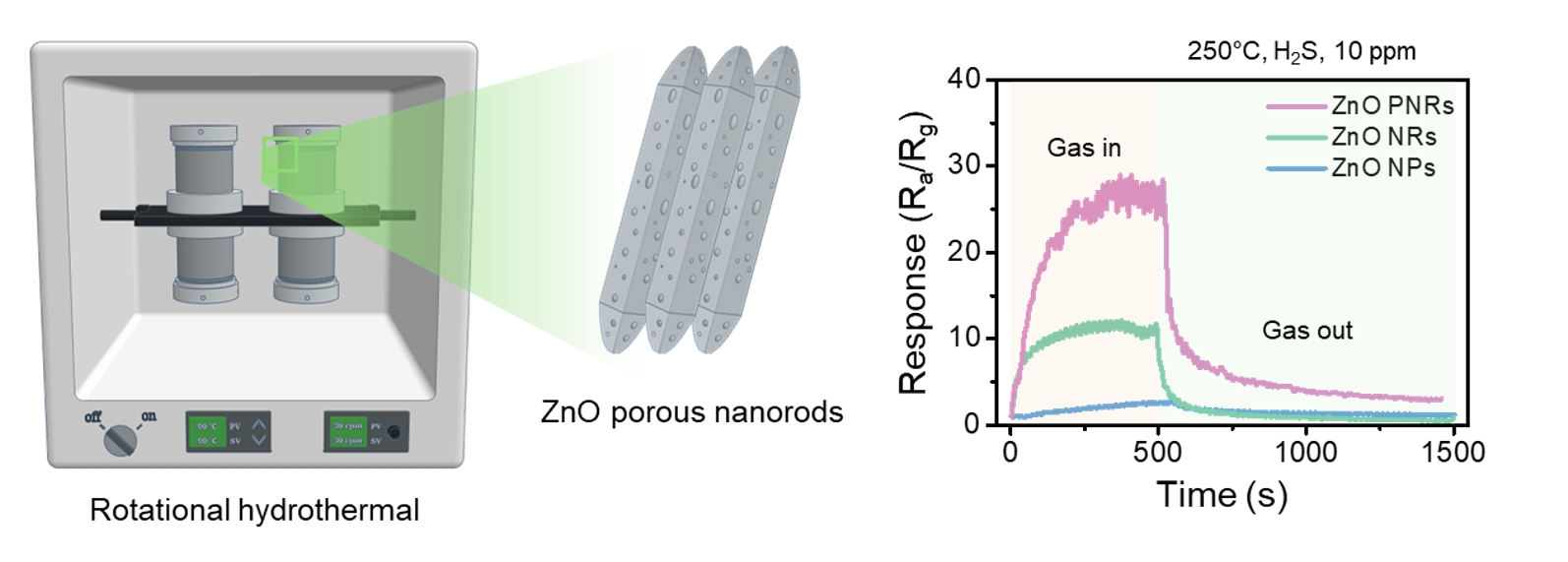

- Enhanced H2S Gas Sensing Using ZnO Porous Nanorod Synthesized via a Rotational Hydrothermal Method

- Jimyeong Park, Changyu Kim, Minseo Kim, Jiyeon Shin, Jae-Hyoung Lee, Myung Sik Choi

- J Powder Mater. 2025;32(5):406-415. Published online October 31, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00262

- 412 View

- 7 Download

-

Abstract

Abstract

PDF

PDF - In this study, ZnO porous nanorods were synthesised using a rotational hydrothermal process, and their performance as hydrogen sulphide (H2S) gas sensors was analysed. Compared to commercial ZnO nanoparticles and conventionally hydrothermally synthesised ZnO nanorods, the ZnO porous nanorods exhibited a more uniform structure and improved crystal growth in the (002) plane, with surfaces rich in porosity and oxygen vacancies. These structural and chemical characteristics significantly improved the sensitivity toward H2S, showing high detection performance at 250°C across various concentrations of H2S gas. Additionally, the sensor demonstrated excellent selectivity against other gases such as C2H5OH, C6H6, C7H8, and NH3. This study indicated that the rotational hydrothermal process is an effective method for developing high-performance ZnO-based gas sensors and suggests its applicability to other metal oxide materials.

- [English]

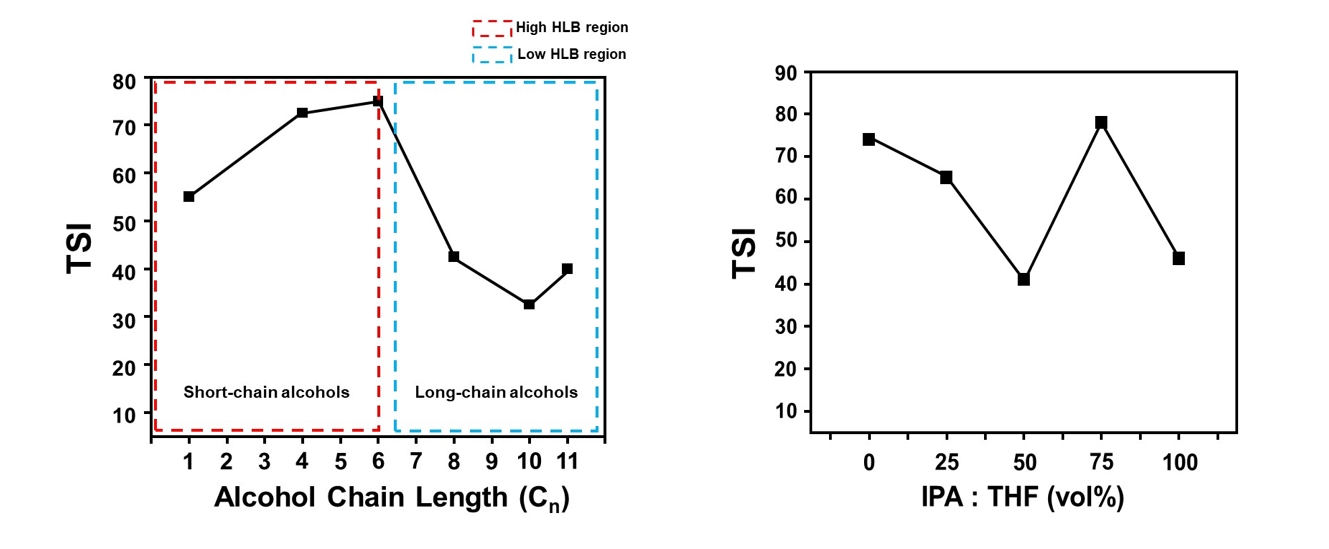

- Enhancing the Dispersion Stability of Exfoliated MoS2 Nanoflakes for Na⁺ Intercalation

- Jae Min Sung, Dong-Won Kyung, Ammad Ali, Kee-Ryung Park, Mi Hye Lee, Da-Woon Jeong, Bum Sung Kim, Haejin Hwang, Leeseung Kang, Yoseb Song

- J Powder Mater. 2025;32(5):390-398. Published online October 31, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00255

- 475 View

- 6 Download

-

Abstract

Abstract

PDF

PDF - This study investigated the dispersion stability of exfoliated MoS₂ nanoflakes in various organic solvents and binary mixtures using a Turbiscan optical analyzer. Sedimentation behavior was quantitatively evaluated via transmittance variation (ΔT), backscattering variation (ΔBS), and the Turbiscan stability index (TSI). Alcohol-based solvents were categorized by hydrophilic-lipophilic balance values. Long-chain alcohols, such as 1-undecanol, showed increased stability due to high viscosity and strong hydrophobic affinity with MoS2 basal planes, while short-chain alcohols exhibited poor stabilization. Binary mixtures of isopropanol (IPA) and tetrahydrofuran (THF) were also assessed, with the 5:5 volume ratio showing the best stability profile, including the lowest TSI and minimal ΔT and ΔBS values. This improvement is attributed to synergistic interactions, as IPA stabilizes hydrophilic edge sites, while THF engages with hydrophobic basal surfaces. These findings highlight the importance of balancing physicochemical properties when selecting solvents to improve MoS2 dispersion for structural modification and electrocatalytic applications.

- [English]

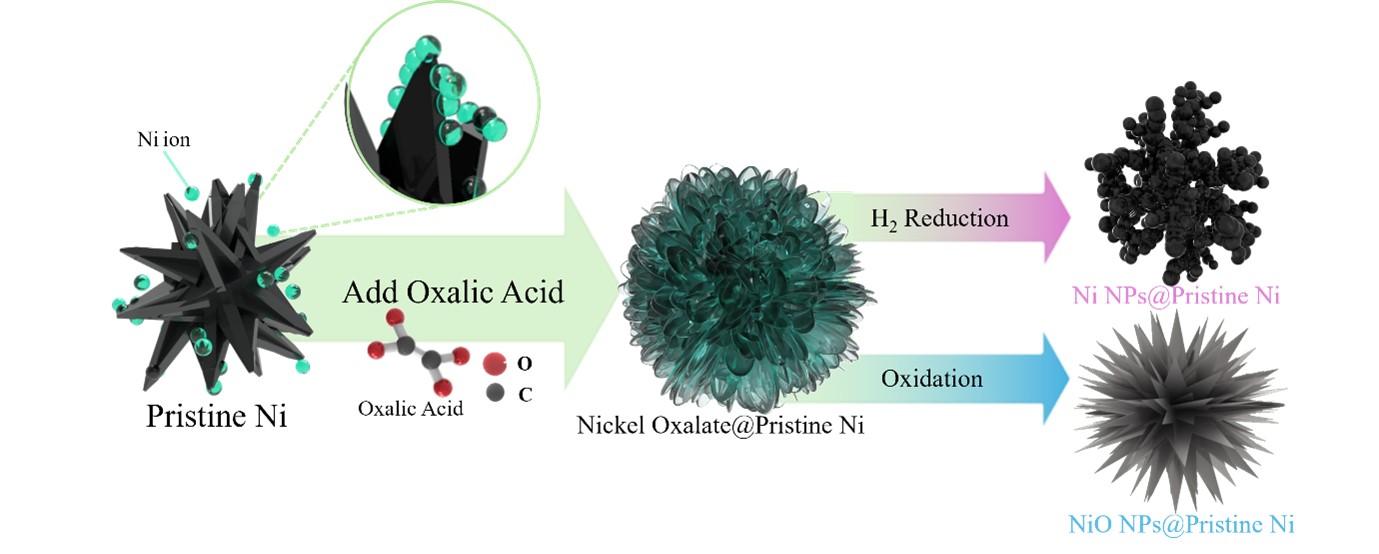

- Morphological Control and Surface Modification Characteristics of Nickel Oxalate Synthesized via Oxalic Acid Precipitation

- Eunbi Park, Jongwon Bae, Sera Kang, Minsu Kang, Suseong Lee, Kun-Jae Lee

- J Powder Mater. 2025;32(5):375-382. Published online October 31, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00248

- 1,084 View

- 21 Download

-

Abstract

Abstract

PDF

PDF - Nickel is widely used in industrial fields such as electrocatalysis and energy storage devices. Although micron-sized nickel particles exhibit excellent mechanical durability, their low specific surface area limits their reactivity. We modified the surface of micron-sized nickel particles with nanostructured nickel oxalate and investigated the effects of the solvent dielectric constant, surfactant, and thermal treatment atmosphere on the resulting particle morphology and phase transformation. Rietveld refinement analysis confirmed that changes in the solvent dielectric constant led to increased or diminished crystallinity of specific planes in nickel oxalate, resulting in diffraction patterns distinct from standard JCPDS data. These structural changes were also found to influence the morphology of the synthesized nickel oxalate. The results demonstrate that nickel oxalate serves as an effective precursor for producing Ni and NiO phases, and shape control of the final product can increase the surface reactivity of micron-sized nickel materials.

- [English]

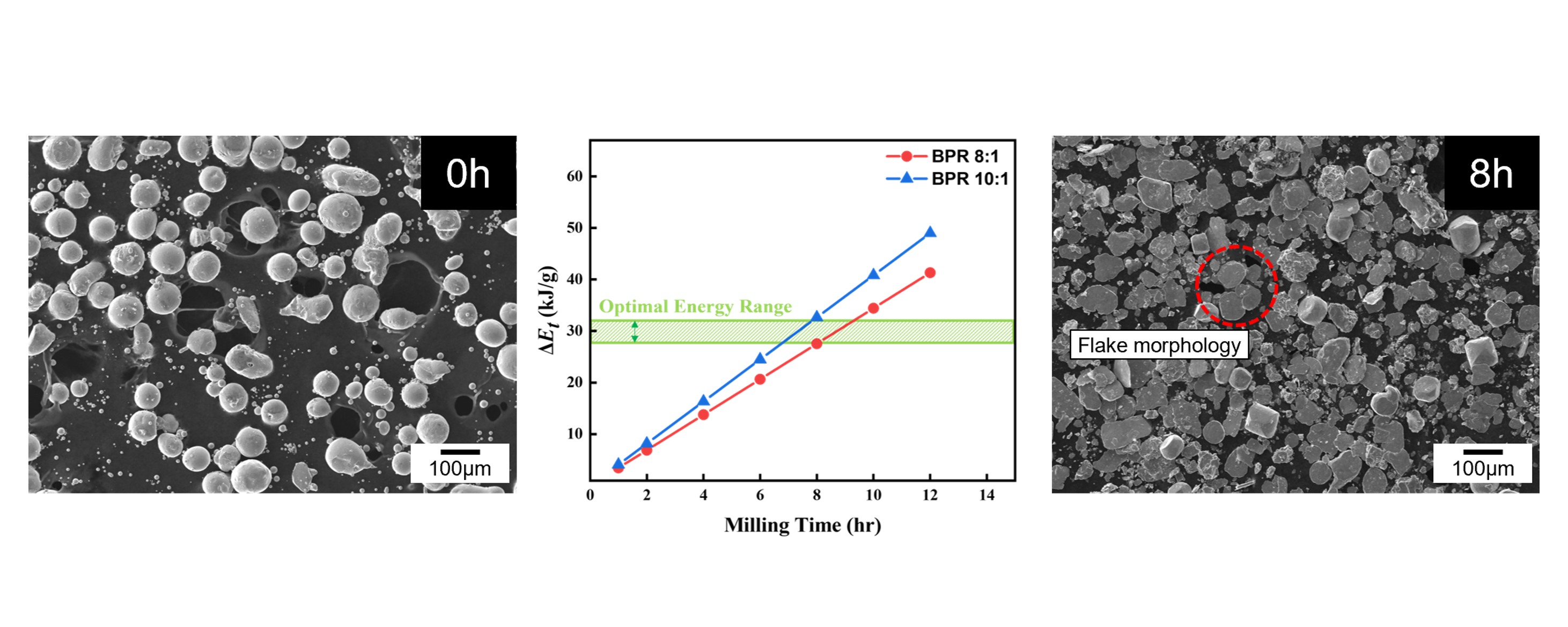

- Preparation of Flake-shape Cobalt Powders by High-Energy Ball Milling for rSOC Current Collectors

- Poong-Yeon Kim, Min-Jeong Lee, Hyeon Ju Kim, Su-Jin Yun, Si Young Chang, Jung-Yeul Yun

- J Powder Mater. 2025;32(5):383-389. Published online October 31, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00241

- 436 View

- 24 Download

-

Abstract

Abstract

PDF

PDF - Reversible solid oxide cells (rSOCs), which enable two-way conversion between electricity and hydrogen, have gained attention with the rise of hydrogen energy. However, foam-type current collectors in rSOC stacks exhibit poor structural controllability and limited electrode contact area. To address these limitations, this study aimed to convert spherical cobalt powders into flake-type morphology via high-energy ball milling, as a preliminary step toward fabricating flake-based current collectors. Milling parameters—specifically, the ball-to-powder ratio (BPR), milling time, and process control agent (PCA) content—were varied. At an 8:1 BPR, over 90% of the powder became flake-shaped after 8 hours, while extended milling caused cold welding. In contrast, a 10:1 BPR resulted in dominant fragmentation. The Burgio–Rojac model quantified energy input and defined the optimal range for flake formation. Increasing the PCA to 4 wt% delayed flake formation to 16 hours and induced cold welding, as shown by bimodal particle size distributions. These results support the development of Co-based current collectors for use in rSOCs.

- [Korean]

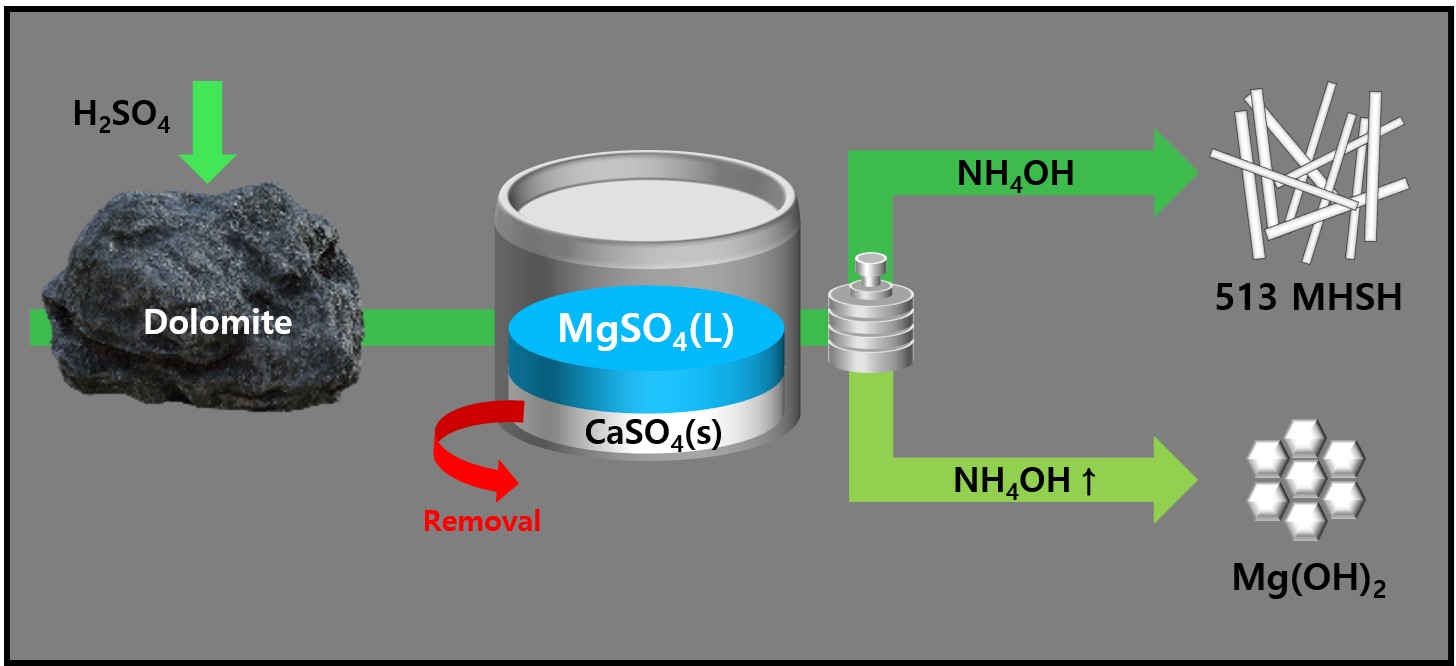

- Synthesis and Morphology Control of Needle Type 513 MHSH and Mg(OH)2 from Dolomite

- Jiyeon Kim, HyunSeung Shim, Seong-Ju Hwang, YooJin Kim

- J Powder Mater. 2025;32(5):399-405. Published online October 31, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00227

- 413 View

- 7 Download

-

Abstract

Abstract

PDF

PDF - 513 magnesium hydroxide sulfate hydrate (MHSH) and Mg(OH)₂ were synthesized by controlling the pH and concentration using a domestic resource, dolomite (CaMg(CO3)2), as the raw material. The MgSO₄ was extracted by treating dolomite with sulfuric acid under various conditions. Hexagonal plate-shaped Mg(OH)₂ and needle-like 513 MHSH were synthesized under the hydrothermal condition. The morphology of the synthesized materials was controlled by adjusting the pH (SO42-/OH- ratio) and hydrothermal reaction time. As the pH of the solution increased, the formation of plate-like structures became dominant, whereas lower pH values (higher SO42- concentration) led to needle-like forms. The results of the 513 MHSH, which was synthesized using reagents and sea bittern, are consistent with the synthesis conditions, and we observed changes in the length and aspect ratio of the needle-shaped structure in response to adjusting the hydrothermal reaction time.

- [English]

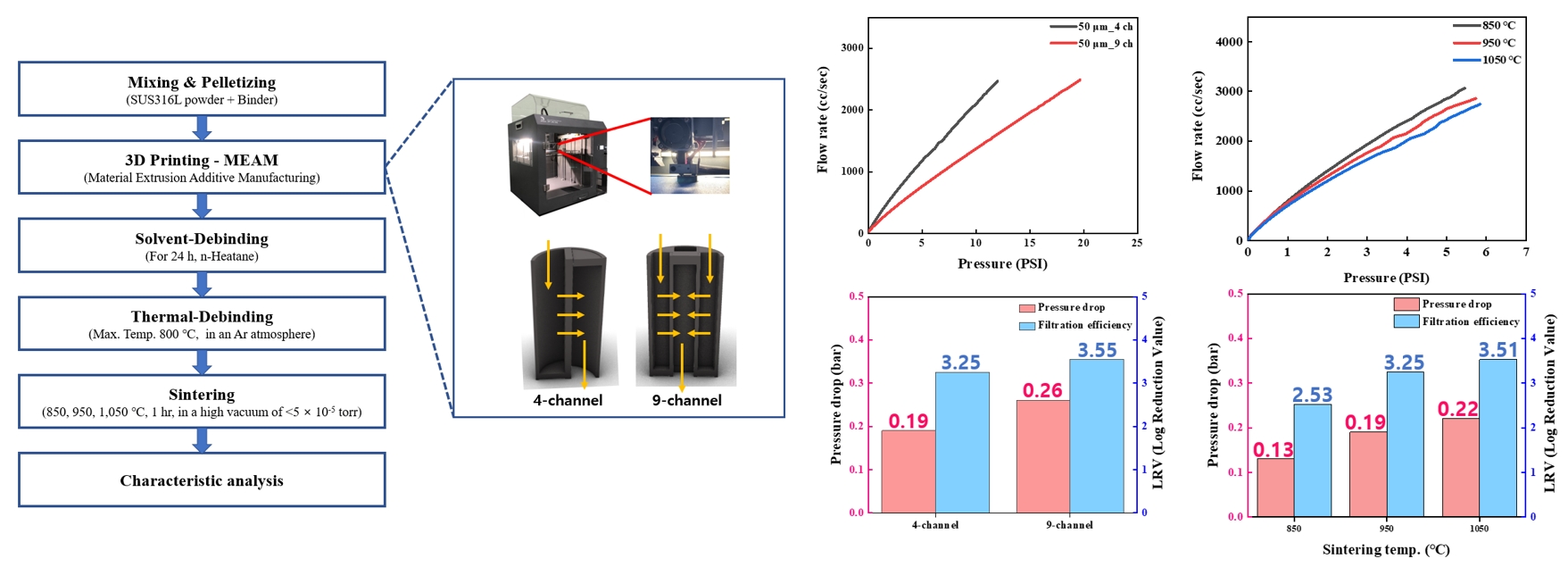

- Fabrication and Pore Characteristics of Metal Powder Filters with a Cross-Sealed Honeycomb Shape Using Material Extrusion Additive Manufacturing

- Minji Kim, Min-Jeong Lee, Su-Jin Yun, Poong-Yeon Kim, Hyeon Ju Kim, Juyong Kim, Jung Woo Lee, Jung-Yeul Yun

- J Powder Mater. 2025;32(4):299-308. Published online August 29, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00234

- 957 View

- 26 Download

-

Abstract

Abstract

PDF

PDF - The development of high-performance metal filters is essential for maintaining ultra-clean environments in semiconductor manufacturing. In this study, cross-sealed honeycomb filters were fabricated using STS316L powder via material extrusion additive manufacturing (MEAM) for semiconductor gas filtration. The effects of filter geometry (4 or 9 channels) and sintering temperature (850°C, 950°C, or 1,050°C) on performance were examined. First, 4-channel and 9-channel filters sintered at the same temperature (950°C) exhibited similar porosities of 50.08% and 50.57%, but the 9-channel filter showed a higher pressure-drop (0.26 bar) and better filtration-efficiency (3.55 LRV) than the 4-channel filter (0.19 bar and 3.25 LRV, respectively). Second, for filters with the same geometry (4-channel) increasing the sintering temperature reduced porosity from 64.52% to 40.33%, while the pressure-drop increased from 0.13 bar to 0.22 bar and filtration-efficiency improved from 2.53 LRV to 3.51 LRV. These findings demonstrate that filter geometry and sintering temperature are key factors governing the trade-off between air permeability, pressure-drop, and filtration efficiency. This work provides insights and data for optimizing MEAM-based high-performance metal powder filter design.

- [Korean]

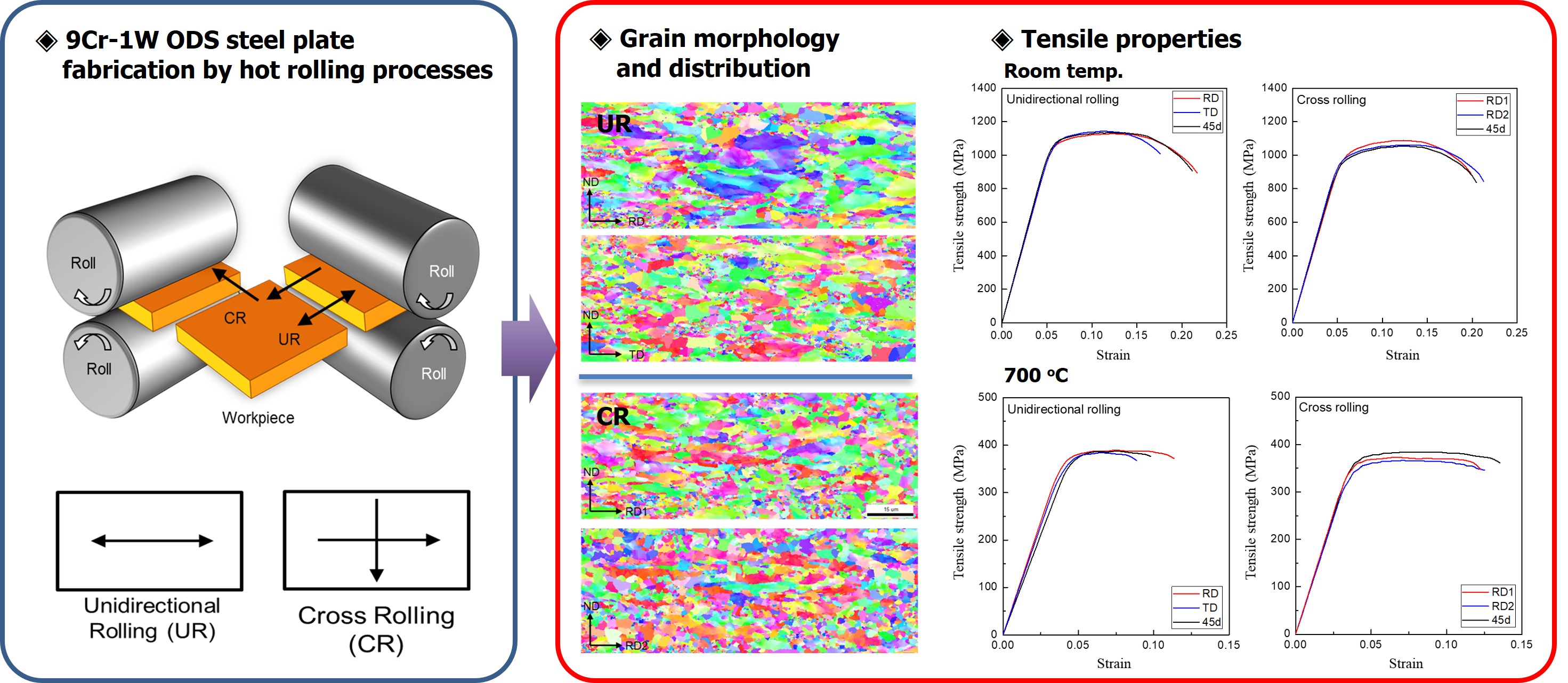

- Effect of Fe and Cr on ω Phase Formation in Metastable β-Ti Alloy

- Sun-Young Park, Young-Bum Chun

- J Powder Mater. 2025;32(4):354-360. Published online August 29, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00220

- 996 View

- 15 Download

-

Abstract

Abstract

PDF

PDF - This study investigated the effects of Fe and Cr contents on ω phase formation and transformation during solution treatment and the subsequent aging process, for which four model alloys with varying Fe and Cr contents but keeping Mo equivalent of ~ 12.6 were prepared by plasma arc melting and fabricated into plates by hot forging followed by hot-rolling. The atherrmal ω phase was observed in all Ti alloys after solution treatment followed by water quenching through XRD and TEM analysis. The largest volume fraction of athermal ω phase is formed in Ti alloy with only Fe 4 wt.% among all Ti alloys, leading to the highest Vickers value due to hardening effect ω phase. It was found that not only Mo equivalent but also each characteristic of β stabilizing elements should be considered to understand a microstructure evolution and mechanical properties.

- [English]

- Cost-effective Fabrication of Near β-Ti Alloy via L-PBF: Process Optimization of In-situ Alloying Ti-3Fe

- Sehun Kim, Ukju Gim, Taehu Kang, Jongik Lee, Sanghee Jeong, Jimin Han, Bin Lee

- J Powder Mater. 2025;32(4):288-298. Published online August 29, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00213

- 1,141 View

- 23 Download

-

Abstract

Abstract

PDF

PDF - This study presents a cost-effective approach to fabricating near β-Ti alloys via in-situ alloying during laser powder bed fusion (L-PBF). A blend of non-spherical pure Ti, 3 wt.% Fe, and 0.1 wt.% SiO2 nanoparticles was used to induce β-phase stabilization and improve flowability. Twenty-five process conditions were evaluated across a volumetric energy density range of 31.75-214.30 J/mm3, achieving a maximum relative density of 99.21% at 89.29 J/mm3. X-ray diffraction analysis revealed that the β-Ti phase was partially retained at room temperature, accompanied by lattice contraction in the α’-Ti structure, indicating successful Fe incorporation. Elemental mapping confirmed that the Fe distribution was homogeneous, without significant segregation. Compared to pure Ti, the Ti-3Fe sample exhibited a 49.2% increase in Vickers hardness and notable improvements in yield and ultimate tensile strengths. These results demonstrate the feasibility of in-situ alloying with low-cost elemental powders to produce high-performance near β-Ti alloys using L-PBF.

- [Korean]

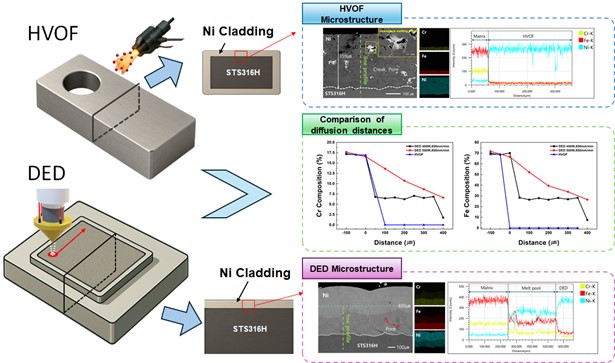

- Evaluation of Mechanical Properties of Pure Ni Coatings on a Type 316H Stainless Steel Substrate via High-Velocity Oxy-fuel and Directed Energy Deposition Processes

- Won Chan Lee, Seung Ju Nam, Ji-Hyun Yoon, Jeoung Han Kim

- J Powder Mater. 2025;32(4):309-314. Published online August 29, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00185

- 825 View

- 9 Download

-

Abstract

Abstract

PDF

PDF - This study compares pure Ni coatings deposited on type 316H stainless steel using high-velocity oxy-fuel (HVOF) and directed energy deposition (DED) processes. Microstructural analysis showed that DED produced more uniform claddings with fewer pores, while HVOF resulted in incomplete melting and cracks. Elemental diffusion of Cr and Fe from the substrate into the cladding was evident in DED samples, especially at higher laser power, but minimal in HVOF due to low heat input. Vickers hardness testing revealed that DED claddings had higher hardness near the interface, which was attributed to solid solution strengthening and reduced porosity. Although HVOF better suppressed diffusion, it exhibited inferior mechanical properties due to internal defects. Overall, the DED process demonstrated superior coating quality and mechanical performance, suggesting its suitability for corrosion-resistant applications requiring both structural integrity and thermal stability, such as molten salt reactors.

- [Korean]

- Influence of Powder Particle Size on the Microstructure of UO2 Fuel Pellets with High Gd2O3 Content

- Ji-Hwan Lee, Jae Ho Yang, Ji-Hae Yoon, Dong-Joo Kim, Dong-wook Shin, Dong Seok Kim

- J Powder Mater. 2025;32(4):344-353. Published online August 29, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00178

- 1,006 View

- 25 Download

-

Abstract

Abstract

PDF

PDF - The recent development of small modular reactors (SMRs) and the adoption of higher-enrichment fuels have intensified the need for advanced burnable absorbers to ensure effective reactivity control and extended fuel cycles. Among various designs, UO2 fuels with high Gd2O3 (gadolinium oxide) content provide notable benefits; in particular, they are compatible with established fabrication methods for burnable absorber fuels. However, achieving a homogeneous dispersion of Gd2O3 at high loading levels remains challenging, and the frequent occurrence of phase segregation and non-uniform microstructures can limit fuel reliability and performance. Overcoming these limitations requires an understanding of the powder characteristics and mixing behaviors during fabrication. In this study, we investigate the effects of the initial particle size and mixing method of UO2 and Gd2O3 powders on the microstructure and mixing homogeneity of high-Gd2O3-content fuels. The findings indicate that both the mixing method and the preparation state of the starting powders significantly affect the resulting microstructure and mixing uniformity.

- [Korean]

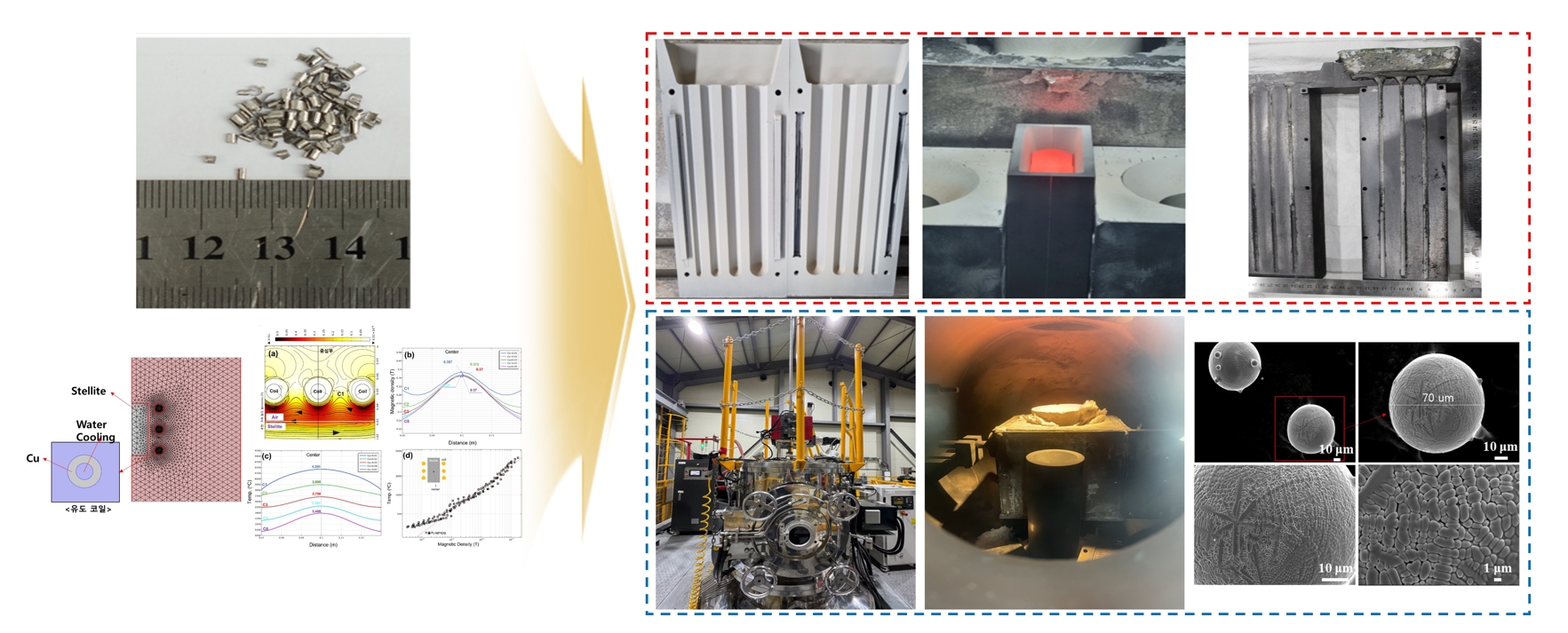

- The Recycling Process and Powderization Technology of Stellite 6 Scrap: A Thermodynamic and Heat Transfer Analysis

- YongKwan Lee, Hyun-chul Kim, Myungsuk Kim, Soong Ju Oh, Kyoungtae Park, JaeJin Sim

- J Powder Mater. 2025;32(4):330-343. Published online August 29, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00136

- 1,083 View

- 14 Download

-

Abstract

Abstract

PDF

PDF - Co-Cr alloys are widely used in cutting tools and turbine components due to their high strength and resistance against wear and corrosion. However, scrap generated during hardfacing is often discarded due to impurities and oxidation, and research on its recycling remains limited. This study aimed to optimize the recycling process of Stellite 6 scrap to reduce waste and minimize costs while maintaining material quality. Melting, casting, and powdering processes were designed using HSC Chemistry, FactSage, and COMSOL Multiphysics, with optimization of key parameters such as the crucible material and temperature control. The recycled alloy and powder were analyzed using X-ray fluorescence analysis, inductively coupled plasma optical emission spectroscopy, and X-ray diffractometry, showing mechanical and chemical properties comparable to commercial Stellite 6. The Co and Cr contents were maintained, with a slight increase in Fe. These findings demonstrate the potential for producing high-quality recycled Stellite 6 materials, contributing to the sustainable utilization of metal resources in high-performance applications.

- [English]

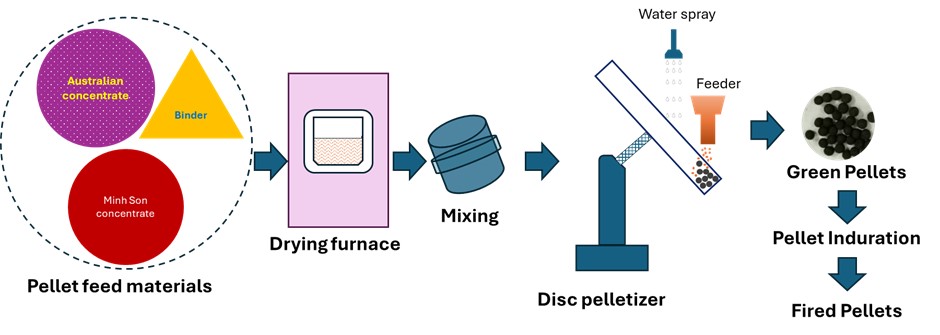

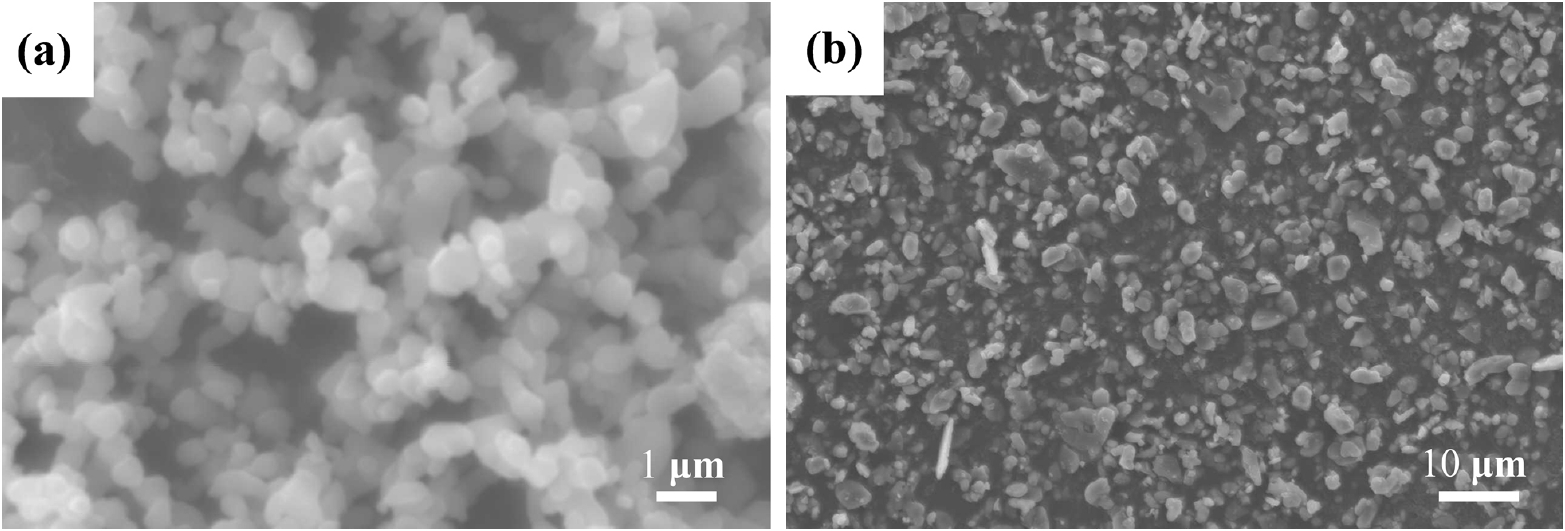

- Enhanced Compressive Strength of Fired Iron Ore Pellets: Effects of Blending Fine and Coarse Particle Concentrates

- Ngo Quoc Dung, Tran Xuan Hai, Nguyen Minh Thuyet, Nguyen Quang Tung, Arvind Barsiwal, Nguyen Hoang Viet

- J Powder Mater. 2025;32(4):315-329. Published online August 29, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00129

- 1,809 View

- 70 Download

-

Abstract

Abstract

PDF

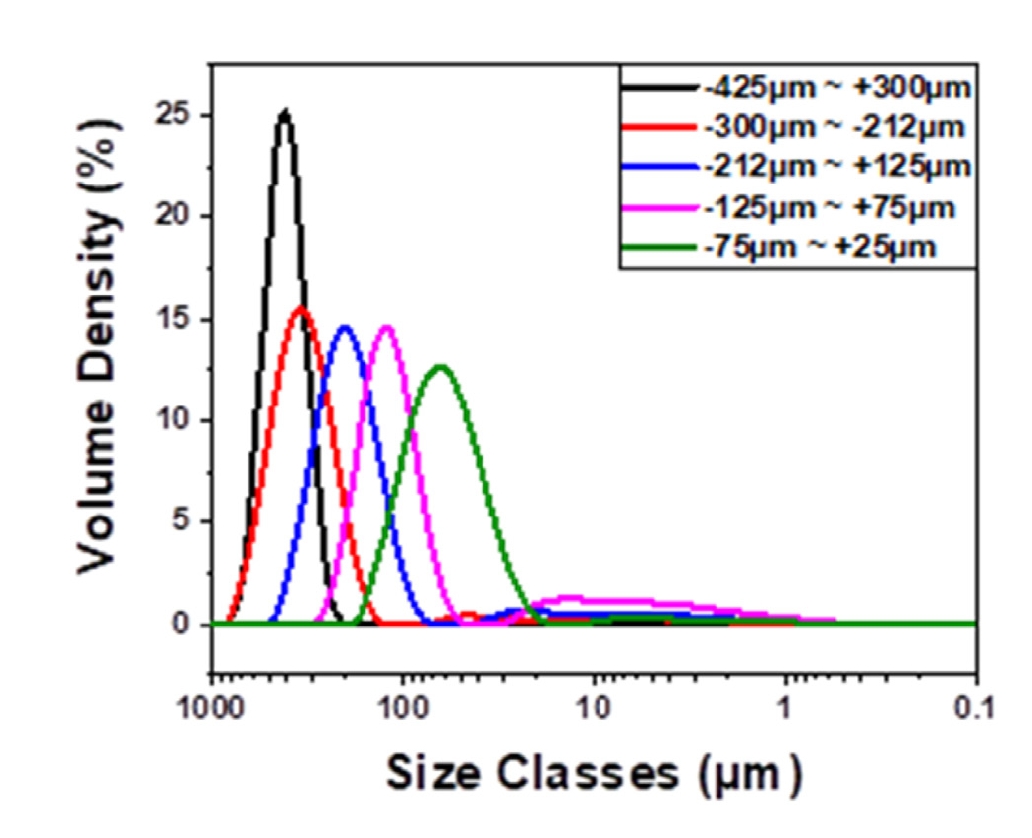

PDF - This study investigated the effects of oxidative firing parameters and raw material characteristics on the pelletization of Australian and Minh Son (Vietnam) iron ore concentrates. The influence of firing temperature (1050°C–1150°C) and holding time (15–120 min) on pellet compressive strength was examined, focusing on microstructural changes during consolidation. Green pellets were prepared using controlled particle size distributions and bentonite as a binder. Scanning electron microscopy and energy-dispersive X-ray spectroscopy analyses revealed that grain boundary diffusion, liquid phase formation, and densification significantly improved mechanical strength. X-ray diffraction confirmed the complete oxidation of magnetite to hematite at elevated temperatures, a critical transformation for metallurgical performance. Optimal firing conditions for both single and blended ore compositions yielded compressive strengths above 250 kgf/pellet, satisfying the requirements for blast furnace applications. These results provide valuable guidance for improving pellet production, promoting the efficient utilization of diverse ore types, and enhancing the overall performance of ironmaking operations.

- [English]

- Laser Processing of an Al0.1CoCrFeNi High Entropy Alloy + Cu Composite Powders via Laser Powder Bed Fusion

- Kwangtae Son, Ji-Woon Lee, Soon-Jik Hong, Somayeh Pasebani

- J Powder Mater. 2025;32(4):277-287. Published online August 29, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00101

- 1,103 View

- 25 Download

-

Abstract

Abstract

PDF

PDF - This study examined process–structure relationships in laser powder bed fusion of Al₀.₁CoCrFeNi + Cu composites, focusing on densification, elemental distribution, and solidification cracking. Mechanically mixed Al₀.₁CoCrFeNi and Cu powders were processed across a range of laser powers (100–250 W) and scan speeds (200–800 mm/s). Increased volumetric energy density (VED) improved densification, with a plateau near 200 J/mm³ yielding ~96% relative density; however, this value was still below application-grade thresholds. At low VED, insufficient thermal input and short melt pool residence times promoted Cu segregation, while higher VED facilitated improved elemental mixing. Elemental mapping showed partial co-segregation of Ni with Cu at low energies. Solidification cracks were observed across all processing conditions. In high VED regimes, cracking exhibited a minimal correlation with segregation behavior and was primarily attributed to steep thermal gradients, solidification shrinkage, and residual stress accumulation. In contrast, at low VED, pronounced Cu segregation appeared to exacerbate cracking through localized thermal and mechanical mismatch.

- [Korean]

- The Manufacturing Process of Clean Ni-Cr-Co-Based Superalloy Powder Using a Plasma Rotating Electrode

- Kyu-Sik Kim, Dae Woong Kim, Yeontae Kim, Jung Hyo Park

- J Powder Mater. 2025;32(3):222-231. Published online June 30, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00171

- 760 View

- 23 Download

-

Abstract

Abstract

PDF

PDF - Ni-based superalloys are widely used for critical components in aerospace, defense, industrial power generation systems, and other applications. Clean superalloy powders and manufacturing processes, such as compaction and hot isostatic pressing, are essential for producing superalloy discs used in turbine engines, which operate under cyclic rotating loads and high-temperature conditions. In this study, the plasma rotating electrode process (PREP), one of the most promising methods for producing clean metallic powders, is employed to fabricate Ni-based superalloy powders. PREP leads to a larger powder size and narrower distribution compared to powders produced by vacuum induction melt gas atomization. An important finding is that highly spheroidized powders almost free of satellites, fractured, and deformed particles can be obtained by PREP, with significantly low oxygen content (approximately 50 ppm). Additionally, large grain size and surface inclusions should be further controlled during the PREP process to produce high-quality powder metallurgy parts.

- [English]

- SnF2-Induced LiF Interphase for Stable Lithium Metal Anodes with Suppressed Dendrite Growth

- Yeong Hoon Jeon, Seul Ki Choi, Yun Seung Nah, Wonil Shin, Yong-Ho Choa, Minho Yang

- J Powder Mater. 2025;32(3):212-221. Published online June 30, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00164

- 1,735 View

- 53 Download

-

Abstract

Abstract

PDF

PDF - Lithium (Li) metal is a promising anode for next-generation batteries due to its high capacity, low redox potential, and low density. However, dendrite growth and interfacial instability limit its use. In this study, an artificial solid electrolyte interphase layer of LiF and Li-Sn (LiF@Li-Sn) was fabricated by spray-coating SnF2 onto Li. The LiF@Li-Sn anode exhibited improved air stability and electrochemical performance. Electrochemical impedance spectroscopy indicated a charge transfer resistance of 25.2 Ω after the first cycle. In symmetric cells, it maintained a low overpotential of 27 mV after 250 cycles at 2 mA/cm2, outperforming bare Li. In situ microscopy confirmed dendrite suppression during plating. Full cells with NMC622 cathodes and LiF@Li-Sn anodes delivered 130.8 mAh/g with 79.4% retention after 300 cycles at 1 C and 98.8% coulombic efficiency. This coating effectively stabilized the interface and suppressed dendrites, with promising implications for practical lithium metal batteries.

- [English]

- The Effect of Aluminum Powder Size on the Structure and Mechanical Properties of Foam

- Seunghyeok Choi, Sungjin Kim, Tae-Young Ahn, Yu-Song Choi, Jae-Gil Jung, Seung Bae Son, Seok-Jae Lee

- J Powder Mater. 2025;32(3):232-243. Published online June 30, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00157

- 1,345 View

- 51 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF - In this study, we analyzed the structural and mechanical properties of aluminum foams fabricated using aluminum powders of varying sizes and mixtures. The effects of sintering and pore structure at each size on the integrity and mechanical properties of the foams were investigated. Structural characteristics were examined using scanning electron microscopy and micro–computed tomography, while mechanical properties were evaluated through compression testing. The experimental results demonstrated that smaller powder sizes improved foam integrity, reduced porosity and pore size, and resulted in thinner cell walls. In combination, these effects increased compressive strength as the powder size decreased. The findings of this study contribute to the understanding and improvement of the mechanical properties of aluminum foams and highlight their potential for use in a wide range of applications.

-

Citations

Citations to this article as recorded by- Sustainable Manufacturing of Graphene–Aluminum Composites: A Comparative Life Cycle Assessment

Xinwei Yang, Qian Peng, Changke Chen, Qingcui Liu, Yudai Huang

Journal of Sustainable Metallurgy.2026; 12(1): 727. CrossRef

- Sustainable Manufacturing of Graphene–Aluminum Composites: A Comparative Life Cycle Assessment

- [Korean]

- Development of Aluminum Alloys for Additive Manufacturing Using Machine Learning

- Sungbin An, Juyeon Han, Seoyeon Jeon, Dowon Kim, Jae Bok Seol, Hyunjoo Choi

- J Powder Mater. 2025;32(3):202-211. Published online June 30, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00150

- 768 View

- 49 Download

-

Abstract

Abstract

PDF

PDF - The present study introduces a machine learning approach for designing new aluminum alloys tailored for directed energy deposition additive manufacturing, achieving an optimal balance between hardness and conductivity. Utilizing a comprehensive database of powder compositions, process parameters, and material properties, predictive models—including an artificial neural network and a gradient boosting regression model, were developed. Additionally, a variational autoencoder was employed to model input data distributions and generate novel process data for aluminum-based powders. The similarity between the generated data and the experimental data was evaluated using K-nearest neighbor classification and t-distributed stochastic neighbor embedding, with accuracy and the F1-score as metrics. The results demonstrated a close alignment, with nearly 90% accuracy, in numerical metrics and data distribution patterns. This work highlights the potential of machine learning to extend beyond multi-property prediction, enabling the generation of innovative process data for material design.

- [English]

- Thermodynamic and Electronic Descriptor-Driven Machine Learning for Phase Prediction in High-Entropy Alloys: Experimental Validation

- Nguyen Lam Khoa, Nguyen Duy Khanh, Hoang Thi Ngoc Quyen, Nguyen Thi Hoang Oanh, , Le Hong Thang, Nguyen Hoa Khiem, Nguyen Hoang Viet

- J Powder Mater. 2025;32(3):191-201. Published online June 30, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00143

- 2,382 View

- 76 Download

- 3 Citations

-

Abstract

Abstract

PDF

PDF - High-entropy alloys (HEAs) exhibit complex phase formation behavior, challenging conventional predictive methods. This study presents a machine learning (ML) framework for phase prediction in HEAs, using a curated dataset of 648 experimentally characterized compositions and features derived from thermodynamic and electronic descriptors. Three classifiers—random forest, gradient boosting, and CatBoost—were trained and validated through cross-validation and testing. Gradient boosting achieved the highest accuracy, and valence electron concentration (VEC), atomic size mismatch (δ), and enthalpy of mixing (ΔHmix) were identified as the most influential features. The model predictions were experimentally verified using a non-equiatomic Al₃₀Cu₁₇.₅Fe₁₇.₅Cr₁₇.₅Mn₁₇.₅ alloy and the equiatomic Cantor alloy (CoCrFeMnNi), both of which showed strong agreement with predicted phase structures. The results demonstrate that combining physically informed feature engineering with ML enables accurate and generalizable phase prediction, supporting accelerated HEA design.

-

Citations

Citations to this article as recorded by- Effect of annealing temperature on thermal expansion and cryogenic mechanical properties of low-thermal-expansion Co22.2Cr6.2Fe48.8Ni17.8Cu5.0 medium-entropy alloy

Wooyoung Lee, Munsu Choi, Sungwook Kim, Dae-Kyeom Kim, Myungsuk Song, Taek-Soo Kim, Jungwan Lee, Hyoung Seop Kim, Hyunjoo Choi, Soo-Hyun Joo

Materials Science and Engineering: A.2026; 954: 149811. CrossRef - Preparation and Arc Erosion Behavior of Cu-Based Contact Materials Reinforced with High Entropy Particles CuCrNiCoFe

Jiacheng Tong, Jun Wang, Huimin Zhang, Haoran Liu, Youchang Sun, Zhiguo Li, Wenyi Zhang, Zhe Wang, Yanli Chang, Zhao Yuan, Henry Hu

Metallurgical and Materials Transactions B.2025; 56(5): 5948. CrossRef - Recent progresses on high entropy alloy development using machine learning: A review

Abhishek Kumar, Nilay Krishna Mukhopadhyay, Thakur Prasad Yadav

Computational Materials Today.2025; 8: 100038. CrossRef

- Effect of annealing temperature on thermal expansion and cryogenic mechanical properties of low-thermal-expansion Co22.2Cr6.2Fe48.8Ni17.8Cu5.0 medium-entropy alloy

- [English]

- Self-Assembled Monolayers in Area-Selective Atomic Layer Deposition and Their Challenges

- Si Eun Jung, Ji Woong Shin, Ye Jin Han, Byung Joon Choi

- J Powder Mater. 2025;32(3):179-190. Published online June 30, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00094

- 4,679 View

- 174 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF - Area-selective atomic layer deposition (AS-ALD) is a bottom-up process that selectively deposits thin films onto specific areas of a wafer surface. The surface reactions of AS-ALD are controlled by blocking the adsorption of precursors using inhibitors such as self-assembled monolayers (SAMs) or small molecule inhibitors. To increase selectivity during the AS-ALD process, the design of both the inhibitor and the precursor is crucial. Both inhibitors and precursors vary in reactivity and size, and surface reactions are blocked through interactions between precursor molecules and surface functional groups. However, challenges in the conventional SAM-based AS-ALD method include thermal instability and potential damage to substrates during the removal of residual SAMs after the process. To address these issues, recent studies have proposed alternative inhibitors and process design strategies.

-

Citations

Citations to this article as recorded by- Temperature-Dependent Surface Structural Change in Self-Assembled Monolayers Studied with Vibrational Sum-Frequency Generation and QM/MD Simulation

Hojeong Yoon, Saima Sadiq, Junhyeok Park, Kyungwon Kwak, Minhaeng Cho

The Journal of Physical Chemistry Letters.2026; 17(4): 1119. CrossRef

- Temperature-Dependent Surface Structural Change in Self-Assembled Monolayers Studied with Vibrational Sum-Frequency Generation and QM/MD Simulation

- [Korean]

- Effect of Support Structure on Residual Stress Distribution in Ti-6Al-4V Alloy Fabricated by Laser Powder Bed Fusion

- Seungyeon Lee, Haeum Park, Min Jae Baek, Dong Jun Lee, Jae Wung Bae, Ji-Hun Yu, Jeong Min Park

- J Powder Mater. 2025;32(3):244-253. Published online June 30, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00087

- 1,077 View

- 46 Download

-

Abstract

Abstract

PDF

PDF - Ti-6Al-4V alloy is widely utilized in aerospace and medical sectors due to its high specific strength, corrosion resistance, and biocompatibility. However, its low machinability makes it difficult to manufacture complex-shaped products. Advancements in additive manufacturing have focused on producing high-performance, complex components using the laser powder bed fusion (LPBF) process, which is a specialized technique for customized geometries. The LPBF process exposes materials to extreme thermal conditions and rapid cooling rates, leading to residual stresses within the parts. These stresses are intensified by variations in the thermal history across regions of the component. These variations result in differences in microstructure and mechanical properties, causing distortion. Although support structure design has been researched to minimize residual stress, few studies have conducted quantitative analyses of stress variations due to different support designs. This study investigated changes in the residual stress and mechanical properties of Ti-6Al-4V alloy fabricated using LPBF, focusing on support structure design.

- [Korean]

- Fabrication and Alloying Behavior of Ultra-Lightweight AlTiCrVMg High-Entropy Alloy via Al-Mg Mutual Solubility and Sintering Control

- Eunhyo Song, Hansung Lee, Byungmin Ahn

- J Powder Mater. 2025;32(3):254-261. Published online June 12, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00059

- 650 View

- 23 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF - High-entropy alloys (HEAs) incorporating low-melting-point elements (Mg and Al) and high-melting-point elements (Ti, Cr, and V) were fabricated via mechanical alloying and spark plasma sintering. Sintering temperatures were varied to investigate phase behavior and microstructural evolution. X-ray diffraction was used to identify phase structures, scanning electron microscopy to analyze microstructures, X-ray fluorescence to determine elemental composition, and a gas pycnometer to measure density. Micro-Vickers hardness testing was conducted to evaluate mechanical properties. Mechanical-alloyed HEAs exhibited a body-centered cubic (BCC) phase and lamellar structures with element-enriched regions. Sintering introduced additional BCC and Laves phases, while higher temperatures promoted Mg liquid-phase sintering, increasing density and hardness. This study highlights the effects of sintering on HEAs containing elements with differing melting points to optimize their properties.

-

Citations

Citations to this article as recorded by- Effect of annealing temperature on thermal expansion and cryogenic mechanical properties of low-thermal-expansion Co22.2Cr6.2Fe48.8Ni17.8Cu5.0 medium-entropy alloy

Wooyoung Lee, Munsu Choi, Sungwook Kim, Dae-Kyeom Kim, Myungsuk Song, Taek-Soo Kim, Jungwan Lee, Hyoung Seop Kim, Hyunjoo Choi, Soo-Hyun Joo

Materials Science and Engineering: A.2026; 954: 149811. CrossRef

- Effect of annealing temperature on thermal expansion and cryogenic mechanical properties of low-thermal-expansion Co22.2Cr6.2Fe48.8Ni17.8Cu5.0 medium-entropy alloy

- [Korean]

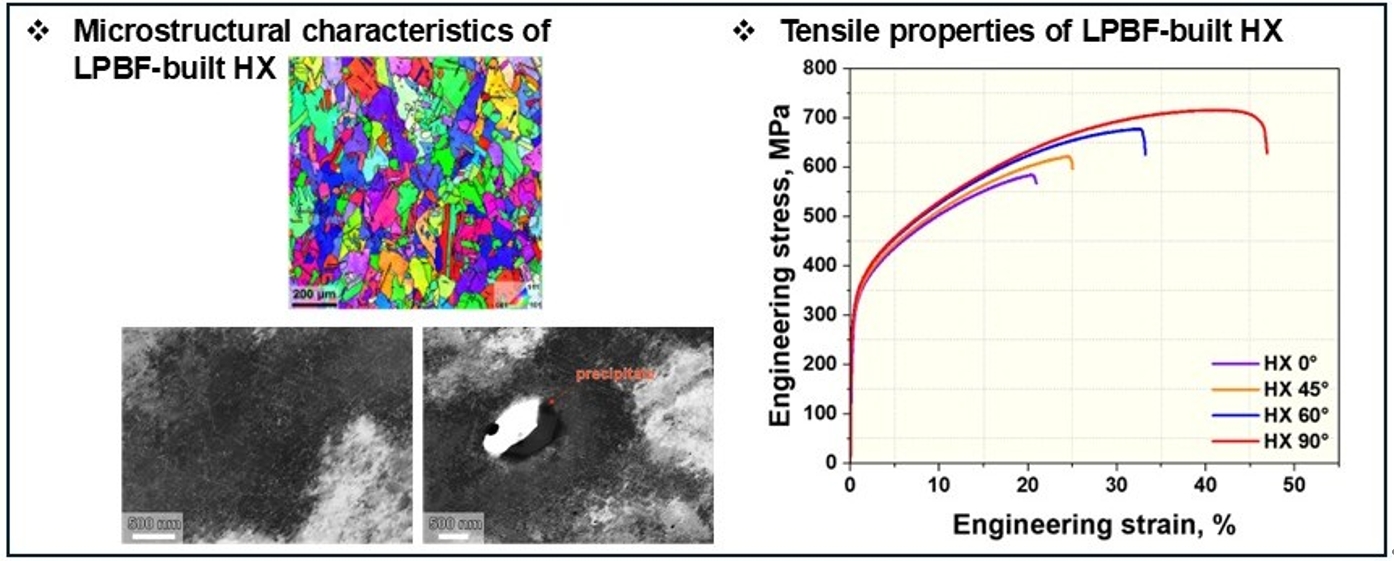

- Effect of Building Orientation on Tensile Properties of Hastelloy X alloy Manufactured by Laser Powder Bed Fusion

- Seong-June Youn, GooWon Noh, Seok Su Sohn, Young-Sang Na, Young-Kyun Kim

- J Powder Mater. 2025;32(2):131-137. Published online April 30, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00080

- 1,122 View

- 32 Download

-

Abstract

Abstract

PDF

PDF - In this study, the effect of build orientation on the mechanical properties of Hastelloy X fabricated by laser powder bed fusion (LPBF) process was investigated. Initial microstructural analysis revealed an equiaxed grain structure with random crystallographic orientation and annealing twins. Intragranular precipitates identified as Cr-rich M23C6 and Mo-rich M6C carbides were observed, along with a dense dislocation network and localized dislocation accumulation around the carbides. Mechanical testing showed negligible variation in yield strength with respect to build orientation; however, both ultimate tensile strength and elongation exhibited a clear increasing trend with higher build angles. Notably, the specimen built at 90° exhibited approximately 22% higher tensile strength and more than twice the elongation compared to the 0° specimen.

- [Korean]

- Extraction of MgSO4 from dolomite and synthesis of Mg(OH)2 in Bittern

- HyunSeung Shim, Jiyeon Kim, Areum Choi, Nuri Oh, YooJin Kim

- J Powder Mater. 2025;32(2):122-130. Published online April 30, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00073

- 907 View

- 32 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF - We synthesized magnesium hydroxide using bittern and dolomite, which are domestic resources. In Bittern, there is a high concentration of Mg2+ ions, but the impurity Ca2+ ion content is also significant, requiring a purification process to remove it. There are two main methods for this purification. Firstly, there is a separation method that utilizes the difference in solubility between Mg2+ ions and Ca2+ ions by using sulfuric acid on dolomite. Adding MgSO4 solution from dolomite to Bittern removes Ca2+ ions as CaSO4. This process simultaneously purifies Ca impurities and increases the Mg/Ca ratio by adding extra Mg2+ ions. In this study, purified bittern was obtained by using dolomite and sulfuric acid to extract MgSO4, which was then used to purify Ca2+ ions. High-purity Mg(OH)2 was synthesized by optimizing the NaOH and NH4OH ratio as an alkaline precipitant.

-

Citations

Citations to this article as recorded by- Synthesis and Morphology Control of Needle Type 513 MHSH and Mg(OH)2 from Dolomite

Jiyeon Kim, HyunSeung Shim, Seong-Ju Hwang, YooJin Kim

Journal of Powder Materials.2025; 32(5): 399. CrossRef

- Synthesis and Morphology Control of Needle Type 513 MHSH and Mg(OH)2 from Dolomite

- [English]

- Ultra-Low-Temperature (4.2 K) Tensile Properties and Deformation Mechanism of Stainless Steel 304L Manufactured by Laser Powder Bed Fusion

- Seung-Min Jeon, Young-Sang Na, Young-Kyun Kim

- J Powder Mater. 2025;32(2):95-103. Published online April 30, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00066

- 1,892 View

- 57 Download

- 3 Citations

-

Abstract

Abstract

PDF

PDF - This study investigated the ultra-low-temperature (4.2 K) tensile properties and deformation mechanisms of stainless steel 304L manufactured via laser powder bed fusion (LPBF). The tensile properties of LPBF 304L were compared to those of conventional 304L to assess its suitability for cryogenic applications. The results revealed that LPBF 304L exhibited a significantly higher yield strength but lower ultimate tensile strength and elongation than conventional 304L at 4.2 K. The temperature dependence of the yield strength also favored LPBF 304L. Microstructural analysis demonstrated that LPBF 304L features a high density of dislocation cells and nano-inclusions, contributing to its greater strength. Furthermore, strain-induced martensitic transformation was observed as a key deformation mechanism at cryogenic temperatures, where austenite transformed into both hexagonal-closed packed (HCP) and body-centered cubic (BCC) martensite. Notably, BCC martensite nucleation occurred within a single HCP band. These findings provide critical insights into the mechanical behavior of LPBF 304L at cryogenic temperatures and its potential for applications in extreme environments.

-

Citations

Citations to this article as recorded by- Extremely low-temperature tensile behavior of 316L stainless steel additively manufactured by laser powder bed fusion

Haeum Park, Heechan Jung, Min Young Sung, Young-Kyun Kim, Jaimyun Jung, Yoona Lee, Namhyun Kang, Kyung Tae Kim, Young-Sang Na, Seok Su Sohn, Jeong Min Park

Materials Science and Engineering: A.2026; 950: 149460. CrossRef - Twinning- and transformation-induced high cryogenic strength and ductility of the CoCrFeNi high-entropy alloy: Experiment and MD simulation

Yuze Wu, Zhide Li, Charlie Kong, M.W. Fu, Hailiang Yu

International Journal of Plasticity.2026; 196: 104553. CrossRef - Understanding the unique appearance behavior of shear bands during tensile deformation of α-brass at 4.2 K

Seon-Keun Oh, Sang-Hun Shim, Young-Kyun Kim, Young-Sang Na

Materials Science and Engineering: A.2025; 945: 148989. CrossRef

- Extremely low-temperature tensile behavior of 316L stainless steel additively manufactured by laser powder bed fusion

- [Korean]

- Effect of Cellulose Fiber Density Variation on Energy Harvesting Performance in a Hydrovoltaic Generator

- Seung-Hwan Lee, So Hyun Baek, Hyun-Woo Lee, Yongbum Kwon, Kanghyuk Lee, Kee-Ryung Park, Yoseb Song, Bum Sung Kim, Ji Young Park, Yong-Ho Choa, Da-Woon Jeong

- J Powder Mater. 2025;32(2):113-121. Published online April 30, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00052

- 1,260 View

- 34 Download

-

Abstract

Abstract

PDF

PDF - Energy harvesting has become a crucial technology for sustainable energy solutions; in particular, the utilization of ambient water movement in hydrovoltaic generators has emerged as a promising approach. However, optimizing performance requires an understanding of structural factors affecting energy harvesting, particularly capillary effects. This study aimed to improve hydrovoltaic generator performance by adjusting internal fiber density, which influences water transport and ion mobility. Using cold isostatic pressing, cellulose acetate (CA) loading in a urethane mold was varied to optimize internal density. As CA loading increased, the fiber arrangement became denser, narrowing capillary pathways and reducing proton mobility. While open-circuit voltage (VOC) remained stable, short-circuit current (ISC) decreased with higher CA mass. The sample with a loading of 0.3 g exhibited the highest energy harvesting efficiency, achieving ISC = 107.2 μA, VOC = 0.15 V, and power (P) = 16.7 μW. This study provides insights into methods of improving hydrovoltaic generator efficiency through internal structural modifications.

- [Korean]

- Effect of the Initial Porosity of Needle Coke-Pitch Carbonized Blocks on Impregnation-Related Physical Properties

- U-Sang Youn, Sang-Hye Lee, Jae-Seung Roh

- J Powder Mater. 2025;32(2):138-144. Published online April 30, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00038

- 703 View

- 14 Download

-

Abstract

Abstract

PDF

PDF - Carbonized blocks with different porosities were prepared by varying the particle size of the filler and subsequent impregnation. The impregnated carbonized blocks were re-carbonized. The use of smaller particles in the filler in the carbonized block was associated with larger porosity, smaller pore size, and a higher impregnation ratio. The block with the smallest average particle size (53 μm), CB-53, had a porosity of 35.9% and pores of approximately 40 μm, while the block with the largest average particle size (413 μm), CB-413, had a porosity of 30.5% and pores of approximately 150 μm. CB-53 had the highest bulk density, electrical resistivity, flexural strength, and impregnation ratio. This is due to the large porosity, which is believed to be due to the presence of more interfaces between particles during the re-carbonization of the impregnated carbonized block, resulting in a better pore-filling effect.

- [English]

- Stretch-Flangeability of Laser Powder Bed Fusion-Processed 316L Stainless Steel

- Rae Eon Kim, Yeon Taek Choi, Sang Guk Jeong, Do Won Lee, Hyoung Seop Kim

- J Powder Mater. 2025;32(2):87-94. Published online April 30, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00017

- 2,254 View

- 23 Download

-

Abstract

Abstract

PDF

PDF Supplementary Material

Supplementary Material - Metal additive manufacturing (AM) facilitates the production of complex geometries with enhanced functionality. Among various AM techniques, laser powder bed fusion (LPBF) is distinguished by its precision and exceptional mechanical properties achieved via laser fusion deposition. Recent advancements in AM have focused on combining LPBF with post-processing methods such as cold rolling, high-pressure torsion, and forming processes. Therefore, understanding the forming behavior of LPBF-processed materials is essential for industrial adoption. This study investigates the stretch-flangeability of LPBF-fabricated 316L stainless steel, emphasizing its anisotropic microstructure and mechanical properties. Hole expansion tests were employed to assess stretch-flangeability in comparison to wrought 316L stainless steel. The results demonstrate that LPBF-processed samples exhibit significant anisotropic behavior, demonstrating the influence of microstructural evolution on formability. These findings contribute valuable insights into optimizing LPBF materials for industrial forming applications.

Critical Review

- [English]

- A Review of Recent Developments in CoCrFeMnNi High-Entropy Alloys Processed by Powder Metallurgy

- Cheenepalli Nagarjuna, Sheetal Kumar Dewangan, Hansung Lee, Eunhyo Song, K. Raja Rao, Byungmin Ahn

- J Powder Mater. 2025;32(2):145-164. Published online April 30, 2025

- DOI: https://doi.org/10.4150/jpm.2024.00430

- 4,470 View

- 116 Download

- 3 Citations

-

Abstract

Abstract

PDF

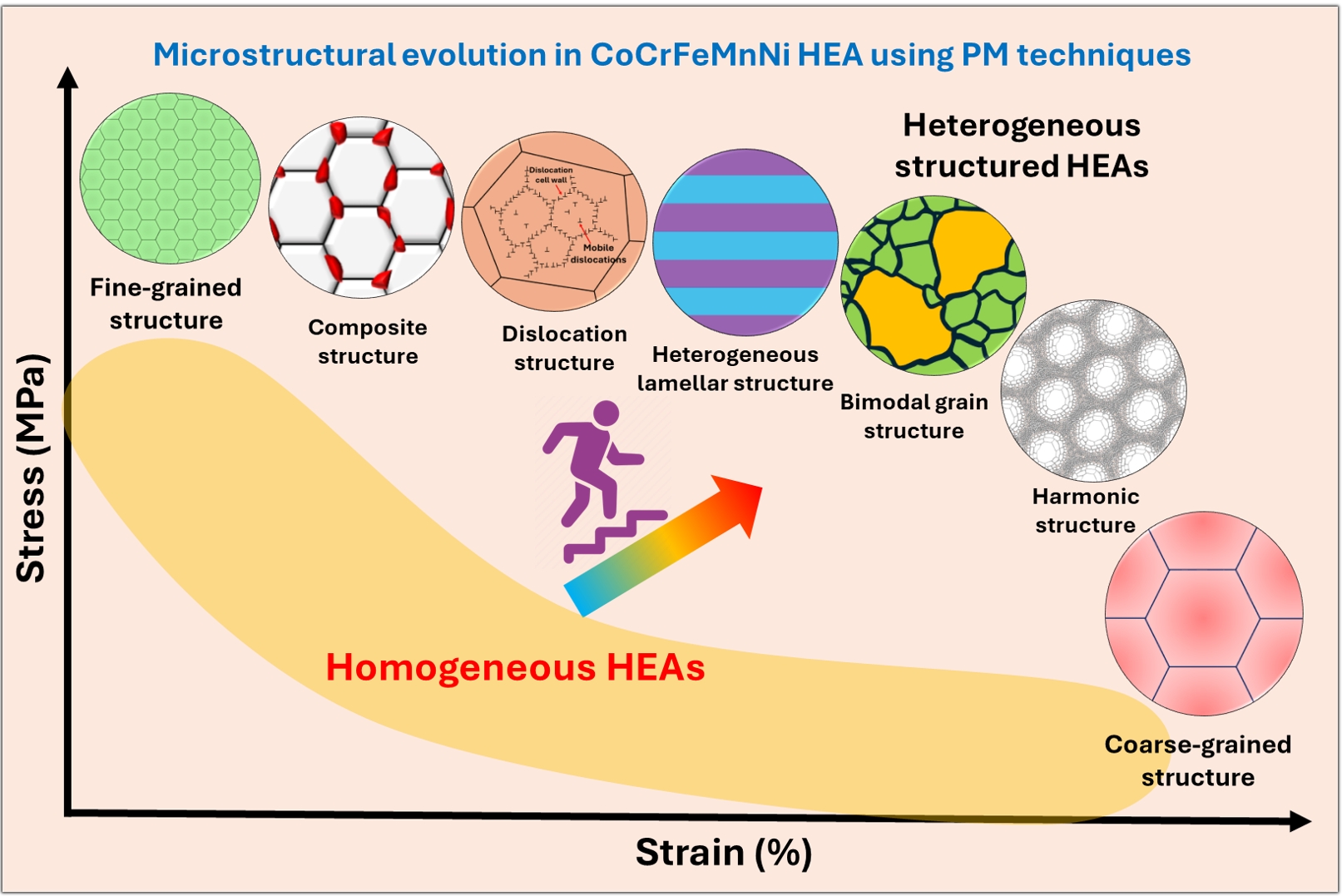

PDF - In recent years, high-entropy alloys (HEAs) have attracted considerable attention in materials engineering due to their unique phase stability and mechanical properties compared to conventional alloys. Since the inception of HEAs, CoCrFeMnNi alloys have been widely investigated due to their outstanding strength and fracture toughness at cryogenic temperatures. However, their lower yield strength at room temperature limits their structural applications. The mechanical properties of HEAs are greatly influenced by their processing methods and microstructural features. Unlike traditional melting techniques, powder metallurgy (PM) provides a unique opportunity to produce HEAs with nanocrystalline structures and uniform compositions. The current review explores recent advances in optimizing the microstructural characteristics in CoCrFeMnNi HEAs by using PM techniques to improve mechanical performance. The most promising strategies include grain refinement, dispersion strengthening, and the development of heterogeneous microstructures (e.g., harmonic, bimodal, and multi-metal lamellar structures). Thermomechanical treatments along with additive manufacturing techniques are also summarized. Additionally, the review addresses current challenges and suggests future research directions for designing advanced HEAs through PM techniques.

-

Citations

Citations to this article as recorded by- Effect of annealing temperature on thermal expansion and cryogenic mechanical properties of low-thermal-expansion Co22.2Cr6.2Fe48.8Ni17.8Cu5.0 medium-entropy alloy

Wooyoung Lee, Munsu Choi, Sungwook Kim, Dae-Kyeom Kim, Myungsuk Song, Taek-Soo Kim, Jungwan Lee, Hyoung Seop Kim, Hyunjoo Choi, Soo-Hyun Joo

Materials Science and Engineering: A.2026; 954: 149811. CrossRef - Structural and mechanical characteristics of high-entropy CoCrFeMnNi alloys manufactured by vacuum induction melting

V. K. Drobyshev, I. A. Panchenko, S. V. Konovalov, E. M. Zapolskaya

Russian Physics Journal.2026;[Epub] CrossRef - Thermodynamic and Electronic Descriptor-Driven Machine Learning for Phase Prediction in High-Entropy Alloys: Experimental Validation

Nguyen Lam Khoa, Nguyen Duy Khanh, Hoang Thi Ngoc Quyen, Nguyen Thi Hoang, Oanh, Le Hong Thang, Nguyen Hoa Khiem, Nguyen Hoang Viet

Journal of Powder Materials.2025; 32(3): 191. CrossRef

- Effect of annealing temperature on thermal expansion and cryogenic mechanical properties of low-thermal-expansion Co22.2Cr6.2Fe48.8Ni17.8Cu5.0 medium-entropy alloy

Research Articles

- [Korean]

- Flexible Hybrid Energy Harvester based on Thermoelectric Composite Film and Electrospun Piezopolymer Membranes

- Hyomin Jeon, Cheol Min Kim, Hyeon Jun Park, Bitna Bae, Hyejeong Choi, HakSu Jang, Kwi-Il Park

- J Powder Mater. 2025;32(2):104-112. Published online March 4, 2025

- DOI: https://doi.org/10.4150/jpm.2024.00458

- 954 View

- 32 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF - A hybrid energy harvester that consisted of thermoelectric (TE) composite film and electrospun piezoelectric (PE) polymeric membranes was constructed. TE composites were fabricated by dispersing inorganic TE powders inside polyvinylidene fluoride elastomer using a drop-casting technique. The polyvinylidene fluoride-trifluoroethylene, which was chosen due to its excellent chemical resistance, mechanical stability, and biocompatibility, was electrospun onto an aluminum foil to fabricate the ultra-flexible PE membranes. To create a hybrid energy harvester that can simultaneously convert heat and mechanical energy resources into electricity, the TE composite films attached to the PE membrane were encapsulated with protective polydimethylsiloxane. The fabricated energy harvester converted the outputs with a maximum voltage of 4 V (PE performance) and current signals of 0.2 μA (TE performance) under periodical heat input and mechanical bending in hybrid modes. This study demonstrates the potential of the hybrid energy harvester for powering flexible and wearable electronics, offering a sustainable and reliable power source.

-

Citations

Citations to this article as recorded by- Unidirectional porous PVDF Piezoelectrets fabricated via gradient ice-templating for enhanced energy harvesting performance

HyoMin Jeon, Seo Young Yoon, Nagamalleswara Rao Alluri, Momanyi Amos Okirigiti, HakSu Jang, Changyeon Baek, Tiandong Zhang, Geon-Tae Hwang, Min-Ku Lee, Gyoung-Ja Lee, Kwi-Il Park

Sustainable Materials and Technologies.2026; 47: e01888. CrossRef

- Unidirectional porous PVDF Piezoelectrets fabricated via gradient ice-templating for enhanced energy harvesting performance

- [Korean]

- Friction Stir Spot Welding Characteristics of Dissimilar Materials of Aluminum-Based Damping Composites and Steel Plates

- Si-Seon Park, Young-Keun Jeong

- J Powder Mater. 2025;32(1):43-49. Published online February 28, 2025

- DOI: https://doi.org/10.4150/jpm.2025.00010

- 663 View

- 10 Download

-

Abstract

Abstract

PDF

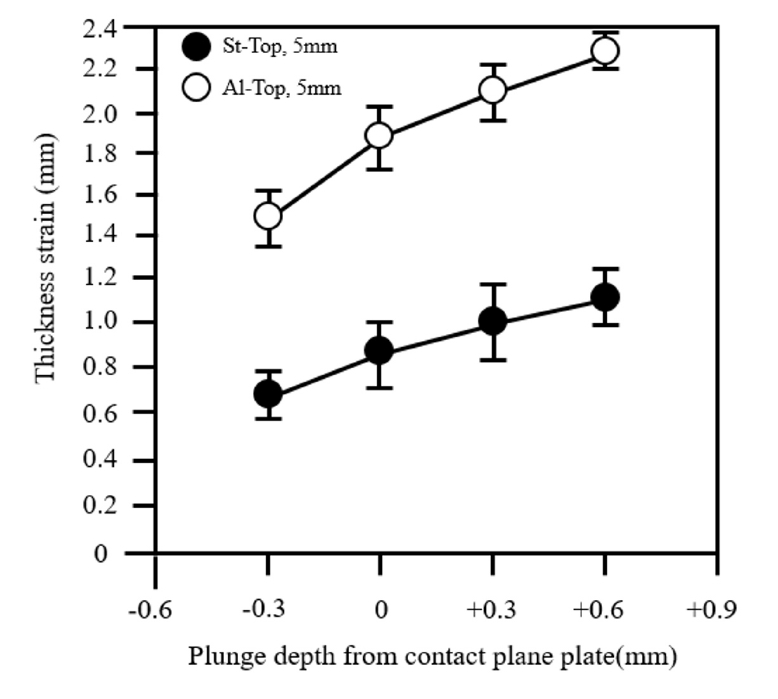

PDF - Friction Stir Spot Welding (FSSW) is a solid-state welding technology that is rapidly growing in the automotive industry. Achieving superior welding characteristics requires the proper selection of tool geometry and process conditions. In this study, FSSW was performed on dissimilar materials comprising AA5052-HO/hot-melt aluminum alloy sheets and Steel Plate Cold Rolled for Deep Drawing Use(SPCUD) steel sheets. The effects of tool geometry, plate arrangement, and tool plunge depth on the welding process were investigated. At the joint interface between the aluminum alloy and the steel sheet, new intermetallic compounds (IMCs) were observed. As the plunge depth increased, thicker and more continuous IMC layers were formed. However, excessive plunge depth led to discontinuous layers and cracking defects. An analysis of the IMCs revealed a correlation between the IMC thickness and the shear tensile load. Furthermore, compared to the conventional Al-Top arrangement, the St-Top arrangement exhibited reduced deformation and superior shear tensile load values. These findings indicate that plate arrangement significantly influences the mechanical properties of the joint.

- [Korean]

- Effect of Hatch Spacing on the Microstructure and Mechanical Properties of SA508 Gr.3 Steel Fabricated by Laser Powder Bed Fusion

- Yuanjiu Huang, Ho Jin Ryu, Kee-Ahn Lee

- J Powder Mater. 2025;32(1):50-58. Published online February 28, 2025

- DOI: https://doi.org/10.4150/jpm.2024.00479

- 1,148 View

- 27 Download

- 1 Citations

-

Abstract

Abstract

PDF

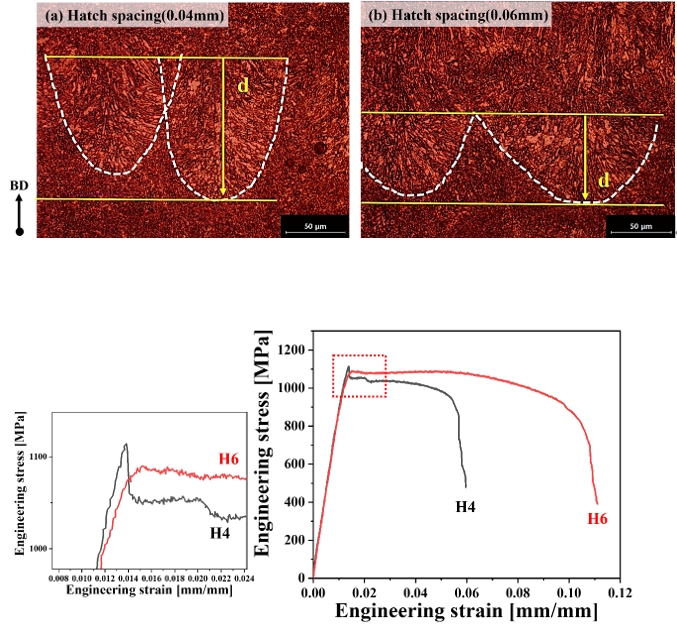

PDF - This study investigated the effect of the hatch spacing parameter on the microstructure and mechanical properties of SA508 Gr.3 steel manufactured by laser powder bed fusion (L-PBF) for a nuclear pressure vessel. Materials were prepared with varying hatch spacing (0.04 mm [H4] and 0.06 mm [H6]). The H4 exhibited finer and more uniformly distributed grains, while the H6 showed less porosity and a lower defect fraction. The yield strength of the H4 material was higher than that of the H6 material, but there was a smaller difference between the materials in tensile strength. The measured elongation was 5.65% for the H4 material and 10.41% for the H6 material, showing a significantly higher value for H6. An explanation for this is that although the H4 material had a microstructure of small and uniform grains, it contained larger and more numerous pore defects than the H6 material, facilitating stress concentration and the initiation of microcracks.

-

Citations

Citations to this article as recorded by- Extremely low temperature mechanical behavior of in-situ oxide containing 304L stainless steel fabricated by laser powder bed fusion

Kwangtae Son, Seung-Min Jeon, Brian K. Paul, Young-Sang Na, Kijoon Lee, Young-Kyun Kim

Journal of Materials Science & Technology.2025; 234: 319. CrossRef

- Extremely low temperature mechanical behavior of in-situ oxide containing 304L stainless steel fabricated by laser powder bed fusion

- [English]

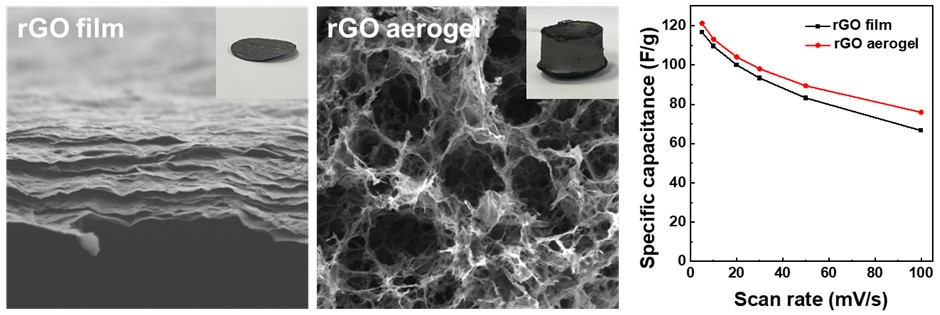

- Comparative Study of Reduced Graphene Oxide Aerogels and Films for Supercapacitor Electrodes

- Sunghee Choi, Seulgi Kim, Seojin Woo, Dongju Lee

- J Powder Mater. 2025;32(1):23-29. Published online February 28, 2025

- DOI: https://doi.org/10.4150/jpm.2024.00472

- 1,751 View

- 34 Download

- 1 Citations

-

Abstract

Abstract

PDF

PDF - Supercapacitors, renowned for their high power density and rapid charge-discharge rates, are limited by their low energy density. This limitation has prompted the need for advanced electrode materials. The present study investigated reduced graphene oxide (rGO) in two distinct structures, as a film and as an aerogel, for use as supercapacitor electrodes. The rGO film, prepared by vacuum filtration and thermal reduction, exhibited a compact, lamellar structure, while the aerogel, synthesized through hydrothermal treatment, was a highly porous three-dimensional network. Electrochemical analyses demonstrated the aerogel’s superior performance, as shown by a specific capacitance of 121.2 F/g at 5 mV/s, with 94% capacitance retention after 10,000 cycles. These findings emphasize the importance of structural design in optimizing ion accessibility and charge transfer. They also demonstrate the potential of rGO aerogels for increasing the energy storage efficiency of advanced supercapacitor systems.

-

Citations

Citations to this article as recorded by- Laser-Induced Porous Graphene Electrodes for Flexible Heater

Min Gi An, Jaehak Lee, Jung Hwan Park

Journal of Powder Materials.2025; 32(6): 492. CrossRef

- Laser-Induced Porous Graphene Electrodes for Flexible Heater

- [Korean]

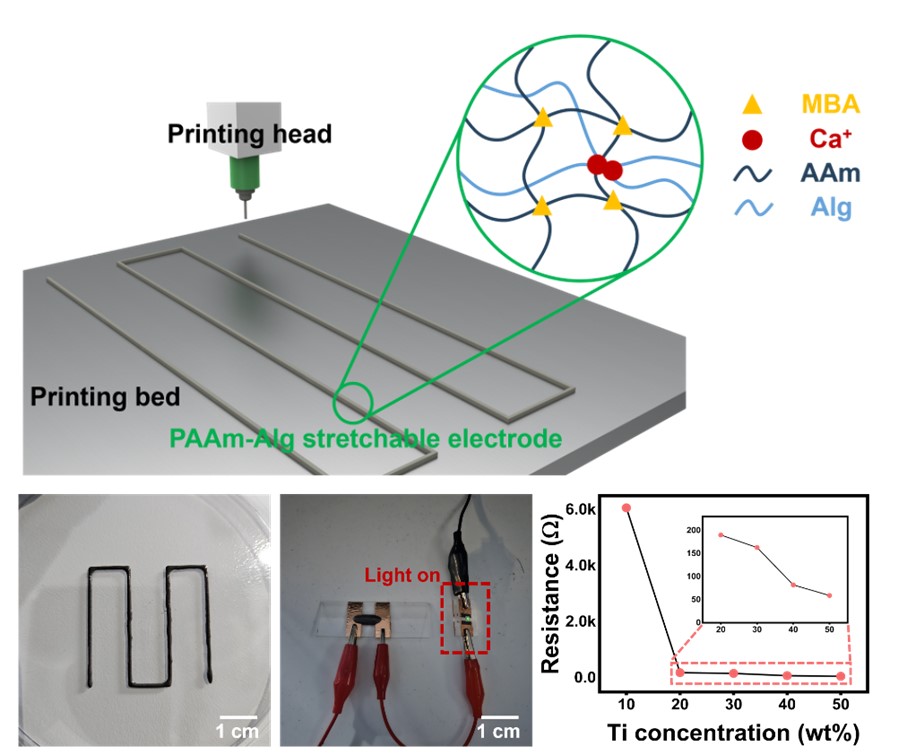

- 3D-Printed Stretchable Electrodes Enabled by a Titanium/Acrylamide-Based Hydrogel Nanocomposite

- Se Jin Choi, Han Eol Lee

- J Powder Mater. 2025;32(1):67-72. Published online February 28, 2025

- DOI: https://doi.org/10.4150/jpm.2024.00465

- 836 View

- 18 Download

-

Abstract

Abstract

PDF

PDF - Wearable electronics have been the focus of considerable interest in various fields, such as human-machine interfaces, soft robotics, and medical treatments, due to their flexibility, stretchability, and light weight. To address the shortcomings of existing metal thin film-based wearable devices, stretchable conductive polymers have been developed. In particular, double networking hydrogels are being actively studied as a polymer with a three-dimensional stereoscopic structure that can be patterned. Nonetheless, they have shortcomings such as poor electrical properties and cumbersome manufacturing processes, making it difficult to apply them in electronic devices. Herein, we report 3D-printed stretchable electrodes enabled by a titanium/polyacrylamide-alginate-based hydrogel nanocomposite. This research suggests the strategy for resolving the challenges of high costs and complex fabrication processes associated with stretchable electrode, providing a solution to accelerate the commercialization of wearable electronic devices.

- [Korean]

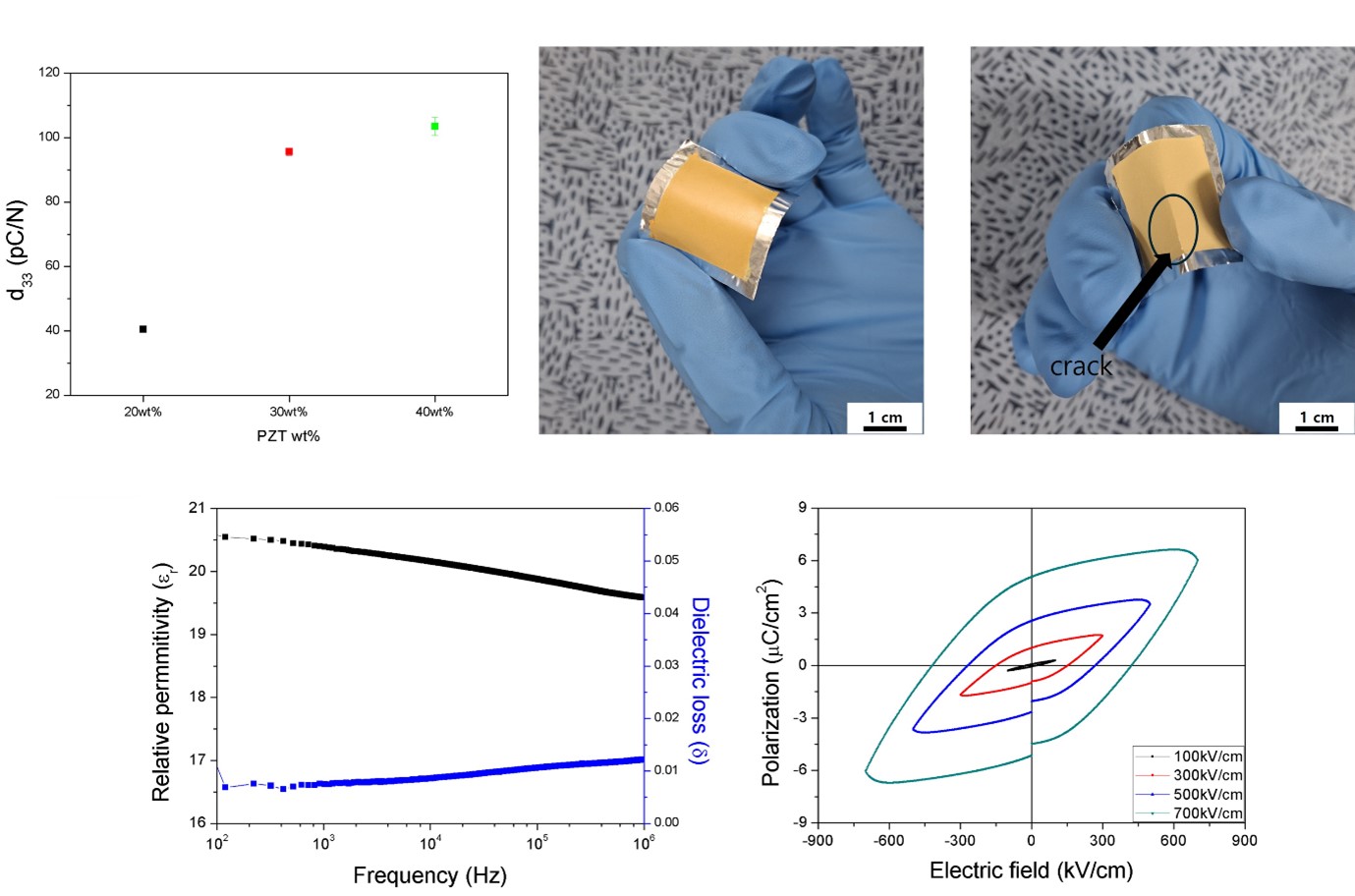

- Optimized Process and Mechanical and Electrical Analysis of Polyimide/Pb(Zr,Ti)O3-Based Flexible Piezoelectric Composites

- Junki Lee, Sang-il Yoon, Hyunseung Kim, Chang Kyu Jeong

- J Powder Mater. 2025;32(1):16-22. Published online February 28, 2025

- DOI: https://doi.org/10.4150/jpm.2024.00444

- 943 View

- 30 Download

-

Abstract

Abstract

PDF

PDF - Piezoelectric composites have attracted significant research interest as sustainable power sources for electronic devices due to their high mechanical stability and electrical output characteristics. This study investigated the optimal processing conditions for fabricating a flexible piezoelectric energy harvester based on Pb(Zr,Ti)O₃ (PZT) powder and a polyimide (PI) matrix composite. Various parameters, including the optimal mixing ratio of PI/PZT, ultrasonic treatment, homogenization, vacuum oven, and UV/O₃ treatment, were optimized to achieve a uniform piezoelectric composite. A PZT content of 30 wt% and 20 minutes of homogenization were identified as the most effective conditions for increasing the uniformity of the composite. The optimized composite exhibited a high piezoelectric coefficient, a typical P-E hysteresis loop, and dielectric properties, exhibiting a voltage output that adjusts in response to variations in the applied touch force. This study provides foundational data for the uniform fabrication of flexible piezoelectric energy harvesters and next-generation miniaturized electronic devices.

- [English]

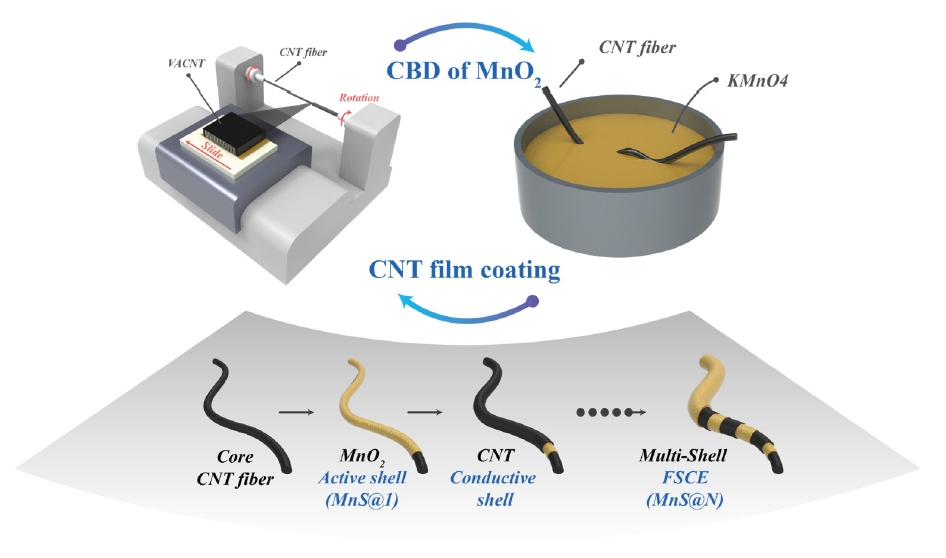

- The Effect of a CNT/MnO2 Nanoparticle Composite–Based Multi-Shell Typed Electrode for a Fiber Supercapacitor (FSC)

- Yeonggwon Kim, Hyung Woo Lee

- J Powder Mater. 2025;32(1):30-36. Published online February 28, 2025

- DOI: https://doi.org/10.4150/jpm.2024.00416

- 1,122 View

- 26 Download

-

Abstract

Abstract

PDF

PDF - Fiber supercapacitors have attracted significant interest as potential textile energy storage devices due to their remarkable flexibility and rapid charge/discharge capabilities. This study describes the fabrication of a composite fiber supercapacitor (FSC) electrode through a multi-shell architecture, featuring layers of carbon nanotube (CNT) conductive shells and MnO₂ nanoparticle active shells. The number of layers was adjusted to assess their impact on FSC energy storage performance. Increasing the number of shells reduced electrode resistance and enhanced pseudocapacitive characteristics. Compared to the MnS@1 electrode, the MnS@5 electrode exhibited a high areal capacitance of 301.2 mF/cm², a 411% increase, but showed a higher charge transfer resistance (RCT) of 701.6 Ω. This is attributed to reduced ion diffusion and charge transfer ability resulting from the thicker multi-shell configuration. These results indicate that fine-tuning the quantity of shells is crucial for achieving an optimal balance between energy storage efficiency and stability.

Critical Review

- [English]

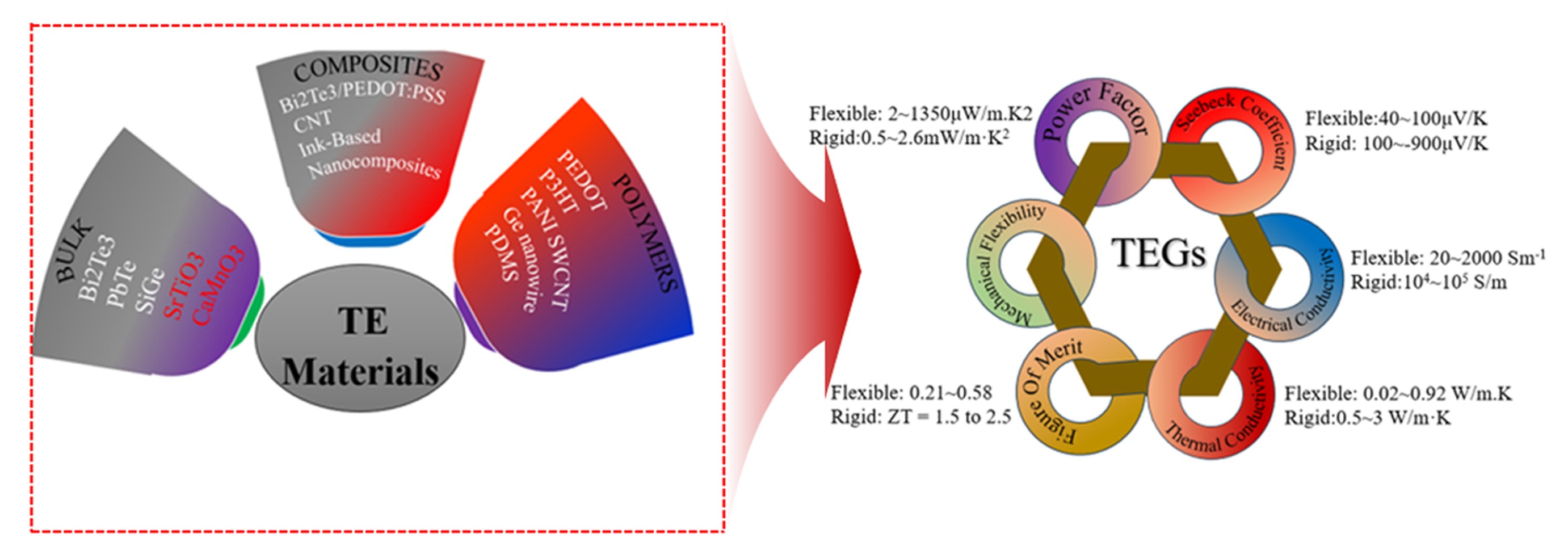

- Recent Advances in Thermoelectric Materials and Devices: Improving Power Generation Performance

- Momanyi Amos Okirigiti, Cheol Min Kim, Hyejeong Choi, Nagamalleswara Rao Alluri, Kwi-Il Park

- J Powder Mater. 2025;32(1):1-15. Published online February 28, 2025

- DOI: https://doi.org/10.4150/jpm.2024.00395

- 9,633 View

- 212 Download

- 4 Citations

-

Abstract

Abstract

PDF